-

Failure is always an option.

04/08/2018 at 13:09 • 0 commentsI wish I could say otherwise, but this project looks like a failure, at least for high accuracy positioning. It's works great for torque multiplication and appears to have pretty good precision, but a 3D printer Z axis needs both precision and accuracy.

There's a problem visible in the video below: when the Z axis is moved in 1 mm intervals, every other step is right on and those in between are a little off.

UMMD 40:1 worm drive precision testing and belt stretch under load from Mark Rehorst on Vimeo.

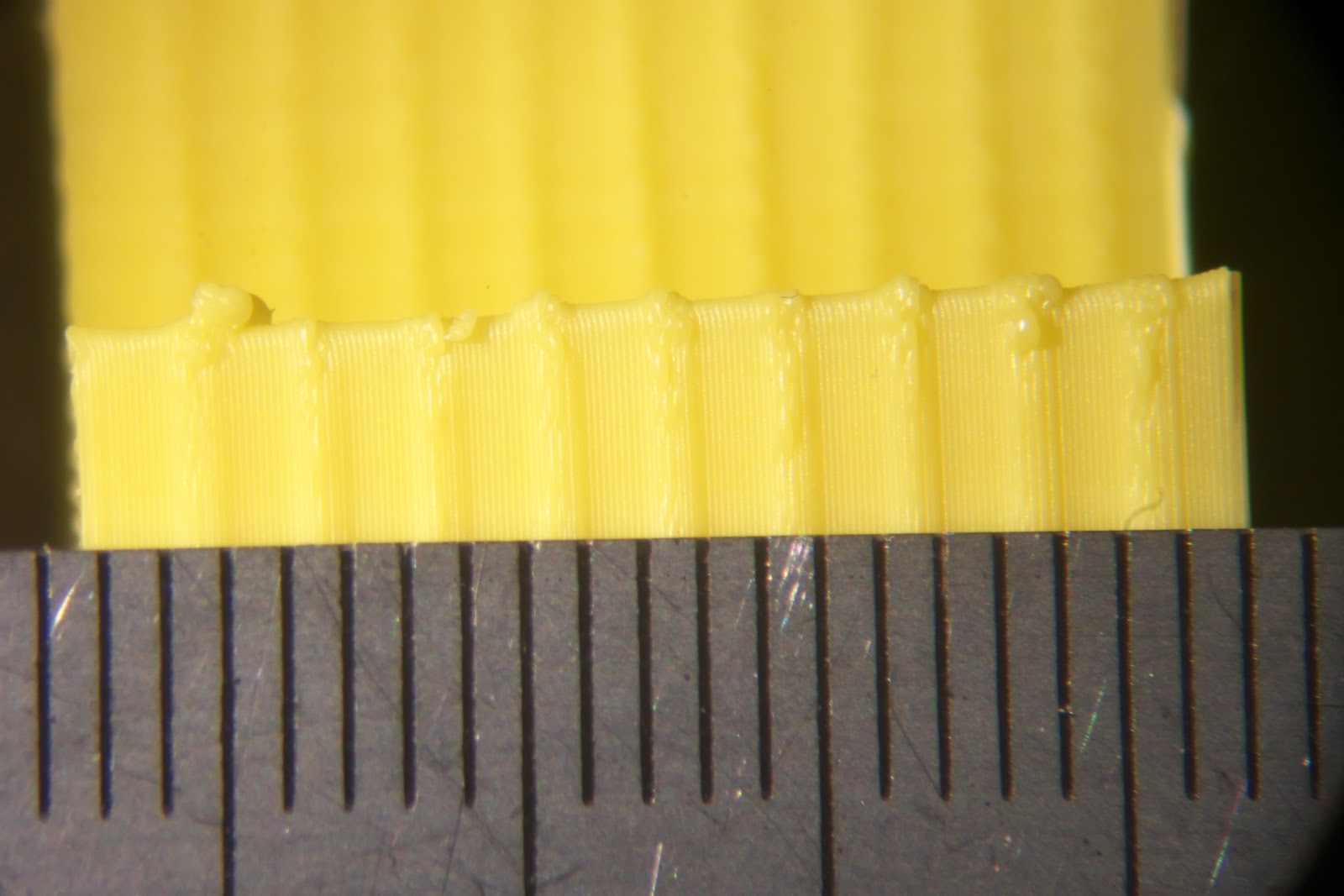

I managed to repair the extruder and ran a test print yesterday and got Z ribbing every 2 mm, most likely because of a problem with the worm gear which spins 1 revolution for every 2 mm of Z axis movement.

![]()

I don't think there's anything that can be done to fix this. I'll be putting the Rino back into the machine today.

-

Update 2: first load tests in printer

04/06/2018 at 23:07 • 0 commentsI installed the printed gearbox in UMMD last night and ran the first test: lifting 4 kg at 10 mm/sec (the bed and support assembly weigh 3.5 kg):

First test of printed worm gear box in UMMD from Mark Rehorst on Vimeo.

Details:

1600 usteps/mm

100 full steps/mm

40:1 gear reduction

3 kg cm NEMA-17 stepper

40 tooth drive pulleys

2 mm pitch GT2 belt

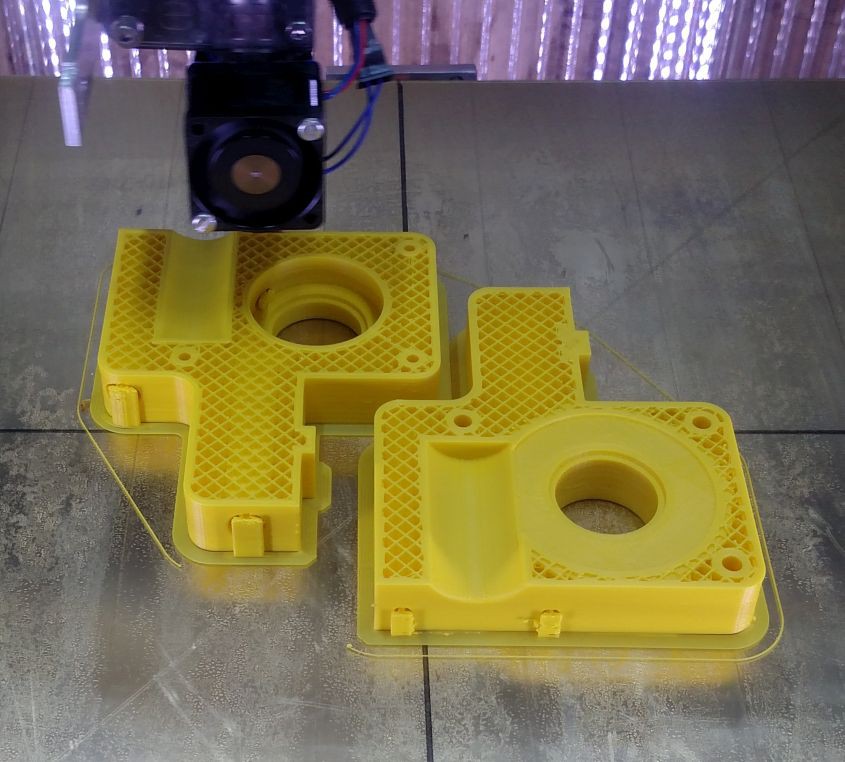

![Gearbox printed in two pieces. Gearbox printed in two pieces.]()

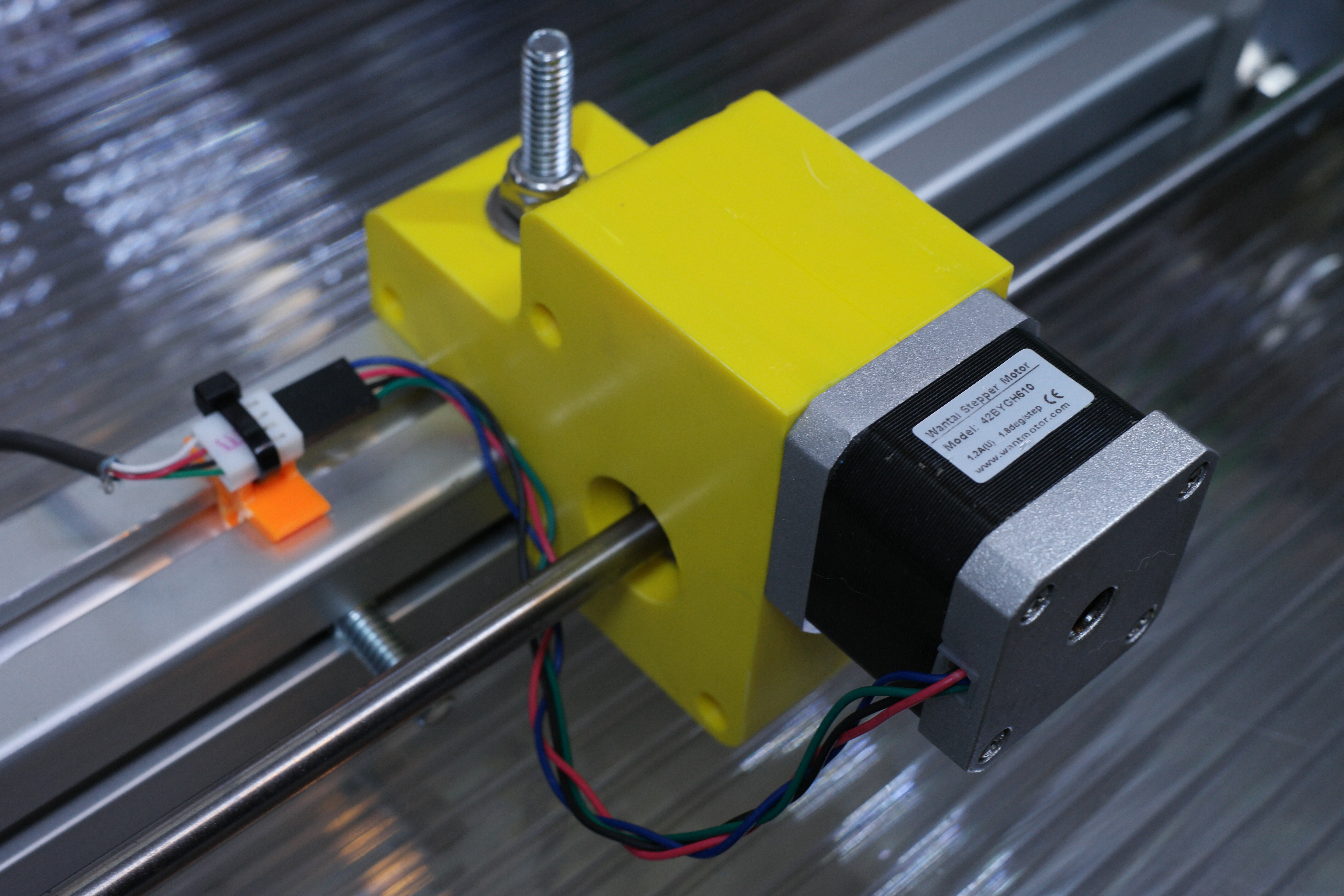

This is one generation earlier than the one in the video, but it was printed the same way. ![Gearbox installed in UMMD Gearbox installed in UMMD]()

This the gearbox installed in UMMD's Z axis. The motor is a 3 kg cm holding torque, 40 mm long NEMA-17 unit running at 1A. At 10 mm/sec the motor is spinning at 300 RPM. A lower inductance motor might be able to spin a bit faster. More tests to come...

-

Update 1: first tests

04/06/2018 at 23:05 • 0 commentsI assembled it and connected to a stepper driver. While it was running I attempted to prevent rotation by holding a pair of 40 tooth pulleys with my hands. I couldn't stop it. This thing will be able to lift a decent amount of weight.

I was thinking of building a structure to test it, but after looking at options, decided the easiest thing to do would be to pull the Rino out of UMMD and replace it with this gearbox. When it finishes printing (rev 3, now), I'll install it in UMMD and run some tests. UMMD currently uses HTD-3M belts - I'll be replacing them with GT2.

Planned tests include lifting capacity, precision and accuracy tests to be made by bolting a gauge to the printer's frame and letting the bed bump the probe. I'll also run some speed tests. At 40:1 the maximum speed may be less than the Rino's 20 mm/sec.

Low cost worm gear drive for 3D printer Z axis

A low cost worm gear drive that prevents a belt-lifted bed from dropping when motor power is cut.

Mark Rehorst

Mark Rehorst