-

V1

07/02/2016 at 05:17 • 0 commentsFinally I decided to make a brand new design.

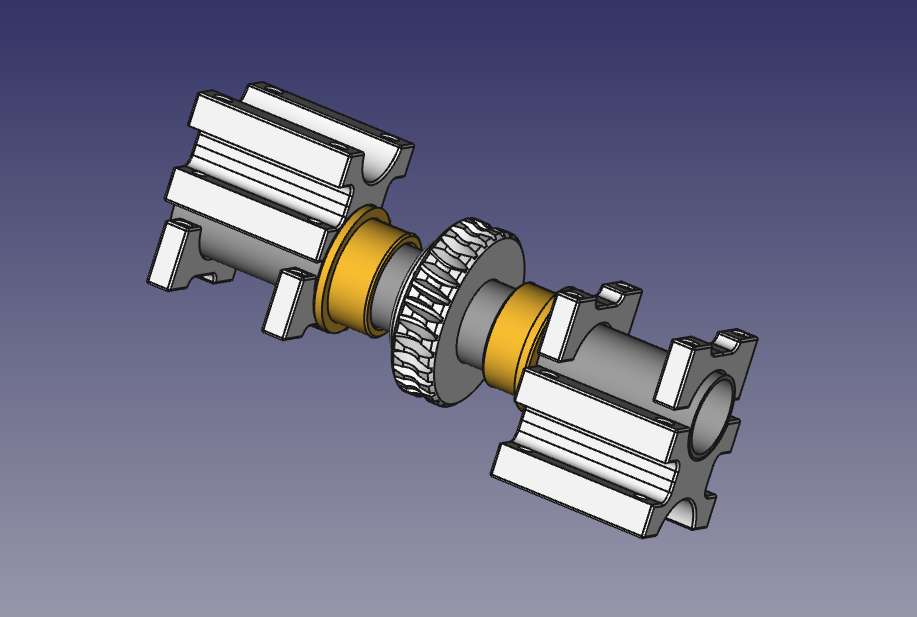

For now I am drawing it with FreeCAD exclusively.

Here is a sneak peek:

![]()

This is the beginning of the crankshaft :)

All the files are available on the dedicated github repository!

-

Month wrap-up

05/29/2016 at 12:52 • 0 commentsLast week-end I was faced with issues on powering the system. I did not manage to solve them during the week so I will end the first prototype here.

This is the perfect moment to take so time and think on how I worked and what I achieved here.

To start I am quite happy with the quality of the results, knowing that I only used a driller and a hand saw.

However, I think I should have designed everything before trying to make it instead of trying to make something out of what I could find at the store down the hackerspace.

Especially, I should have started with the power block and validated a power transmission because it is what really prevents me from moving forward with this prototype and this is also what was a bit weak on the prototype that I made a few years before.

As for the price, I estimate it around 1100 HKD for the parts only, knowing that it does not include any control board and batteries.

To sum up, it was a fun month trying to make this prototype. I did not managed to make it in only four week-ends but that is surely because every week-end I had to make design decisions. I'm going to do better next month !

-

Trying to make pulleys

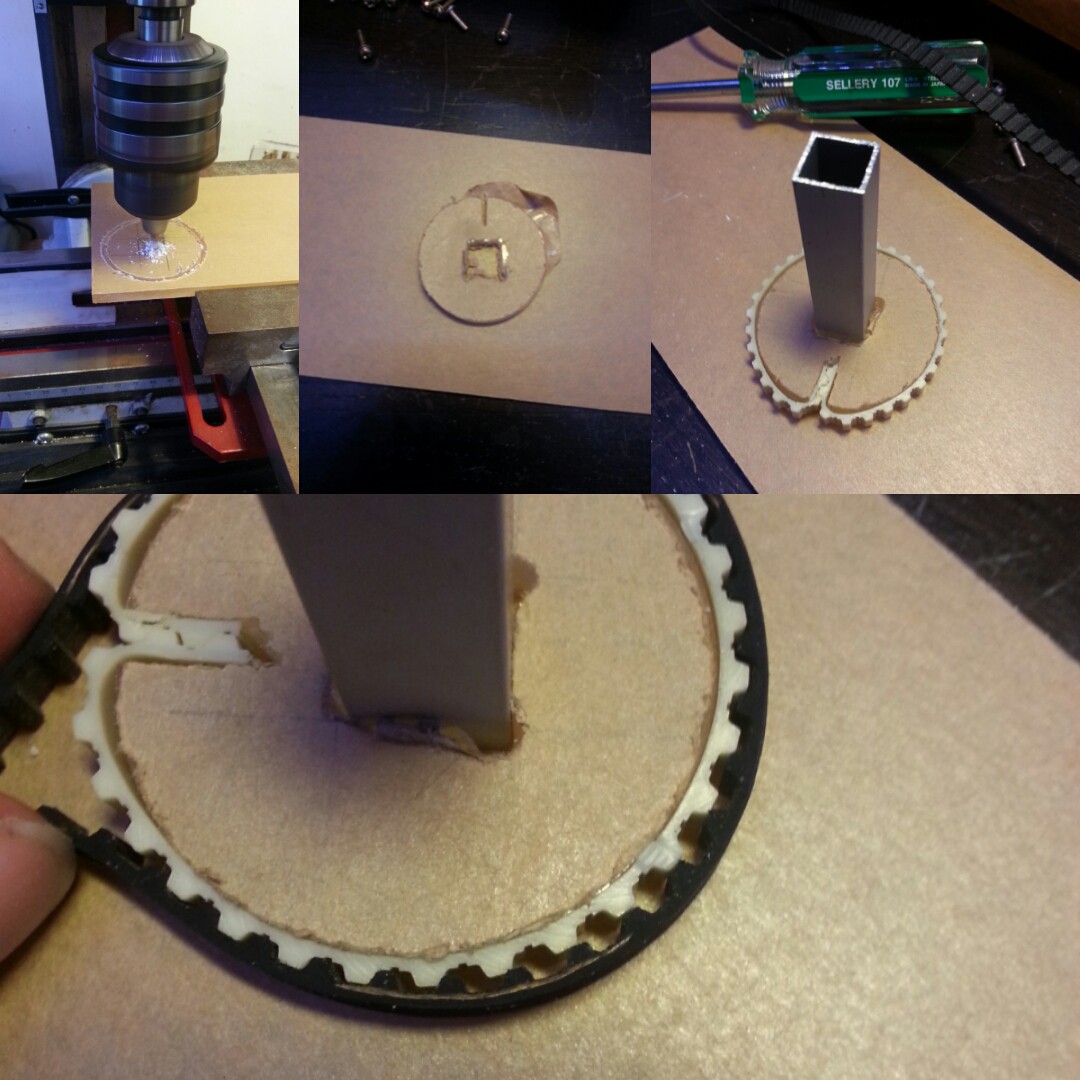

05/23/2016 at 13:38 • 0 commentsin a I spent a large amount of the weekend working on several ways to make pulleys or at least power transmission with what was available to me.

Sadly, I didn't make it. Hopefully, you can still have some fun looking at the fails !

![]()

This first collage shows you how I thought I could use one belt to drive another one. On the big picture at the bottom you can see that the belt does not match the pulley. Which now that I thought about it absolutely makes sence. It would require the radius of the pulley to be infinite to work.

My second try was to use wheels and use the toothed belt on the reverse side as a flat belt. So I had this wheel in which I managed to drill a square hole. Which is an achievement I would say. But sadly I couldn't manage to get the pulleys and the belt to fit so I declare this as another failure.![]()

To give a positive note to this post, I still have made some progress on the architecture but those failures plus other problems raise questions on the design. I will pursue on this first prototype until the end of the Anything Goes contest since it will probably raise other issues that I can take into account while designing the second prototype.

-

Second weekend, success!

05/15/2016 at 14:35 • 0 commentsThis week-end turned out to be quite successful. Of course, since I applied the lessons from the first week-end ;)

So here are the pictures, and comments.

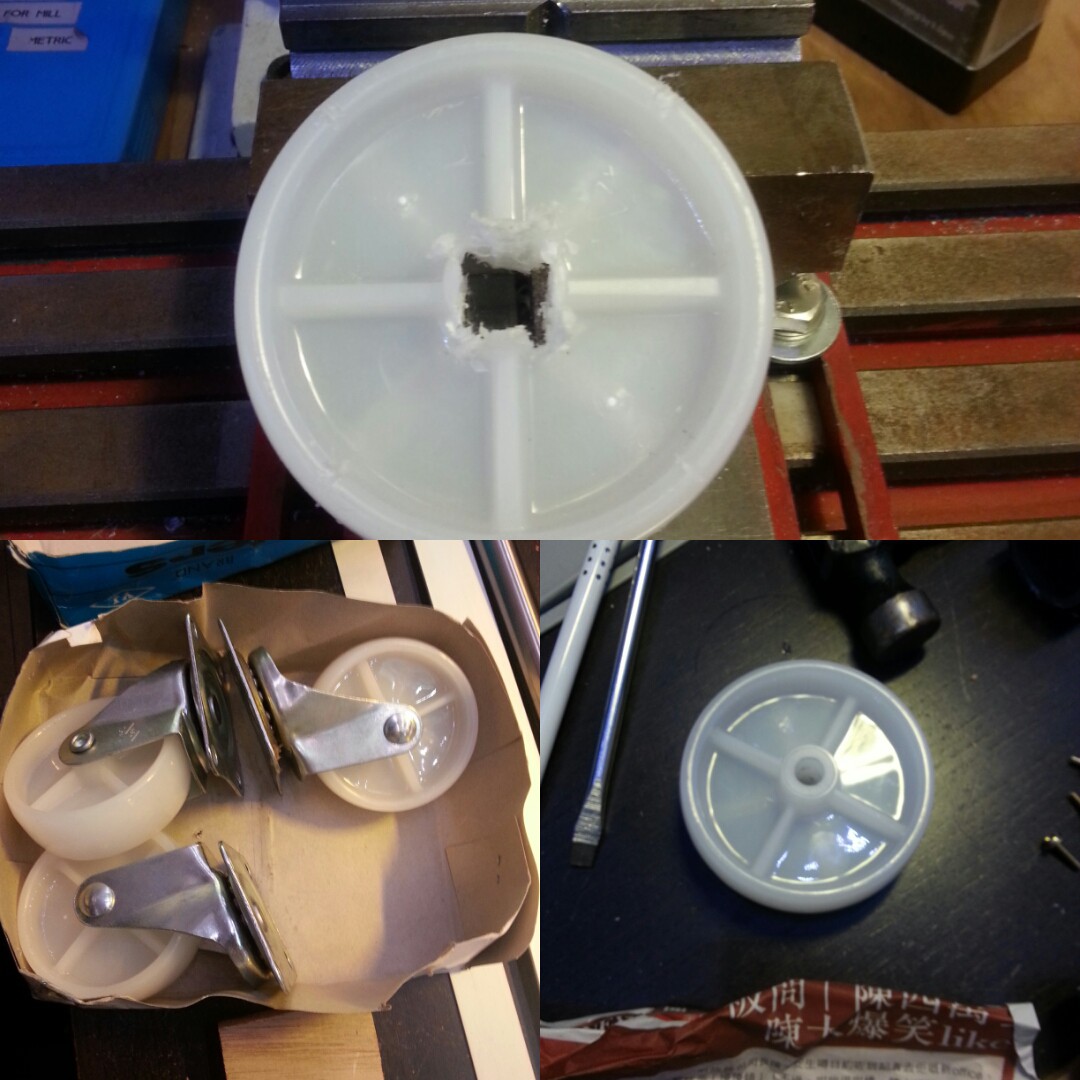

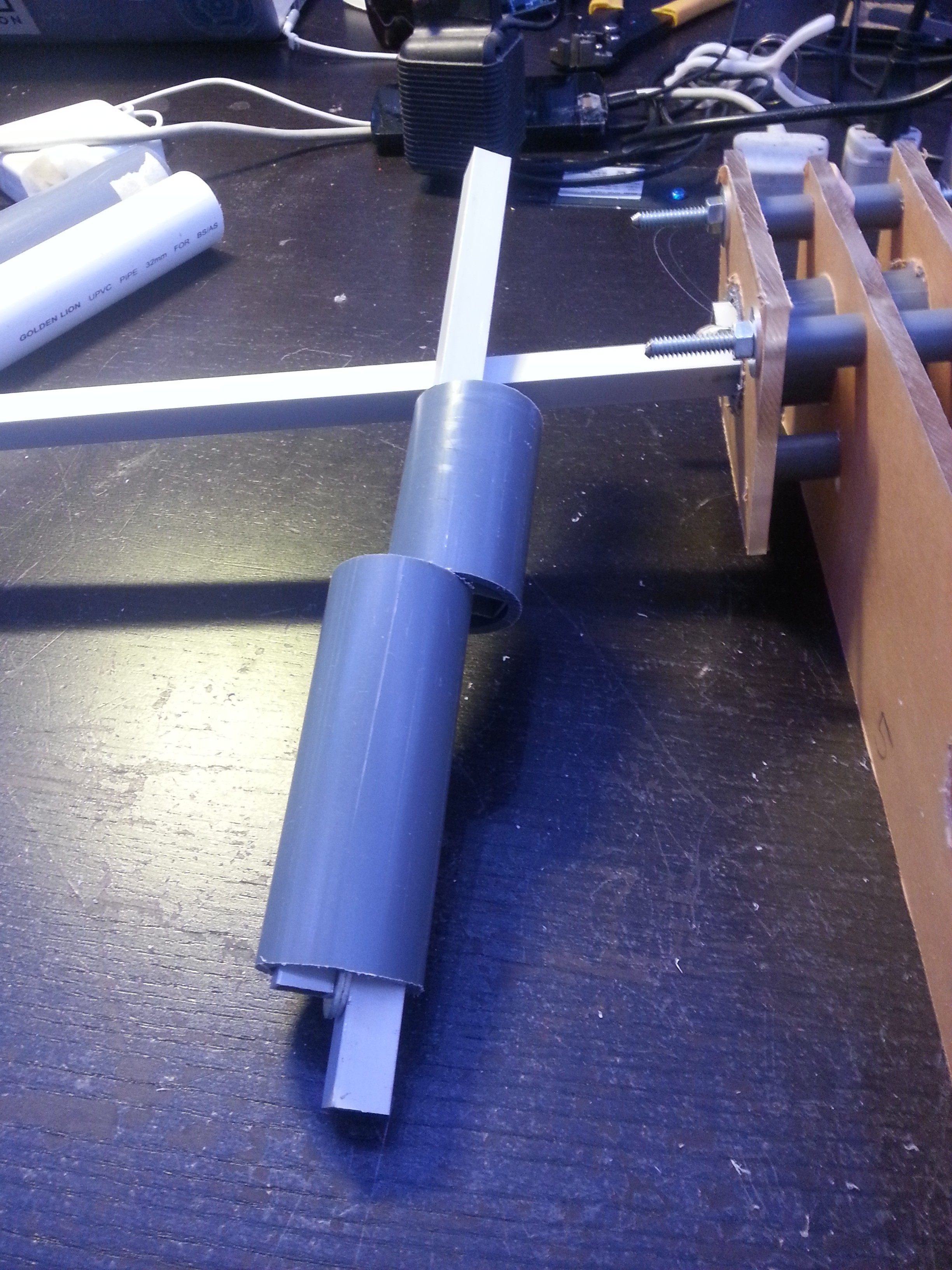

This first picture shows what the crankshaft will look like. It's made of very cheap materials, as you can see. My issue here is on how to make it robust yet easily repaired. I'm thinking about it. The answer probably next week!

![]()

The second pictures shows the legs. You can see a ressemblance with the pictures in the project page, because it is exactly the same mechanism and kinematics. However, I am really happy because making those two "legs" took me only a few hours while it took me and my team a few hours to make all the parts when this was the student project ! I can really see an improvement in iterative design here.

![]()

That's all for tonight folks.

I'm thinking hard on the crankshaft and powering right now.

-

First week-end session: failures or not?

05/14/2016 at 13:59 • 0 comments"Never a failure, always a lesson". This is how I would describe the first week-end I spent on this project.

This was my first real working session on the project. I started very innocently by buying some stuff from the hardware shop down Dim Sum Lab, which is at the 14th floor of a building.

Then I went to the lab, and I spent the afternoon drilling some plastic sheets.

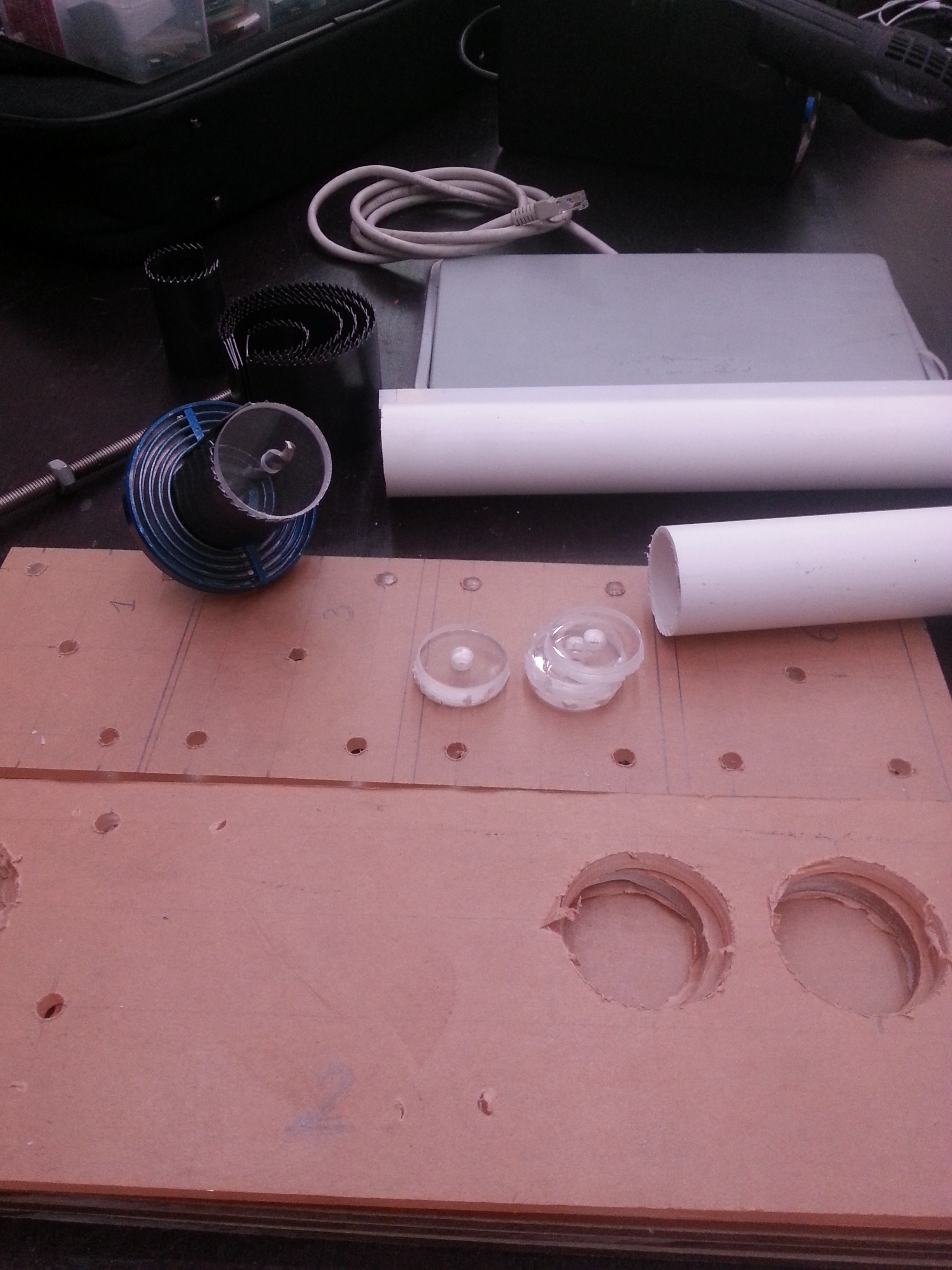

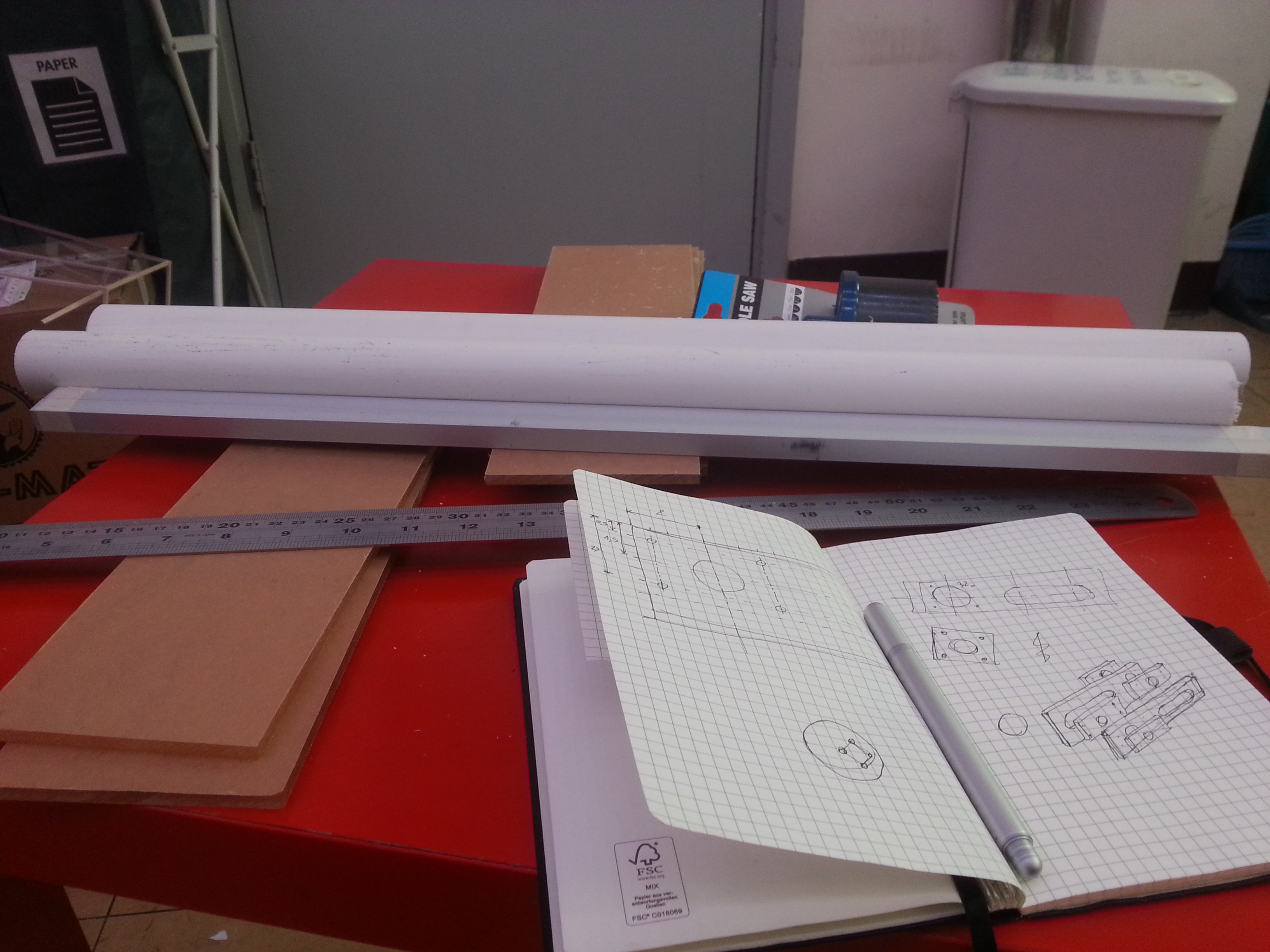

This is the stuff that I had at the beginning of the day.

![]()

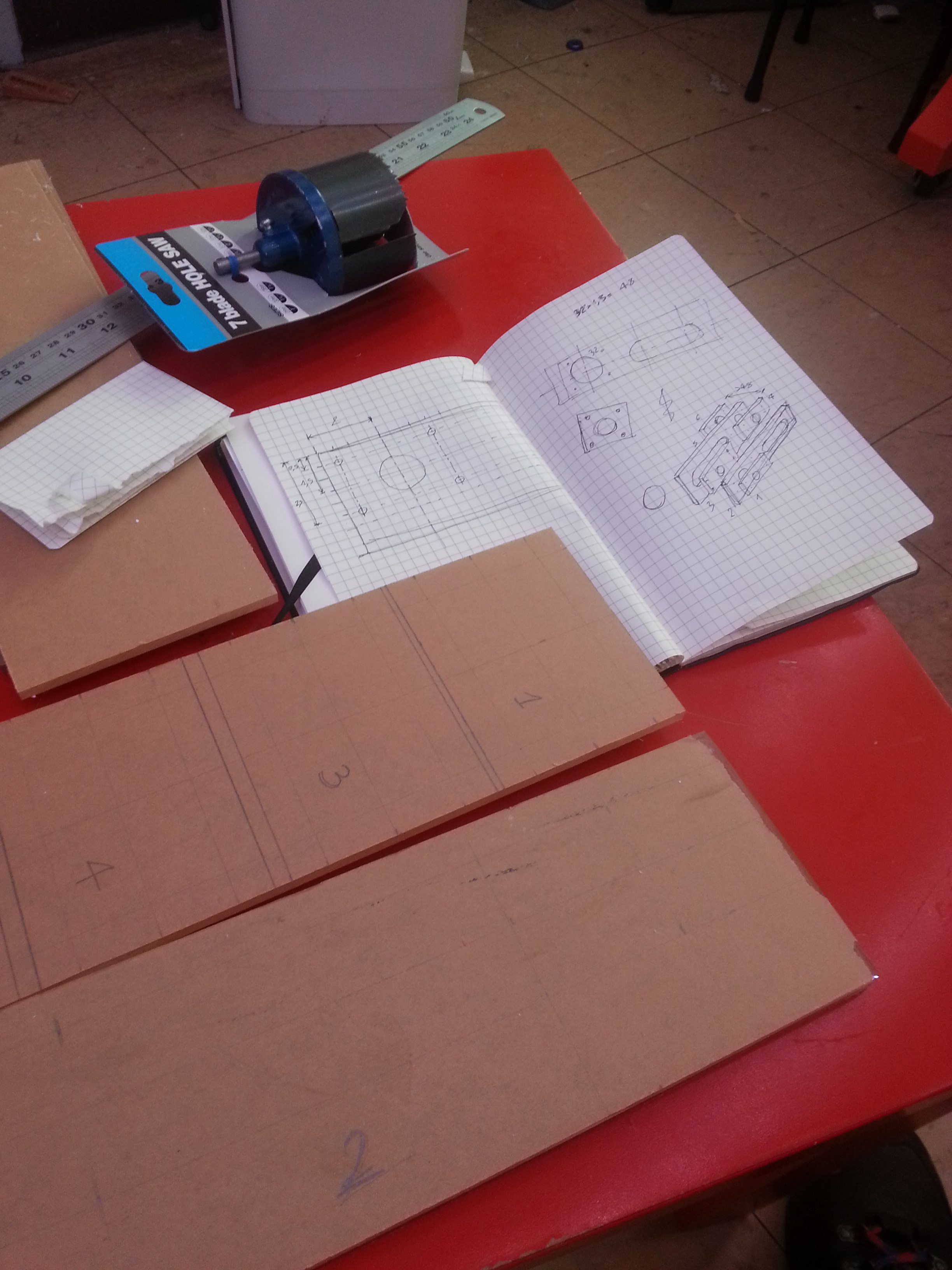

This is how everything was planned to be:

![]() Everything looks nice on those pictures, right?

Everything looks nice on those pictures, right?However, at the end of the day, I realized that the holes did not match the tubes that I bought and that were supposed to go into it. One of a few mismatch that I discovered that day.

Below is the picture of what was done that day. The tubes, the discs, and the holes don't match.

![]()

I tried to go back to the shop but it was closing, and it would stay closed for the rest of the week-end. So, I just had to go back home and meditate on the lessons of that weekend.

So here they are.

The first one, is on the way I work on this project. I can't go and try and see if it works at the end of the day. Because this is never going to work at the end of the day. I will now apply a much more rational approach to this project, as engineers do. This month is dedicated to exploring the landscape of this project. If I want usefull answers, I need to ask the right questions. First and foremost, I need to think about this questions.

Luckily, this week-end already answered some questions.

It showed that I could absolutely realize this project at Dim Sum Labs.

Also, I learned that using plastic tubing and plastic sheet is relevant for prototyping because it is really to work on.

At last, it gave me confidence that I can really make this project.

That was all for that week-end, not so much achievements but a lot of usefull feedback that will hopefully speed-up the next work sessions!

Alain Sanguinetti

Alain Sanguinetti

Everything looks nice on those pictures, right?

Everything looks nice on those pictures, right?