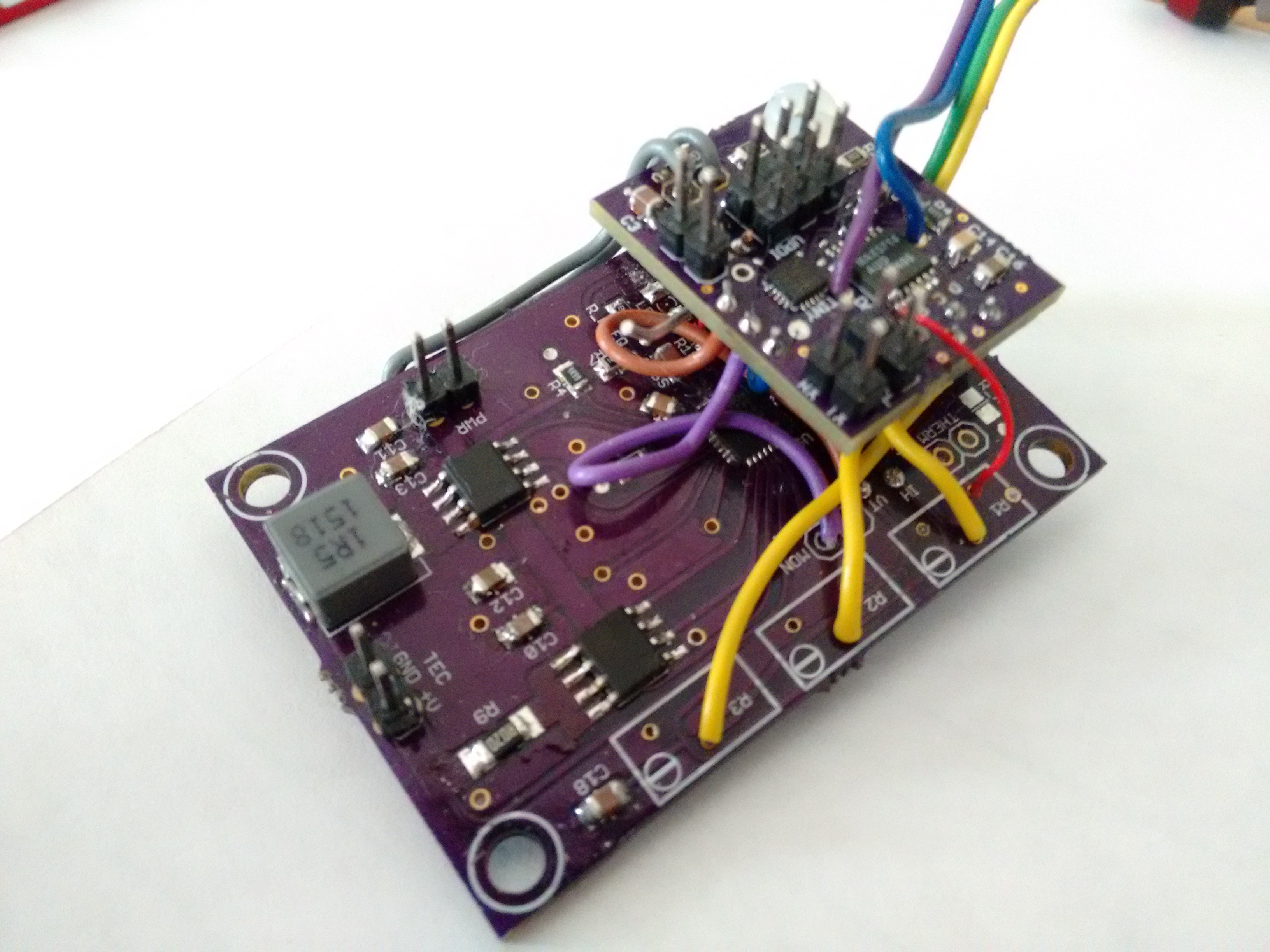

From the Datasheet;

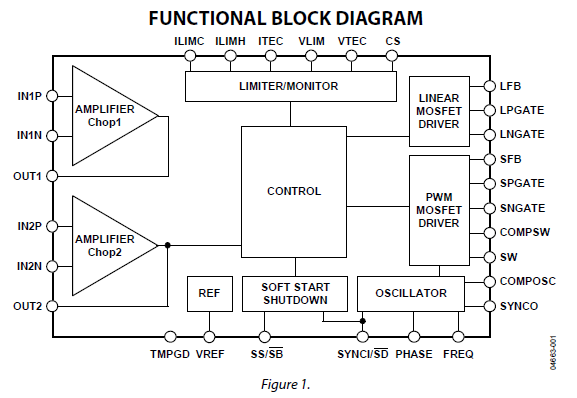

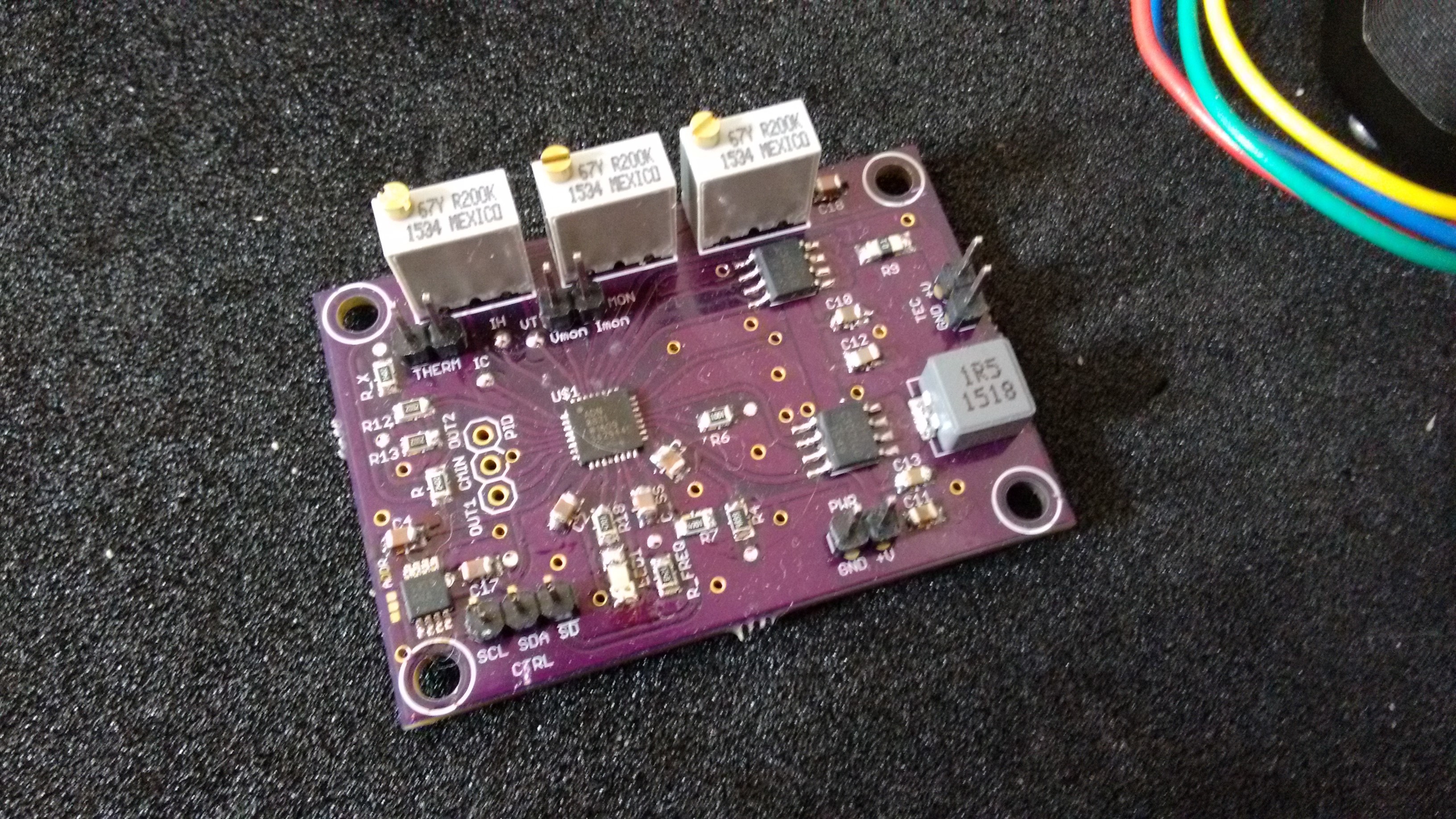

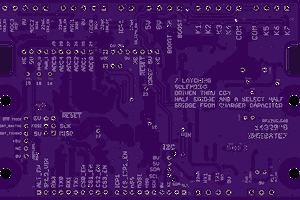

The ADN8831 is a monolithic TEC controller. It has two integrated, zero drift, rail-to-rail comparators, and a PWM driver. A unique PWM driver works with an analog driver to control external selected MOSFETs in an H-bridge. By sensing the thermal detector feedback from the TEC, the ADN8831 can drive a TEC to settle the programmable temperature of a laser diode or a passive component attached to the TEC module.

The ADN8831 supports NTC thermistors or positive temperature coefficient (PTC) RTDs. The target temperature is set as an analog voltage input either from a DAC or from an external resistor divider driven by a reference voltage source.

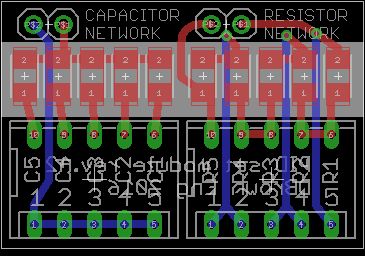

A proportional integral differential (PID) compensation network helps to quickly and accurately stabilize the ADN8831 thermal control loop. An adjustable PID compensation network example is described in the AN-695 Application Note, Using the ADN8831 TEC Controller Evaluation Board. A typical reference voltage of 2.5 V is available from the ADN8831 for thermistor temperature sensing or for TEC voltage/current measuring and limiting in both cooling and heating modes.

Designs shared under the Creative Commons - Attribution - ShareAlike 3.0 license.

David Brown

David Brown

ronald.sutherland

ronald.sutherland

Chris Slothouber

Chris Slothouber

The Big One

The Big One

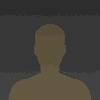

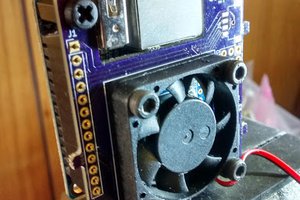

Are you having better luck with the motor amp? are you able to control both voltage and current limits?