-

Another printing test without resin

01/15/2015 at 22:18 • 0 commentsJust fixed some bugs in the software. I think i can do first resin test with the new prototype this weekend.

-

First Laser Test with new firmware.

01/15/2015 at 15:44 • 0 commentsThe new open exposer firmware supports G-Code now. I also wrote some tools to handle g-code files.

The toolchain works as follows:

1. generate a stl file with your favourite cad software

2. sclice the stl to svg with slic3r

3. use the open-exposer slicer to post process the svg file and generate the g-code file

4. send g-code to open exposer with open exposer sender

All tools are written in python. I implemented a small plugin interface for the post processor. With plugins the post processor can be extended to handle different input file formats. By default it supports svg ( slic3r export).

Here is a small video which shows the exposure process with the new firmware.

-

New design printed and assembled

12/11/2014 at 08:17 • 2 commentsAfter two weeks of hard work, finally i present you the new version of the open exposer 3D Printer....

-

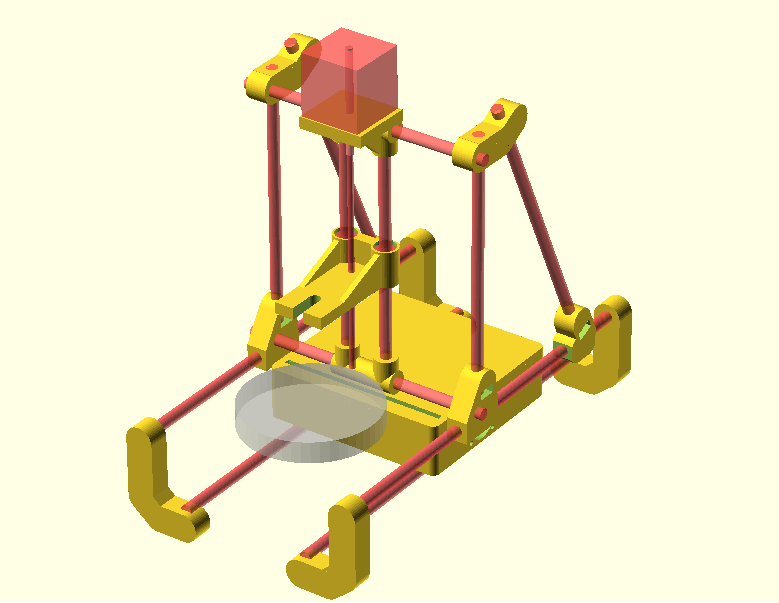

New Design

11/21/2014 at 14:17 • 0 commentsI am working on a new printable Open Exposer Design. This is a first rough draft.

![]()

-

New Laser Cut Design

09/17/2014 at 22:15 • 0 commentsToday i worked until the late evening at our local Fablab. I finished the Open Exposer laser cut design. It contains the following components.

- Open Exposer base unit

- PCB Exposer extension

- Bearing extension

This weekend i will be at Kerkrade Mini Maker Faire (NL) .

![]()

-

PCB exposing extension

09/15/2014 at 20:12 • 0 commentsI am working on the pcb extension unit for the Open Exposer project. This is a first rough approach.

![]()

I will laser cut the new Open Exposer design and the pcb extension on wednesday. I also designed a bearing extension for the bottom of the Open Exposer project.

-

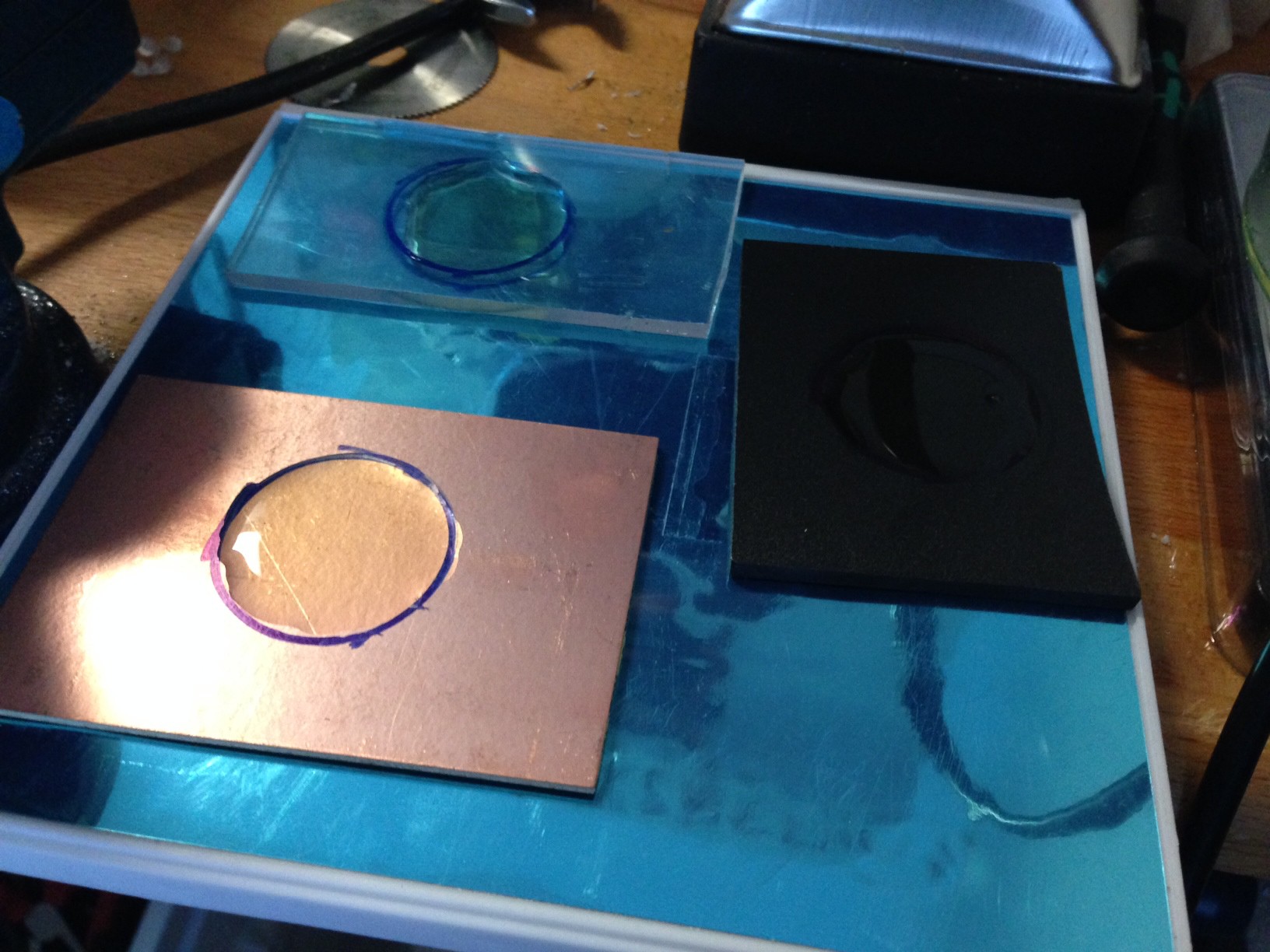

Looking for a good stage material.

09/09/2014 at 16:57 • 0 commentsI am just testing some materials. Hope i will find the best solution soon.

This time : copper (again), PVC foam and polycarbonate.

-

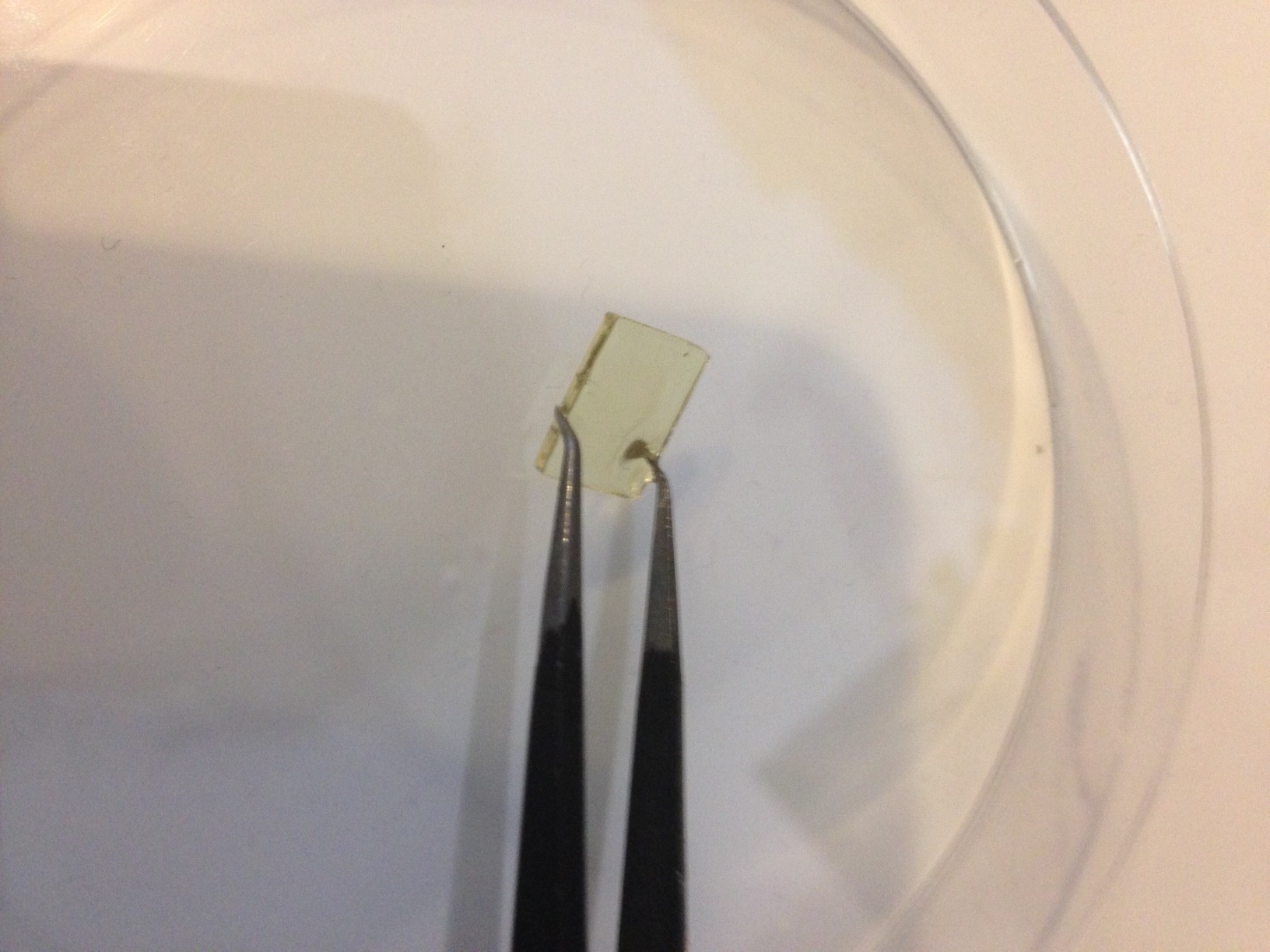

First printer test with vat tilt

09/09/2014 at 16:28 • 1 commentHere are some pictures of the first print test with the new vat tilt mechanism.

I still have problems with the build stage material and stickiness of the prints. I already tried acrylic and a copper plate. Any suggestions?

-

New stage with magnetic mount.

09/01/2014 at 19:51 • 0 commentsMounting and unmounting the build stage was a time wasting process. So i decided to redesign the stage. I use magnets for mounting now instead of a screw.

-

Vat tilt mechanism - Servo test.

09/01/2014 at 19:37 • 0 commentsAfter hours of designing and printing new parts... Here is the first test video of the new vat tilt mechanism.

OpenExposer

An affordable Arduino controlled multipurpose laser exposing device. Use it for SLA Printers, PCB Exposing, Laser Harp etc.

Mario Lukas

Mario Lukas