-

The definitive, complete, sanctimonious guide on...

02/03/2022 at 16:16 • 0 commentsMade a video that fully summarizes conveyor belt 3D printing, enjoy!

Let me know what you think of the new design.

-

After three years.....AN UPDATE!

11/20/2021 at 01:02 • 0 commentsHey Hackaday, it's a been a while!

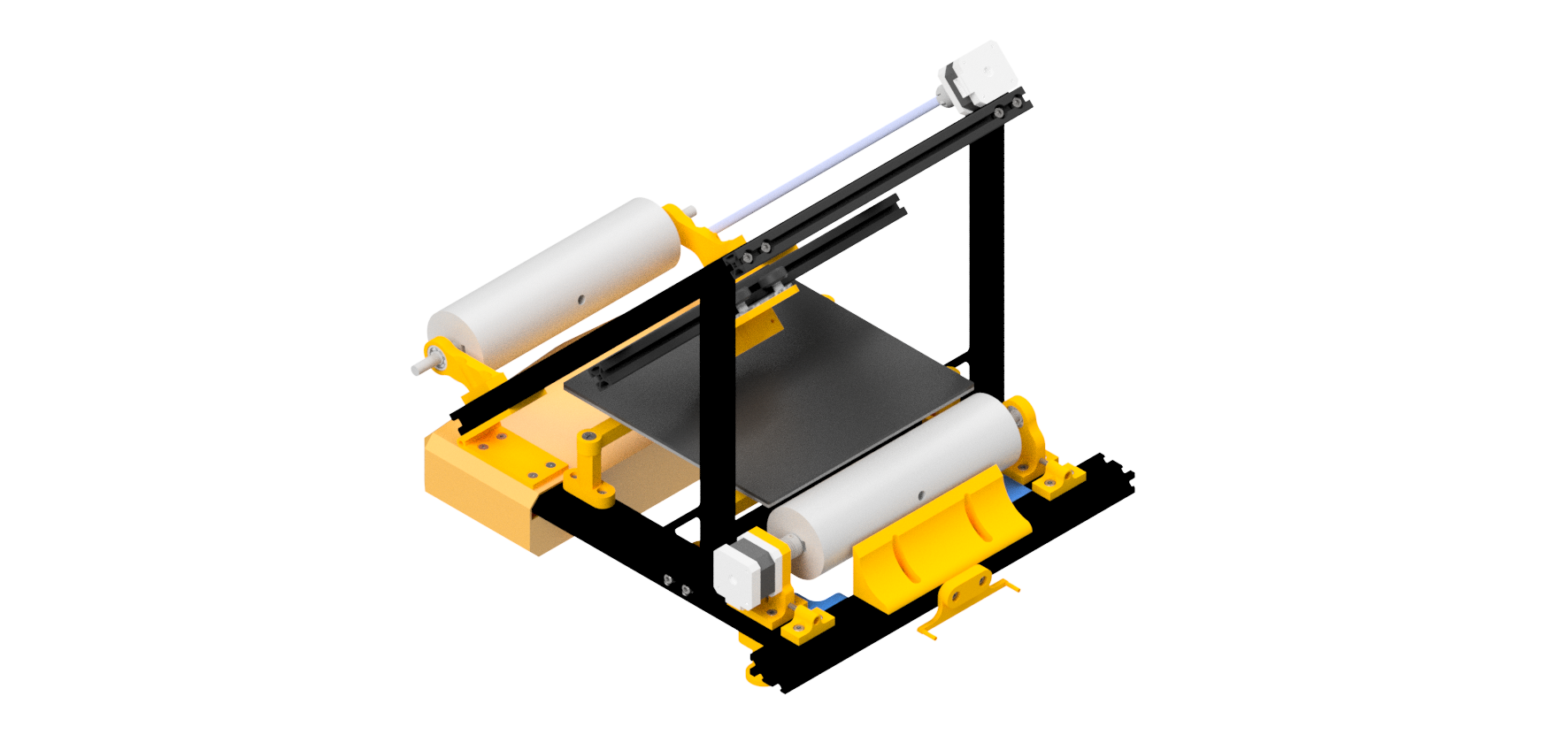

After a long time, I have decided to revisit my conveyor belt 3D printer project. Over the past few months, I have completed redesigned and rebuilt a brand new conveyor belt 3D printer. Here are some brief demos.

When designing this conveyor belt 3D printer, my goal was to make it extremely easy for other makers/hackers to replicate the machine. That way the community can work together to iterate upon conveyor belt 3D printers and move the technology forwards. I am currently cleaning up the CAD and plan on posting it to GrabCAD soon.

![]()

[Render of new conveyor belt 3D printer]

If there is enough interest, I can also make a tutorial video explaining how to build a conveyor belt 3D printer.

Let me know if that is something you guys would like!

-

New Design Iteration

10/22/2018 at 12:31 • 1 commentHere is the fourth iteration of the Automatic Infinite 3D Printer.

In future iterations, I hope to explore computer vision applications that automate 3D printing.

-

Testing Automatic Ejection

05/29/2018 at 01:11 • 0 comments[3D Printer Automatically Ejecting Print Job]

-

Test Print with WorkHorse 3D Printer Mk. 3

05/25/2018 at 05:18 • 0 commentsI have managed to print quite a few parts with the integrated conveyor belt. Next up, I'll tinker with the infinite build capabilities.

-

Ejecting Parts from WorkHorse 3D Printer Mk. 3

05/23/2018 at 05:51 • 1 commentI have finished making the belt of the WorkHorse 3D Printer and I ran a few quick 3D printing tests.

I need to make multiple adjustments to the firmware to finalize the machine. For example, the y axis movement is not proportional. The printed object should be circular.

I would also like to give a shoutout to the Deltesian project. The Deltesian is an open source 3D printer designed by a crew of extremely knowledgeable and friendly hackers. I've spent a lot of time communicating with the team on advice and queries about 3D printing.

-

WorkHorse 3D Printer Mk. 3: Mechanical Construction

05/17/2018 at 01:24 • 0 commentsI have finished building most of the WorkHorse 3D Printer.

I have a solid frame to test this design with. The last major component to build is the belt.

The next steps involve me making new firmware for the 3D Printer and then testing:)

-

CAD of WorkHorse 3D Printer Mk 3

04/28/2018 at 17:39 • 0 commentsI have finished a rough CAD mock up of my third prototype autonomous 3D printer.

[Figure 1: WorkHorse 3D Printer Mk. 3 Rough CAD]

The printer features a hybrid delta-conveyor belt design. The linkage system provides the X and Z Axes movement and the Conveyor Belt provides the Y Axes movement. The design change greatly reduces the complexity of the mechanism.

I plan to allow the printer to print at an angle to provide infinite build volume functionality.

A common aspiration of open source 3D printers is to be able to print all the components required for a printer. This allows the machine to be self replicating. With the new prototype 3D printer, hackers will finally be able to print long structural extrusion pieces.

![Image result for long aluminium extrusion]() [Figure 2: Prototype Should be Able to Print Structural Pieces as Seen Above]

[Figure 2: Prototype Should be Able to Print Structural Pieces as Seen Above]References

[2]RoverCNC. (2017). V-Rail Aluminium. Barrier, Ontario. [Electronic]. Available: www.rovercnc.com/

-

Revisions for WorkHorse 3D Printer Mk3

04/24/2018 at 20:43 • 0 commentsI am currently developing a third iteration of the WorkHorse 3D Printer.

In this revision, I am placing a special emphasis on building an industry grade machine. NO MORE DUCT TAPE! I am still working on the new design, but I am quite happy with how I simplified many of the components.

To pay for the high quality machine, I am hoping to be able to use the Hackaday Funding.

So if I am lucky enough to have a judge read this post, I implore them to consider the below details while selecting the top 20 candidates.

- Is this a unique solution to a particular challenge facing the world today?

- 3D Printers have the potential to democratize manufacturing. Currently, mass production technology is only within the reach of large factories and businesses. Most hackers/makers lack the financial means and technological aptitude to use automation machinery. 3D printers are inexpensive and easy to use. Providing 3D printers with the ability to automatically eject/start print jobs would allow anyone to setup a small scale factory. Empowering tinkerers with this ability is sure to generate exciting and innovative hacks.

- How thoroughly documented were the design process & design decisions?

- I understand that this project is more likely to succeed with the help of the hacker community. Therefore, I am being completely transparent during project development. I am posting all notes, designs, and software online so that others can critique and improve my work.

- How easily can this design be implemented by other people in future projects?

- The project is completely open source. This will make it easy for others to incorporate my automatic print job ejection mechanism into other 3D printers. Furthermore, I am committed to making my automatic print job ejection mechanism into a single modular unit that can be easily attached to any 3D printer.

- How complete is the project?

- At this point, I have completed two successful prototypes of the WorkHorse 3D Printer and a robust software application. Both prototypes were able eject a consistent stream of print jobs automatically. My software application provides users with a simple interface to send print jobs to the printer. By my no means is this project complete, but I am satisfied by my progress to date. I strongly believe that my next prototype will exhibit the drastic usefulness of automatic 3D print job ejectors. Being a university engineering student, I do not have the largest budget to spend on this project. I am hoping to use the Hackaday Prize money to pay for expenses. I would know exactly how to spend the prize money, since I already have a refined parts list for building Mk. 3.

Also, I would like to thank everyone that liked my Hackaday entry for helping support this project.

During the robotics module contest, I will attempt to turn my mechanism into an independent module.

My next post will be on the CAD and design changes for Mk. 3.

- Is this a unique solution to a particular challenge facing the world today?

-

Mass Production Test with Y-Axis Conveyor Belt

04/15/2018 at 01:44 • 0 commentsI printed a queue of parts on my integrated conveyor. The parts all printed and ejected successfully, but there were still some issues.

[Figure 1: Printing Queue of Jobs with 3D Printer]

I am currently printing on a roll of duct tape. While the print surface is fine, duct tape cannot withstand the high temperature of the nozzle. If the hot end touches the duct tape, the tape melts and fuses with the extruded plastic. This adhesion makes it more difficult for the part to be ejected later on.

![]()

[Figure 2: Duct Tape Belt Damaged by Hot End]

I plan on replacing the belt with a stainless steel shim.

Automatic Infinite 3D Printer

The Automatic Infinite 3D Printer (i3D) gives anyone the power of a factory.

Swaleh Owais

Swaleh Owais

[Figure 2: Prototype Should be Able to Print Structural Pieces as Seen Above]

[Figure 2: Prototype Should be Able to Print Structural Pieces as Seen Above]