-

In the meantime ...

06/27/2016 at 16:15 • 0 commentsWell, right now i'm waiting for the parts to arrive, so in the meantime i would like to explain the reason this project was started and how controlling humidity helps us do our job.

I work at a branch of an LCD TV manufacturer company (i'm not sure if i can say what company), in this branch we do refurbishment of LCD Open Cell that didn't met customer specifications, such as polarize stains, foreign materials, vertical lines etc.

As you already know these are delicate electronics, specially when dealing with expensive 80" ~ 90" sizes (yikes).

For the repair process we have a clean room with controlled access, temperature & humidity, for these last two the control is manual, that means that someone has to be checking the temperature & humidity monitor and adjusting the devices accordingly to be within specified range.

We are human after all, we make mistakes, forget things and when we think we are really awesome we tend to do both at the same time.

The big issue this project is trying to solve is air particle control by having an automatic system instead of a manual one. These pesky particles can screw up things big time, polarize repairs are the ones affected the most, imagine applying a polarizer sheet to an 80" Open Cell, only to have a particle less than a mm in size screw up the whole process, throwing away a $300 polarizer sheet, making you start all over risking breaking the Open Cell ...

Other affected area is SOF repair (they are the Tabs you see at the top & sides of the Open Cell), the part of the SOF that's bonded to the LCD glass has tiny traces for wish we need a microscope, having a particle fall in this place can cause vertical lines to appear in the LCD or if the particle is big enough it can create irregular heat pattern when bonding, and this can cause the LCD to brake.

By controlling the humidity we can lower the amount of particles in the air, and avoid dispersing particles someone might have already with them.

-

AC/DC

05/24/2016 at 23:27 • 0 commentsTurns out the valves i'm going to use are AC solenoid valves, so i will have to add Relays to my BOM.

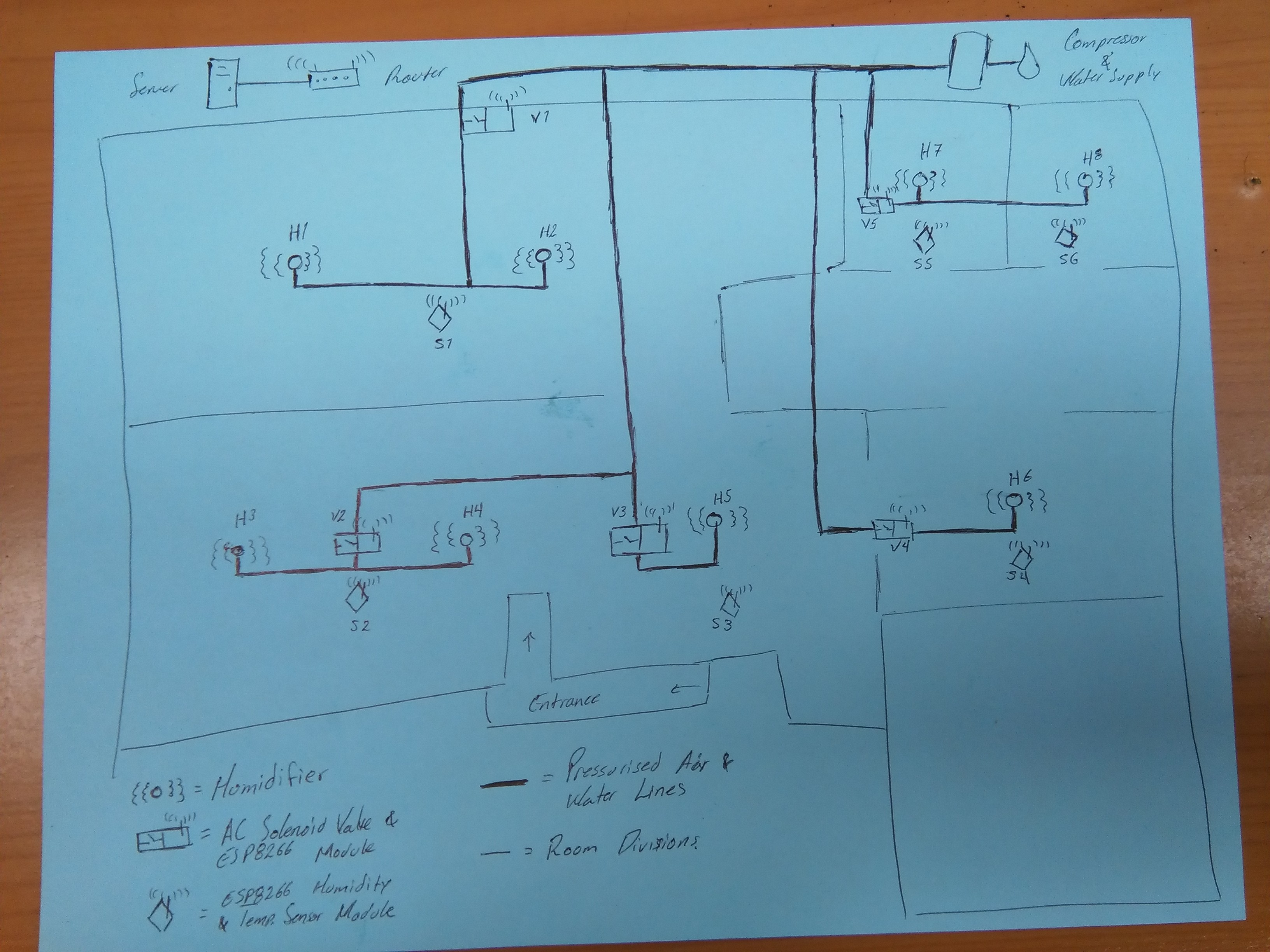

I have been doing my research to make the project as simple as possible, and all point out that i will be using the ESP8266 Module to connect the Humidity & Temperature sensors and the relay modules that actuate the valves.

The advantages of using the ESP8266 are price, modularity, price, small package, price, independent, price, there are a ton of libraries already available so i think this makes a good start, BTW did i mentioned how cheap it is?.

Believe it or not one of my colleagues that has been out of the electronics scene for a while (he became a business manager with a degree in electronics engineering), was surprised to see how inexpensive this modules are, from the looks of his face he might be tempted to buy some and experiment with it in his free time.

That's all for today, checkout my mad drawing skills in the bellow layout diagram, its the projected final result but i might start working in some areas (H1, H2, H3, S1, S2, V1 & V2) first before automating the whole thing.

![]()

Arturo Aldaco Perea

Arturo Aldaco Perea