-

Testing

05/30/2016 at 00:44 • 0 commentsTo test the project, as it is summer at the time of this project creation, I have placed the PCB of the project on a place of wax paper and used a refrigerator to test the code and hardware. Along with the refrigerator, I have used a Peltier unit that is placed against the TMP 36. I have made sure of the temperatures with both the fridge and the Peltier unit using a Ryobi handheld, IR thermometer.

Temperature from Inside the Fridge:

- 45.2 Degrees Fahrenheit

- 7.2 Degrees Celsius

Temperature of Peltier Unit:

- Varied based on voltage and current from a bench power supply.

Picture of the PCB Chillin' in the Fridge (Pun Intended):

The IC socket is bare in this photo, as it is purely a representation of the testing done on the project.

-

3D Printing

05/30/2016 at 00:10 • 0 commentsAt this point I am 3D printing the enclosure of the project. The print is progressing well, yet I have had problems with warpage on the raft that I am printing onto, however this effects the actual enclosure very little, and where it does effect the enclosure, it is purely aesthetic damage.

Printer Details:

- Printrbot Simple Metal

- No Heated Bed

- Print Temp: 196 Celsius

- Blue, Hatchbox PLA

-

Writing Code

05/29/2016 at 23:35 • 0 commentsAt this phase of the project I am writing the code that will run on the ATTINY. I am writing this in the Arduino suite, and programming the chip using an Arduino Uno in the "Arduino as ISP" configuration. You can find a guide on how to program ATTINYs with another Arduino at: http://highlowtech.org/?p=1695. The code can be found at the Github repo. Feel free to post errors within or criticisms of my sloppy code in the comments section.

-

Assembly

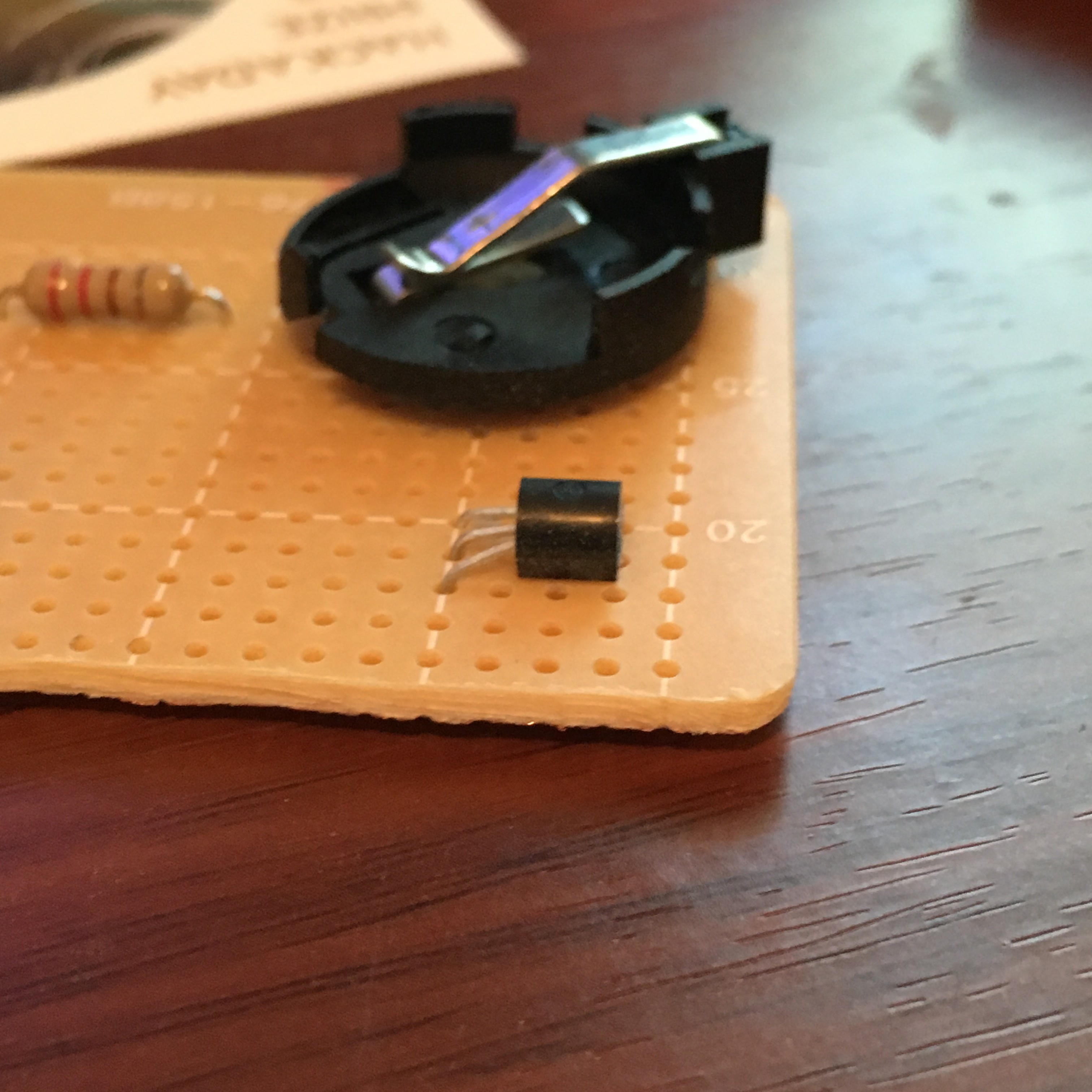

05/29/2016 at 22:49 • 0 commentsIn this phase of the project I am taking all of the components that were previously mentioned in the project, laying them out on a PCB, soldering them down and running hookup wire between them. I found that, much to my surprise, the pinout on the packaging of the 20mm led is totally wrong, and after a quick google search, I found the correct pinout. Thanks, RadioShack! (Sarcasm) When soldering down the TMP 36, a single inline pin IC, I bent the top of the chip down and taped the flat side of the IC to the PCB. I did this to keep things clean and to make soldering much, much easier.

The finished IC is pictured here:

-

Case Design

05/29/2016 at 22:24 • 0 commentsIn this phase of the project I am designing an enclosure to 3D print for the project. The device is meant to be pocketable and a bare PCB does not fit the bill. The design work is being done in Autodesk Fusion 360. The measurements of the PCB are a follows:

- The PCB is 2.8 in. by 1.9 in.

- The tallest component that will be enveloped by the case is .5 in. tall.

- The edges of the LED are .935 and 1.1 inches from the edge of the PCB.

STL Files and CAD files can be found in the files section of the project.

Frostbite Detector and Alarm

A small pocketable or wearable device that can warn the user of prolonged exposure to cold conditions.

Caleb Hanneman

Caleb Hanneman