Project video:

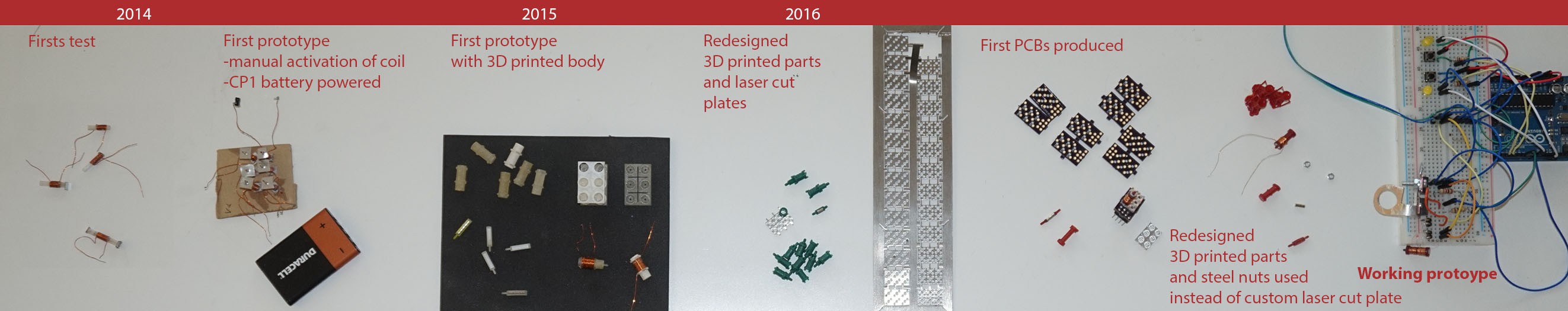

This image shows the development of the project, from the beginning to the current status of development.

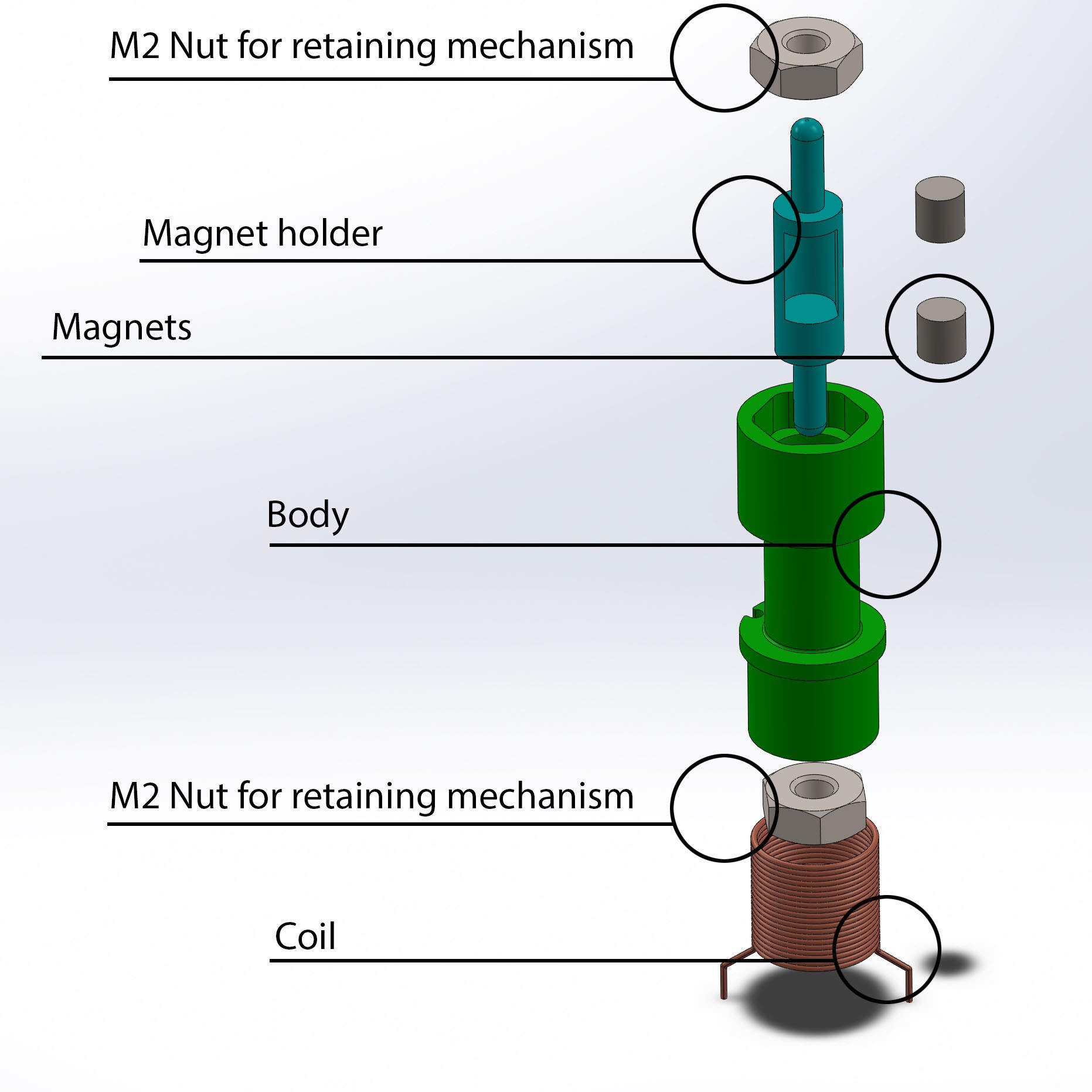

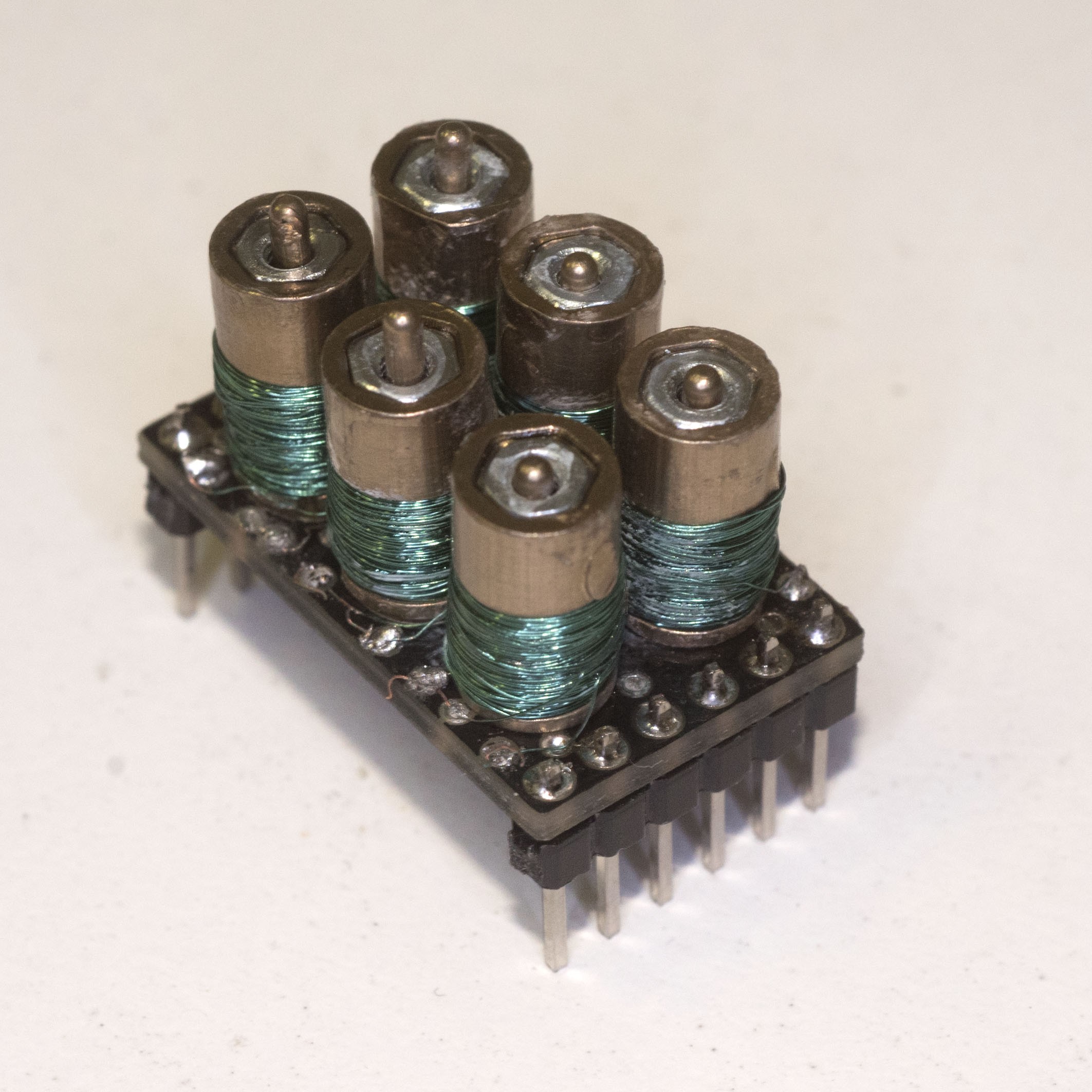

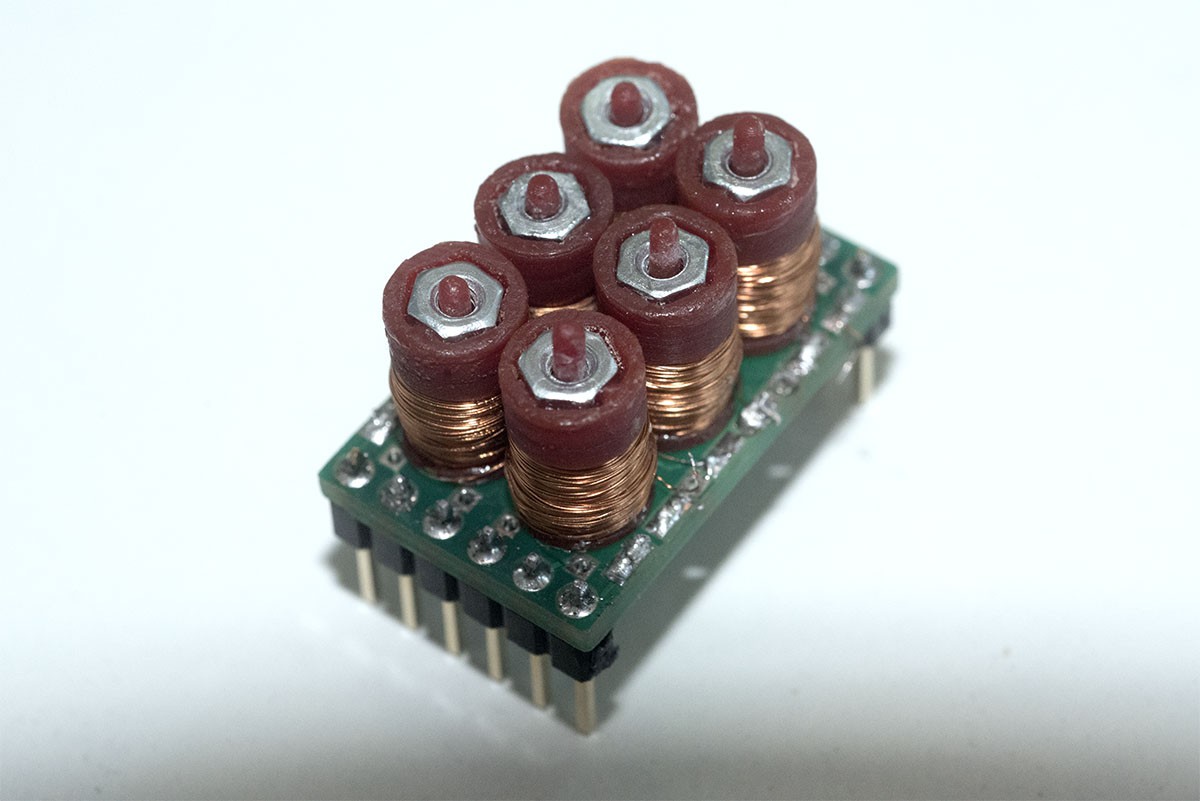

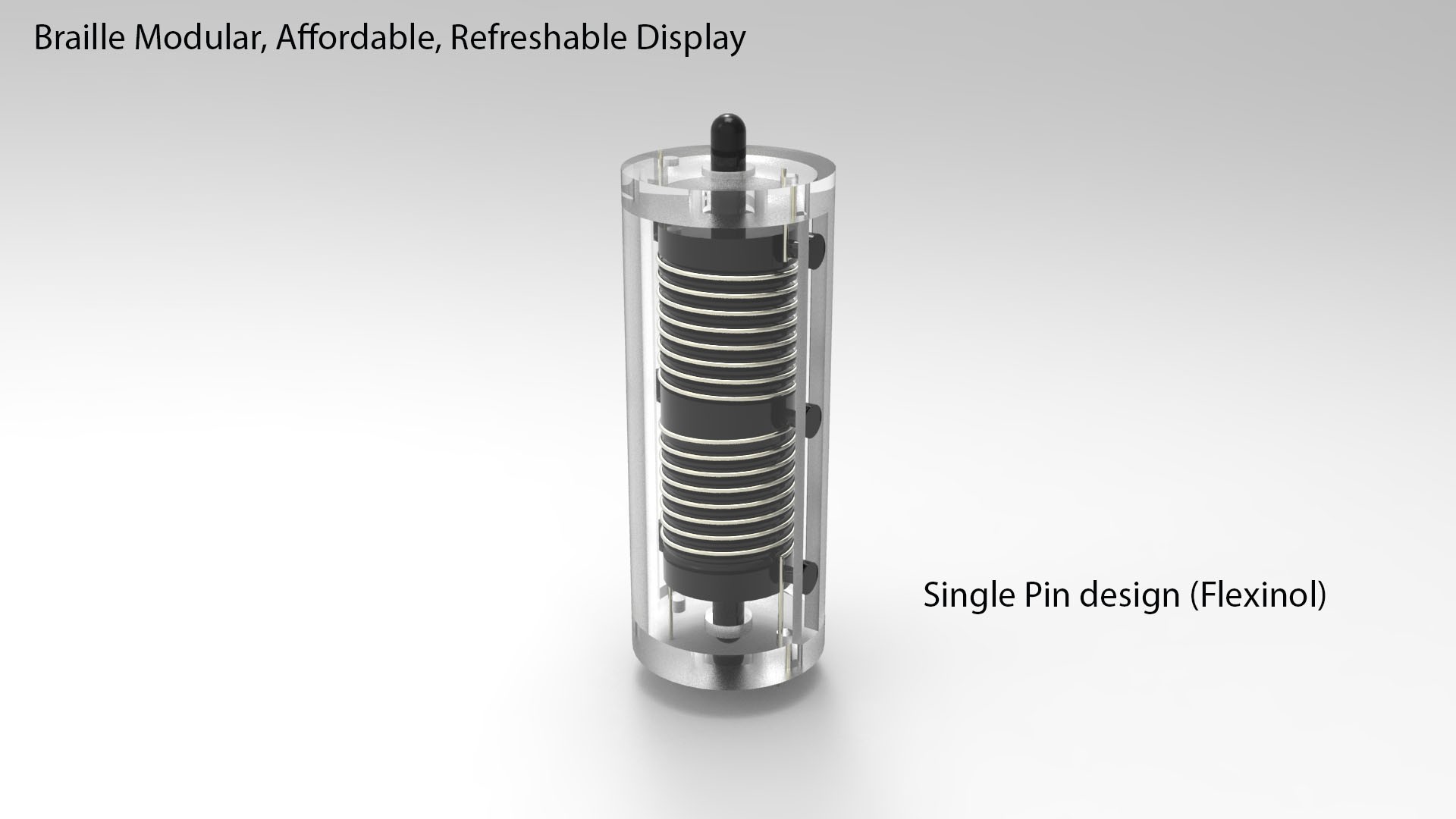

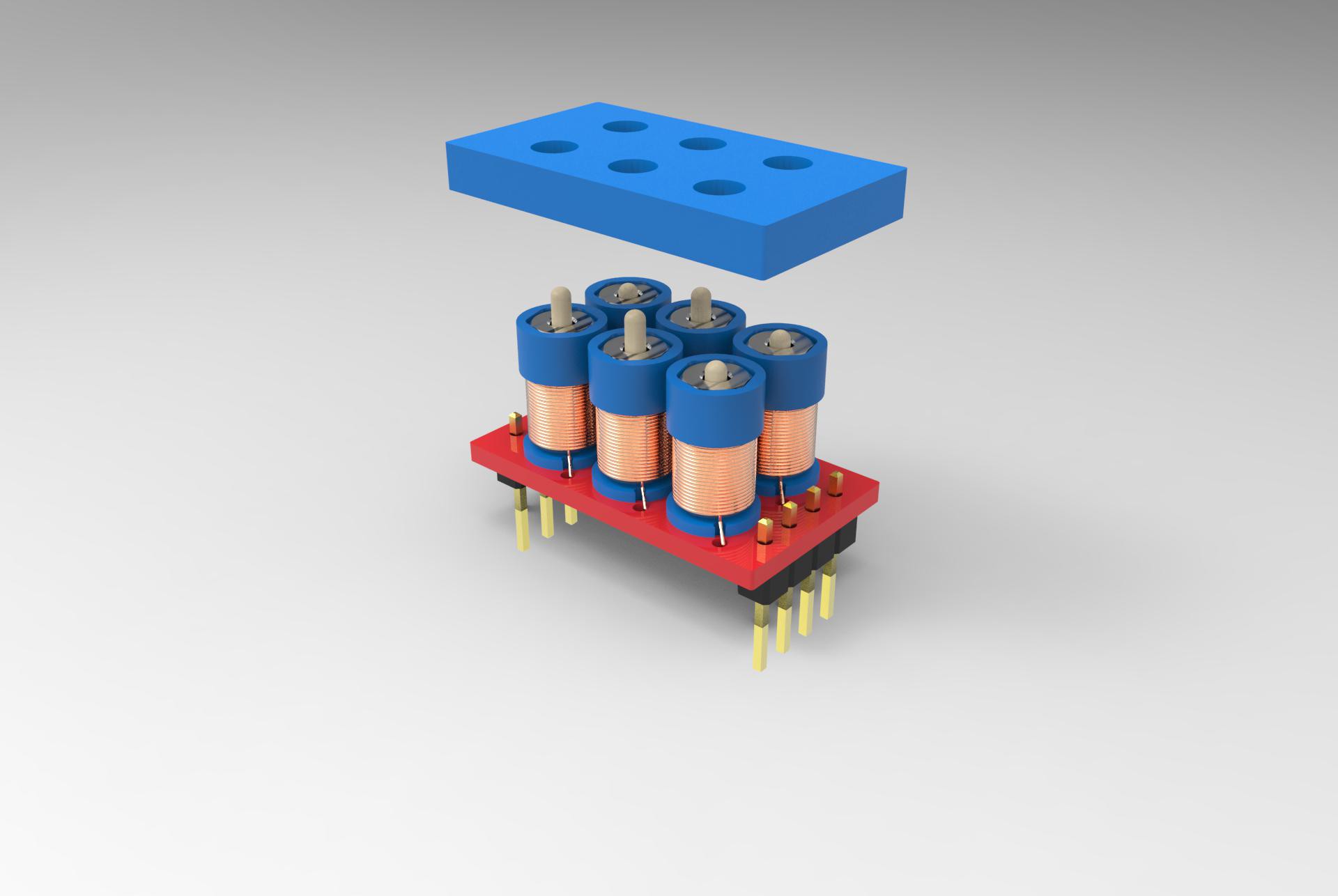

The main idea behind the project is quite simple: For each pin, one coil can move move some very small magnets from one end of a cylindrical body; at each end, two small pieces of ferromagnetic material will hold the pin in position. With this design, power is not needed to keep the state of the pins.

I have successfully tested the pin mechanism, and built some character modules; of course the project is still work in progress and the final size and performances can be greatly optimized.

Now the development has been organized in phases.

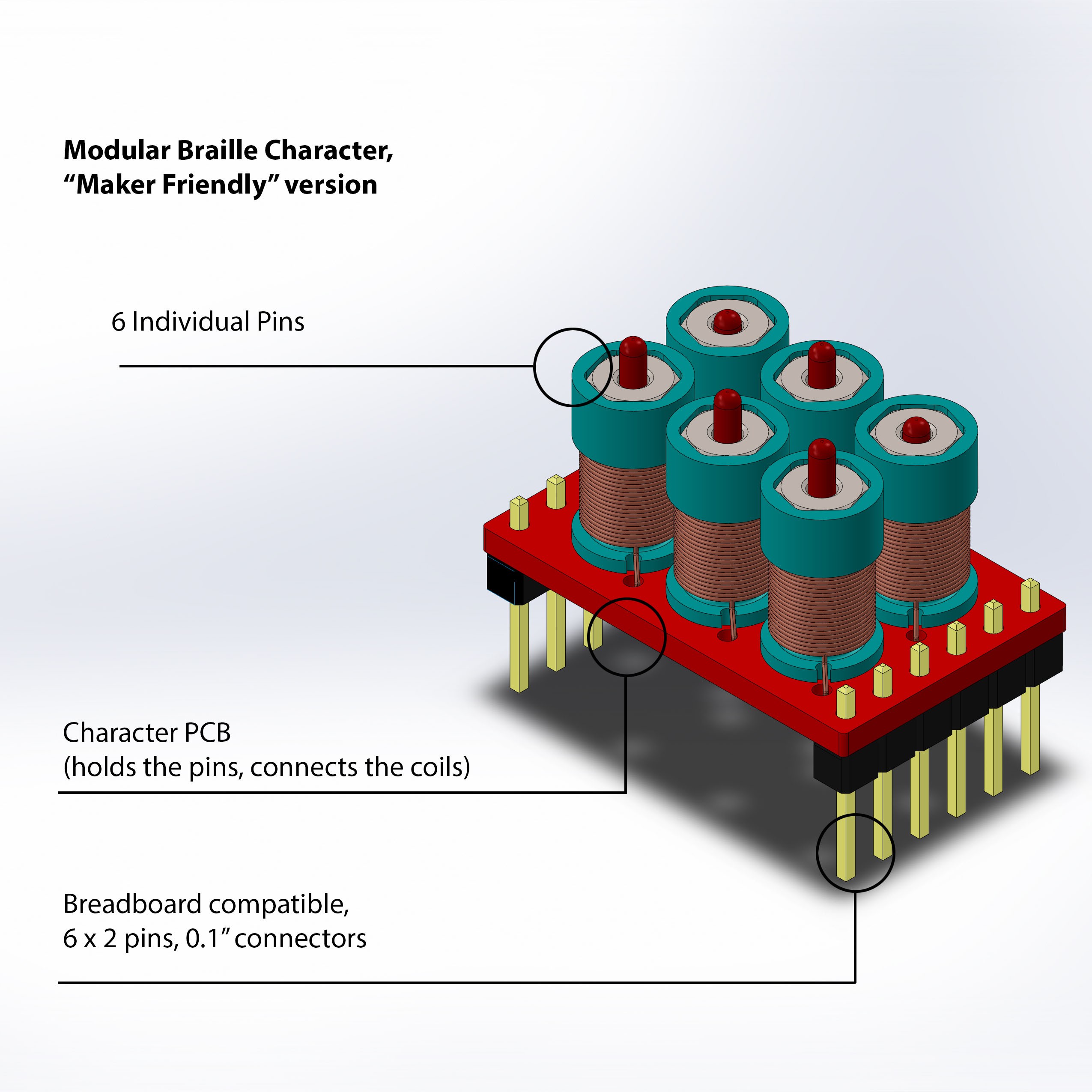

- In the first one, a Maker friendly, breadboard compatible Braille character will be developed. An Arduino demo shield will be developed to test the system and showcase the project.

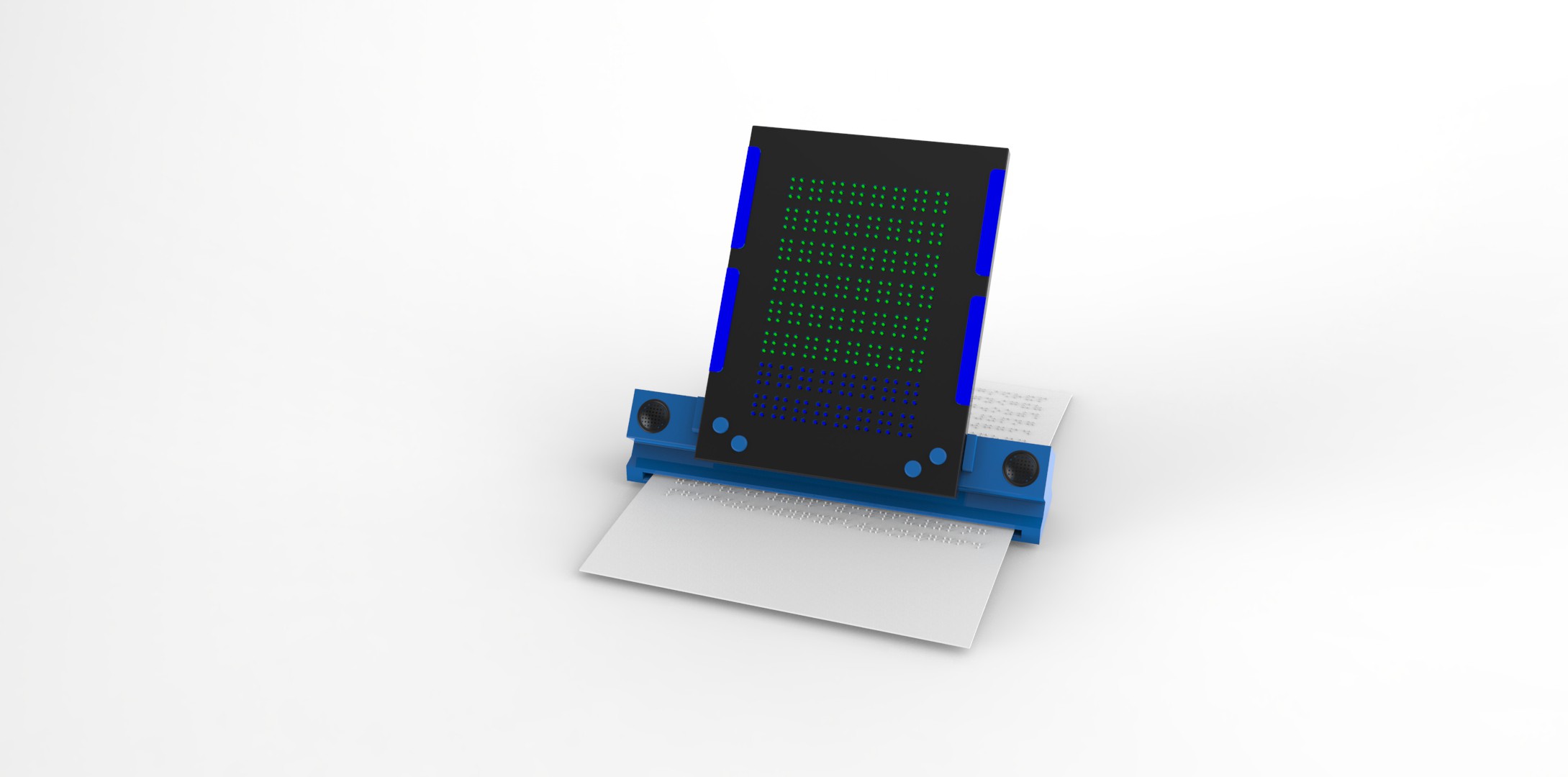

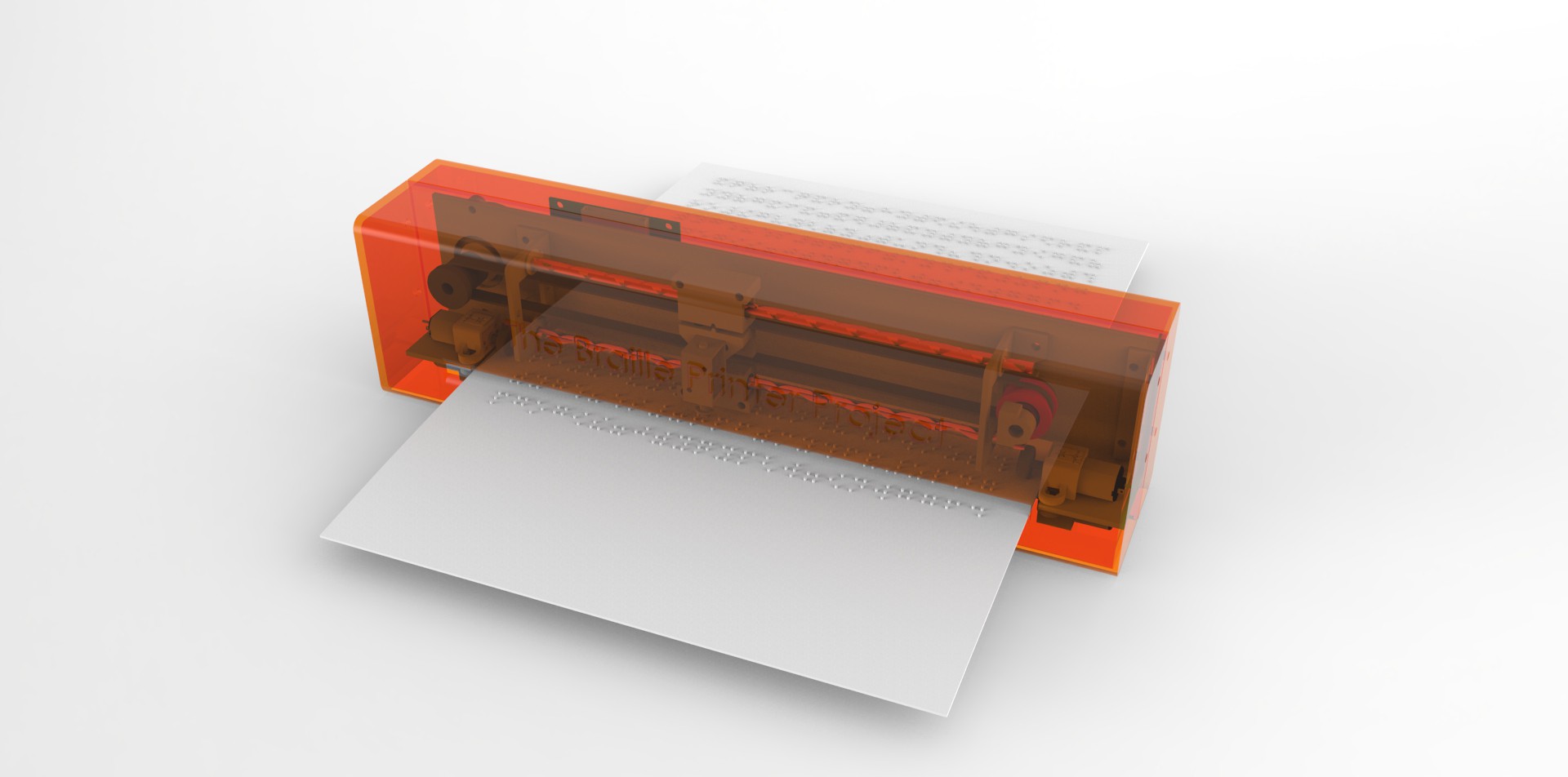

- When the character system will be refined enough, a “LinePCB” will be designed, and will hold 8-10 characters, with a modular approach. A “PagePCB” will then be designed, and will hold 6-8 lines.

- Finally, an entire Braille refreshable screen will be developed, and it may be used for a standalone device like a Braille Tablet, or incorporated into an existing device.

How does it work?

With the current design, each "dot" on a character module is made up of 2 3D printed parts (Body and Magnet holder), 2 M2 nuts, 2 magnets, and 0.1mm enameled wire. A controlling PCB also hold the bodies. This design uses a really low parts count, and efforts have been put to use parts already available, such as the M2 steel nut; this design allows for a very low cost per character.

A (not definitive) cost analysis

The cost for a single pin , for a production in the order of hundreds, is estimated around or less then 0.85€. It includes nuts, 2 injection molded parts (magnet holder and body), magnets, and coil.

The cost for a single character is thus in the order of 5/6€ per character, with a small/medium sized production.

The cost for an entire line of 10 characters is around 120€, including 60€ of characters and 60€ of pcb, most of it due to the TB6612 currently used which are quite expensive.

An hypothetical device with 8 lines, a controlling board, sensors, battery and enclosure should have a total cost of less than 1000€ for a medium/small production, allowing a final retail price of probably 2000€... which is quite not bad compared to the commercial products available today!

Madaeon

Madaeon This is a short list of their suggestions / requirements:

This is a short list of their suggestions / requirements:

Gabriel D'Espindula

Gabriel D'Espindula

ben.brochtrup

ben.brochtrup

Ryan

Ryan

can you send the circuit diagram of braille project, what you have used in it and also with which code you have run it?