-

Latest revision OpenNURBS (.3dm) files posted

11/26/2016 at 21:16 • 0 commentsI can't work on this project anymore as my trial copy of Rhinoceros has expired so I'm posting my progress on the JouleBox and hoping I was actually finished with the latest revisions I was making to the design before it expired.

I wasn't able to do a test print but at a glance it looks like the pieces might at least fit together. I can't even check with my copy of Rhino now crippled.

Oh, I think I found what needed to get done. I had finished the revision only to realize I had borked the insets for the M2.5 machine screws. You were supposed to need 10mm screws but the posts I had designed places the heads flush to the top of the case.

If you print these files as-is you'll need to procure so very long M2.5 machine screws ... 29.1mm long to be precise. What an odd length for a screw ... sorry!

https://www.fastenal.com/products/details/91184

These look like they might be long enough.

-

Aaaaand the printer is down ...

09/19/2016 at 23:15 • 0 commentsMy MP Select Mini's heatbreak needs a new PTFE lining. The printer jammed while I was printing the latest revision of the JouleBox's base plate. It should be up and running soon, the new version of the JouleBox will be 2mm thick for additional structural stability especially where the two shells overlap.

-

Files pulled, need major revisions.

09/11/2016 at 04:24 • 0 comments![]()

Finally got some PLA and fired up the new printer on the 1st of September. The good news is I was able to print the JouleBox files and test to see how well they fit together. The bad news is that they kinda don't. The files have been pulled until revisions can be made.

A lot has been learned about 3D printing in the last few days. I've successfully printed the first draft version of this case and before even testing it on an actual Joule Expansion Board I can already say that major revisions need to be made. The PLA plastic I printed the case with is strong but more brittle than my expectation. The thinnest pieces need to be about twice as thick. The panheads of my M2.5 bolts won't sink into their insets either. The print time is quite a bit longer than the slicer was predicting: not 5 hours, more like 7+. That can't be helped but the other problems will need to be fixed before I can asked anyone to bother testing the case with their Joule.

My other project, the PocketPi, had similar issues but the connectors all lined up well which boosts my confidence about the JouleBox substantially. I've revised the PocketPi to as close to perfection as I can muster and will be applying the lessons learned to a revised Joule case. I haven't gotten any feedback about the JouleBox so I don't actually know if the ports line up. I think I'll make a stencil of where I've decided the ports are that won't take seven hours to build so a volunteer can let me know how they fit. If I can come up with $370 I'll buy a Joule and test it myself. I might as well since I designed a case for it and all.

-

Intel Joule Case is here!

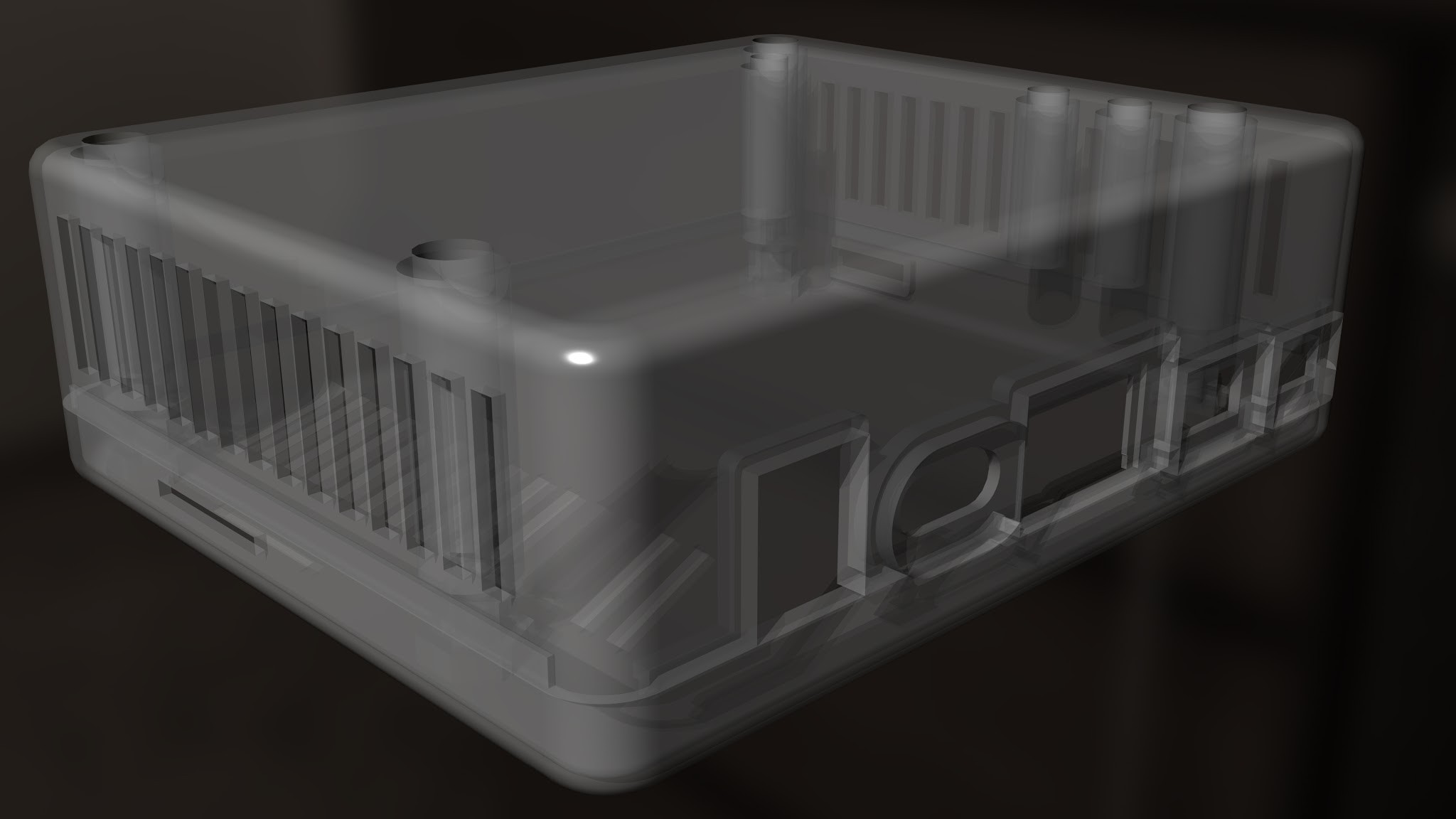

08/19/2016 at 23:41 • 0 comments![]()

Untested Intel Joule case is untested.

The .OBJ files are now available to download as of this moment: 16:20:00 PST on Friday August 19th, 2016.

If anyone has an Intel Joule 570x Expansion Board and is willing to sacrifice five and a half hours on a 3D printer to test this case so I can confirm that my measurements were accurate let me know about the results.

The JouleBox should weigh in at about 32g and take approximately 5 hours and 20 minutes to print on a printer that extrudes 50mm per second.

Naturally some modifications are still needed as a case fan might be a nice addition or a way to feed ribbon cables into the enclosure for the GPIO pins. The reference heatsink Intel provides will nearly reach the top of the case so I'm wondering if there should be vents above it. There's a lot of empty volume for accessories but this case is only 97mm x 82mm x 30mm which is only about 30% wider than your standard Raspberry Pi enclosure. I was thinking about adding a compartment for a 2.5" HDD/SSD bay in an expanded design and I'm open to ideas for additional features.

-

Beautiful render but it won't import ... !

08/19/2016 at 09:39 • 0 commentsI got a little carried away with the polygons on this one so my slicer choked and I had to roll back some design changes as even at the lowest export setting I was getting around 11,000 polys. Curves, curves everywhere.

I'm going to clean up the kerf between the two shells and will release .obj files that I have confirmed will load into at least my own slicer tomorrow after I sleep some. I'm antipicating CAD nightmares.

JouleBox

Intel just announced the Joule 570x so I designed a 3D-printable enclosure. Who wants a Joule case?

BalinTech

BalinTech