-

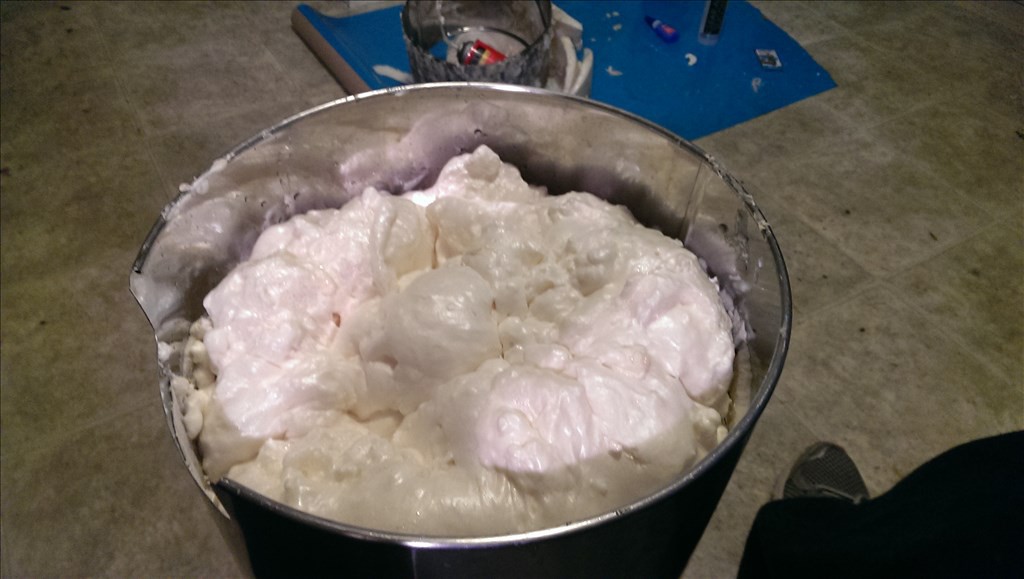

Part 5: Cutting out the excess foam from the bottom

04/15/2018 at 16:26 • 0 comments![]()

![]()

The heat sink fits! foam clean out is done.

-

Part 4: Insulating the bottom of the robot body

04/15/2018 at 16:24 • 0 comments![]()

![]()

A square hole was cut through for the heat sink to pass through the TEC Peltier.

Next I foam sealed the bottom.

![]()

![]()

It made a big mess, I will clean out a hole and then find a way to cleanly cut the excess out in sections. I will do this with a filet knife.

-

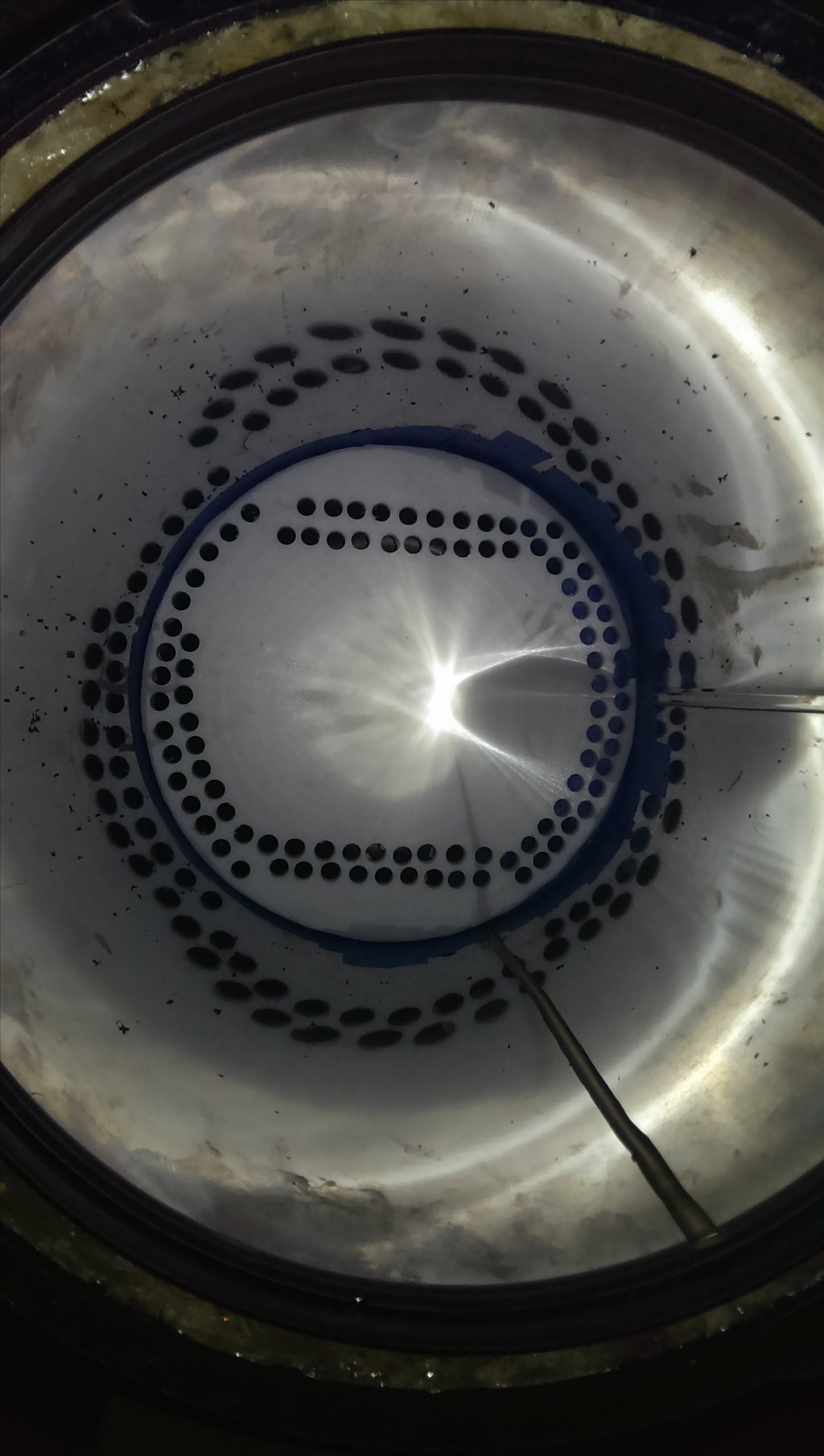

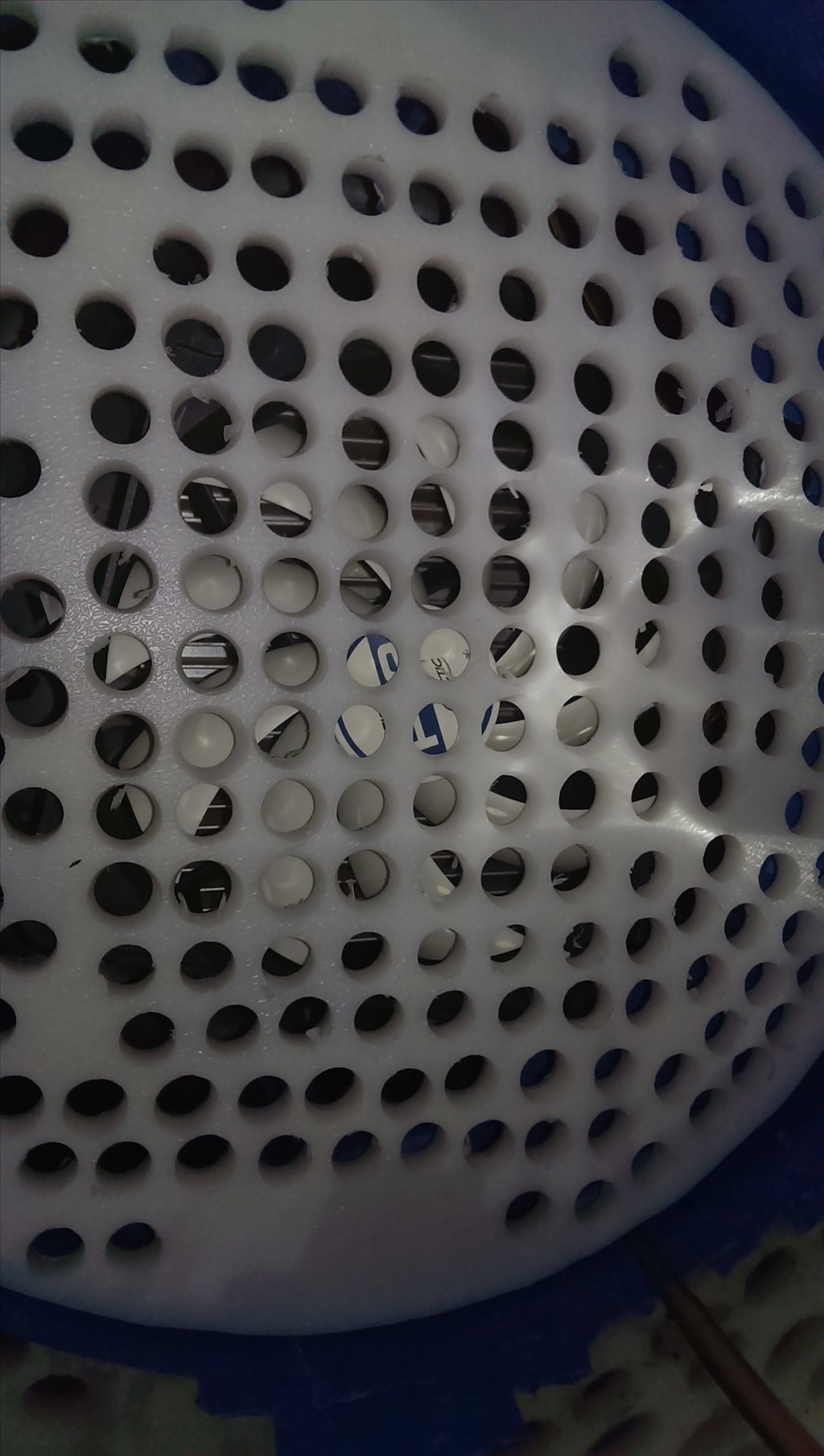

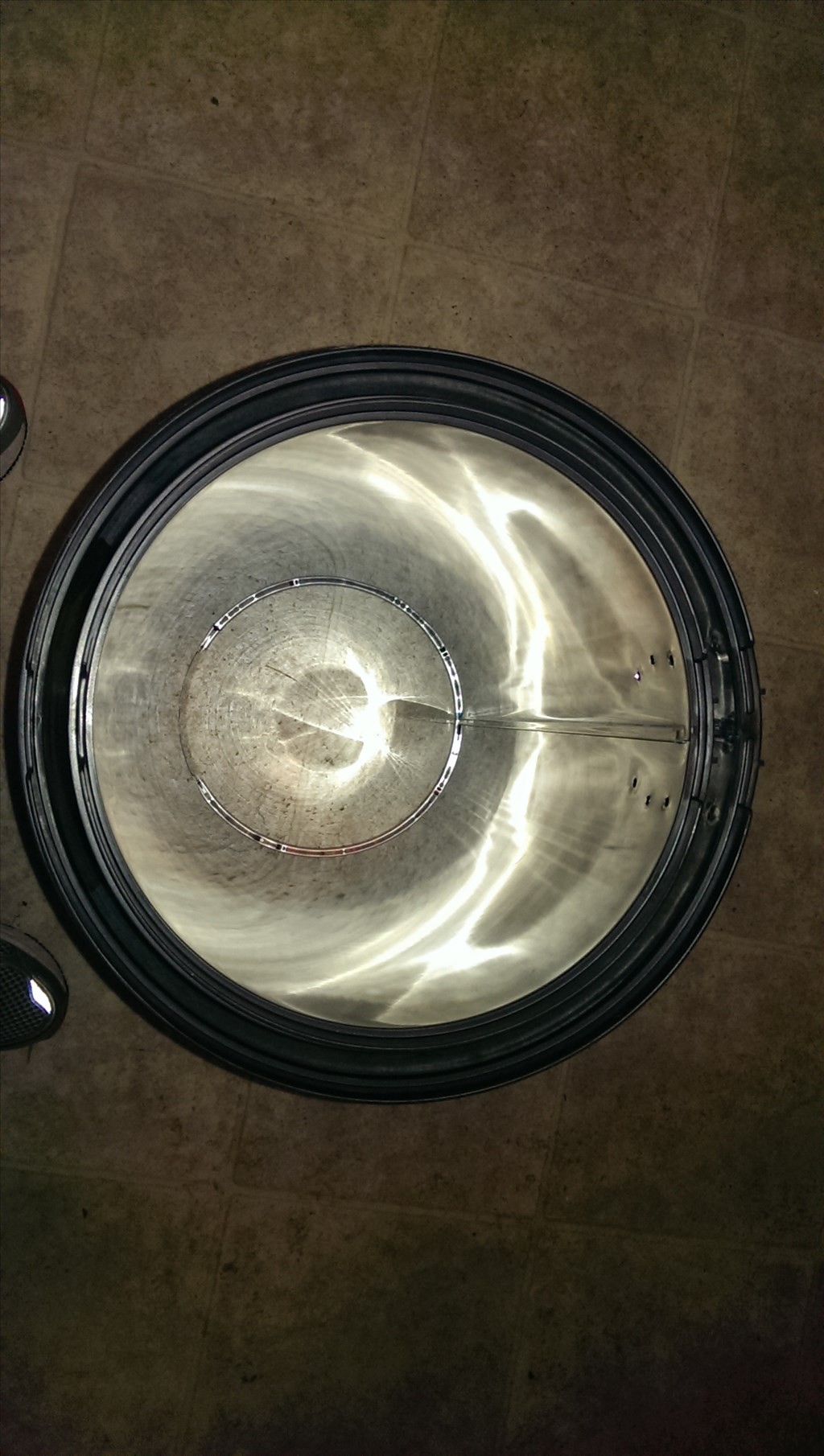

Part 3: Making the Grate

04/15/2018 at 15:44 • 0 commentsThe plastic disk will now fit in side no problem and does not move around. Next we need to machine the plastic so air can flow through and cool our beverages!

![]()

![]()

The outside edges are going well. I am doing these by hang because I do not have a drill press.

![]()

A little closer, almost there.... my hands hurt. If you do this, buy a drill press.

![]()

It is TIME TO TEST FIT !

![]()

Boom! everything fits and the heat sink is in place with the fan. All is fitting well.

Test fit a wine bottle inside :)

![]()

-

Part 2: Making the Grate

04/15/2018 at 15:40 • 0 comments![]()

![]()

Resin as been poured in and now we wait about 20 minutes to harden.

![]()

The resin has hardened and I peeled away the masking tape, it look great! Now we have a continuous ledge to seat the grate on.

-

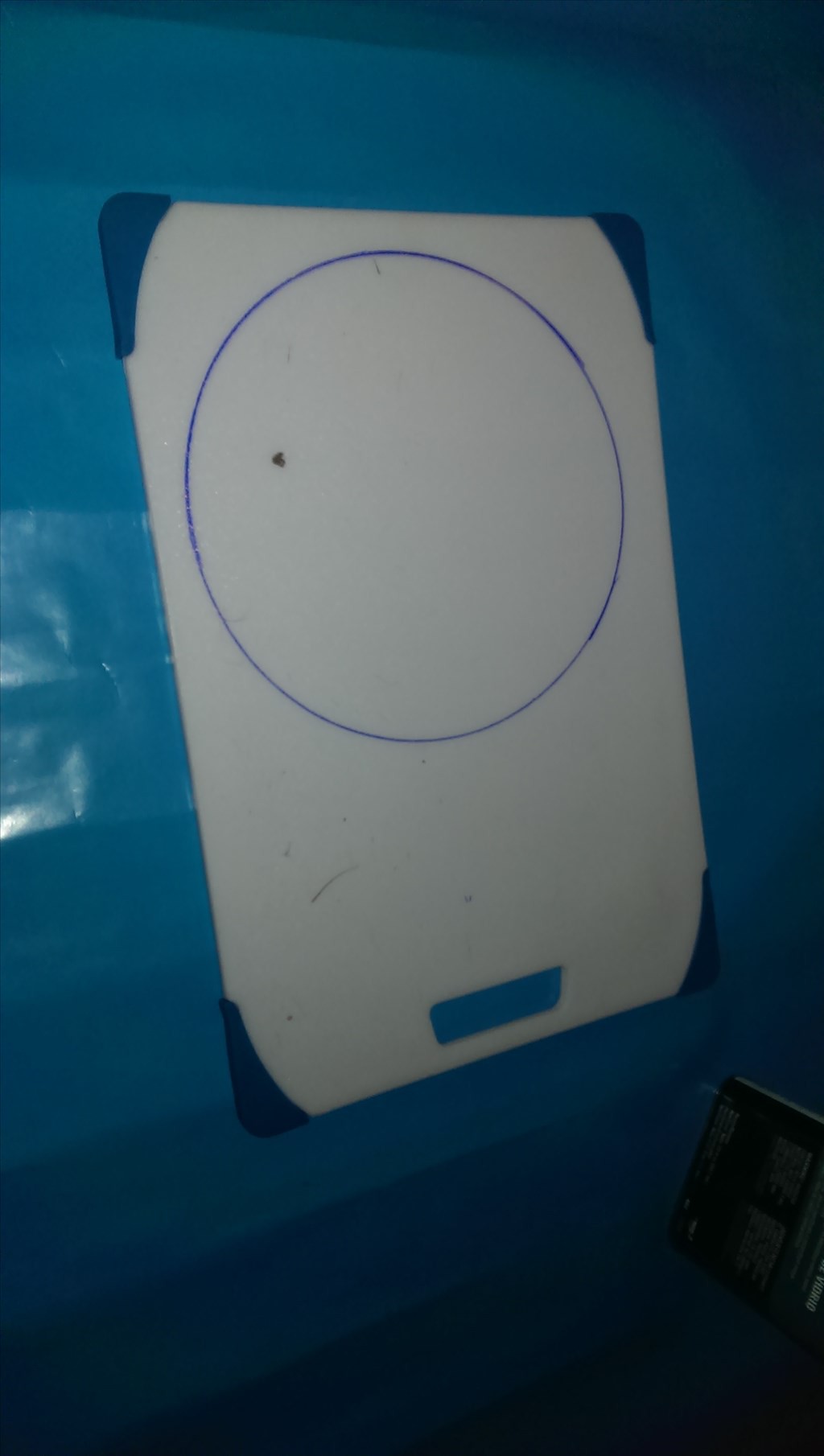

Part 1: Making the grate bottom with food safe plastic

04/15/2018 at 15:36 • 0 commentsI need to make a bottom that air can flow through. I picked up a 12 dollar food safe plastic cutting board. I believe this stuff has "Microban" in the plastic to prevent bacterial growth in abrasions.

![]()

Careful cutting with a Dremel yields good results. Now we have a disc to machine.

![]()

-

Seal the edges with epoxy

04/15/2018 at 15:31 • 0 commentsHere i show how deep the cavity is and that the edges have been sealed with low viscosity epoxy resin.

![]()

![]()

-

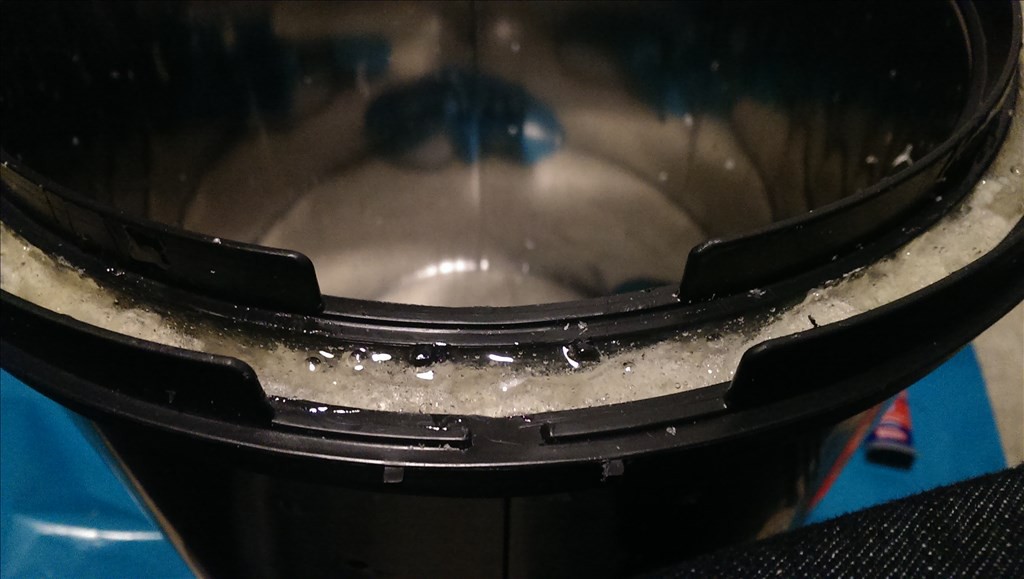

Step 2 on the body insulation, the bottom drip pan

04/15/2018 at 15:29 • 0 comments![]()

![]()

![]()

-

Posted video insulating the body of the robot

04/15/2018 at 15:27 • 0 comments -

Insulating the body

04/15/2018 at 15:25 • 0 commentsHere is the two containers taken apart and prepping for a foam insulation.

![]()

![]()

![]()

![]()

![]()

![]()

I used great stuff foam sealant, in retrospect I would probably just order a two part foam pour system online because it took a few cans to get this filled up and the straw is not long enough to reach to the bottom so I had to flip it to spray from each end.

Brewster video they started saying " so why don't you have a robot bring you a beer" "why doesn't your robots do something useful". Take in mind cleaning robots are not exactly what guys think is fantastic lol. So beer bot challenge it is! This one is keeping the KISS rule though , keep it simple stupid lol.

-

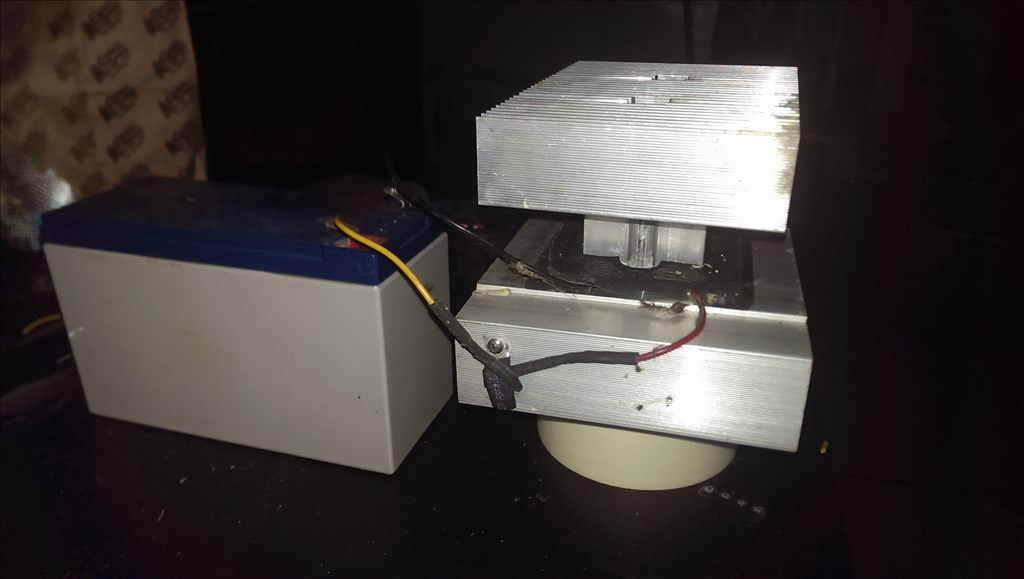

Testing the Peltier TEC Cooling Unit

04/15/2018 at 15:18 • 0 commentsSince I bought my Peltier element and heat sinks from the auction I wanted to make sure it worked. I powered it up without fans. It took about 2 minutes for the hotside to warm up. It appears it will work but I'm still considering buying a higher power Peltier. This one is a 45w to 50 watt.

![]()

Beer Butler Robot, Refrigerator on a Roomba

Mobile refrigerator! An insulated tube built on a hacked Roomba controlled by serial connection. Indoor Nav by QR code ceiling tiles

Josh Starnes

Josh Starnes