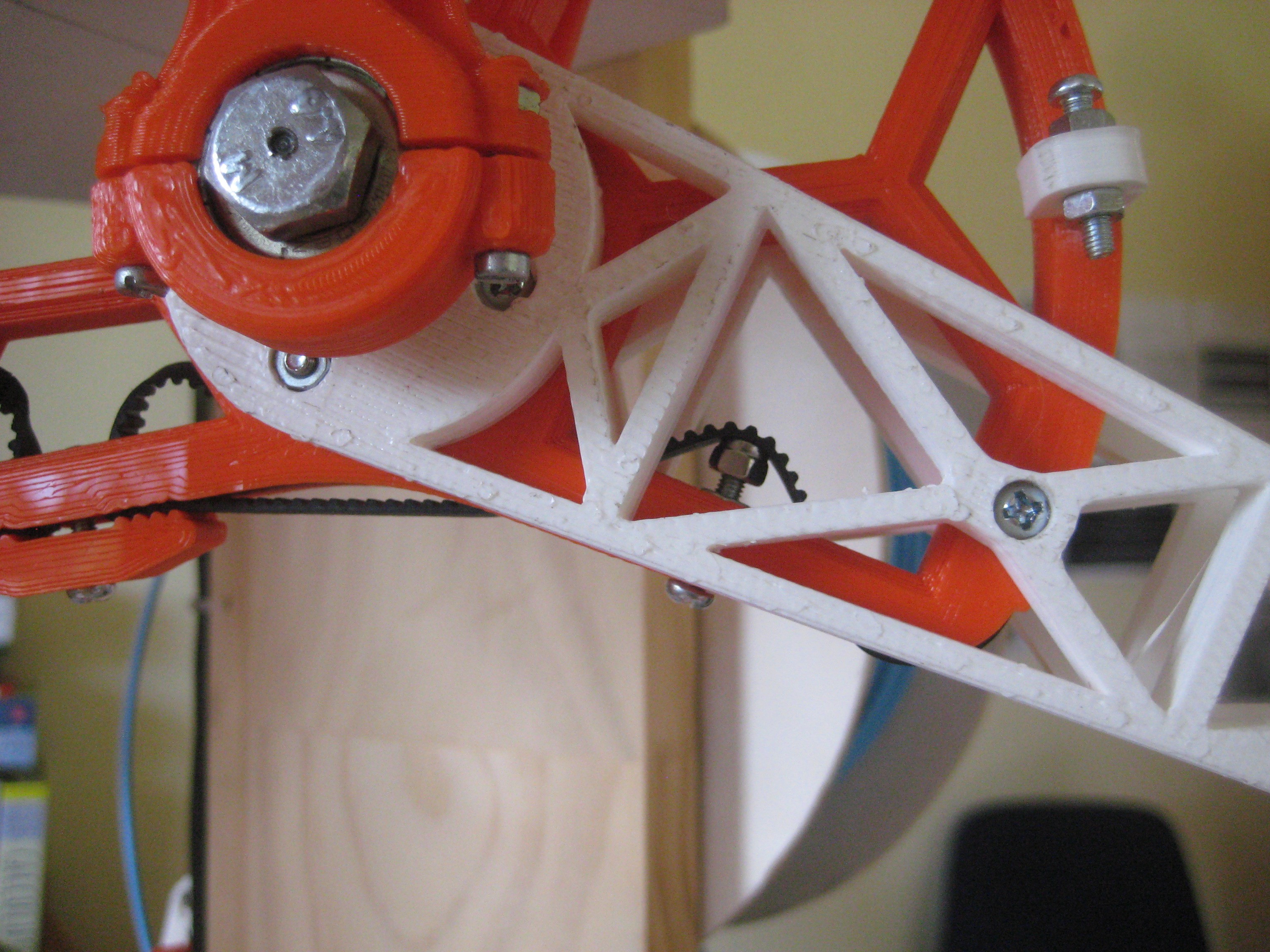

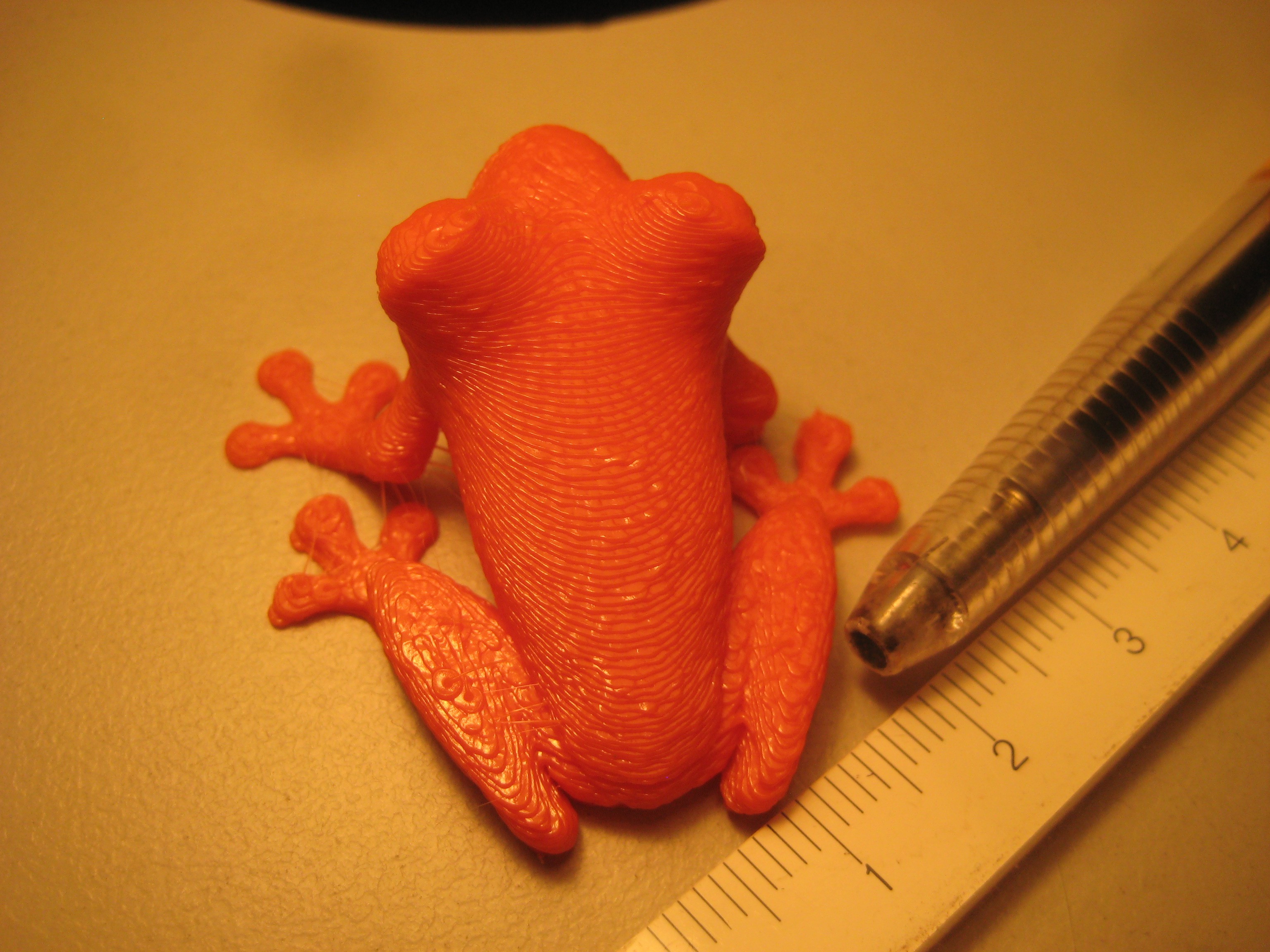

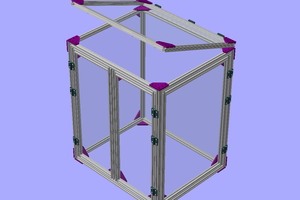

The design goals of low cost have been met. I

think this is about as cheap as one can build a 3D printer. Looking

back, going straight from repstrapping to building a printer like this

has been very challenging and educational. Lots of fun and learning has

taken place. Overall it has been a great learning experience. As the

saying goes, everything is hard before it's easy. For example, when I

started this project I didn't know how to use CAD. I have definitely

learned a lot in the process.

I'll be shelving this project, it has met its goals of being super cheap and printable.

This

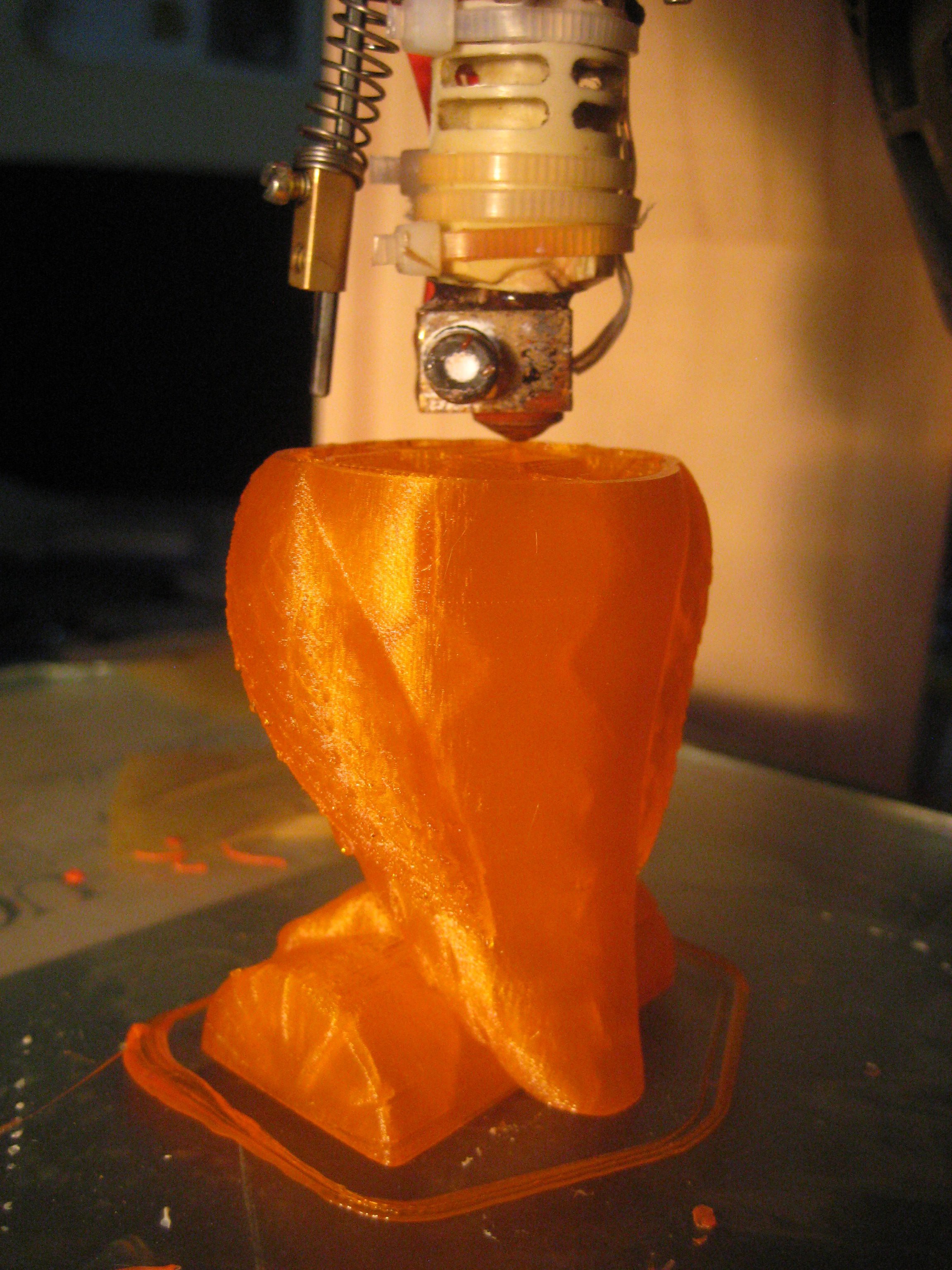

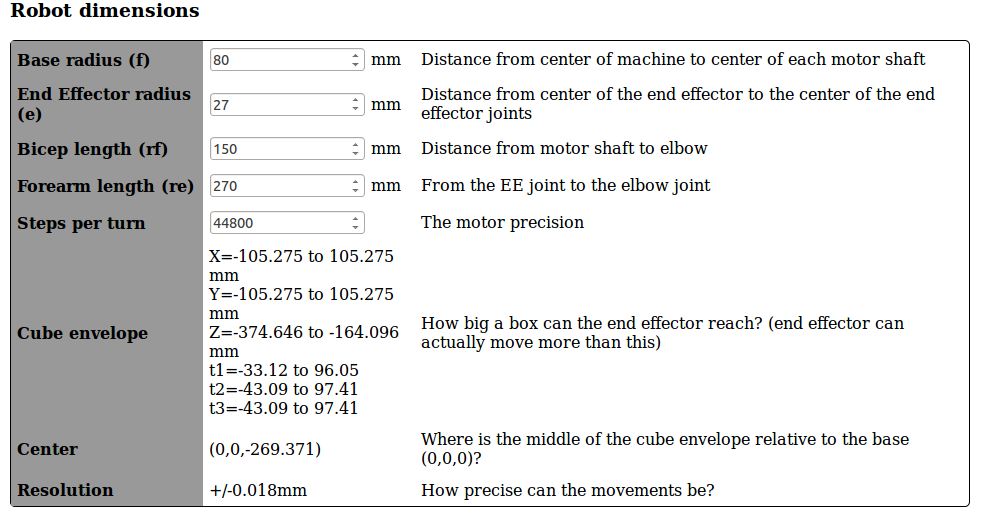

hasn't been without cost though. Calibration is very tricky. All parts

must be produced and measured precisely to be able to print anything at

all!

Dialing it in is very time consuming. Calibration is not

impossible, it must simply be done in a logical order, making sure at

every step that every part is measured accurately.

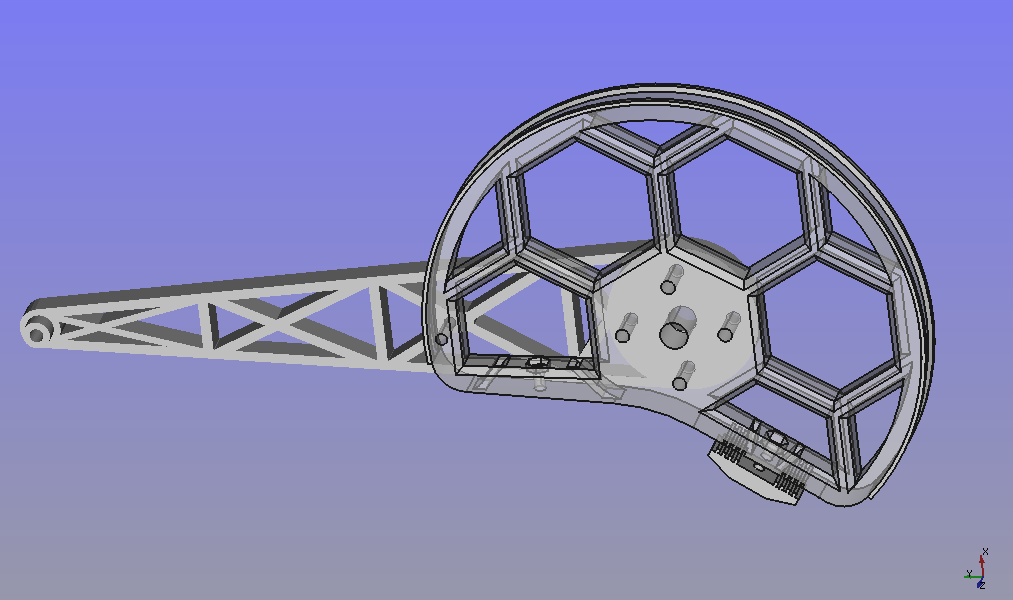

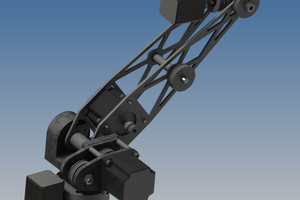

This leads me

to the next design phase. I would like to design a Reprap that is easy

to calibrate, has a rock bottom bill of materials, highly printable, and

can reprint copies of its own parts. All this while maintaining

accuracy of the parts.

I hope you enjoyed reading!

P.S. I have set up a new project page.

Credits

Special thanks goes to Matt Kimbal for teaching me how to use FreeCad. I would also like to thank the Firepick Delta team for inspiring this project. Without you guys this project would not have been.

TTN

TTN

Andrew Becker

Andrew Becker

TheStumbler

TheStumbler

Steve Pendergrast

Steve Pendergrast

Matthew James Bellafaire

Matthew James Bellafaire

First of all: I very much admire your ambition and work ethic in making this machine, and making it work. Thou art indeed the man.

As for for printing accuracy: You've had a couple years to think about it now, and I want to ask you a few questions please.

Today, how much of the IcePick's printing inaccuracy do you mentally chalk-up to the harder inverse-kinematics sticking you with just ~40 segments per second?

As for tooth-belts, plenty of linear-slide delta-type machines do just fine with tooth-belts, so do you still (partially) "blame" the arms (instead of linear-slides) for its inaccuracy problems?

In general, I'm puzzled as to why there's be so little work being done on delta-arm type machines like this. I'm not calling the whole world stupid, but I AM genuinely confused as to what their inherent deficiencies -- if any -- might actually be. So your comments will be very much appreciated. And thank you.