Step-and-Scan Digital Microlithography

submicron-scale patterning of silicon and dielectrics

submicron-scale patterning of silicon and dielectrics

To make the experience fit your profile, pick a username and tell us what interests you.

We found and based on your interests.

While I don't have such a posh lens, you might enjoy "DIY Photolithography using 1980s Carl Zeiss S-Planar Lens (405nm)" by Huygens Optics in the meantime:

Just so we're clear, and I'm referring to this HaD article,

https://hackaday.com/2018/04/24/first-lithographically-produced-home-made-ic-announced/

- whatever we as hobbyists can cook up, the ultimate measure of our achievements will be not what we can demonstrate in principle but how well we can catch up with decades of research and commercial development.

And in an necessary act of defining what my project will not be about: it will not be about competing with this product:

and these specs:

https://www.newport.com/f/dynamyx-gt-high-throughput-stage

As a starting point: a 50x50 cm² grade AA surface plate will set you back $600-700 and that's just the seat at the table :)

I've picked up meditation again - drilling, tapping, filing, sanding and lapping. One tends to get lethargic and lazy just watching youtube machinists do their thing; one of the few activities that get me in the mood is grabbing some stock and make it do things. One day I'll have a shop to call my own again. Meanwhile I occasionally sneak in half an hour at work while some experiment is running, so I appreciate your patience.

Building the machine could be designed planned and then executed with discipline but.. this is not that. So let's start in an unstructured manner by manufacturing and assembling the mechanical components:

Ok.. I admit I made drawings, telling myself that's so as to not look suspicious in the shop and to reduce the likelyhood of drilling and counterboring a mirrored hole pattern.

There it is, starring my nemesis, the chinese rip-off stage - raised to a level that establishes some clearance for the micrometer screws. The plates are only 7.5mm thick (no idea why, they ought to be 8mm extrusions) so I couldn't bring myself to do 4.5mm deep counterboring.

The rotating stage doesn't have axial spring preload yet and has to be set manually to minimal play so every minute deformation of the base or turntable results in it seizing up, promting me to spend more time lapping the mating surfaces.

On the micrometer scale everything is a spring element so with the kinematic mount adapter plate done I created an annular pattern of kapton tape stripes, hoping to achieve proper seating without wobble:

The 2-axis tilt/yaw stage now bolts to the rotating mount turntable with a central M5 screw (flat washer + spring washer in between)

Unfortunately the turntable reacts to deformation most unfavorably. The fact that lapping the top plate reduced the issue points to the turntable being very susceptible to z-deformation with an azimuthal dependence.

On top of that it also seems to react to radially varying z-deformation to a lesser degree (convex warpage by pulling the screw upwards against the outer zone).

It is what it is, I guess. Maybe it's telling me I should use the outer M4 threads but they're not accessible with the plate in place, leaving just the central screw. I'm now using it to adjust play :D Mechanical parts have their own way of telling you what's right and what's wrong.

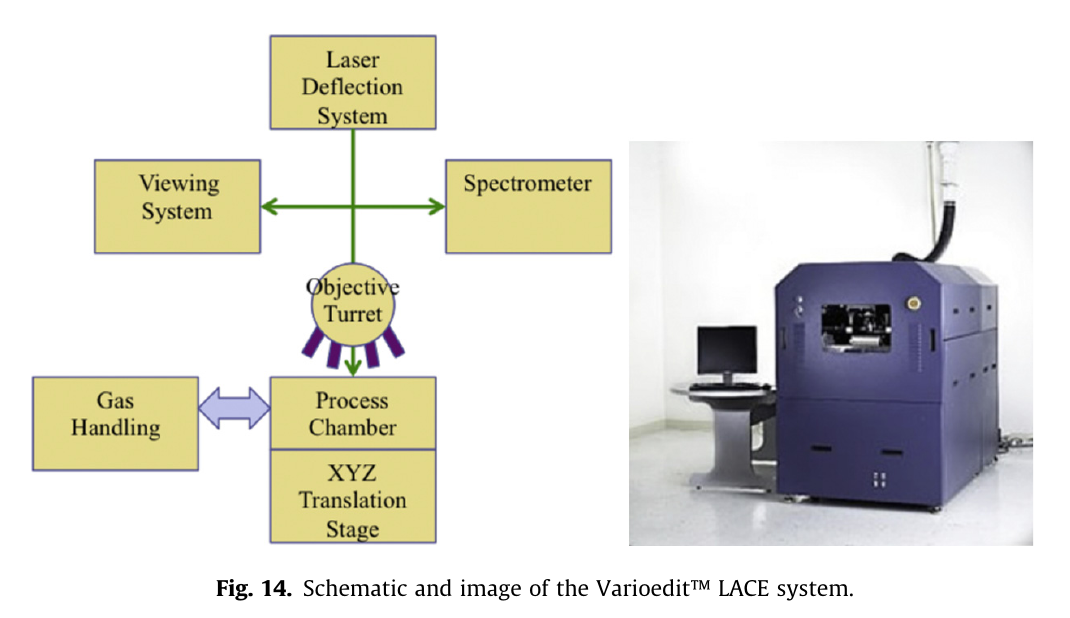

And there's the whole 5-axis stack bolted together:

I'll have to leave the sketchy 3D printed stepper assemblies in place for now. They contain skew gear reductions coupled to the spindles... to be improved once the precision/repeatability test results are in.

See you around.

ps. Why build a 5-axis stage?

Ok, actually there'll be a sixth axis with a piezo actuator (focus in z direction).

The cartesian axes are obvious. Tilt and yaw have to be adjustable (at least manually) to get the sample surface leveled. For lambda = 400 nm and NA = 0.85 we're looking at a focal depth of about 350 nm which is almost guaranteed to be violated by room temperature driven thermal expansion, vibrations and looking at the setup the wrong way. Wafer pieces are sufficiently flat for their edges to be used as reference features, enabling on-the-fly focus correction but you'll have to start with the object plane nearly level to within a few micrometers across a 10-20 mm wide sample. If there's still some room left for variability within the zone it's going to be consumed...

Read more »Every click-baity video starts with the final result, so here goes (not my achievement!):

https://www.memsnet.org/links/470/

http://www.eng.utah.edu/~gale/mems/Lecture%2008%20Dry%20Etching.pdf

RIE isn't closed-loop and ultimately it's practically impossible (think: SEM + Cl2 gas jet, super slow etch rates, https://aip.scitation.org/doi/abs/10.1063/1.3525587 ) to make plasma etching a maskless process. I could ignore shallow surface damage and ion implantation for my purposes but I like to avoid it if possible. Here's what that looks like:

https://www.sciencedirect.com/science/article/pii/0921510789902845

Chlorine on its own or in Ar has a tendency to photo-dissociate at visible wavelengths:

Here's the absorption cross section of Cl2 gas with an onset compatible with 405nm laser diodes and a maximum that's screaming "homebrew TE nitrogen laser":

With a bond dissociation energy of 242.58kJ/mol (2.515 eV/bond) plus (I'm guessing) some additional energy to end up in an excited state the molecular absorption peaks in the UV, capable of causing localized generation of chlorine radicals.

Our goal here is to generate volatile silicon tetrachloride (cue youtube video from NileRed on its conventional synthesis with heated silicon). For this to happen, chlorine radicals must be generated in the vicinity or on the surface of the silicon specimen to be etched and be willing to react with the silicon atoms presented at the wafer surface.

Seriously, Si has to react with Cl. radicals or worse... and there's where the problems start.

http://iopscience.iop.org/article/10.1143/JJAP.24.68/meta

"It was found that n+ poly-Si is etched by chemical reaction with Cl radicals photodissociated in the gas phase, while undoped and p+ poly-Si cannot be etched without irradiation by UV light. The primary effect of the photoirradiation is to produce electrons arising from electron-hole pair generation. The etch rates, etched features and etching products depend strongly on the electron concentration in the conduction band. The experimental results are explained by assuming that electron-attached Cl- ions penetrate into the Si lattice."

Since I'm interested in selective backthinning of p- substrates this is not going to be as easy as swapping the samples holder for a gas tight process chamber and iterating between surface profile measurements and exposure phases to achieve a controlled 3D profile.

It's not as bleak as it might look from the 1985 point of view. in fact, Vakanas 2002 states (also refering to the patent below),

https://patents.justia.com/patent/8173552

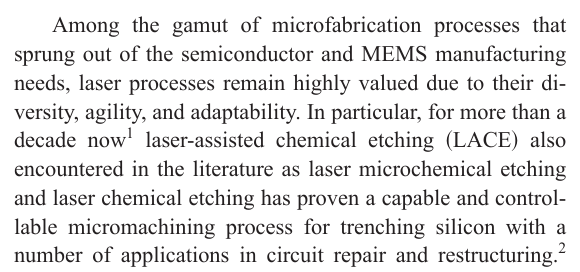

fast forwarding a few years there appears a behemoth called the VarioEdit

(as seen in Henderson 2013 https://linkinghub.elsevier.com/retrieve/pii/S0026271413001893 and https://www.varioscale.com/varioedit ):

There's a project which matches the capabilities of VarioEdit:

"Intel plans to ship 10 nm integrated circuits...

Read more »There are some quality metal parts from China. There are some acceptable parts (like the kinematic mount I analyzed here https://hackaday.io/page/3711-29-chinese-4-axis-kinematic-mount-what-to-expect ) and then... there is this "R Axis Manual Rotating Platform Precision Bearing Linear Stage Load 29.4N 60mm":

Let's start with the few things that are actually right with this interpretation of a rotating stage. There are dimensional drawings:

While the micrometer adjuster is tiny and too close to the plate, it works ok. It even has a ball nose as you'd expect.

And that's about where it ends with the rainbows and the unicorns.

The thumb screws are flimsy and their fit is horrible. Since at least the center one that locks the precision rotator to the turntable seems to be turned on a lathe I assume it just came out way undersize.

Next obvious thing: the top hole pattern is off by 5-ish degrees. While this might be deliberate, you'll have to create a rotated hole pattern if you want to bolt something to it that lines up with the scale. Plus I'm not sure if the scale is just scribed in a random orientation and every part is different. Good luck with that.

But don't worry about the scale marks. You won't be using them anyway.

Seems ok?

No.. it's not. While this was supposed to come out looking like a vernier scale I wouldn't know where to put the zero on that thing.

While these issues are just superficial, let's have a look at how "precision bearing" is being interpreted. And nothing speaks precision like these butchered, rusted countersinks:

Let's compare this to the auction picture:

Something undoubtedly changed anlong the way. But wait, there is more. I'm suspecting that what makes this thing have a precision feel is nothing but a generous helping of this glorious stuff (oh so Very Press):

Undoing the four PH0 screws makes the steel plate come off.

This doesn't look much like a precision bearing, does it? It may be a "bearing surface" but it sure isn't lapped and neither is it precision (such tool marks are usually 10+ µm in roughness). Then again, why would it need to be lapped if it rubs against the paint of the steel disc, getting loaded with paint particles during use. The center is threaded and four set screws lock it in place, also annoyingly backing off the back disc as you tighten them which makes the assembly loose once more. Fun fact: the T-shaped part attached to the ring is a powder metal part. Maybe that's why the thread is so sloppy. Back to topic. Below you can see the bottom reference surface of the turntable.

I then took the rest of it apart, revealing the whole mess. I'm not sure if I'd call the aluminium anodized judging by how it chips away at the edges. Here's the last positive thing of note: they actually relieved the contact surface. I didn't measure the inside and outside residual ring heights but I'm guessing it'll want to make contact on the inner one as well. *sigh*

The conical steel? ring inside is slightly raised and pivots a bit and when the center thumb screw is tightened, it rotates against the main body to translate the 3-4mm of usable travel of the adjuster into some +/-2° of fine rotation while the turntable still slides on the face of the main plate.

The cone also allows it to self adjust or compensate for coplanarity error of the whole clamped stack as the stage rotates (doesn't work in practice once you adjust for zero backlash). The plate looks like it had already been mounted to something so...

Read more »

Create an account to leave a comment. Already have an account? Log In.

Best of luck. here is my implementation: http://sam.zeloof.xyz/maskless-photolithography/

Thanks. Just had another setback, maybe I'll write a log about it....

Become a member to follow this project and never miss any updates

Paul McClay

Paul McClay

Supplyframe DesignLab

Supplyframe DesignLab

David Troetschel

David Troetschel

This reminds me of my mis-spent youth! I used to work on Ultratech projection steppers in the early days of 150mm wafers. They used mercury arc lamps as a UV source. They also had a pneumatic auto-focus system that mostly worked.