-

I tested actual charge current

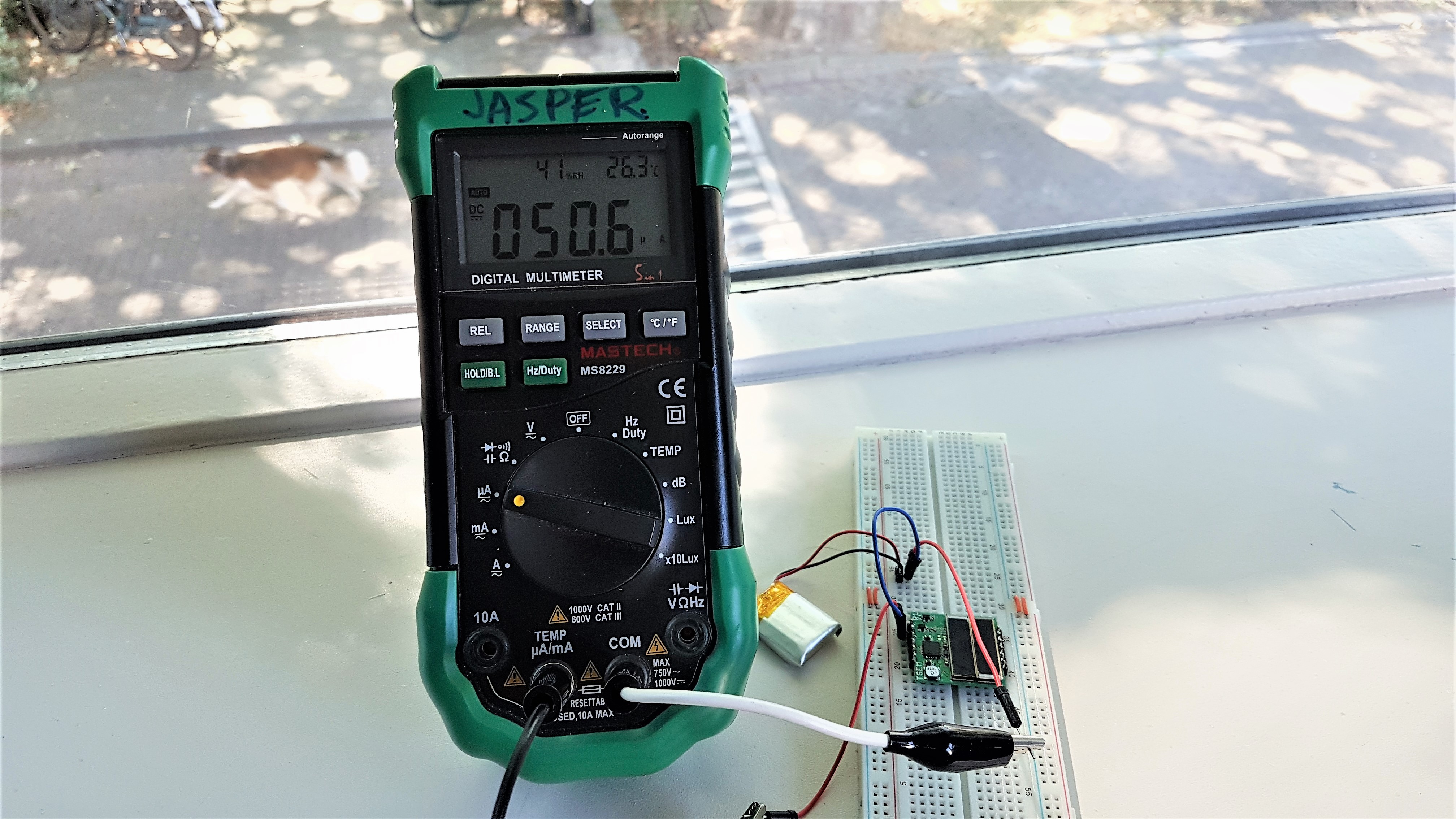

07/08/2018 at 14:56 • 0 commentsIn my previous log I calculated indoor battery charge current would be approximately 50uA. Now I have measured actual charge current. I used a multimeter with lux meter as a reference.

![]()

Indoor at 500 lux I measured 61 uA.

Indoor under a table, 150 lux, I measured 12 uA.

This means that TSEM is indeed able to power a very simple BLE or LoRa application.

-

TSEM can power a simple BLE or LoRa application with indoor light

07/07/2018 at 21:01 • 0 commentsIn this Kickstarter campain Tryst Energy, spinoff from TWTG, promised they could power LoRa and BLE applications from indoor light or even light from underneath a desk using few square cm solar panel. Now my circuit is similar. I am going to calculate how much it can harvests indoors.

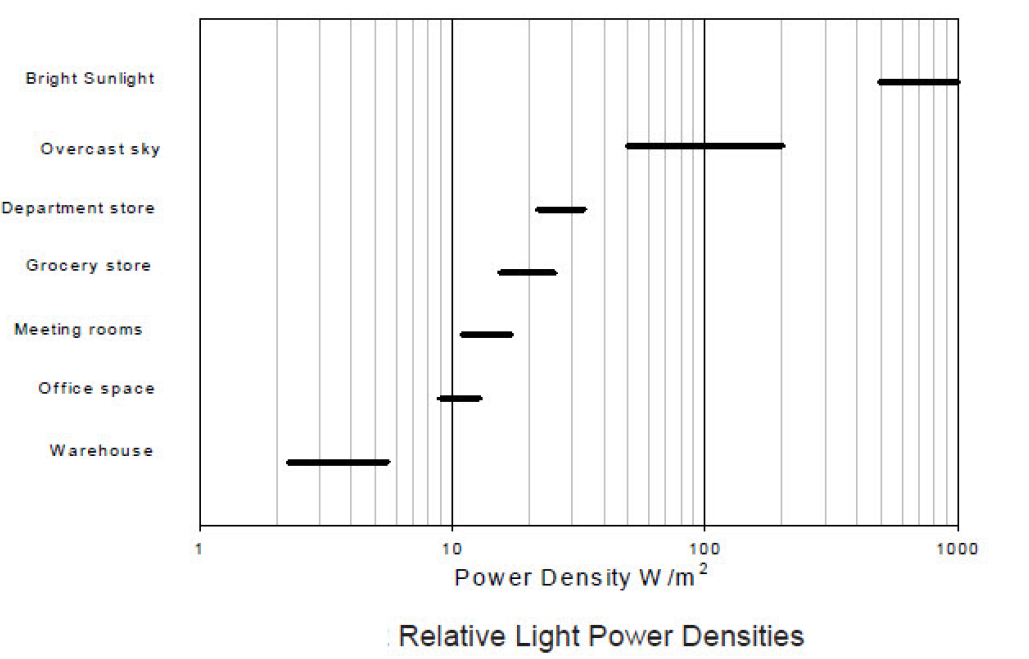

In the solar cell datasheet is a chart that shows indoor light is about 10 W/m2, that is about 1/100th of outdoor light (500-1000W/m2)

![]()

It also shows that solar cell open circuit voltage at 10 W/m2 is 0.458V per cell. Since I have 2 in series it means that the minimum voltage required for cold start of the AEM10941 harvesting IC (0.38V) is easily exceeded. Now I need to calculate the amount of power harvested with my cells. Since 1000W/m2 is same as 100mW/cm2 and my solar cells are 2.2 x 0.7 = 1.54 cm2 each, I have about 3 cm2 in total. So at 1000W/m2 my two solar cells can generate 300mW. And at 10W/m2 (indoors) 3mW. The AEM10941 harvesting IC requires minimum 3uW input power for cold start so that is easily exceeded. So how much current is actually going into the battery?

Well, solar cell voltage is about 70% of the open circuit voltage (2*0.458=0.92) so 0.64V. At that voltage the boost efficiency is about 75% according to the datasheet.

1/100th * 44mA * 75% boost efficiency * 95% charge efficiency * 0.64V/4.12V = 50uA. The harvesting IC itself uses only 0.5uA so that is insignificant. So if we have 50uA for 10 hours a day then 0.5mAh is stored in the battery every day. So for an application that runs 24 hours a day the average current should be less than 20uA.

Can TSEM power a simple BLE application from indoor light?

Three years ago I made a BLE beacon with average 15uA current. These days they are much more efficient. So YES, it seems simple BLE applications can run from the TSEM.

Can TSEM power a simple LoRa application from indoor light?

Sending a LoRa message is about 30mA for 1 second. To bring average current down to 15uA you should send once every 2000s or roughly once per 30 mins, which is still a acceptable interval for a simple application. So YES, from indoor light TSEM can power simple LoRa applications.

All in all I need to conclude that based on my calculations Tryst Energy was right that in an office you can run a very simple BLE or LoRa application from a few square cm solar panel. However I doubt enough power can be harvested from underneath a desk, especially when the application requires a bit processing power.

-

Headers are strong enough

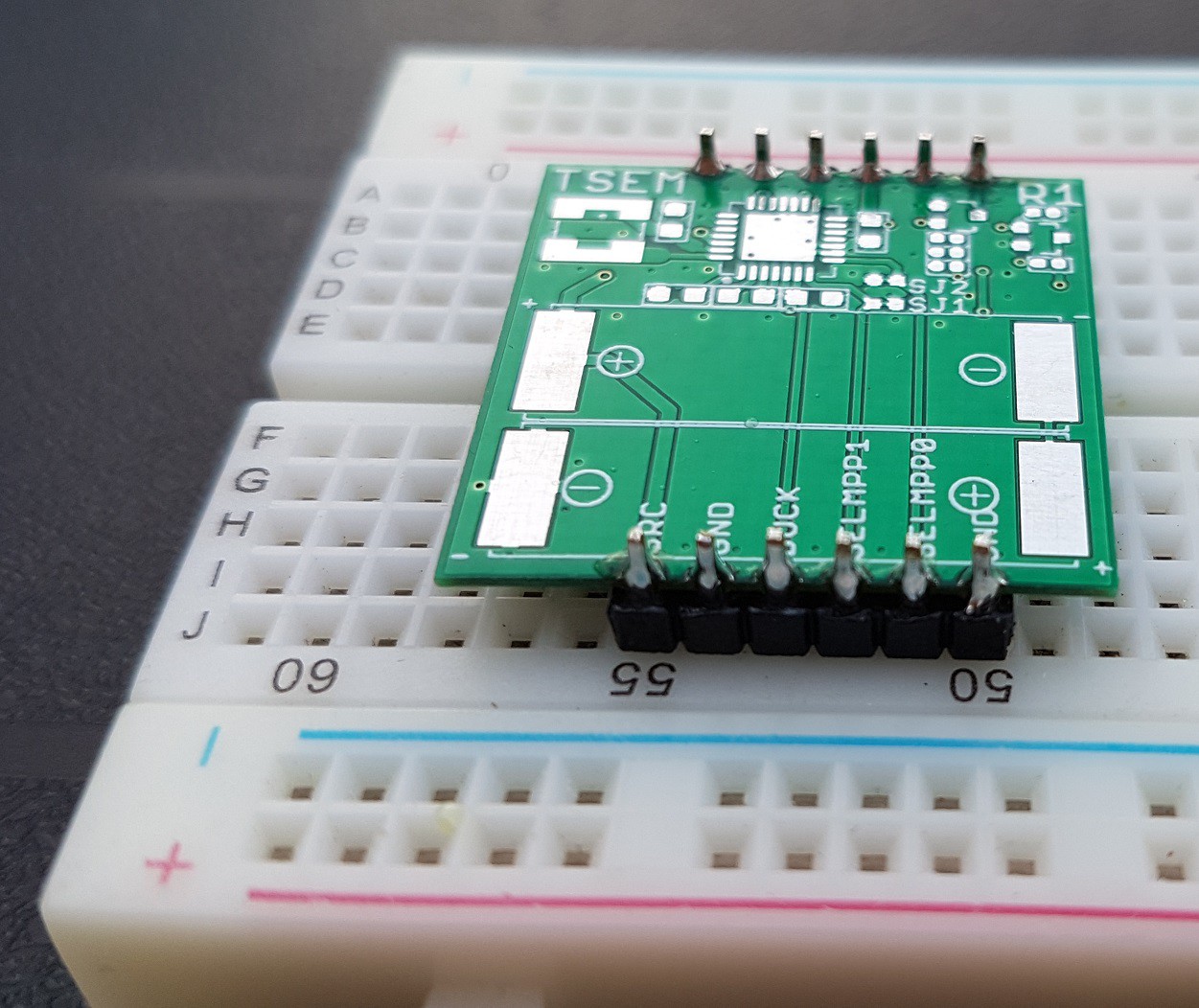

07/07/2018 at 19:01 • 2 commentsThis module can be SMD soldered onto to a PCB, but it could also be placed on 0.1" male pin headers and plugged into a bread board. I had some concern about the strength because the PCB is just 0.6mm thick and so I tested it.

![]()

Aftter soldering I plugged the board many times onto a bread board. After 20 times it still felt rigid and so I conclude it is strong enough for most users.

-

On a sunny day the battery charge current is as expected

07/07/2018 at 12:34 • 0 commentsThe solar cells should generate 44mA at 1000W/m2. At a nearby (20km away) weather station solar radiation is 600-800W/m2. So now I should expect 60-80% of 44mA solar current. I measured solar panel (2 cells in series) voltage is 0.95V. Now I can calculated the expected battery charge current.

700/1000 W/m2 * 44 mA * 0.85 boost efficiency * 0.95 charge efficiency * 4.12V/0.95V = 5.73 mA.

I actually measured 6.0mA. This means that the battery charge current is as expected.

In full sun power (1000W/m2) I expect 8.19mA charge current. Some time soon I want to measure indoor charge current to confirm it is about 1/100th of outdoor charge current.

-

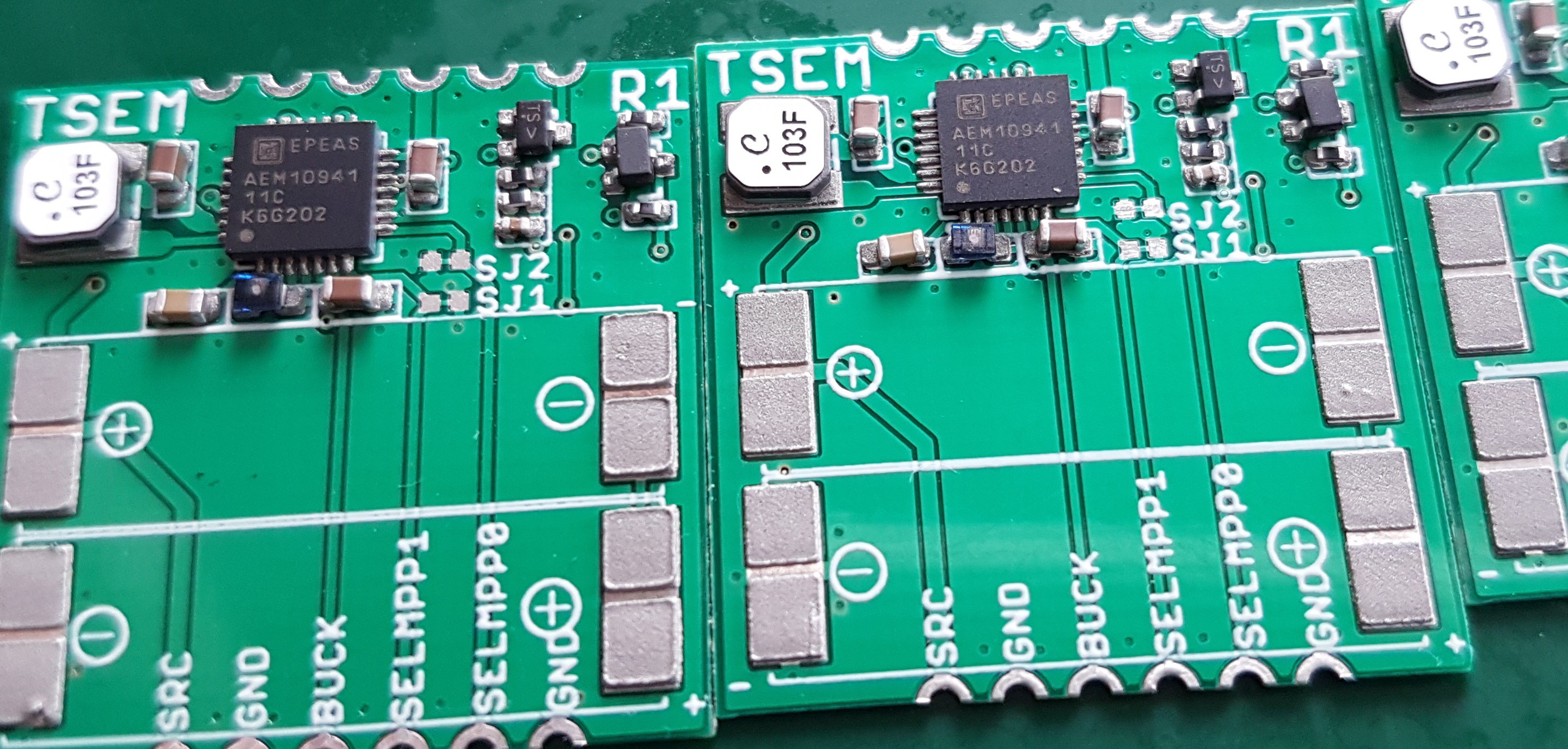

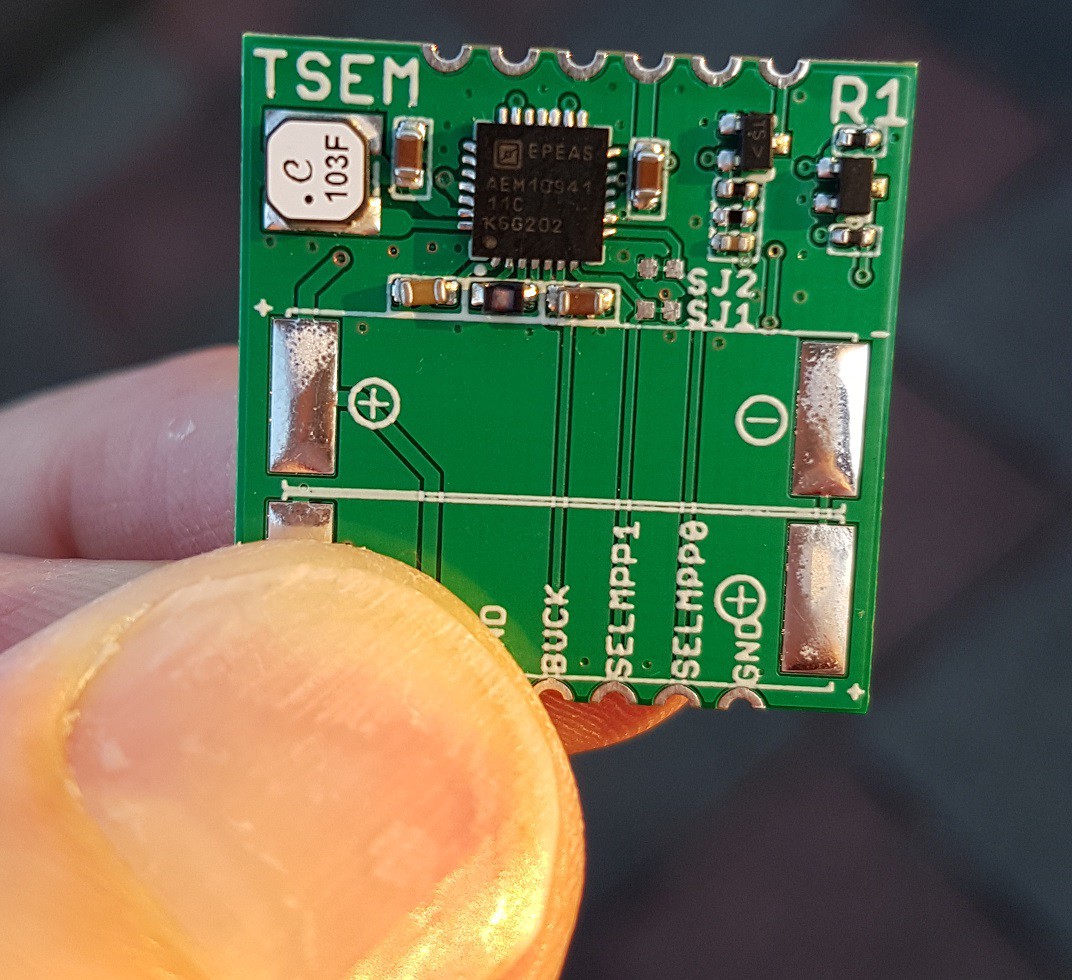

PCBs are soldered and first tests show it's working

07/04/2018 at 19:48 • 0 commentsToday I have received the components from Farnell and the AEM10941 harvesting ICs from E-peas. I used a solder stencil from Elecrow, chipquik SMD291SNL10 solder paste and used an solder paste spreader from OSH Stencil, basically a credit card sized piece of plastic. I placed components on 3 PCBs.

![]()

Using a Yihua 858D hot air gun I have reflowed the board without the solar cells, those I soldered manually because I didn't want to heat them for too long. According to the datasheet they should be soldered using low temperature solder paste or manually but very shortly.

![]()

Then it was time for the first test. I soldered a small Lipo battery (20x20x6mm) and I went outside, the sun had just set I could measure the 3.3V output which is only available after cold start.

![]()

In addition I measured the boost voltage 4.0V and the buck voltage 2.2V and this all is as expected. I measured 0.95V on the solar cells output which is as expected (about 2 x 0.5V). Aparently it is working, but I need to do some more testing to confirm. For example comparing the solar current to the battery charge current, which should be about 5 times lower. After that I can power an application with it. I have a $15 bluetooth low energy temperature/humidity sensor that advertizes sensor data at some interval.

-

I have received revision 1 PCBs

07/02/2018 at 19:16 • 0 commentsOne week and two days after ordering from Elecrow I have received the PCBs. They look great. I really love how thin they are, 0.6mm, and I love the castellated vias. I found it very easy to order. I did not have any human contact with an PCB manufacturer engineer. I chose for 24 hours production time and 2-3 business days shipping. In addition I ordered a solder stencil. All in all about 80 USD, which is very low when compare to for example EuroCircuits. I should have instructed Elecrow to write a low value on the package because I had to pay 50 euro import duties and taxes. My bad.

-

PCBs are ordered from Elecrow

06/23/2018 at 20:03 • 0 commentsDesign is finished.

PCBs are ordered from Elecrow in China. I expect to have the boards in 1.5 week.

PCB will be 0.6mm thick and have castellated via's.

I added Eagle design files, gerber files and images to the project.

I have ordered the solar cells. I am expecting AEM10941 IC samples in a week.

I still need to order the other passive components.

Tiny Solar Energy Module (TSEM)

A 1 square inch PCB module with 2 tiny solar cells, a highly efficient Li-Ion charger and with 3.3V and 1.8V output

Jasper Sikken

Jasper Sikken