-

Crash course on solar energy harvesting

12/15/2024 at 14:33 • 0 commentsIn January 2023 I did a short presentation in the local community. Now I share it online too.

Solar panel, IV and PV curve

Solar panels consist of individual cells, that are 0.5V nominally. A 5V solar panel consists of 10 cells in series.

![Solar panel with 10 series cells Solar panel with 10 series cells]()

The blue line is the IV curve of a solar cell, the current versus voltage. Voc is the open circuit voltage, at no load, typically 0.63V. On top left is the short circuit current Isc. The red line is the PV curve, which is power versus voltage. Most power Vmp is generated at 0.5V (80%) of the Voc (0.63V).

![]()

Effect of irradiance on Vmp

The maximum power voltage is not constant. These are IV curves at different light intensities. It shows at low light levels the Vmp is lower, at 70%. It also shows that the short circuit current is linear with irradiance.

![]()

Effect of temperature on Vmp

Below chart shows at high temperature Vmp can be 20% lower. So Vmp depends on irradiance and temperature.

![]()

Maximum power point methods

- MPPT is maximum power point tracking, it actively finds the peak by constantly adjusting the load, this is the most efficient and complex method

- MPPC is maximum power point control, it regularly measures the open circuit voltage and loads the solar panel to a fixed percentage (80%) of that

- Fixed voltage is the simplest method, it simply loads the solar panel to a fixed voltage, disregarding the effect of irradiance and temperature

![]()

Relative light levels

Bright sunlight is 500-1000 W/m2. Only at the equator the 1000W/m2 is reached. Under the clouds the irradiance is 50-200 W/m2, which is 10 times less. And indoors it is 2-15 W/m2, another ten times less. So indoors there is 100 times energy to harvest than outdoors.

![]()

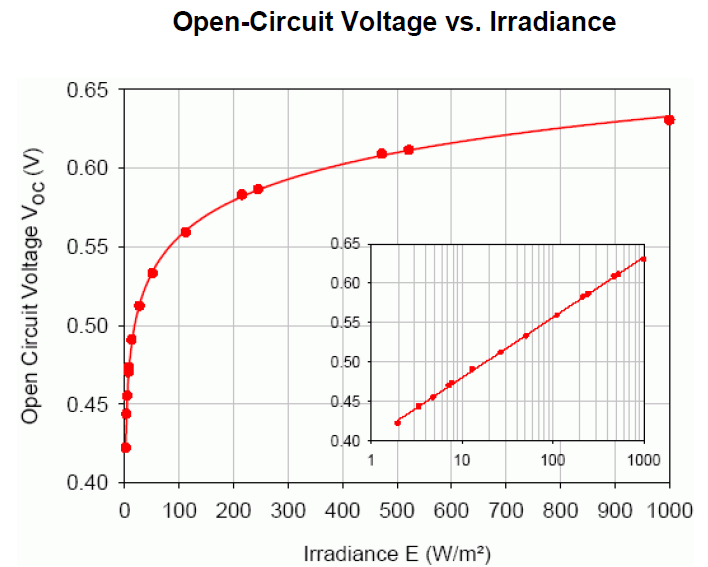

Effect of irradiance on Voc

At very low light levels (20W/m2) Voc already exceeds 0.5V per cell.

![]()

Light spectral distribution

- Daylight has a very wide spectrum. There is a lot of energy in the IR part.

- LED and fluorescent light have narrow light spectra

- From artificial light (indoors) there is 200-500 times less energy to harvest than outdoors

![]()

So if your application sometimes see direct sunlight 1 hour per day it harvests 100 times more than in the other 23 hours.

Advanced energy harvesting chips for low power IoT applications

Chips like AEM10941, BQ25570, SPV1050 are all swithing converters and have a similar efficiency 80-90%, They all do MPPC and work great under low light conditions. AEM10941 is most versatile and requires the least external components. They are all expensive in small quantities 4-6 EUR per chip, plus it needs an inductor.

![]()

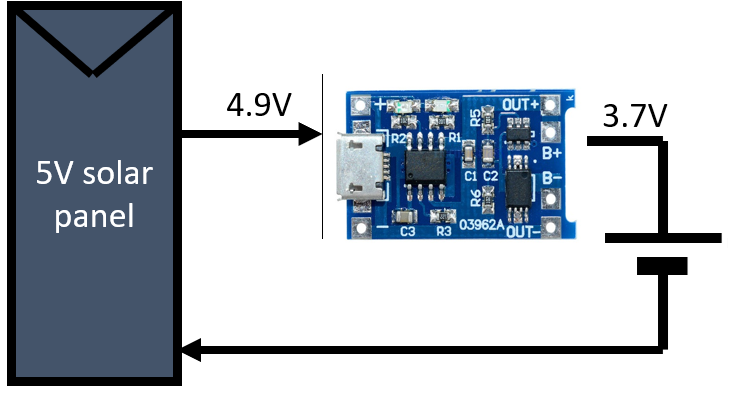

Tested cheap linear USB Li-ion battery charge IC

A few years ago I tested a few cheap linear battery chargers for Lithium Ion Battery on my rooftop terrace.

![]()

- MCP73831 0.40 euro

- TP4056 0.25 euro

- others....

The measured efficiency was 70-75%, so not bad at all. I selected TP4056 as the winner because of large input voltage range and lowest price. Why was it so efficient?

![]()

Because the 5V solar panel worked close to Vmp. The energy is lost because of the drop out voltage over the linear charger Conclusion: for outdoor applications you don’t need advanced MPPC. A TP4056 plus a 5V solar panel is more economic and pretty efficient. It is better to spent your money on a larger solar panel than on a MPPC energy harvesting chip

Batteries versus capacitors

I compared Lithium Ion Batteries (LIB) to Lithium Ion Capacitors and supercapacitors. LIBs have highest energy density, but they have limited charging cycles so after few years they wear out like batteries in smartphones. In addition they are dangerous, they need protection circuits to stay safe, they have dangerous chemicals and need to be disposed with chemical waste and they have a narrow temperature range, at freezing temperatures capacity is severely reduced. A classic alternative is...

Read more » -

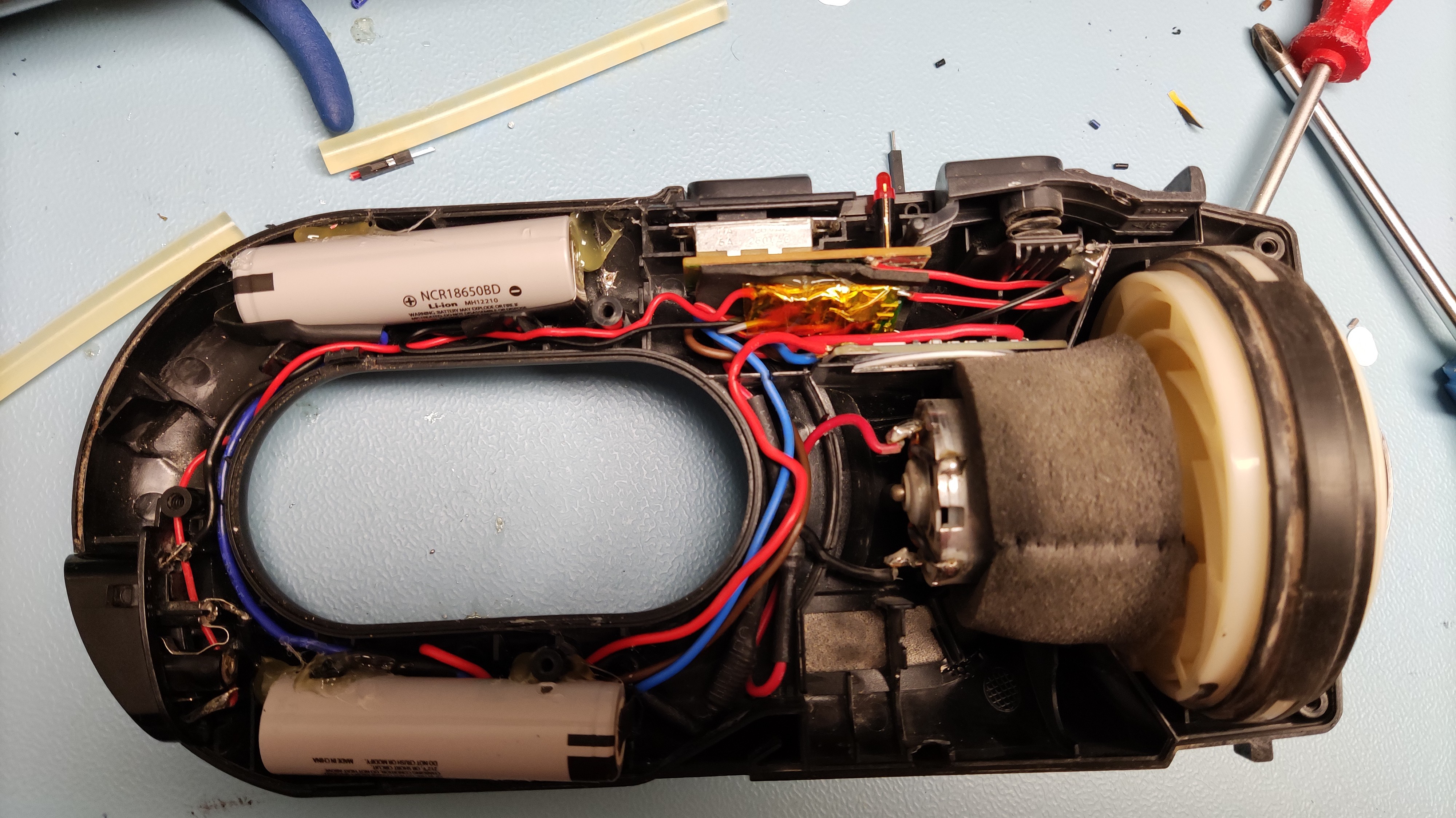

Mini Vacuumer battery replacement

02/25/2021 at 20:35 • 4 commentsI have replaced the batteries and the charger of my Philips FC6149 Mini Vacuumer because the batteries were worn out 1 year after purchase. Only after I started hacking I realised it was still in its 2 years guarantee period, so I might as well have returned it for a new one. My mini vacuumer had always been on it's charging base.

![]()

I have tried to rehresh the batteries by running them all the way down and recharge a few times, but that didn't help. It was time to open it up.

![]()

I found ten 1.2V Ni-MH batteries in series. The charging circuit basically exist of a 18V/200mA external power adapter and a series resistor. What? Oh my god. That is so bad. This charging circuit is designed so cheap, no wonder after 1 years of continuous charging the batteries wear out. Philips, this is so bad!

I have replaced the batteries with two 18650 Li-ion cells in series, a 1A 2S Li-ion charger and a 10A/2S battery protection/balancing board. And the 18V/200mA power adapter was replaced by a 12V/1A adapter. It took a while to remove some internal plastic to make place for these bigger cells.

![]()

Even though the battery voltage (7.4V) is lower than before (12V) it works great again.

My Projects

My Pages

Things I've Built

Internet controlled lights and garage door

I can control my 6 remote controlled wall sockets(lights) and the garage door from my android phone. I connected a arduino microcontroller to my internet connection and added 433 Mhz transmitting functionality. I created the arduino program and

Mbed Gas Water and Electricity meter

My Mbed microcontroller posts electricity, water and gas usage, indoor temperature, humidity, air pressure, light intensity and air quality, PIR motion activity to Xively.com every 60 seconds.

ELectric Imp Heart Rate Bracelet

Measures your heartbeat and sends it through the internet to a light-emitting bracelet that starts beating in the same pulse as your own heart.

Arduino Electric Load

This board is pretty handy to test power suppliers. This board accepts a Arduino Nano. And through the serial monitor you can type desired the constant current, constant power or constant resistance.

Projects I Like & Follow

Share this profile

ShareBits

Become a Hackaday.io Member

Create an account to leave a comment. Already have an account? Log In.

Good evening Jasper and thank you for following my ColorChord project. I am in a bit of shock as I just found out that it is in the top 20 for the HCI contest segment :-D

Thanks for liking and following my project Power Line Adapter for Blue Pill!

Hi Jasper, Thanks for liking and following my project Indoor Light Charged Power Supply. Also your project Tiny Solar Energy Module (TSEM) is awesome!!!

Jasper Sikken

Jasper Sikken

Ultimate Robotics

Ultimate Robotics Mike Moore

Mike Moore Christoph Tack

Christoph Tack Rhea Rae

Rhea Rae Martin

Martin Waldo Wolmarans

Waldo Wolmarans Nick Sayer

Nick Sayer Filip Mulier

Filip Mulier Beast Devices

Beast Devices Lloyd Konneker

Lloyd Konneker Makertronika Labs

Makertronika Labs Nicolò

Nicolò strange.rand

strange.rand Syed Razwanul Haque Nabil

Syed Razwanul Haque Nabil Mahesh Venkitachalam

Mahesh Venkitachalam Ulrich

Ulrich

Hi Jasper, thanks for following my #Motion Capture system that you can build yourself !