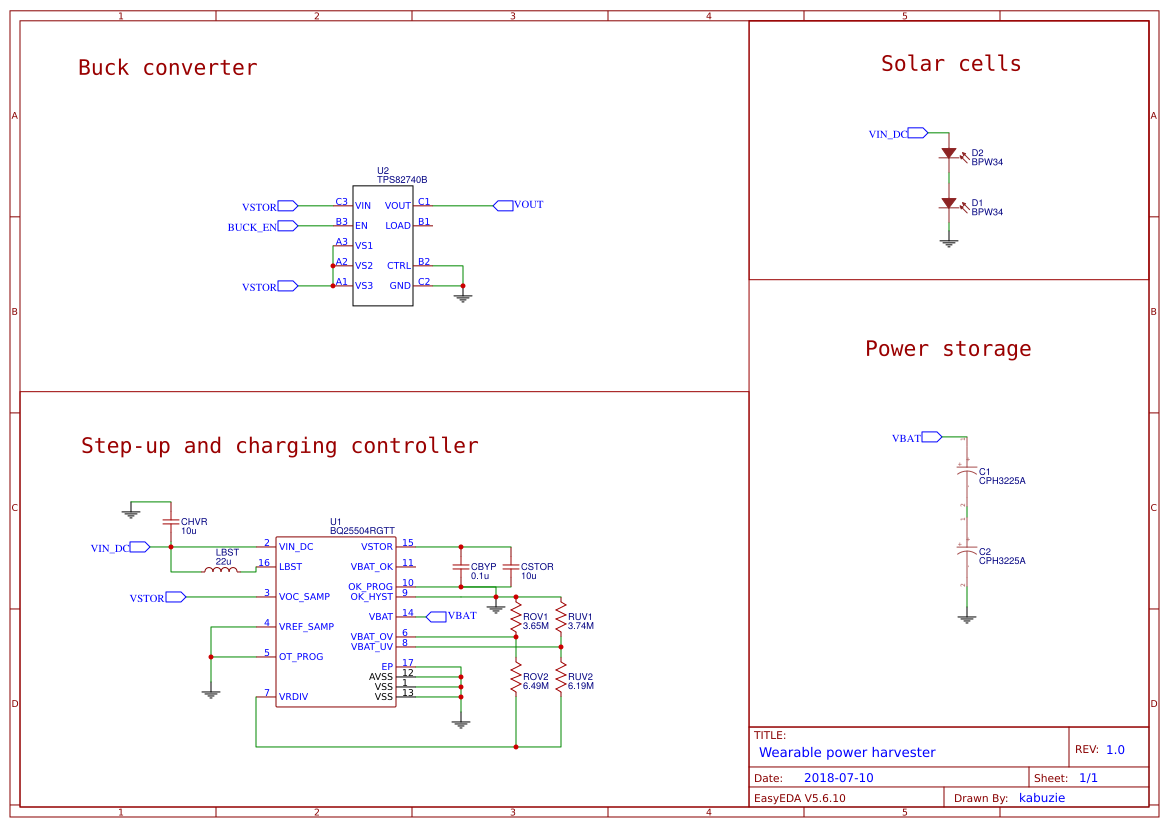

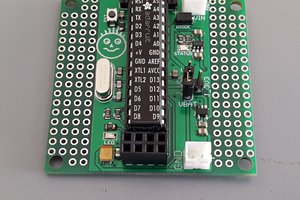

The main components of this project are the tiny BPW34 solar cells, which provides about 300mV. With two in series we can reach the start up cold unit of the power harvester ic BQ25504, and adding more solar cells in parallel helps to reach the minimum start up power (15uW) sooner. This ic regulates the charge of two CPH3225A (0.011F supercapacitor) in series, with a max voltage of 5.25V (limited by the ic max voltage specification). The external buck converter TPS82740B allows discharging it securely (there are programmable overvoltage and undervoltage conditions setted by resistors into the harvester IC) which would discharge the caps from 5.25V to 3.3V.

In ideal conditions, two CPH3255A provides a power storage of 12.74uWh (45.85mJ), which means 3.86uAh at 3.3V. The CPH3225A have an internal resistance of 160ohms, so the module would provide a max of 10mA, which is enough for the most of low power applications.

I chose the CPH3225A for its 0.9mm height, but there are better alternatives which I'm looking, for example the DCK-3R3E204T614-E, which have an 1.4mm height and 200mF, which would provide 834mJ or 231uWh (0.07mAh).

I have not taken into account the inefficiency of the buck converter, which is worse with small currents, so a bit of testing should be made here. In theory an efficiency of 90% is possible at 10uA, but lowering to 1uA will reduce the efficiency to 60%.

All should fit in a small flex pcb one sided, so I would need some 0ohm resistor for make bridges.

Enrique

Enrique

Jasper Sikken

Jasper Sikken

Arnov Sharma

Arnov Sharma

Lithium ION

Lithium ION

Arkadi

Arkadi