-

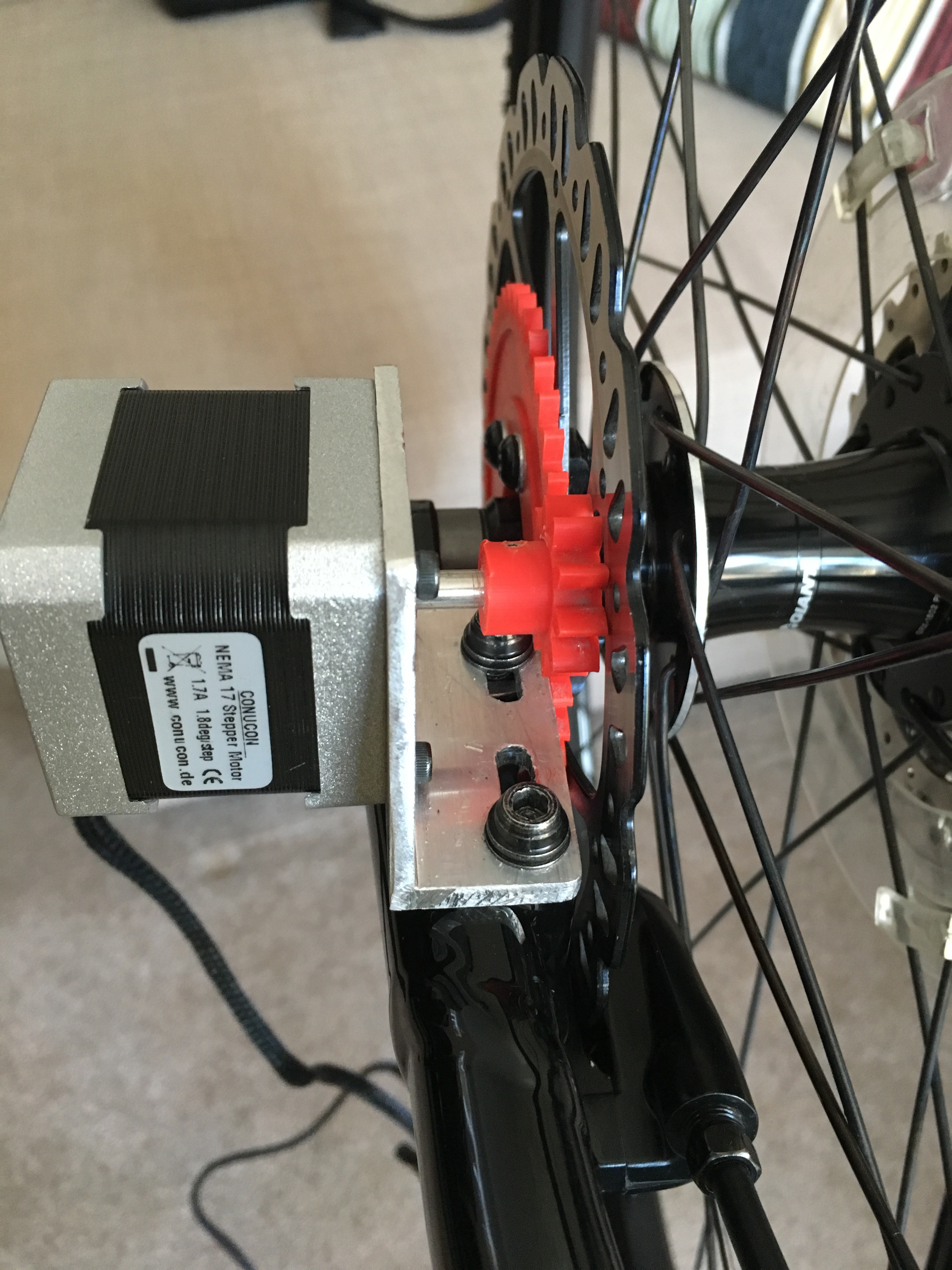

1Power Generation Setup

Components needed:

- 1 x Stepper Motor (17HS4417)

- 1 x JSP XPH-4 male + female + inserts

- 4 x M3 screws

- 1 x Aluminium U channel for the Motor Bracket

- 1 x 3D-printed Spur Gear

- 1 x 3D-printed Pinion Gear

- 1 x M3 Allen Grub Screw

Assembly all the aforementioned components to create a unity and attach it to the rear/front brake disc. You will need a crimping tool for the JSP plug, unless it is already included.

Please, be aware that what it is being shown may differ from your case. It should look like this:

-

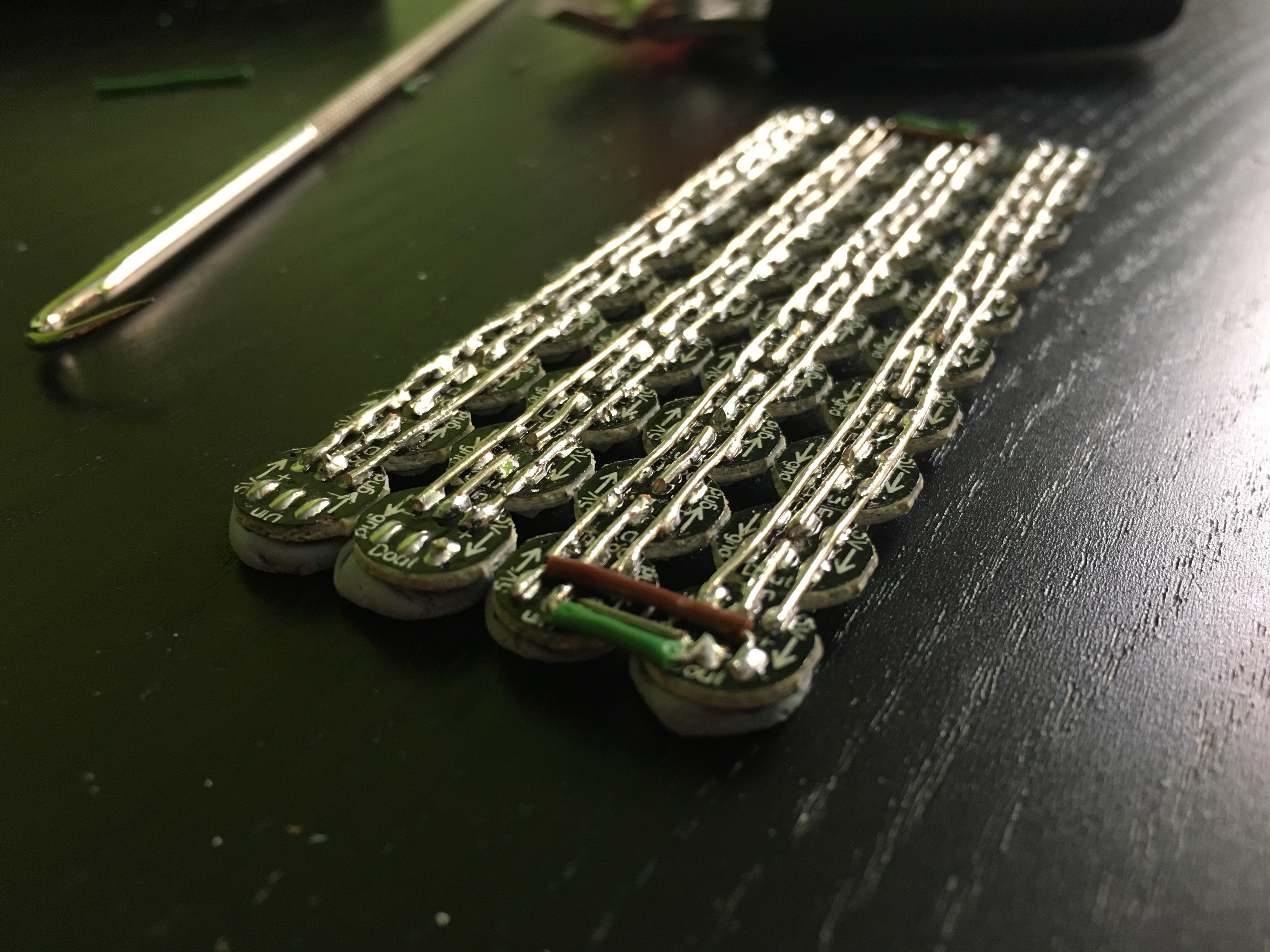

2Smart Lighting System Setup

Components needed:

- 1 x 10x10 RGB LED Matrix (WS2812B)

- 3 x Light Dependant Resistor (LDR)

- 1 x 3D-printed Front Light assembly

- 1 x 3D-printed Rear Light assembly

- 5 x M3 screws + nuts for the headlight and rear light

- 3 x JSP 2.54mm XPH-3 housing (male + female + inserts)

Please, make sure that all printed parts will fit in your bike, so make some measurements first. I also recommend you to solder all wires for the LED matrix very carefully and taking your time. It should look like this when you finish:

It should i;ike the image below when all components are assembled:

-

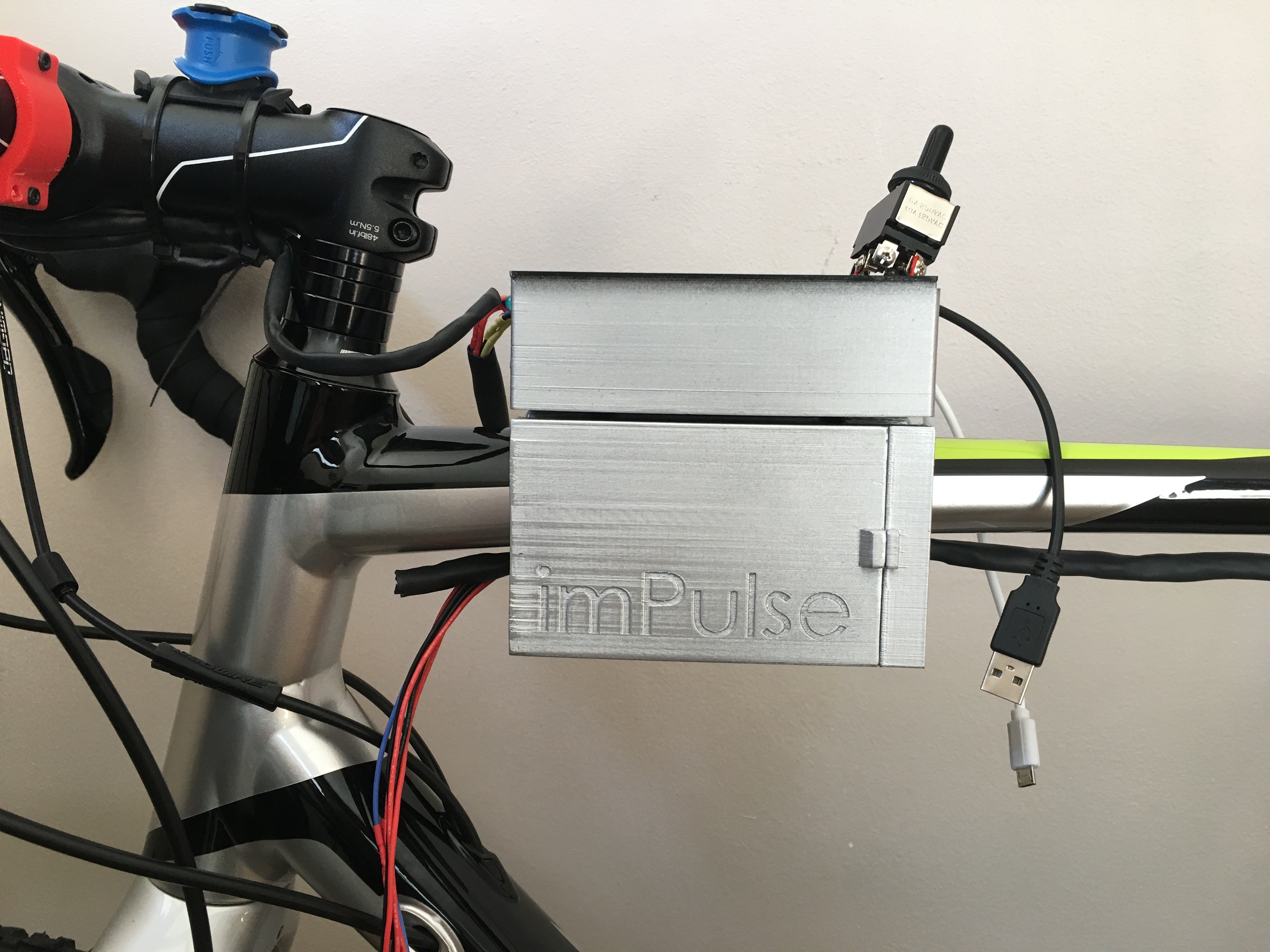

3eBox Setup

Components needed:

- 1 x 3D-printed eBox assembly

- 2 x 3D-printed Power Bank Housing

- 1 x 3D-printed eBox Mounting Bracket

- 1 x Strip Board

- 1 x Relay (SRD-05VDC-SL-C)

- 2 x Diodes (1N4007)

- 2 x USB 2.0 to Micro USB cable (1m)

- 2 x Power bank

- 1 x Single Solid Core (SSC) Black wire (0.6mmx1m)

- 1 x SSC Red wire (0.6mmx1m)

- 1 x SSC Green wire (0.6mmx1m)

- 1 x SSC Yellow wire (0.6mmx1m)

- 1 x SSC Orange wire (0.6mmx1m)

- 1 x SSC Purple wire (0.6mmx1m)

- 2 x M3 screw

- 1 x Rubber Sheet (250x250x1.5mm)

- 2 x M3 Threaded brass insert

- 8 x Neodynium Magnet Disc (3x20mm)

- 1 x Stainless Steel Rod Bar (200x2mm)

- 2 x Blue LED

- 2 x 220Ohm Resistor

- 1 x DPDT Switch

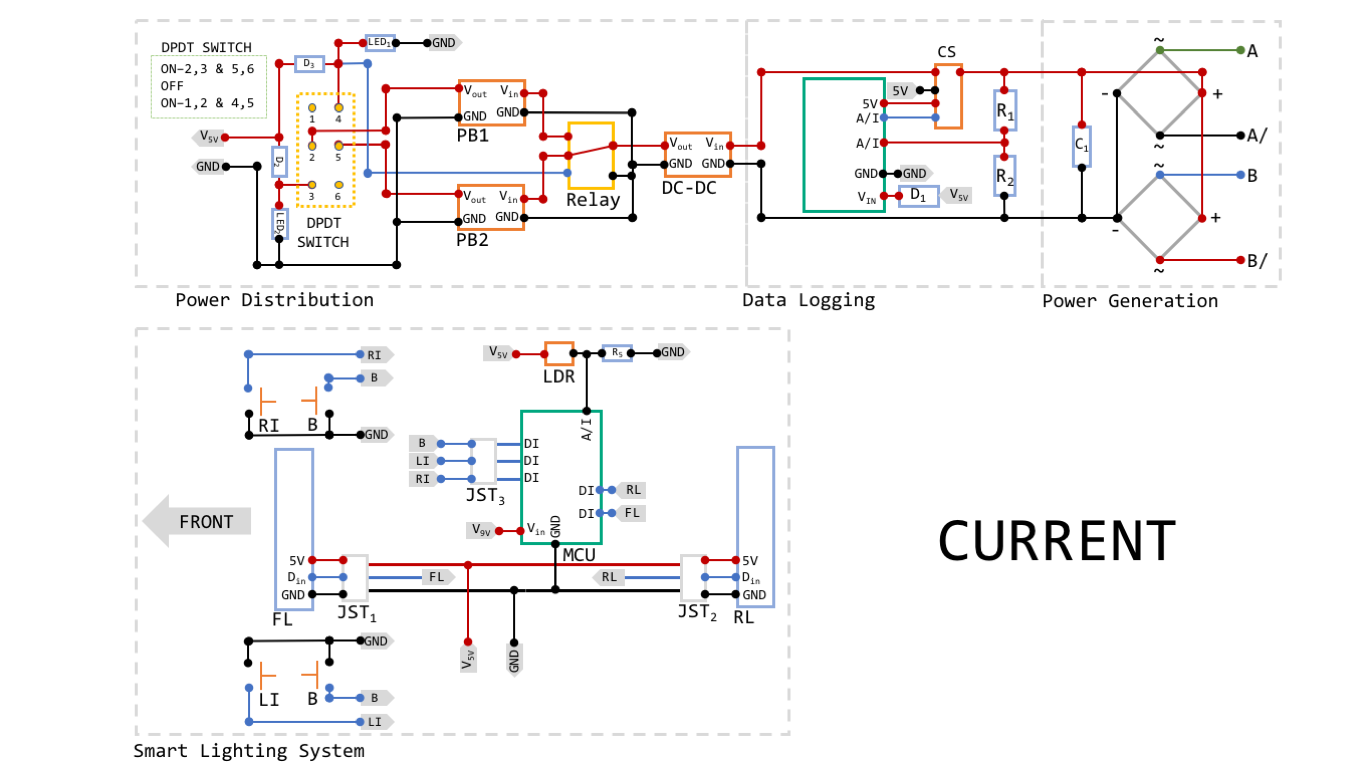

Follow he diagram below for the soldering part. Please, make sure that the perforated board can be trimmed, so allow some tolerance for fitting purposes.

![]()

Again, please make some measurements first for the CAD models. The final result should look like this:

-

4Wiring Harness and testsing

Components needed:

- Black Heat Shrink Tube 3:1 (1m x 10mm)

- Black Heat Shrink Tube 3:1 (2m x 5mm)

- 1 x Blue Silicon AWG 22 wire (5m)

- 1 x Red Silicon AWG 22 wire (10m)

- 1 x Black Silicon AWG 22 wire (10m)

- Cable ties (200mm, 100pcs)

- Cable ties (100mm, 100pcs)

I have some experience doing wiring in race cars. My advice, always leave more wire than expected as there is always a turn here or a bend there. It is a very important part, as this needs to look professional and tidy. On the other side, it should be easy to split and rearrange. The final result should look like this:

imPulse

Energy harvesting alternative for bikes including data logging, smart lighting system and power distribution board for power banks

Javier Betancor

Javier Betancor

Discussions

Become a Hackaday.io Member

Create an account to leave a comment. Already have an account? Log In.