While I wait for my boards to be delivered, I spent some time working on the mechanicals. I've been 3-D printing for a couple years now, but this project made me want to try something new: Flexible Filament. I ordered some green TPU from a brand called Priline.

I designed this as sort of a phone pocket, with extra width so that the front would fit the solar panel. Some space is cut out of the sides for the battery and charger circuit.

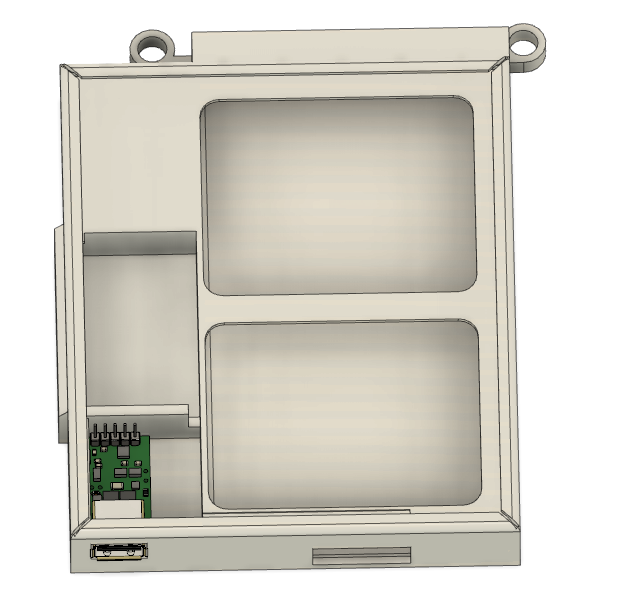

I designed this in Fusion 360. Here's a link to the design: https://a360.co/2MyXXA5

Here it is after a couple revisions:

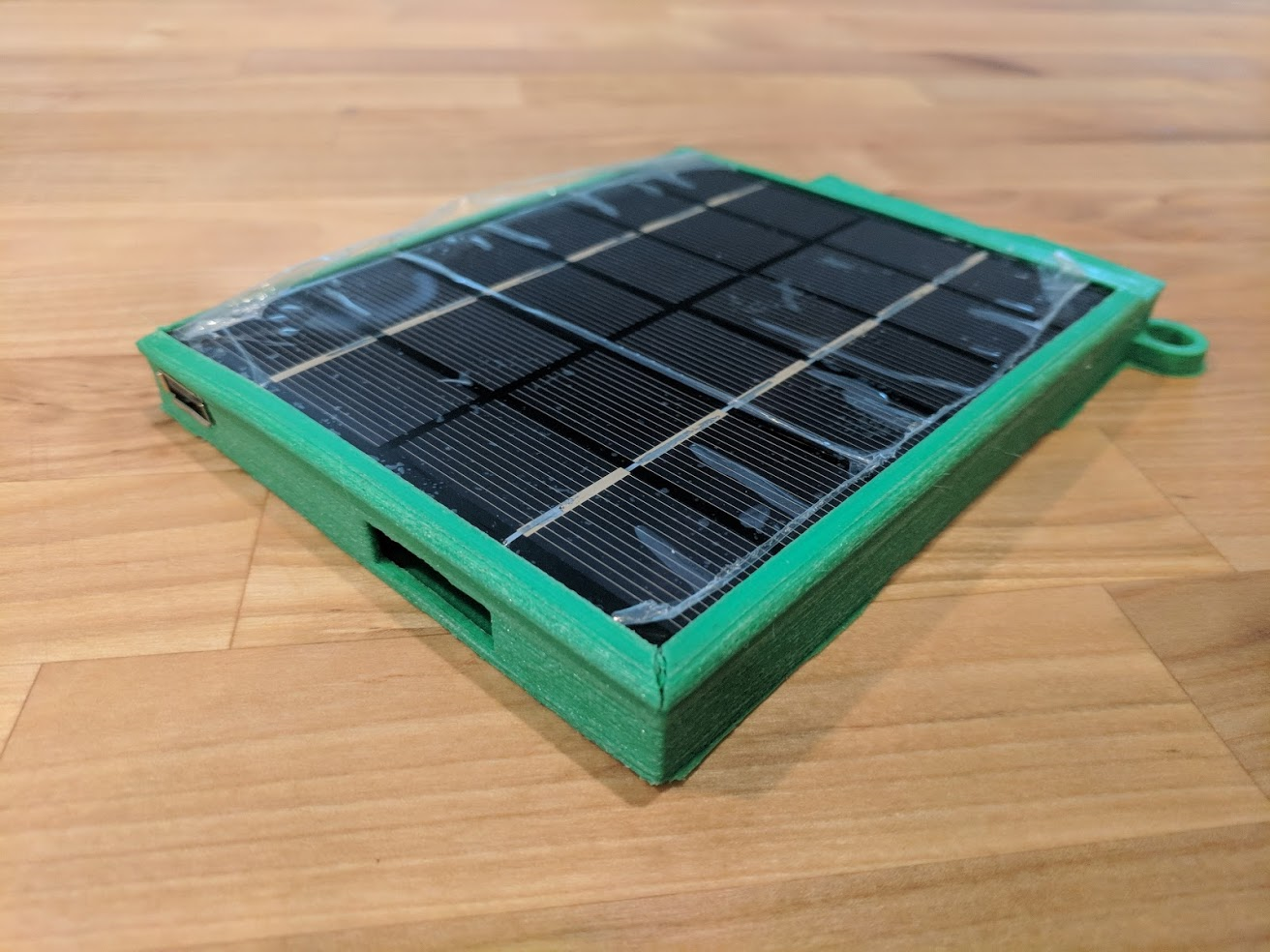

One problem that I came to a neat solution on: sealing in the battery and charger. Eventually I got the idea of using the solar panel itself to close up the "box" that the other parts go in. This saves material (weight) and makes everything a lot simpler.

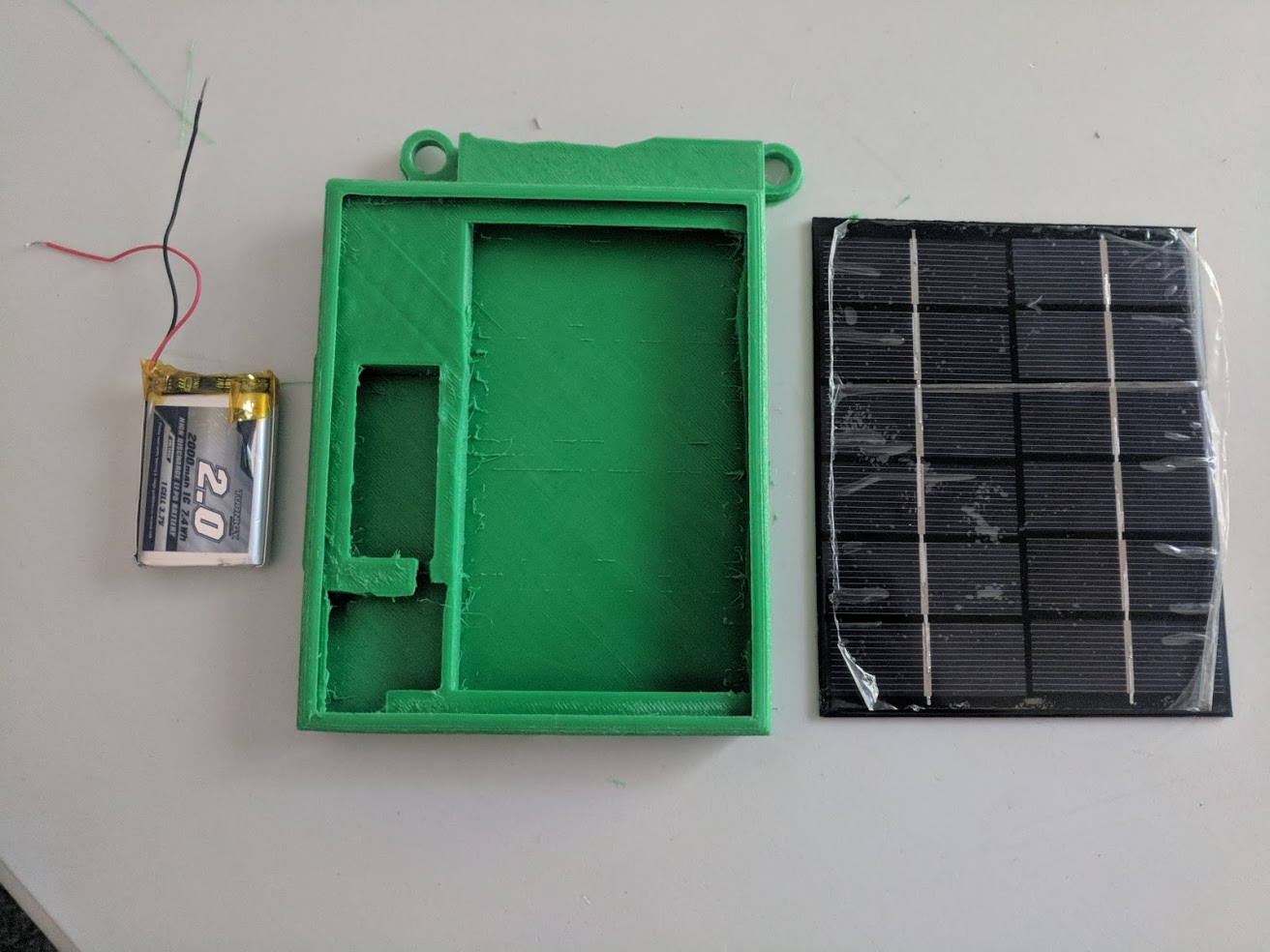

I printed out an early revision to test the fitting. Most of it is encouraging, but I found a lot of things to change. Printing with flexy filament went pretty well once I dialed in the heat settings (reducing the print bed temperature did wonders). But, as expected, the stuff doesn't bridge well, so a part like this takes a quality hit.

Here are my parts layed out...

And assembled...

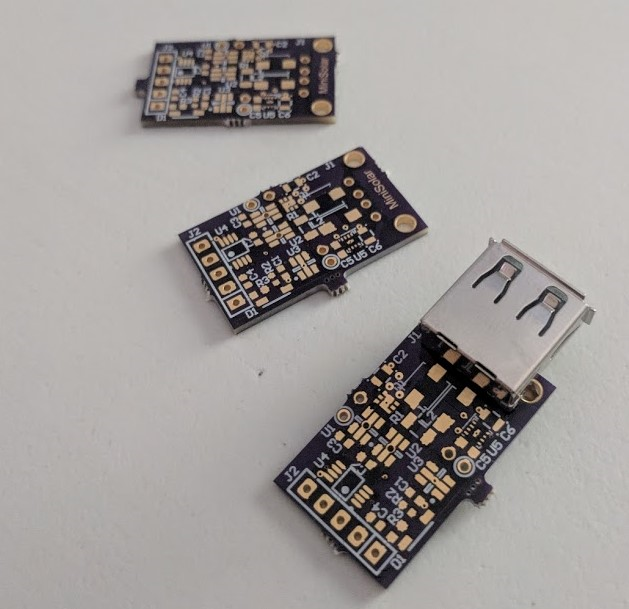

My PCBs just arrived from OSH Park. They look like they might be a little tricky to solder, but I'm up for a challenge. These are the first revision boards that have a length just a hair over one inch, though I already designed a revision that fits in a one inch square. Next up: build and test this thing.

Discussions

Become a Hackaday.io Member

Create an account to leave a comment. Already have an account? Log In.