-

Mass production

08/26/2018 at 10:57 • 0 commentsFor those wondering how we assembled the boards, we compiled a video of all the different steps.

We started off with prototype machinery (Mechatronika M10 and Mechatronika MX70), manual solder paste dispensing using a eC-Stencil-Mate and reflowing them using the MR260 from Mechatronika which has 3 zones. The quality was good, but not perfect. But it was too slow for the amount of badges we had to assemble. Operating the machine for 24 hours on 2 days yielded us only 203 aasembled Ph0xx PCBs. Which led us to the next phase of the assembly.

Mass production at More-at-Mere using high speed equipment and an 8 zone reflow oven. The machinery might not be the latest and newest available but damn, they're fast! The chip shooter has multiple pick-and-place heads, each having multiple nozzles. Instead of the head moving to pick up a part, the part tray is moved to the pickup location. The rotating carousel of pick-and-place heads, shown at the 22 minute mark, goes faster than the human eye can follow. We still did manual paste dispensing, which was an oversight from our side, next time we'll have to order the production stencil a bit earlier. The total time from the start of the line to just before the oven was only 47 seconds for a panel with 2 boards.

A big thanks to the team from More-At-Mere for the effort in getting 460 boards assembled in one day ans all the volunteers helping out with de testing and assembling of the boards.

-

Prototype assembly

08/24/2018 at 12:42 • 0 commentsThe assembly of the first prototypes was done by hand. We did use solder paste and a small reflow oven, but the placement was done manually.

-

First hack right before the camp

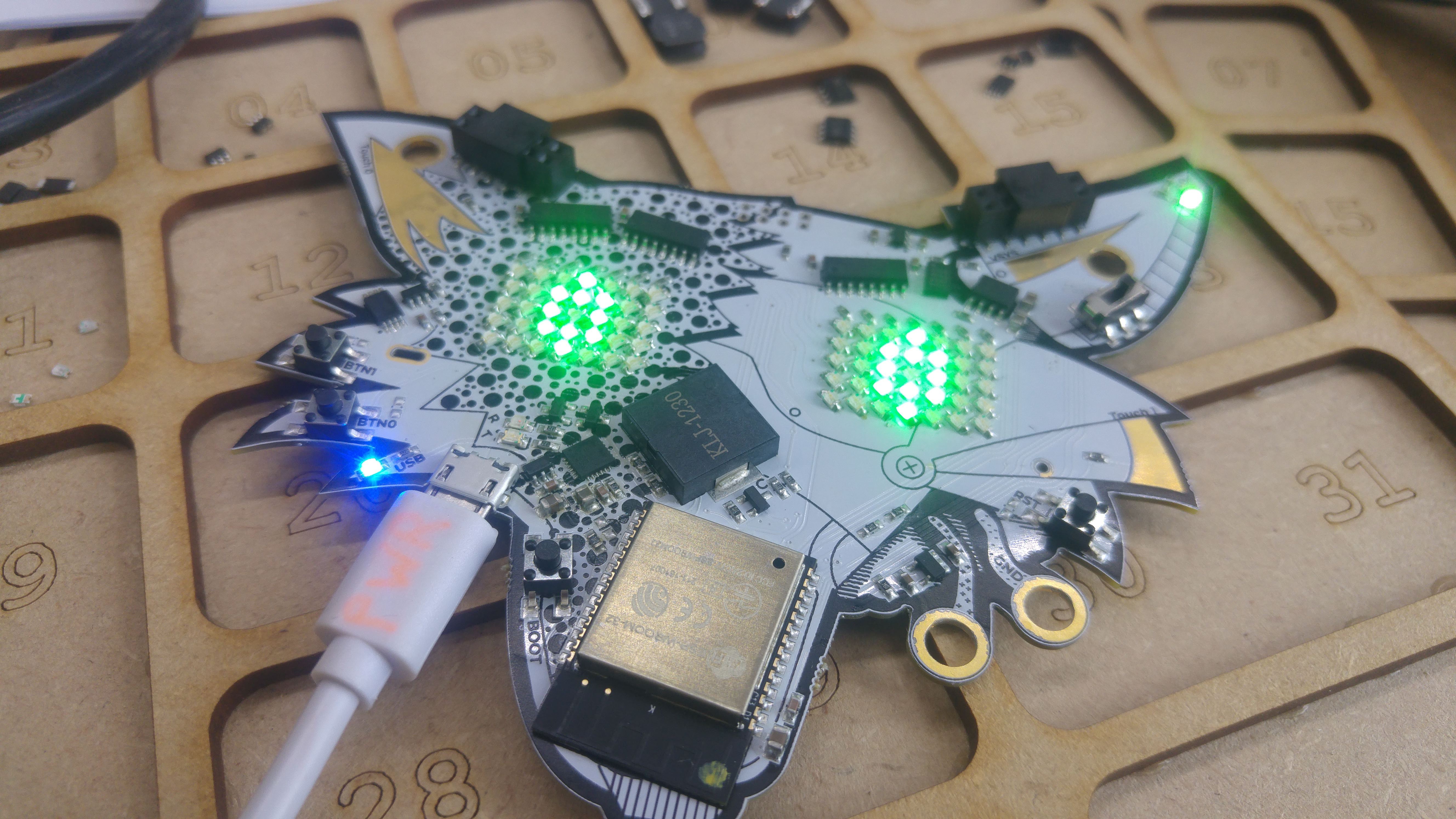

08/24/2018 at 12:39 • 0 comments![]()

right before leaving for Fri3d Camp I quickly desolderd all 70 blue LEDs and replaced them with green ones. Most people didn't think it was possible until I showed them the video. Some of them kept insisting that it was an undocumented feature of Ph0xx to change the color of the LEDs. Mission accomplished!

-

Lego compatibilty

08/24/2018 at 12:35 • 0 comments![]()

One of the gimmicks that was requested by @Daan Gerits was the compatibility with the LEGO® Technic system. This is achieved by placing the 4.2mm holes on a 8mm grid. Thereby enabling the badge to be installed in your new brick design!

-

Mass production scripts

08/24/2018 at 12:31 • 0 commentsSince we had 650 of these boards to test and assemble we designed our default firmware to be our testing firmware. Most common problems during production were a bad, or non-connection to the USB-UART or a LED that moved a little during assembly and therefor was shifted or tombstoned. The script that was designed by Christophe did the trick. It will scan for new USB ports and will automatically start programming the badges. I say badges since it worked perfectly with multiple PCBs attached to the PCB.

-

Up in the air!

08/23/2018 at 06:50 • 0 commentsDuring Fri3d camp we launched a weather balloon which held a Ph0xx with Air jewel so we could measure the air quality going up. At a certain height the dust particle sensor stopped working due to the very low external temperature (as low as -61°C).

-

Easy Animation

08/22/2018 at 09:12 • 0 comments

Wim Van Gool

Wim Van Gool