-

Settings change using GUI.

01/13/2019 at 15:18 • 0 commentsSettings change using OLED screen.

I did some work to refactor gui and add ability to change some settings from interface. It should be very useful at the field.

-

Settings in EEPROM and CLI settings edit

01/05/2019 at 16:19 • 0 commentsToday I've done EEPROM emulation inside FLASH (stm32f103 does not have EEPROM)

Also implemented settings that can be edited from CLI

Now I have commands:

get <setting> set <setting> <value> dump

After tracker starts, processor checking settings version and if it different from hex it just set default values.Now I have that settings can be tuned:

set serial_baud 115200 set gps_baud 9600

In feature I will migrate all constants to settings value.

-

LTM telemetry and test using SITL

12/31/2018 at 13:59 • 0 commentsI've done LTM telemetry.

Used SITL http://ardupilot.org/dev/docs/sitl-simulator-software-in-the-loop.html to emulator quadcopter.

I managed vehicle using APL Planner 2.0

And also I written simple converter that just listen MavLink v1 messages from simulator converts its to LTM and send it to serial port. https://github.com/kiryam/mavlink2LTM

Check video:

Need to improve follow algorithm (now it works like I have only 360 maximum movement limit.)

Also I thinking about to do interpolation and movement prediction algorithm.

I have some problems with parallel smooth moving pan and tilt. Because I have only one core I can't do this job in parallel. I can do it only in concurrency mode, but since I have very small timeouts while stepper moves (sometimes < 1ms) I can't efficient switch to another task (because context switch will require significant amount of ticks ). It makes CPU usage about 100% at fast movings. If I will have separate cores for movement and trajectory processing I can do pan and tilt in parallel.

Very basic version almost done. I need to do settings tuning from CLI and It ready to testflight.

Because in Russia right now not good wheather to flight I think I will do more improvements in this project.

-

Stepper heating

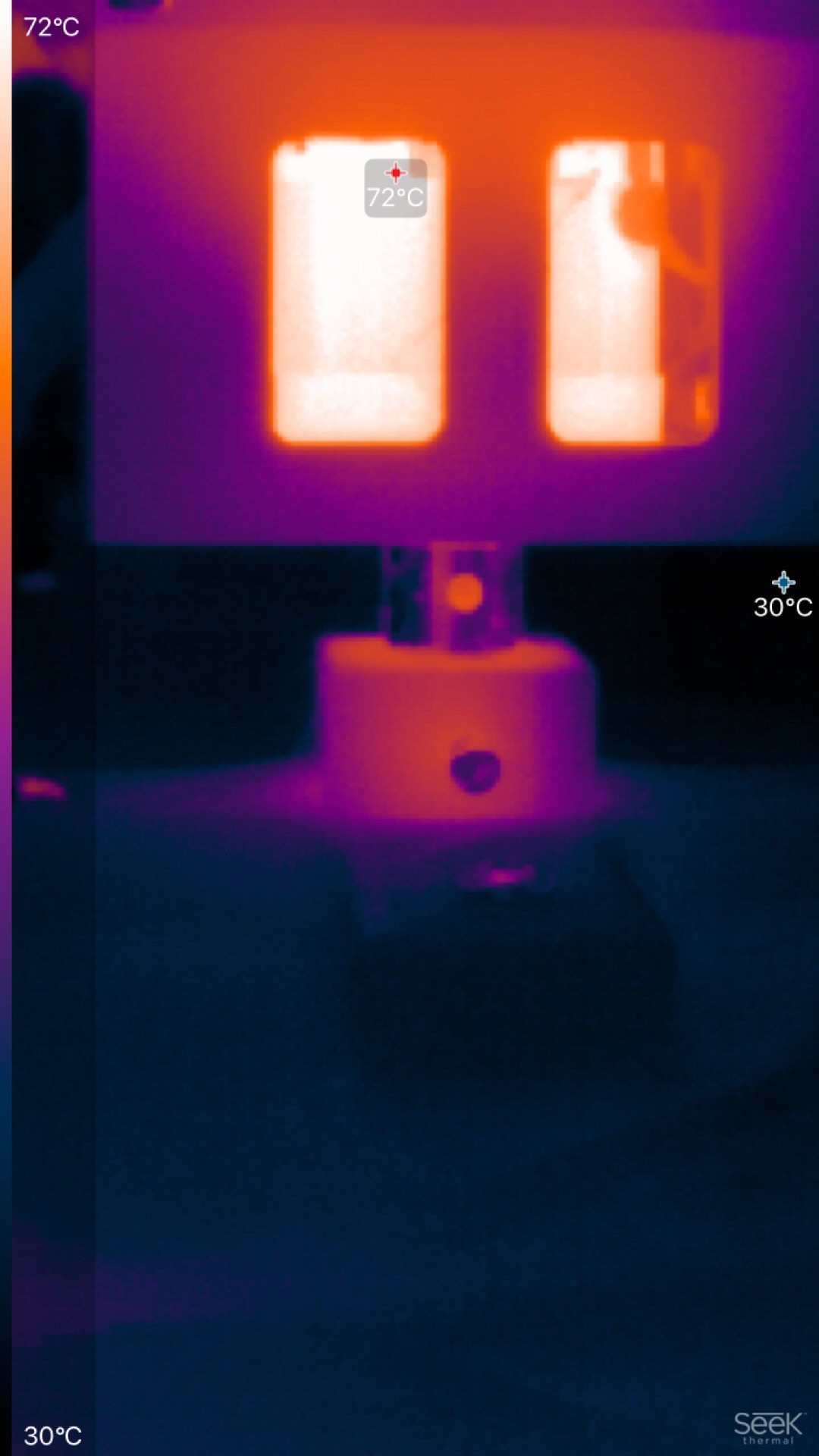

12/30/2018 at 09:32 • 0 commentsJust tested temperature of stepper and driver.

After one hour of working TMC2130 had temperature 88C. I checked datasheet and it is ok. (Overheat protection should started from 100 to 120 degree.) I think we doesn't need active cooling here. May be in future I add some additional holes in box.

Different situation at stepper:

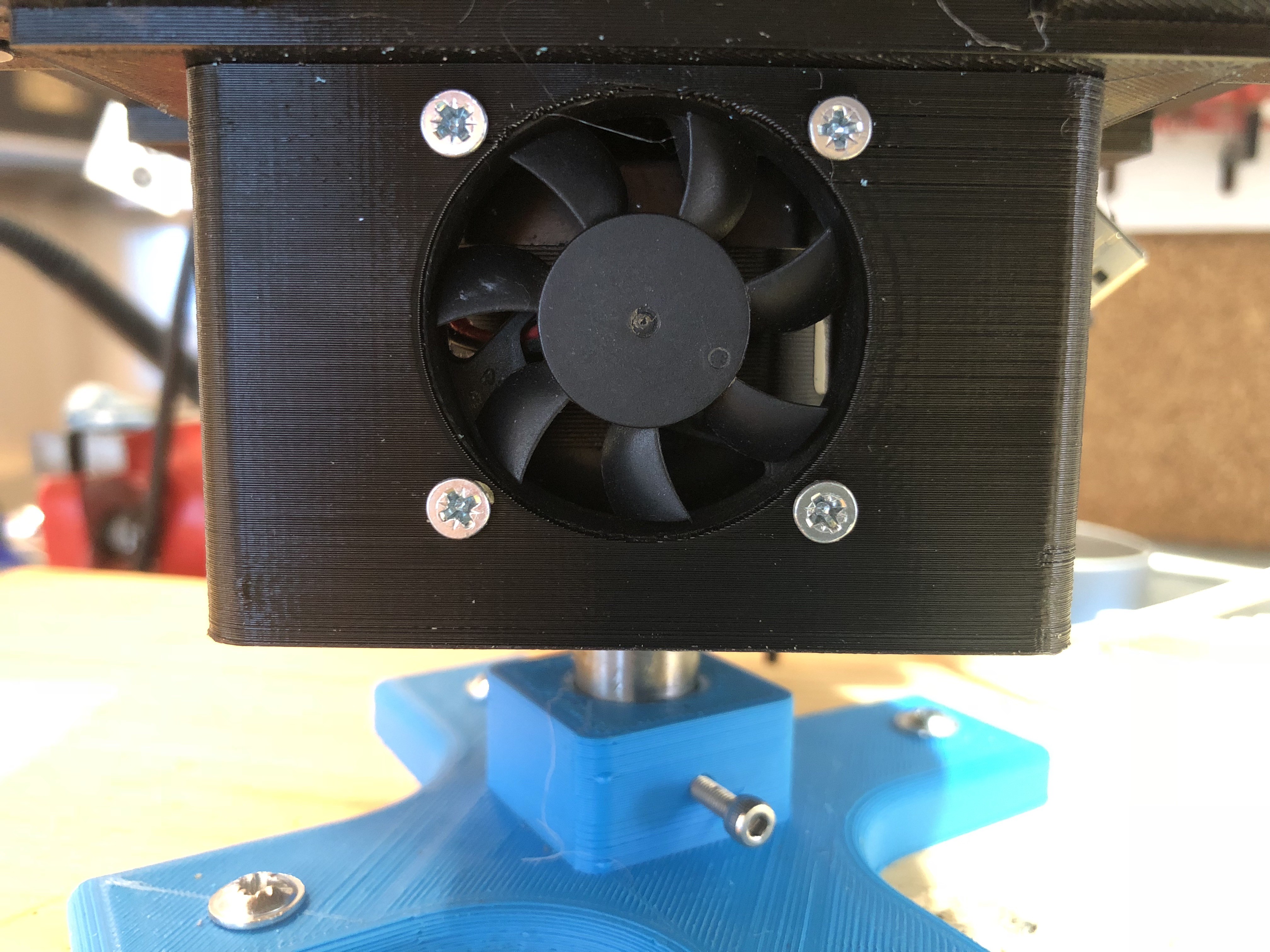

72C not too bad for NEMA 17 stepper (depends on class working temperature is 105-180C) but since it is 3d printable 72 it is maximum for PTEG. I decided to add 40mm cooler fan.

![]()

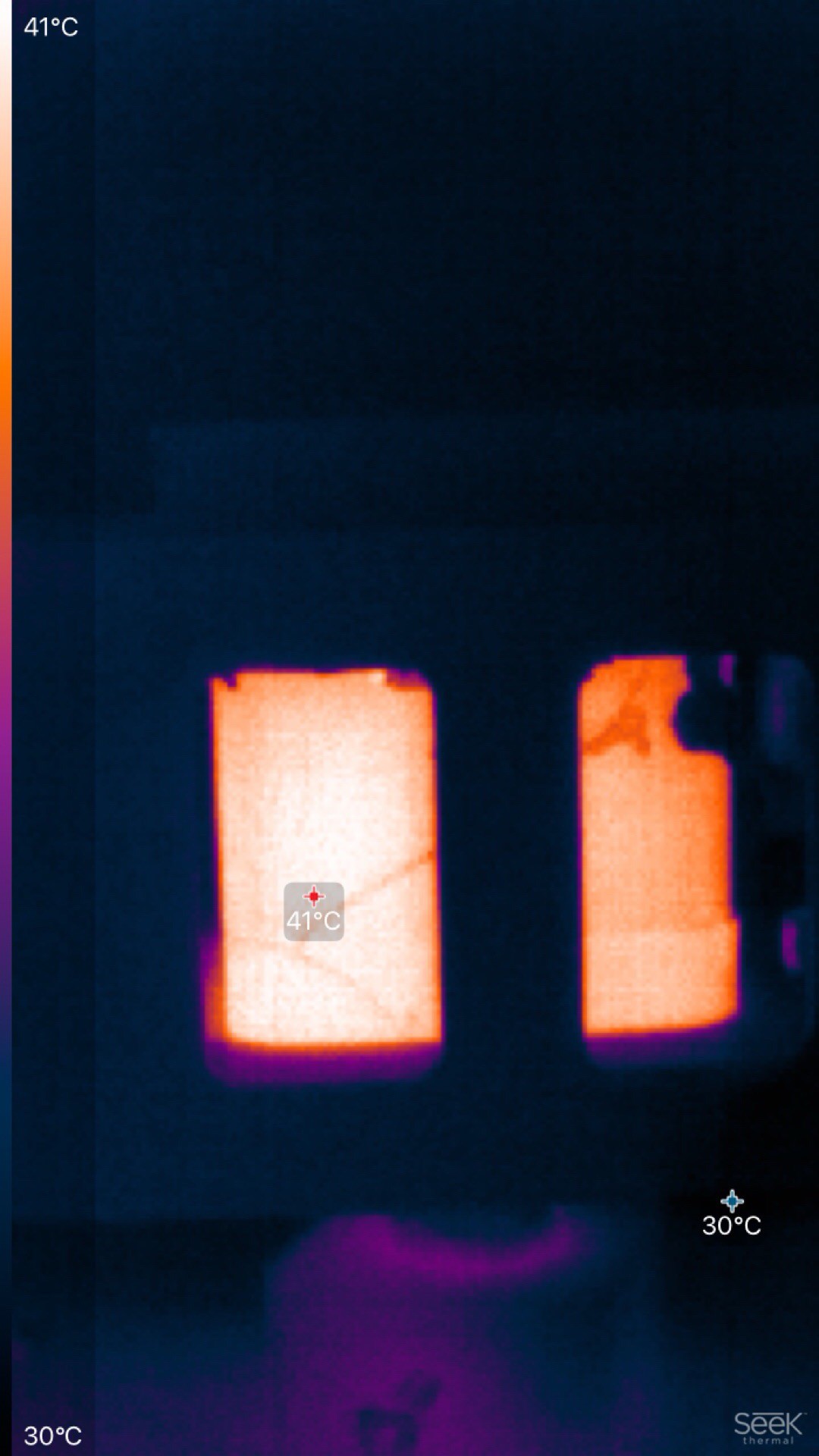

Image changes after one hour of work 41C.

-

Improvement for smooth movement

12/27/2018 at 12:26 • 0 commentsI spent some time to make moves smoothest. Because since i use stepper motors i had step skipping sometimes. So i decided to port Arduino stepper library to STM32. I had a little trouble with microsecond delays which has been used in Arduino library and I changed implementation a little. Now I can control speed acceleration and deceleration of my stepper. Also I switched stepper driver from A4988 to TMC2130 and now I have silent precision and smooth bearing moves.

I liked how it moves and think about to change 20kg servo to stepper with reductor.

Ivannikov Kirill

Ivannikov Kirill