I was inspired by this mechanism : http://507movements.com/mm_131.html .

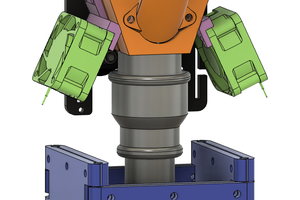

I started by recreating the mechanism in SolidWorks with all the proper mechanical mates so I can see the mechanism for myself. It was really hard to relate the throw of the blade with the sizes of the components and the angles of the dangles. I basically eyeballed it.

To power the saw I had a small but stupid fast BLDC that I bough on eBay because I was bored(I'm sure I'm not the only one who does that sometimes). To counter that speed and lack of torque, I designed a spur stationary ring planetary gear set with a 6:1 reduction ratio.I had some bearing from some server bearings that I got out of a duster that have a convenient 3mm.

You may notice a "counter weight" on the crank, it is pointless. I didn't take into account how heavy the bearing would be so the oscillation is annoying at low speed and an impact driver at medium speed.

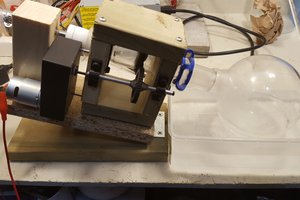

I used the cheapest PLA on ebay. It is junk, don't buy PLA or any filament for that matter that is less than 12 GBP. They are more brittle than dry spaghetti. And yet I have managed to print all of the components with it (the blue gears are from some better one because it was already in the printer).

To fix the blade in I designed a cool mechanism, and then used a soldering iron to smash it in after the tolerances war too small because of the "el cheapo" filament.

Only the ring gear of the planetary set needed supports for the screw holes with integrated nut holders. But I did have to split the main body in two parts and then glue them together.

Finally, here it is running plus a bonus pre-design animation.

BogdanTheGeek

BogdanTheGeek

Otto Gloeckner

Otto Gloeckner

Keith Elliott

Keith Elliott

doctek

doctek

Is it just me or does it seem to retract and extend at different speeds?