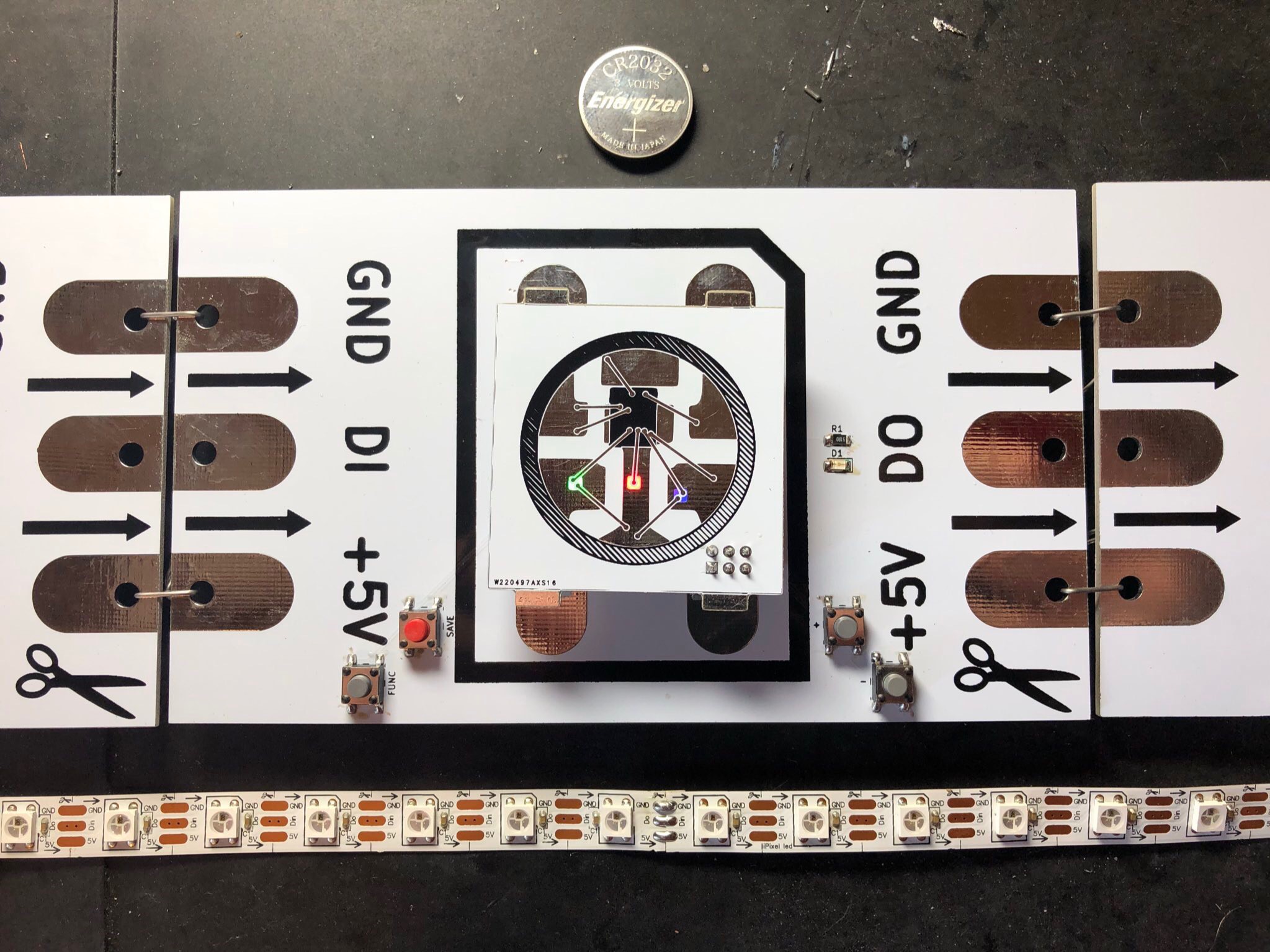

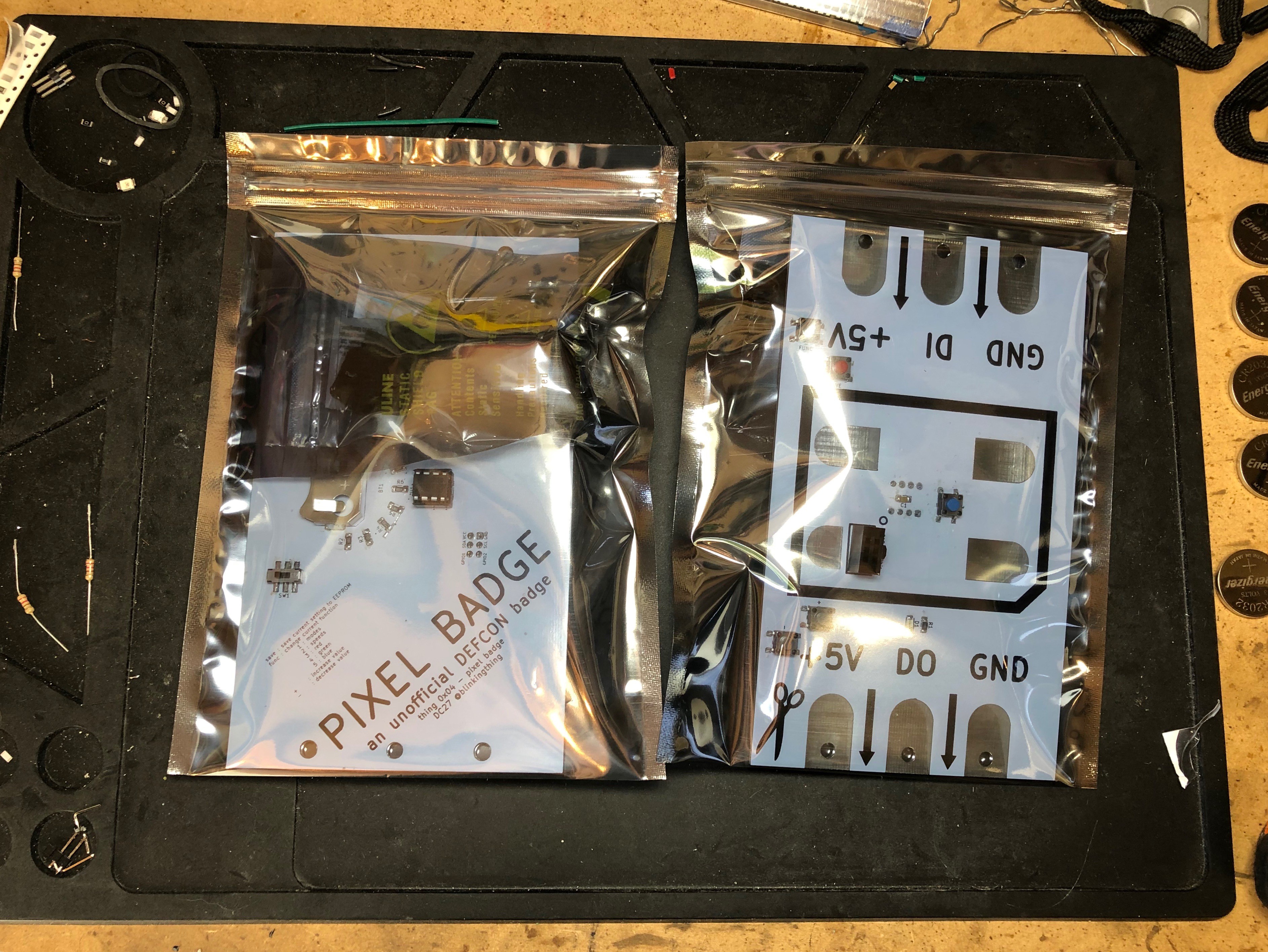

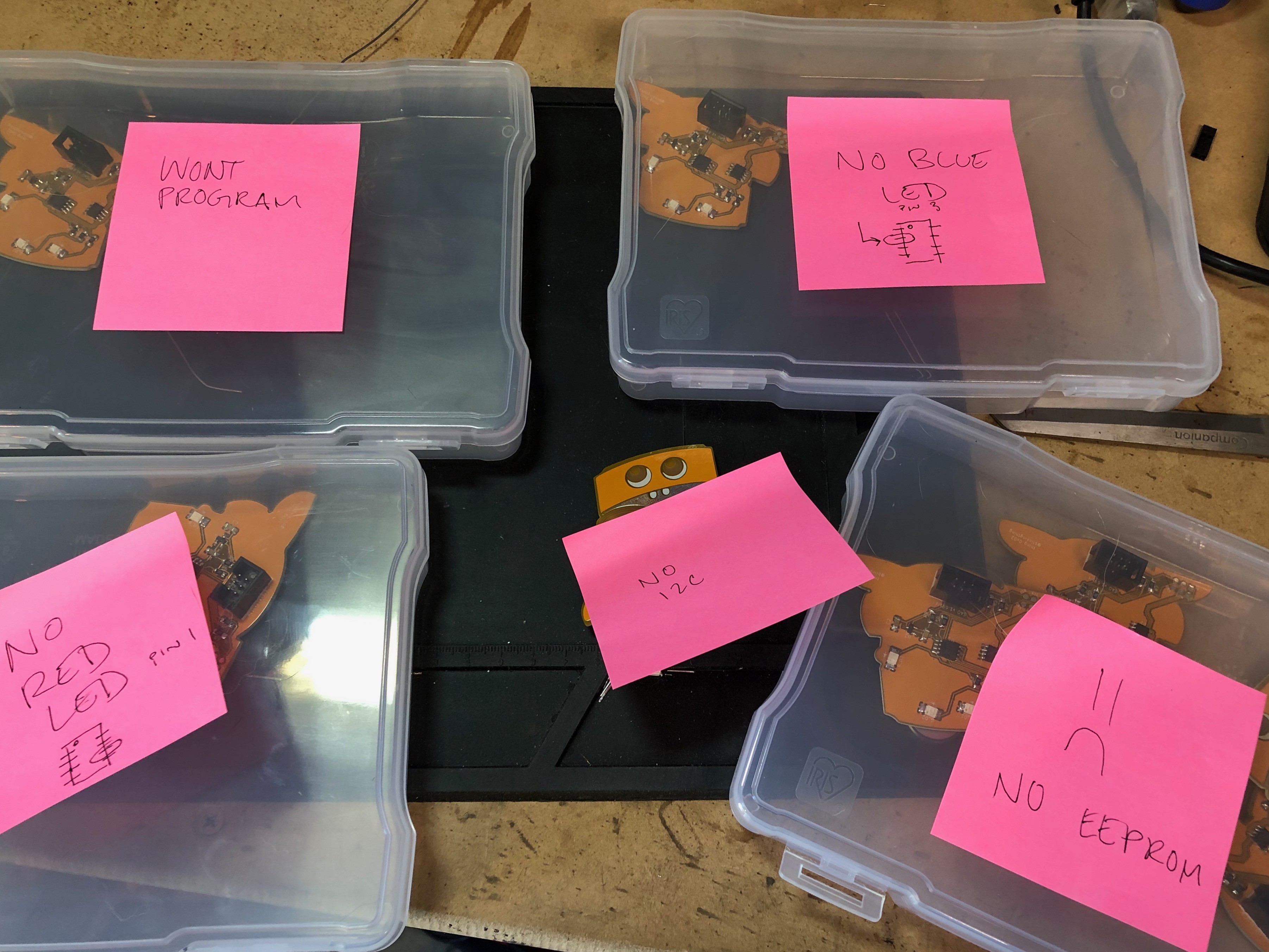

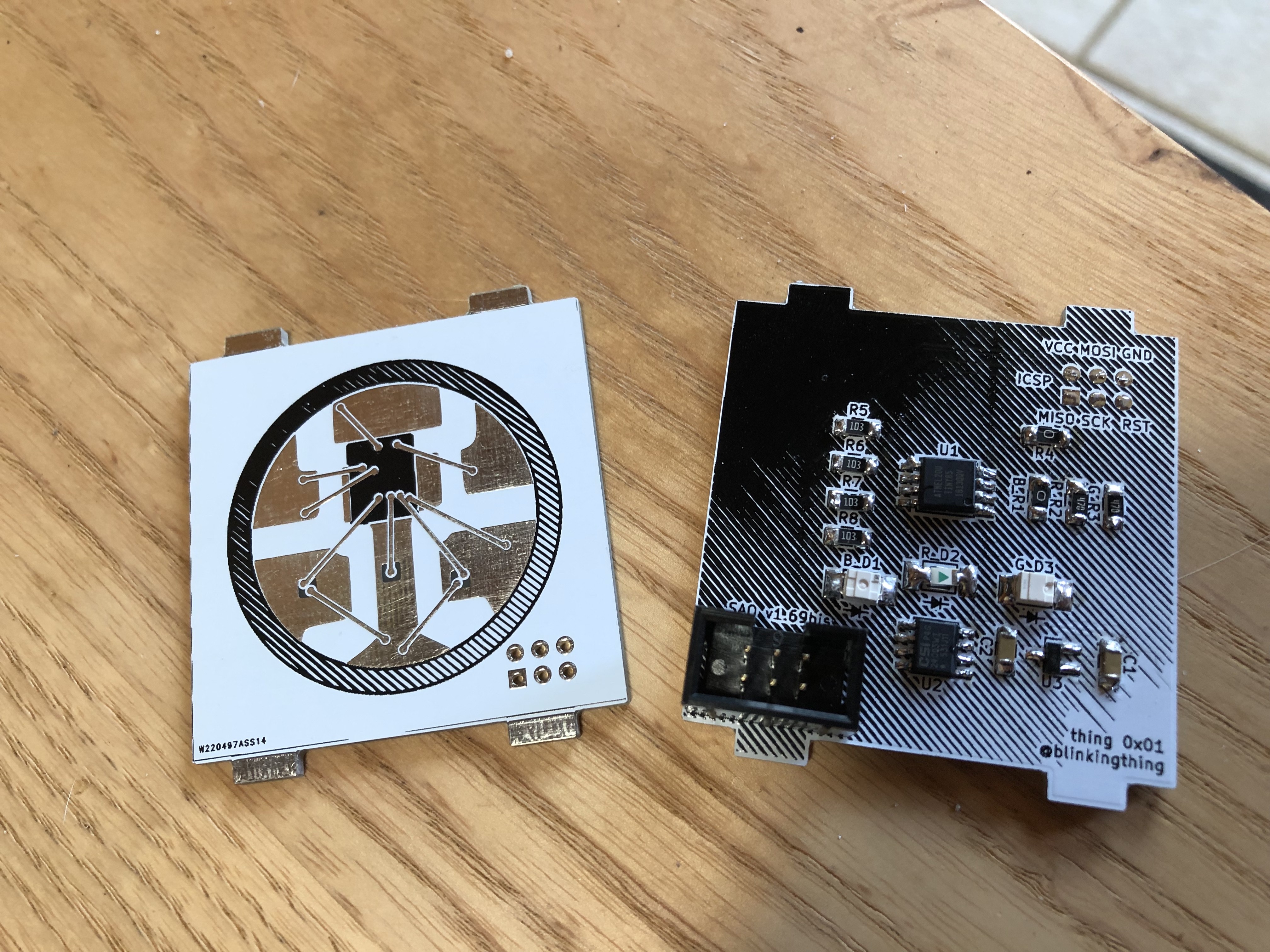

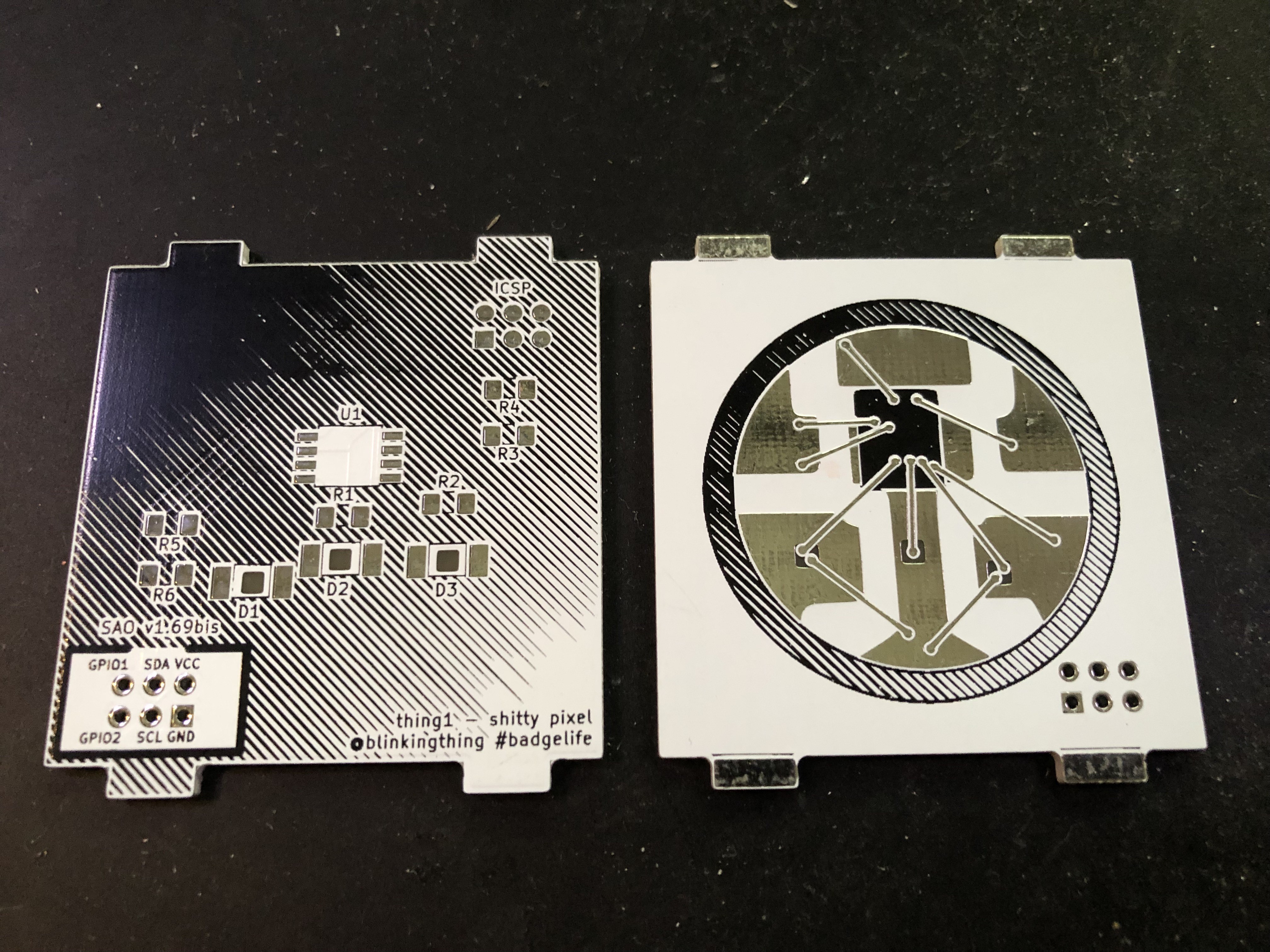

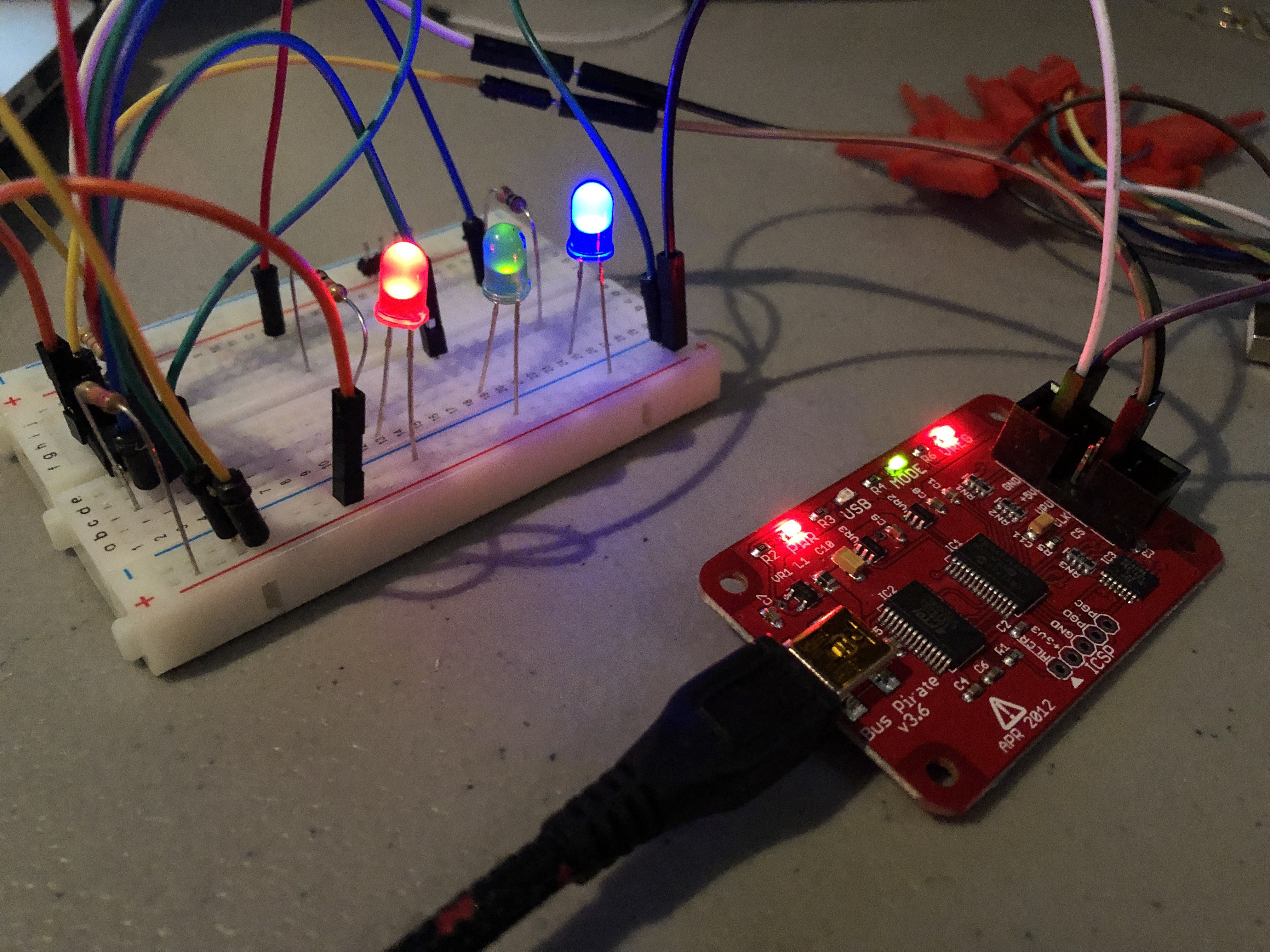

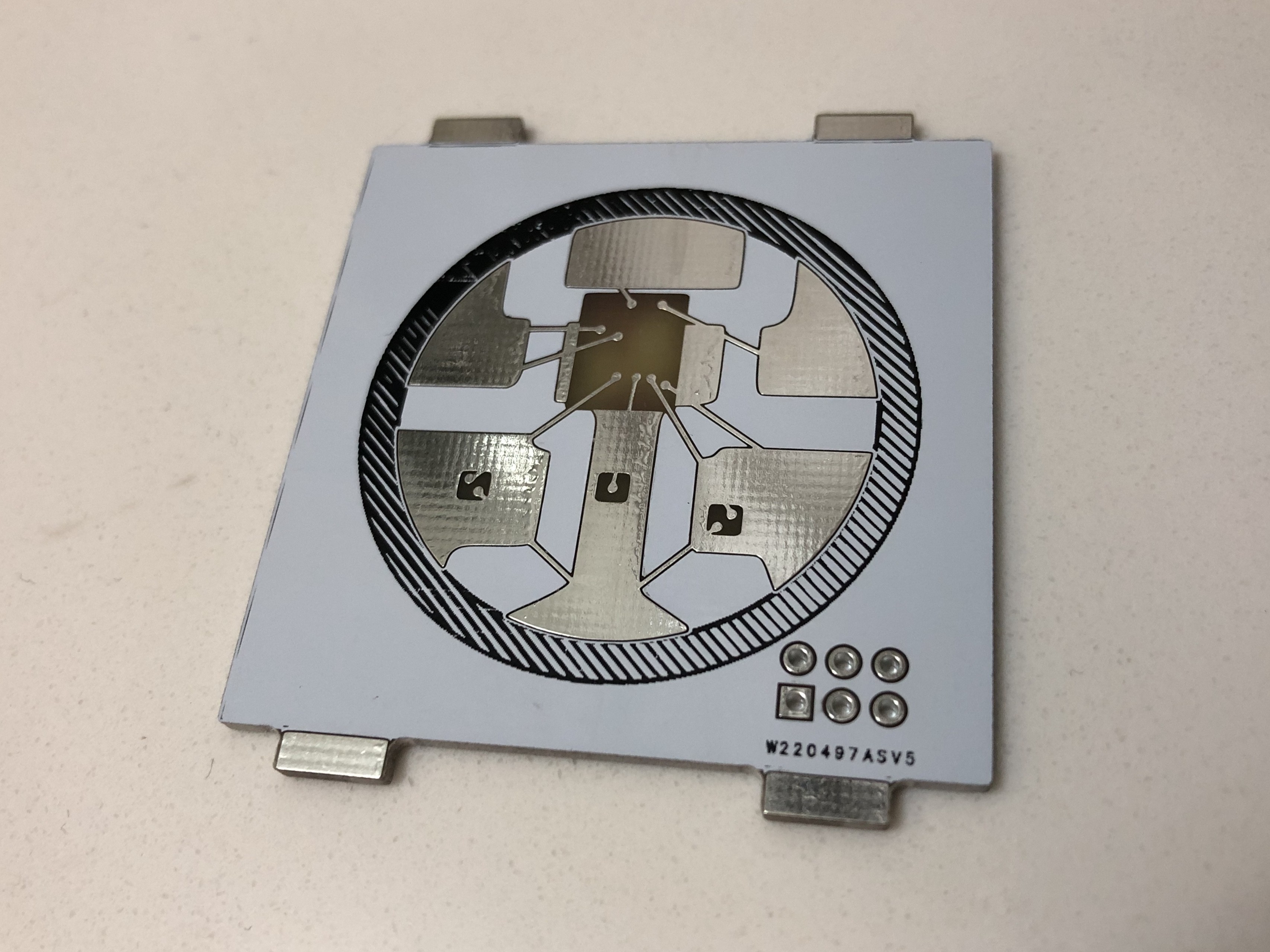

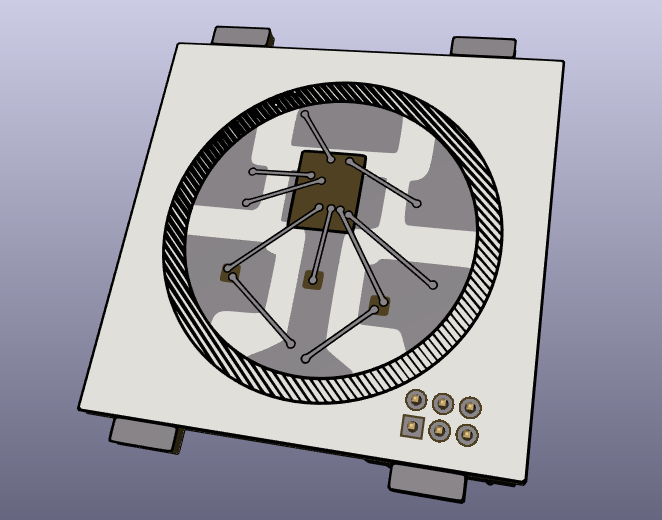

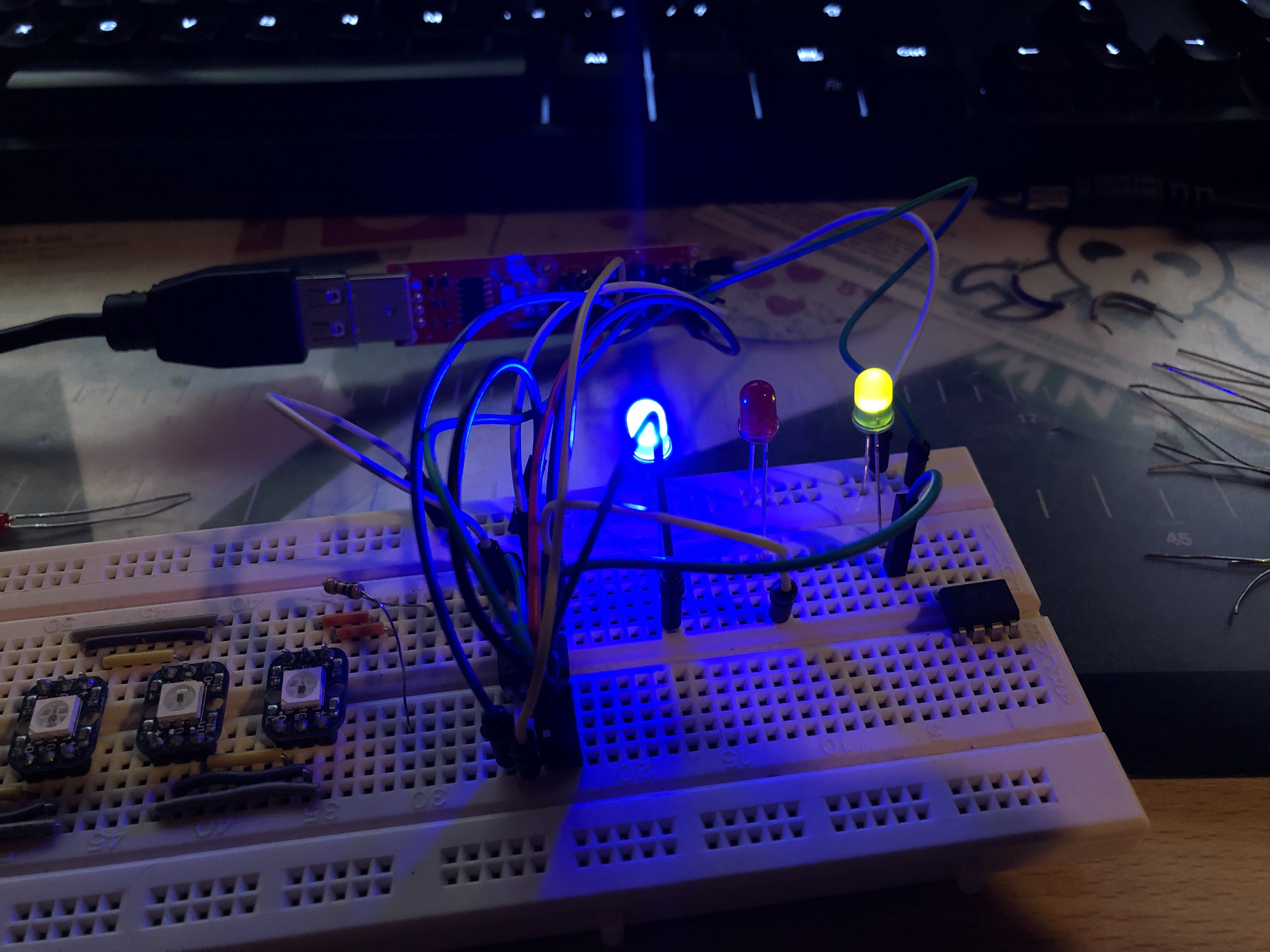

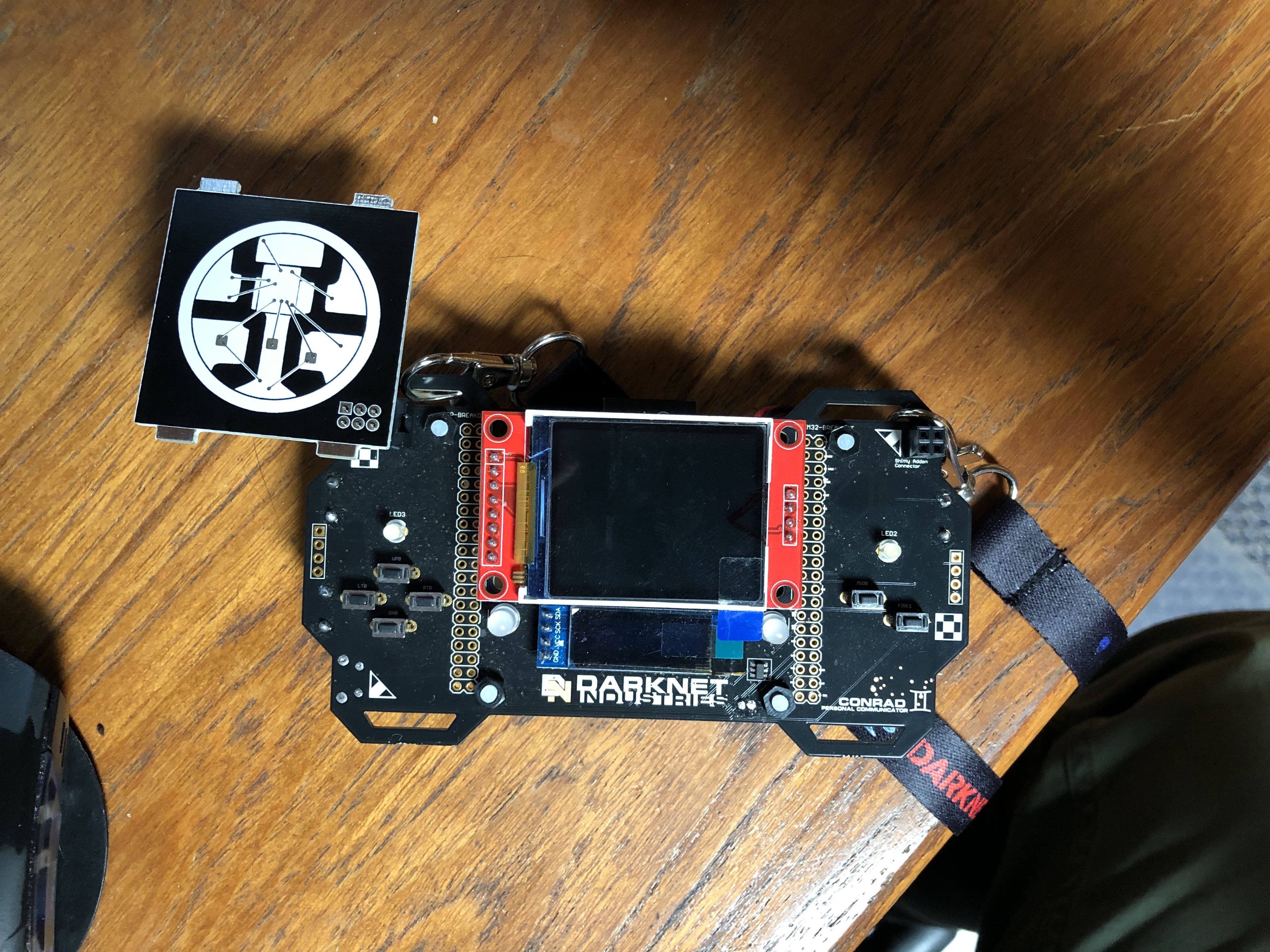

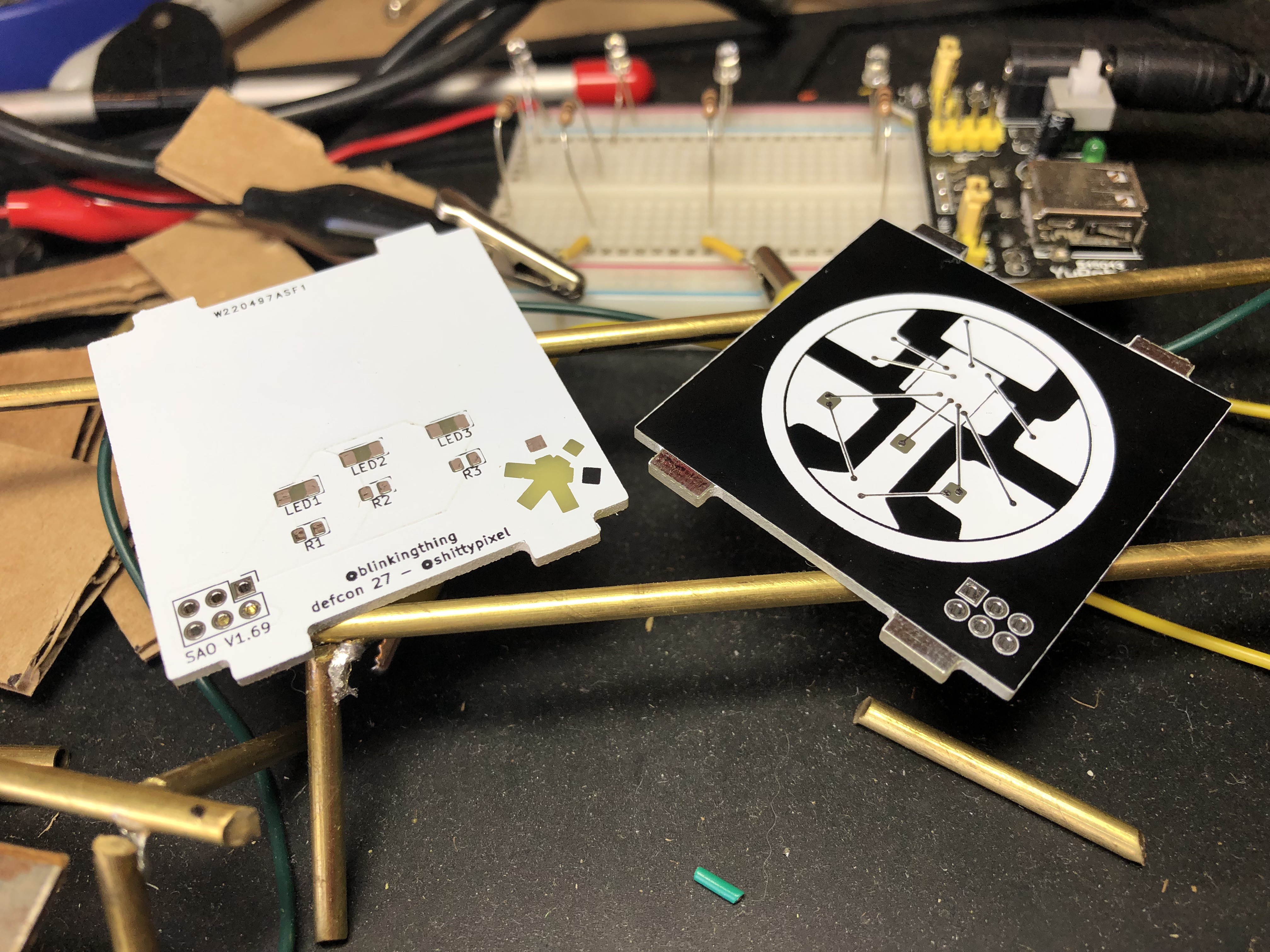

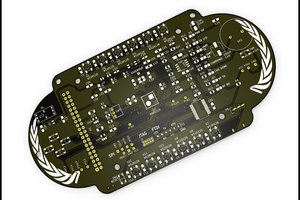

Working on a shitty add on for Defcon 27 utilizing shitty add-on standard v1.69bis. The goal is to have an oversized version of a WS2812 led that can change colors based on commands issued over i2c. By default it will cycle through some animations on it's own by just applying 3.3v, but there will be more to unlock with the appropriate commands.

Features

This shitty add-on has a mediocore ammount of features built in!

- 3 individually controllable LEDs!

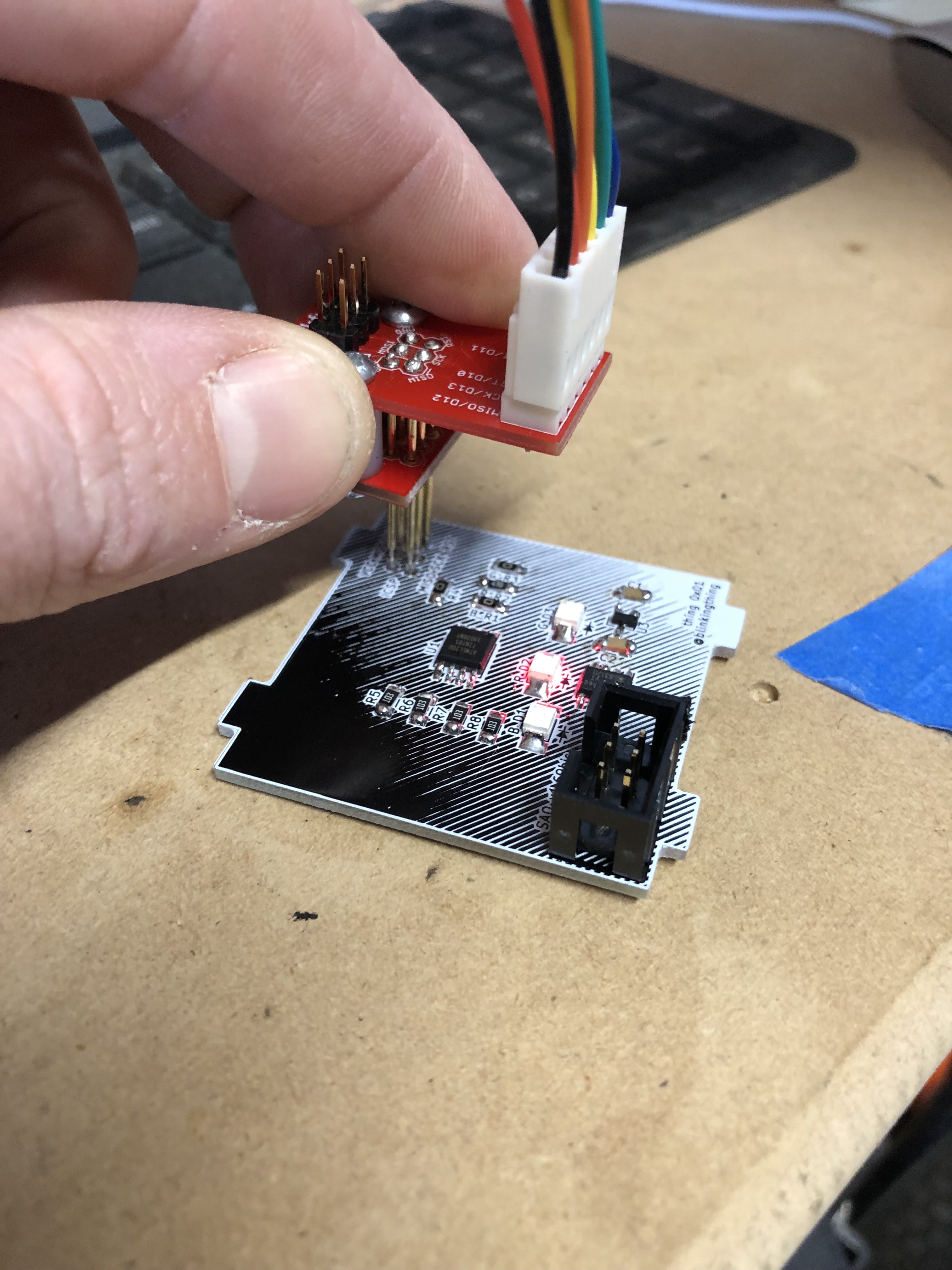

- A microcontroller!

- EEPROM!

- Between 3 and about a dozen (maybe) built in LED animations!

- Secrets!

- Control via I2C. Address TBD.

- Is the artwork a feature?

Files

I removed all the files I had uploaded because things are in a constant state of change. After I make up my mind on what the final version will be, I'll upload everything here to share.

blinkingthing

blinkingthing

davedarko

davedarko

John Adams

John Adams

They look great. Is there any chance to get one without beeing at DC?