-

Prototype 1

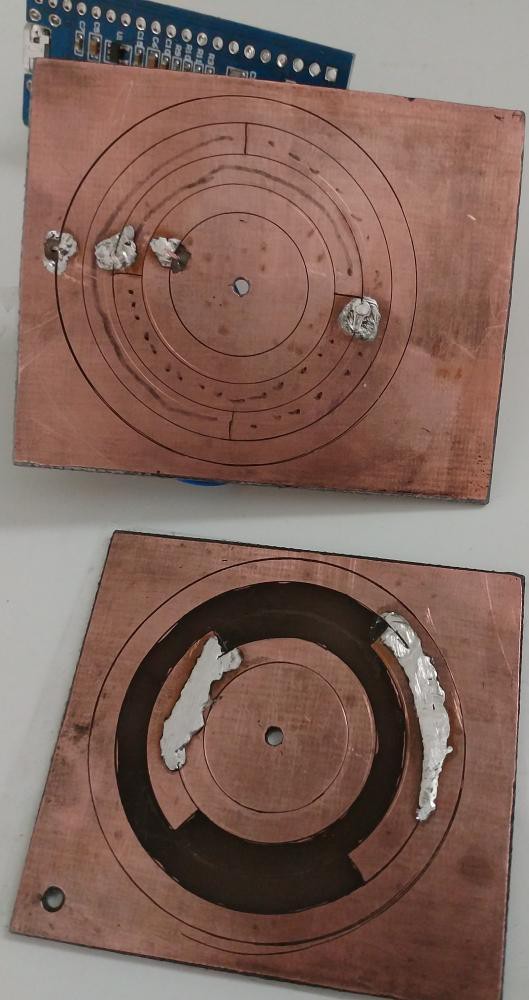

04/07/2019 at 15:20 • 0 commentsToday I tried this ugliness:

---------- more ----------![]()

Circles' biggest outer diameter is about 45 mm. Supposed to be 2 channels, both bad. Heh.

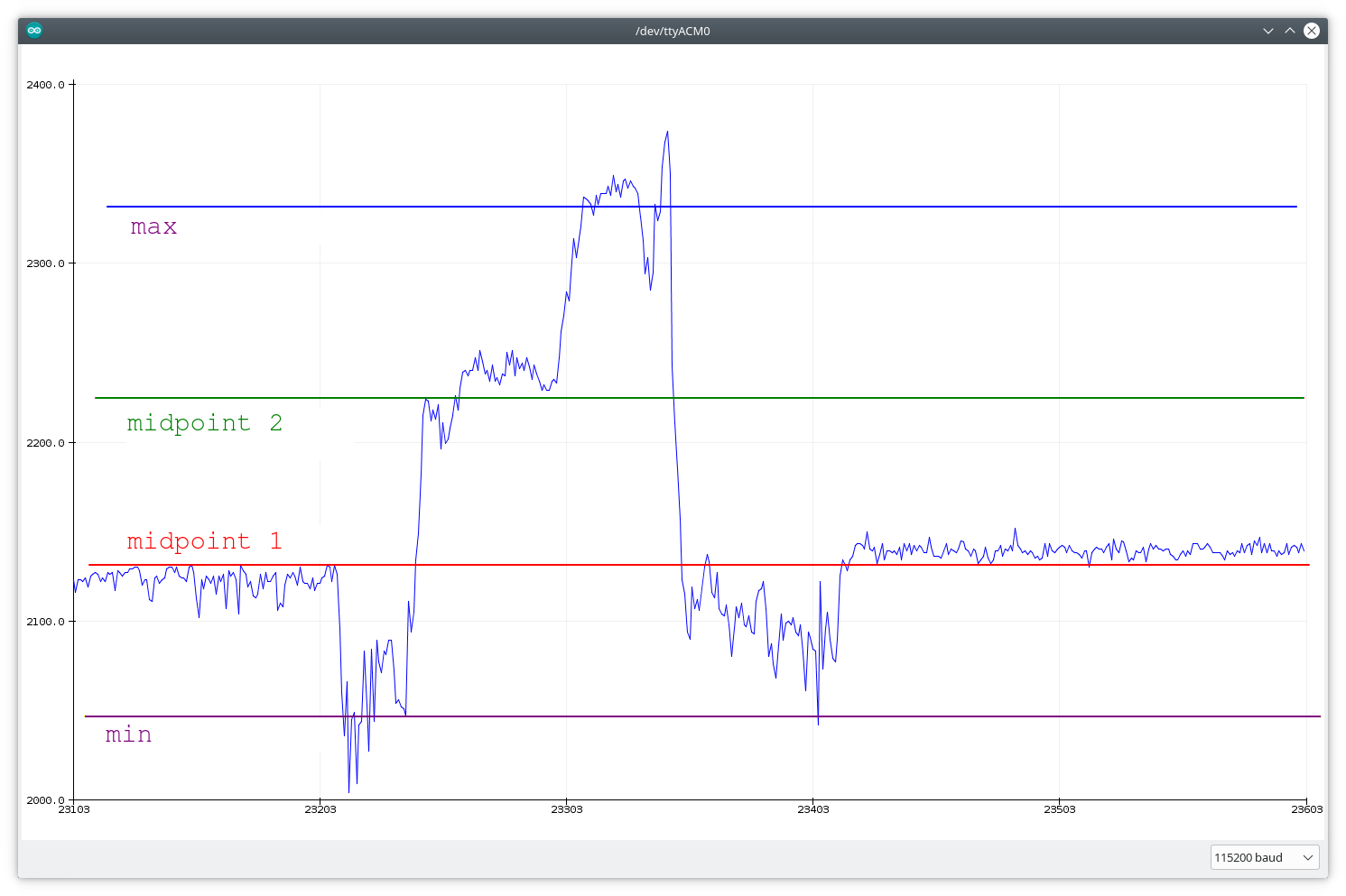

![]()

Midpoints, which should give equal values, aren't the same.

It is very sensitive to alignment. It is not surprising on its own, but the level of it is.

I need to come up with an arrangement, which mitigates at least a few of the potential errors from mechanical inaccuracies.

- Plates not perpendicular to the axis (thus not parallel to each other)

- Axial rotor movement. From imperfect bearings.

- Eccentricity of either parts.

Also electrical noise suppression. Have to research that net pattern used on touchpads and other capacitive sensors. Do I even need that, or plain fill is good enough?

-

PoC2

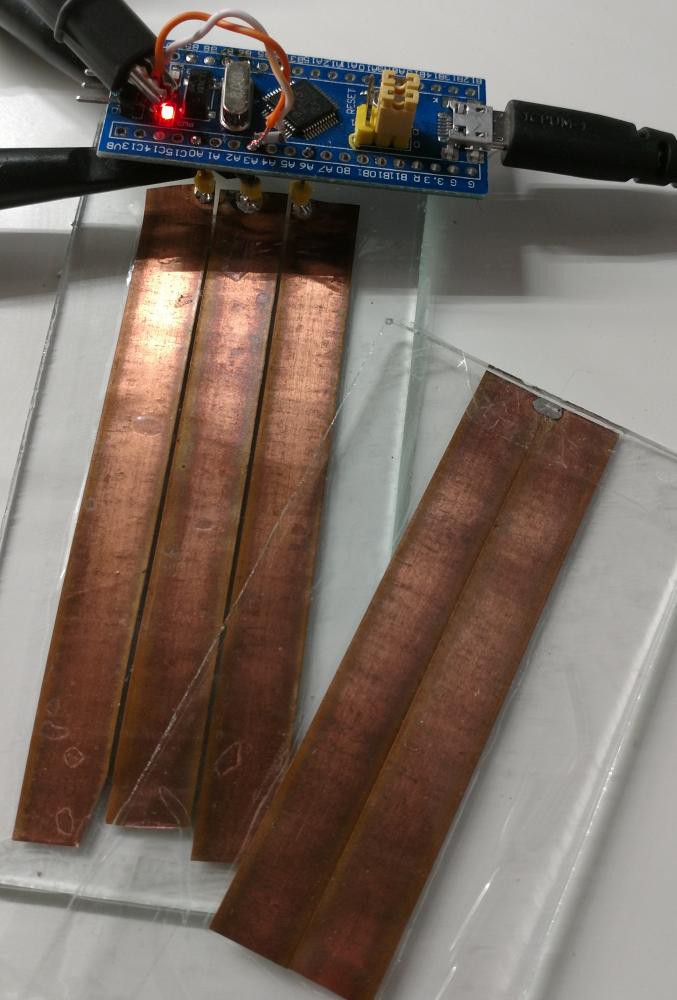

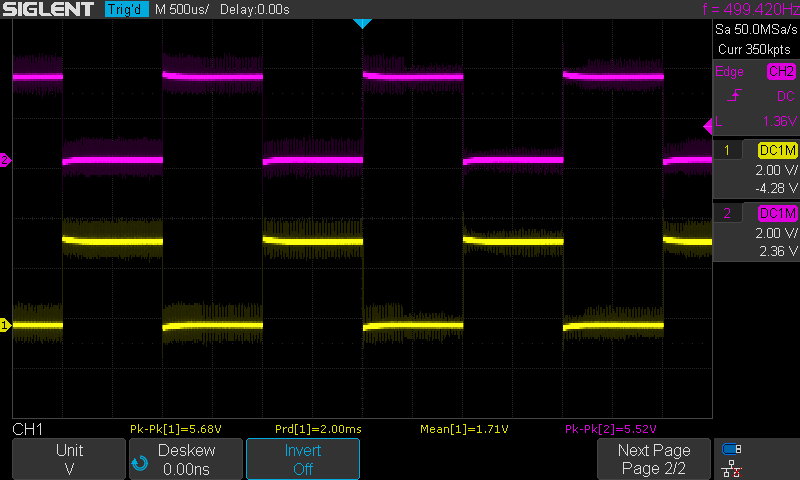

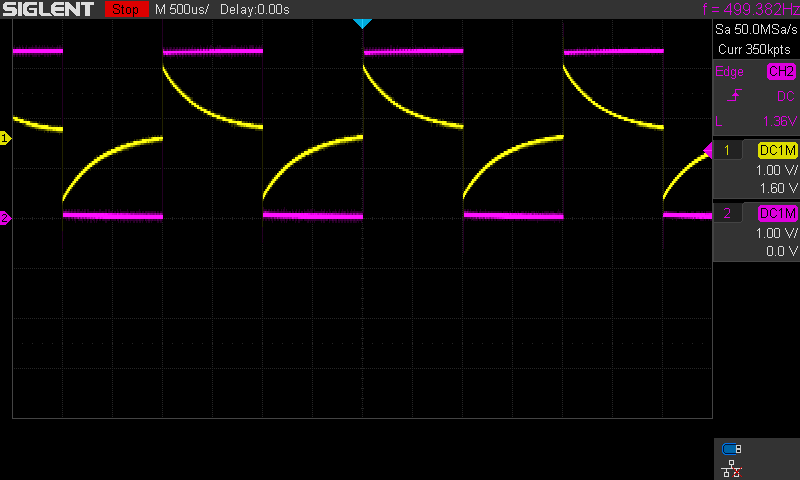

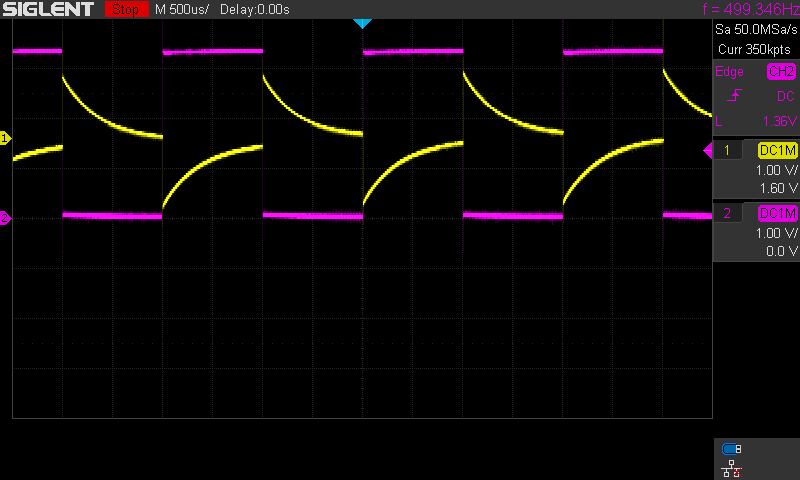

04/06/2019 at 19:33 • 0 commentsNew arrangement, ADC scanning. Noisy, but promising.

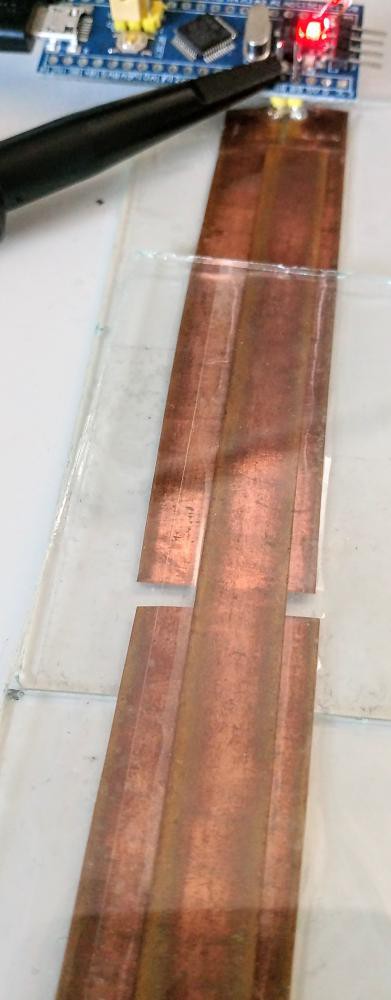

---------- more ----------![]()

drivers on side, sensing in middle, bodged divider for half voltage ![]()

#define ADCpin PA3 int sensorValue = 0; void setup() { pinMode(PA0,OUTPUT); pinMode(PA6,OUTPUT); gpio_write_bit(GPIOA, 0, LOW); gpio_write_bit(GPIOA, 6, HIGH); Serial.begin(19200); pinMode(ADCpin,INPUT_ANALOG); } void loop() { GPIOA->regs->ODR ^= 65; //flip both driver pins; stm32duino specific(?) sensorValue = analogRead(ADCpin); Serial.println(sensorValue); delay(1); GPIOA->regs->ODR ^= 65; delay(10); } -

PoC

04/06/2019 at 16:41 • 0 commentsAFAIK today's capacitive and inductive encoders use continuous AC signal to measure the impedance of variable elements. They need dedicated analog circuits, tuning and close tolerance parts. These make them more expensive.

BTW I'm not deeply familiar with analog circuits, so in my other project from last year I used a different approach. It is easier (for me) to understand.

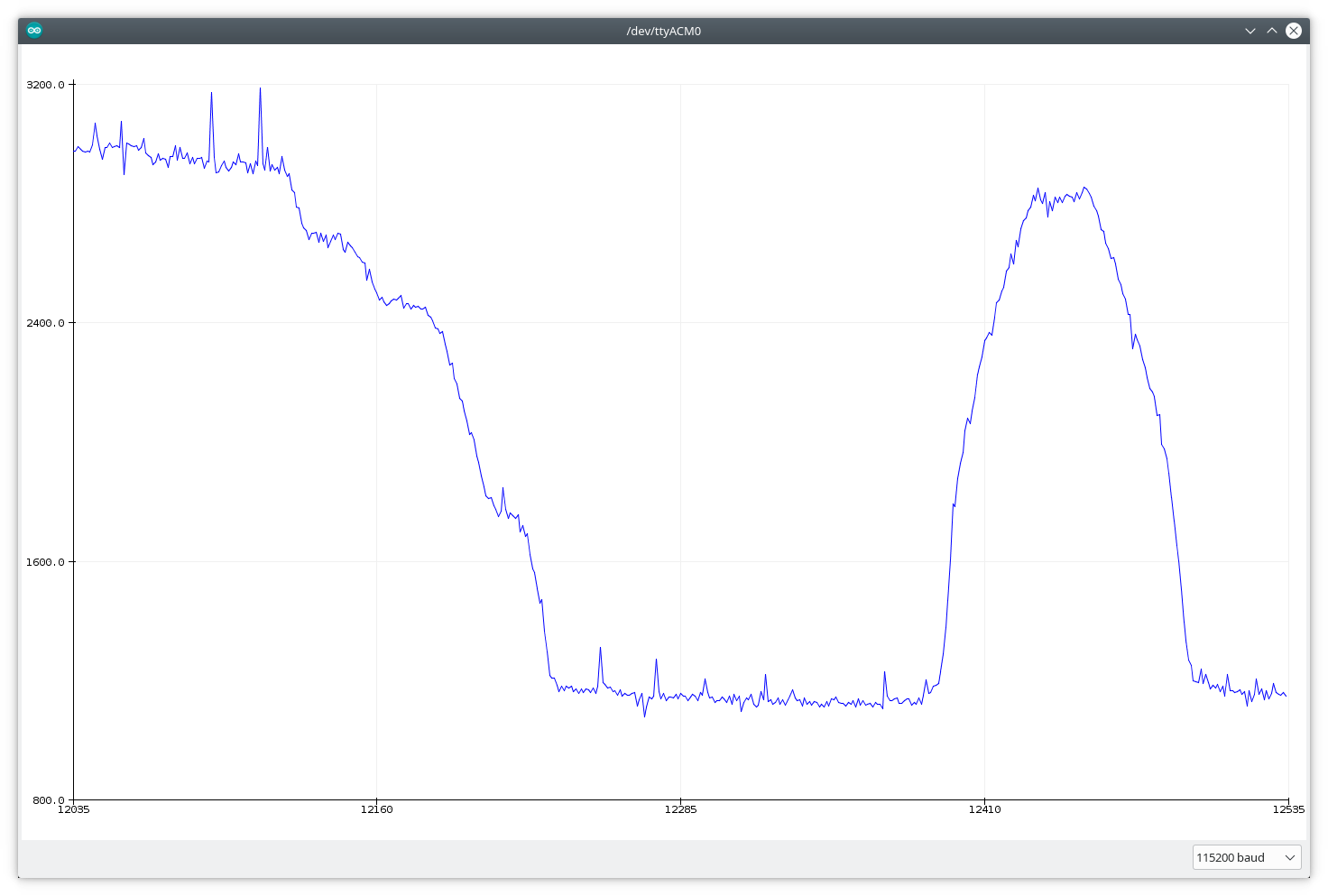

Now I tried this:

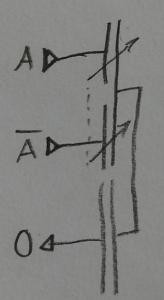

---------- more ----------![]()

left side: stator, right: rotor/slide ![]()

top: two input plates; bottom:output plate; right: slider ![]()

![]()

Input: invert square wave signals. ![]()

one input and output ![]()

slider on the other side -

What about...

04/06/2019 at 16:05 • 0 commentsSo, I like robotics. Pro robots usually use servo motors, they are expensive. Good quality motors are expensive, but decent brushed or brushless DC motors can be found for good price. For one-off projects, even scavanged parts can be used.

High resolution encoders are also expensive, especially absolute scaled, and reliable ones. Cheaper encoders are only incremental and/or bulky. CUI's (AMT series) encoders look nice, but the cca. 50 USD is still a solid investment for a hobbyist (you rarely need only one for a project). Can they be even cheaper? Two PCBs and an MCU cheap?

There was an interesting experiment, even featured on hackaday blog.