-

Design. Prototype. Test. Phase2

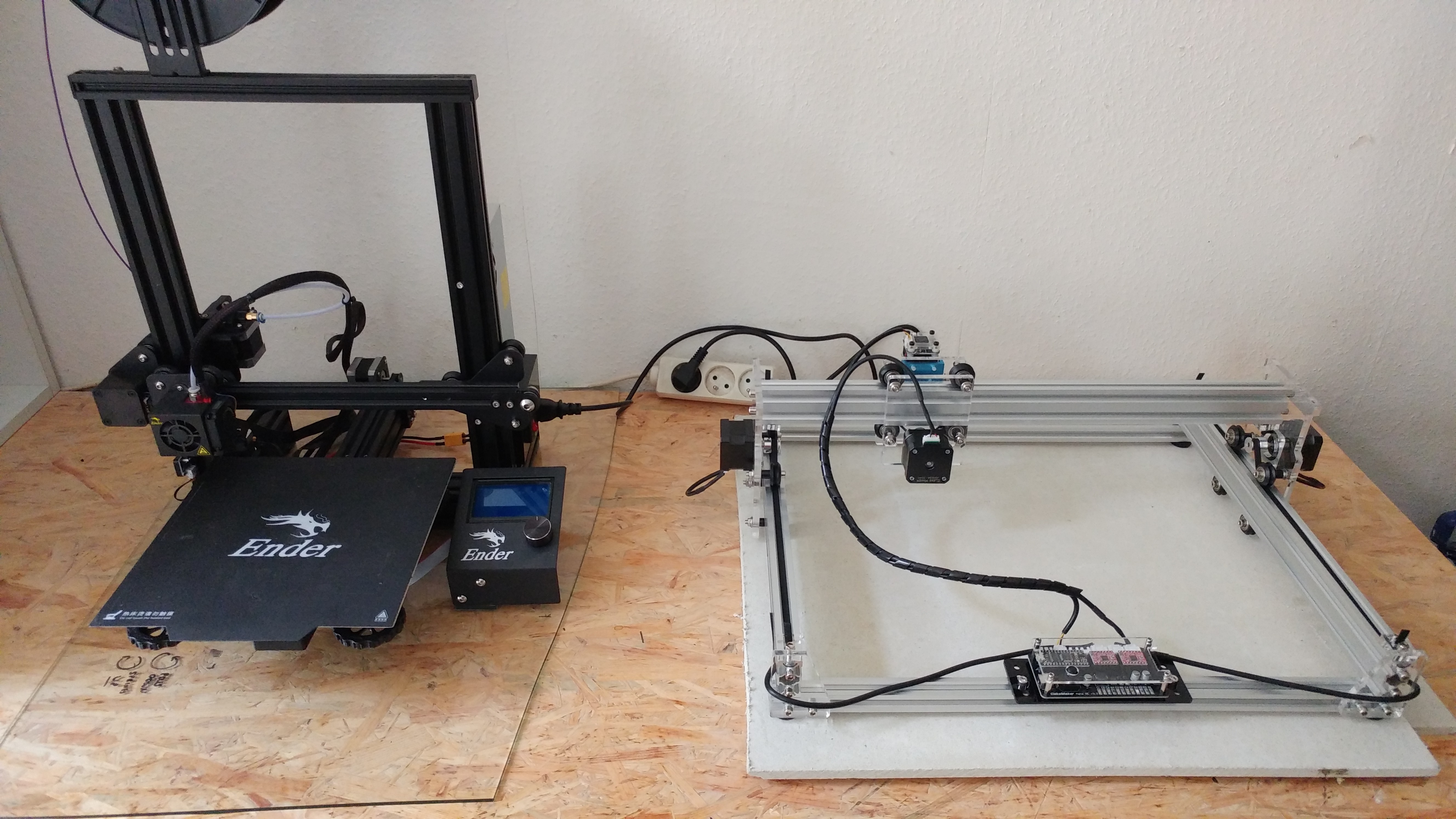

05/02/2019 at 08:37 • 0 commentsWouldn't it be fantastic if these headsets could be made by small local factories using less than $400 of equipment to setup? We're basically already there - all you need is a cheap 3D printer for the camera holders (in our case an Ender 3) and a cheap A3 laser cutter (in this case an Eleksmaker A3 pro). As it happens, I just got a laser cutter for "in house" prototyping to speed things up. I assembled it last night, and now it's time to work on simplifying the design to speed up assembly and reduce dependencies on glue. Perhaps, given the new camera module we've chosen, it might even be possible to get rid of the 3D printed parts entirely!

-

Hello World

04/12/2019 at 12:01 • 0 commentsHi!

We built the first prototype, but there's more to do. Right now we're focused on trying to source the best components at the best prices. How far can we drive the price down? That also depends on how many people want to contribute to the first run. We'll be setting up a mailing list and a CrowdFunding campaign soon.For now, if you want to get involved, just leave a message!

Ben

EyeTracktive - Eye Tracking for Google Cardboard

An ultra-low-cost eye-tracking insert for Google Cardboard V2! Unleash the power of the eyeballs!

ben

ben