-

Programming Tool Chain

06/07/2019 at 21:34 • 0 commentsI'm working on getting the source published on github. In the meantime, here's a short write up about the tool chain.

Happy Clap's toolchain is all Atmel, all the time. I have been using the standard Atmel Windows toolchain for quite a few years now. It uses the GCC compiler, and other open source tools, to build and run code. Over the top of this, it uses a Microsoft Visual Studio based IDE, Atmel Studio.

Atmel Studio

Atmel Studio provides a convenient way to edit, compile, load and debug. It also is adequate at autocomplete suggestions, cross referencing source and highlighting the line that has a compiler error. It's... fine.

That said, Atmel Studio feels a little old and creaky. It seems to be in the process of being deprecated in favor of MPLAB X IDE. However, MPLAB's AVR features are marked "preliminary, beta support, not production tested so I am using Atmel Studio. It's fine.

Atmel START

Atmel START has a website (start.atmel.com) where you configure your part using a point-click-and-occasionally-type interface. Mostly it's about selecting which peripherals you're going to use and how they are configured. START then generates boilerplate code to initialize peripherals as well as libraries and example code to use, all in a form that can be used by one of several IDEs.

Because START provides the source for libraries and configuration code, it's possible to rewrite just about anything you'd prefer to do differently.

I like START. It's not perfect, but it sure beats figuring out every little detail from scratch.

Atmel ICE

Finally, I use Atmel's standard programming tool, the Atmel ICE. It was expensive, but I've had many years' of use out of it, and, with Atmel Studio, it Just Works.

By Just Works I mean, when ICE says the voltages are wrong, I know that the voltages are wrong. When ICE says it programmed a chip, I know that the chip is programmed. And it's reasonably fast, too.

I'm keen to give the new MPLAB Snap a go, to see if it measures up in terms of features and reliability.

-

Software Part 1: Buttons, Lights and Configuration

06/07/2019 at 20:40 • 2 commentsThe clap-switch source is a single file C program, written using the Atmel START framework. This post discusses the main loop, how each of the peripherals are handled. A follow up post will discuss handling of the sound input and the actual clap detection.

If you'd like to see or use the source, it's available at github.com/alanvgreen/clap-switch

All of the interesting code is in main.c.

Main Loop and Top Level

At the core of the software is tick_millis, a 32 bit millisecond counter. tick_millis is updated every millisecond by an interrupt from the PIT (programmable interrupt timer).

ISR(RTC_PIT_vect) { tick_millis++; // Clear interrupt flag to indicate that interrupt has been handled. RTC.PITINTFLAGS = RTC_PI_bm; }The timing is generated by the 3217's internal 32kHz timer, so it will only be correct with a few percent, but that's close enough.

The main loop begins by waiting for tick_millis to be different from the last time it saw tick_millis. It sleeps while waiting, and will wake when an interrupt occurs.

uint32_t last_awake = tick_millis; while (1) { while (last_awake == tick_millis) { __builtin_avr_sleep(); } last_awake = tick_millis; // ... rest of loop here ... }So long as the rest of the main loop takes less than a millisecond, then the loop will execute every millisecond.

Output: WS2812 LEDs

WS2812 LEDs are stateful: you only need to tell them what to do when you want them to change what they're doing. The code keeps track of whether the led status is up-to-date with the leds_updated variable. When that variable is true, the LEDs don't need updating.

Sending Data to WS2812s

Following the advice from Josh Levine, clap-switch simply bit-bangs data out to the LEDs, paying more attention to the length of the high part of the cycle than the low part of the cycle. If you haven't read his article, and you think you might one day program a WS2812/NeoPixel, reading this article will pay back your time investment many-fold.

Here's the code to send one byte. We use cycle delays, knowing our CPU speed to within 20MHz, and keeping in mind that the on-off transition adds a smidgen of delay too.

void sendByte(uint8_t v) { // Working with PB0 register uint8_t on = VPORTB_OUT | 1; register uint8_t off = VPORTB_OUT & 254; for (uint8_t i = 0; i < 8; i++) { if (v & 0x80) { VPORTB_OUT = on; __builtin_avr_delay_cycles(13); // 0.65uS VPORTB_OUT = off; __builtin_avr_delay_cycles(8); // 0.4uS } else { VPORTB_OUT = on; __builtin_avr_delay_cycles(6); // 0.3uS VPORTB_OUT = off; __builtin_avr_delay_cycles(15); // 0.75uS } v <<= 1; } }We call this code three times per WS2812 - once each for Green, Red and Blue (yes, in that order). And we do that 8 times - once per WS2812, for a total of 24 calls to update all of the LEDs.

We calcuate the values of R, G and B to send using an HSL to RGB conversion algorithm. H (hue) and L (luminance) are set using the rotary encoders. We assume S (saturation) is 1, meaning fully saturated. In the context of a bedroom light, the result is a pleasingly useful subset of the full range of the WS2812s color output.

// v is L (because lowercase l looks like 1 and is confusing). // v range 0-255 instead of 0-1. uint16_t v = (config.brightness * config.brightness) / 16; v = min(v, 255); // in case config.brightness == 64 // S is assumed to be 1 (range 0-1) // Calculate chroma - 0 to 255. uint16_t c = (255 - abs((2 * (int16_t) v) - 255)); // config.hue is in range 0-191 uint8_t hue_region = config.hue >> 5; // top 3 bits of region are hue range (0-5) int8_t hue_val = config.hue & 0x1f; // bottom 5 bits are val uint16_t xt = 8 * (hue_region & 1 ? hue_val : 32-hue_val); uint16_t x = (c * (256 - xt)) >> 8; // scale x down to range 0 to 255 uint8_t r = 0, g = 0, b = 0; switch (hue_region) { case 0: r = c; g = x; break; case 1: r = x; g = c; break; case 2: g = c; b = x; break; case 3: g = x; b = c; break; case 4: r = x; b = c; break; default: r = c; b = x; } uint16_t m = v - c/2; sendLeds(min(r + m, 255), min(g + m, 255), min(b + m, 255));This code closely follows the algorithm from Wikipedia. Note that:

- config.brightness is squared before it is used, which allows brightness changes to be perceived more linearly by the human eye.

- Part of the algorithm requires determining in which of six divisions of the color wheel the hue is situated. This is an annoying operation an 8 bit MCU. To make it simpler, we limit config.hue to the range 0-191. Since 192 is 6 * 32., we can easily determine the division by shifting config.hue 5 bits to the right.

- There's also quite a bit of other complication caused by using fixed size integers rather than floating point numbers.

Input: Button

The button reading code simply checks whether it's state is different from how it was last time the code checked, and also includes a 20ms minimum time between reporting changes, which effectively debounces the output.

Input: Rotary Encoder

This code is based on logic from circuits at home (link not working at time of writing). Based on the current and previous states of the encoder, it returns -1 or 1, depending on the direction that the encoder was turned, or zero if there was no change.

// Look up table for intepreting encoder state transitions. // Index is (last_encoder_reading << 2 | // current_reading) static const int8_t enc_states [] PROGMEM = {0,-1,1,0,1,0,0,-1,-1,0,0,1,0,1,-1,0}; // Returns -1 on turn one way, 1, the other way and zero for no change. int8_t readEncoder1() { static uint8_t last = 0; uint8_t curr = (ENC_1A_get_level() ? 2 : 0) | (ENC_1B_get_level() ? 1 : 0); int8_t result = pgm_read_byte(&(enc_states[last << 2 | curr])); last = curr; return result; }I did not find any need for debouncing logic.

Based on whether the encoder returns -1 or 1, we twiddle the brightness and hue pretty much as you would expect. Here is the code for updating brightness:

void updateBrightness(int8_t in) { if (in == -1 && config.brightness >= 1) { config.brightness--; configChanged(); } if (in == 1 && config.brightness < MAX_BRIGHT) { config.brightness++; configChanged(); } }Saving Configuration

I wanted to make sure that when the light was unplugged and then replugged, ti came back in pretty much the same state - whether the light was on or off, as well as hue and brightness. clap-switch accomplishes this by writing the configuration to 'EEPROM' (actually, it's flash) whenever the configuration is changed.

void maybeWriteConfig() { if (!config_written && tick_millis > config_change_millis + CONFIG_WAIT_MS) { FLASH_0_write_eeprom_block(0, (uint8_t *) &config, sizeof(Eeprom)); config_written = true; } }Note that we wait a few tens of milliseconds after each configuration change, in case there is another change in quick succession. This saves wearing out the EEPROM, which only has a lifetime of tens of thousands of writes.

At startup, the EEPROM is read into RAM and the light put back into the same state.

-

Construction

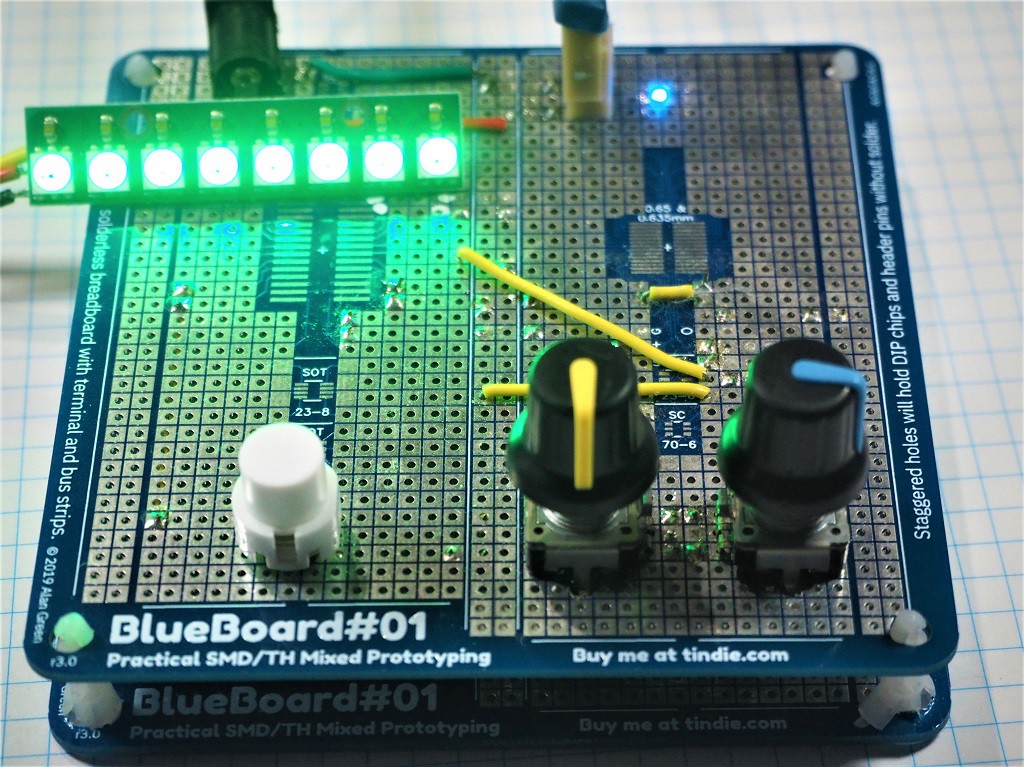

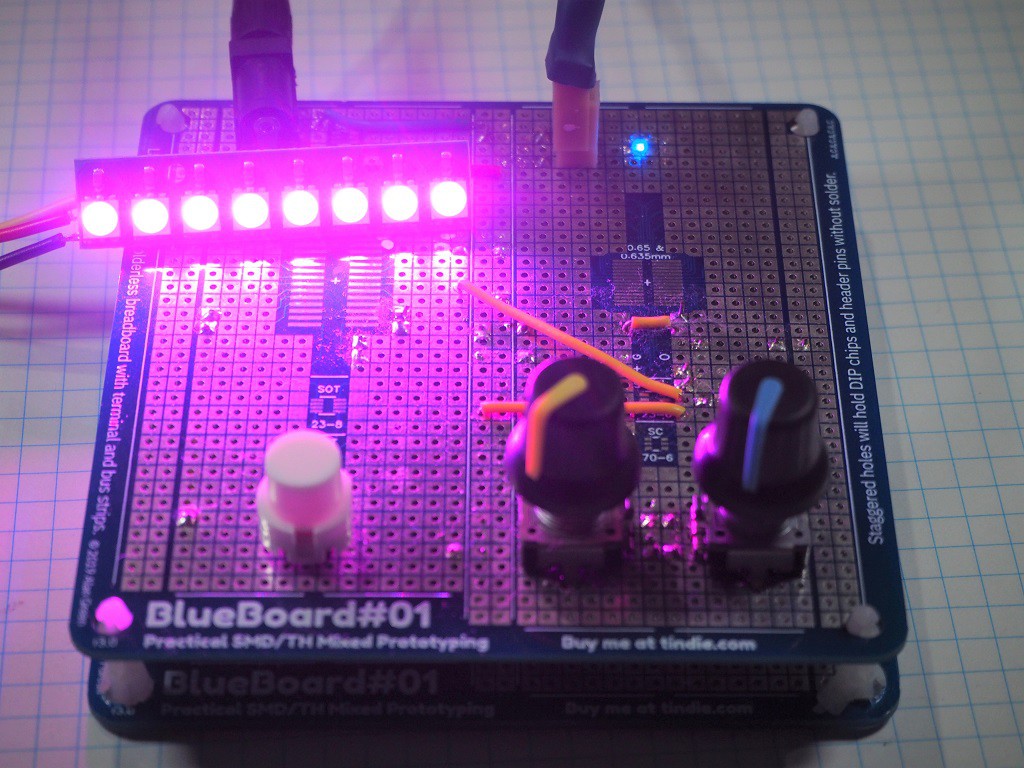

05/21/2019 at 12:00 • 0 commentsIt's green! It's purple! I began by drawing the component layout onto planning sheets.

Sadly, I lost these sheets. It was super-helpful to have them to work from, but I did change my mind, mid-construction on a few items.

Soldering Components

I have done quite a bit of prototyping with BlueBoard#01 and its predecessors. Soldering components is about as quick as soldering to a PCB. Wires are extra, but I minimized wire runs by using through hole component leads to jump between ICs, particularly around the microphone and op-amp,

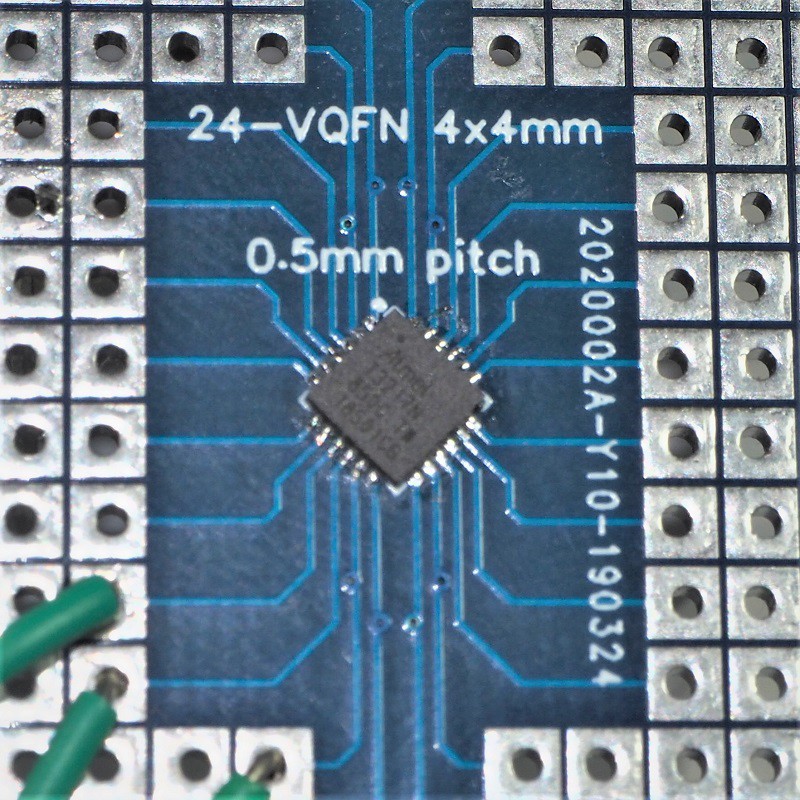

ATTiny3217 - The ATTiny3217 comes in QFN package. I used a hot air gun to solder it. I was a little heavy on the solder paste, and there was one bridged pin, which I was able to touch up with the soldering iron in a few seconds.

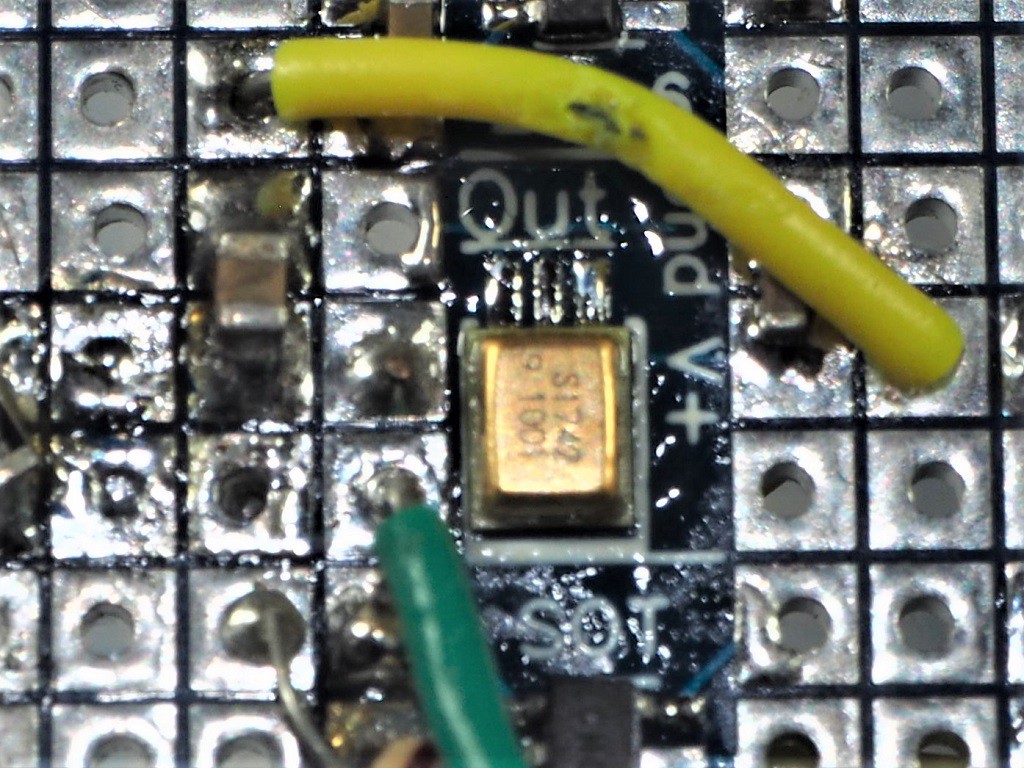

Hand soldered SPU0410 MEMS microphone - The SPU0410 I hand-soldered and got it third try. Fortunately, these things are cheap. Now that I've had practice, I reckon I'll get it first time, next time. The end result looks a bit messy in close up, but its fine from a distance, and anyway, the microphone is on the bottom side of the board.

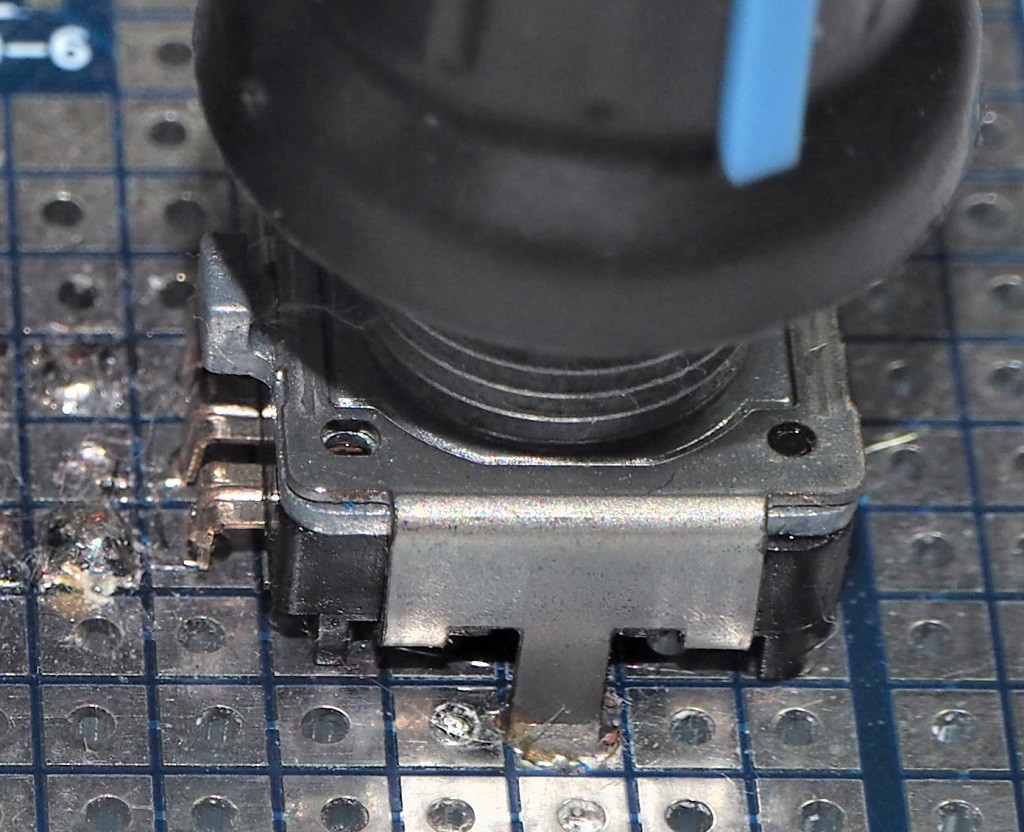

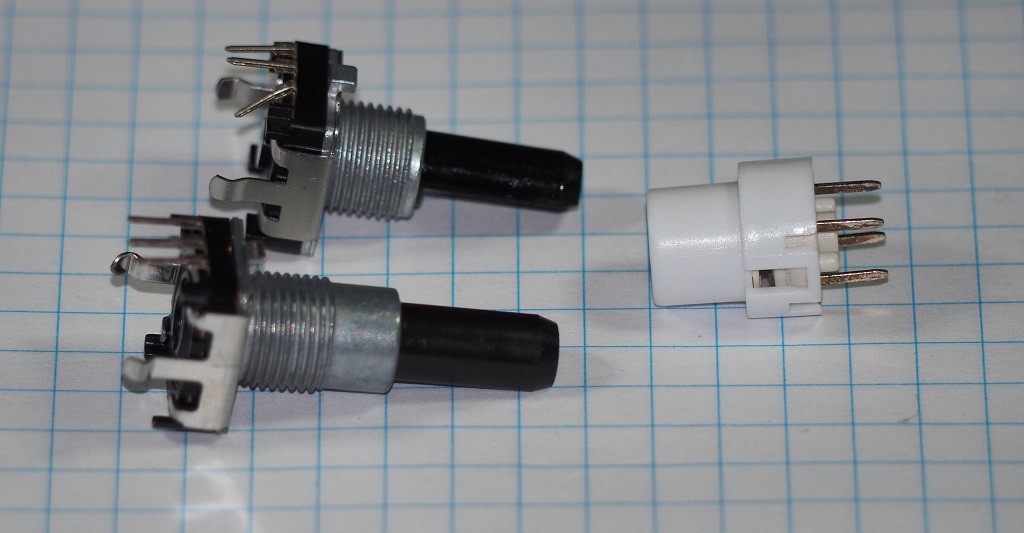

Encoders

Encoder with drilled out hole for peg The encoders each have three leads at 0.1" centers, as well as two additional metal pegs to help secure it to the board. I was able to drill out 2mm holes in the PCB, which fit the pegs perfectly.

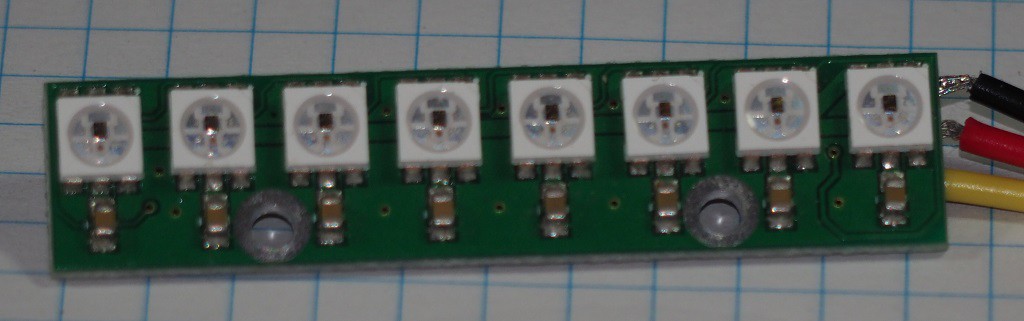

WS2812s

The WS2812s are connected with 3 wires - 5V, Gnd and Data, which I braided together for strength and neatness. I used a 3 pin header and plug because I happened to have them - otherwise I would have soldered the wires directly to the prototype board.

A Case

Initially, I had the idea of laser cutting a case for the switch, but I found some PCB standoffs, and it occurred to me that I had something that already had holes drilled in exactly the right location - another BlueBoard#01, so I used that. I think it looks fine.

The encoders, buttons, connectors and a couple of wires are on the top side of the board, while the rest of the components are on the bottom side, out of view. This is acceptably neat.

-

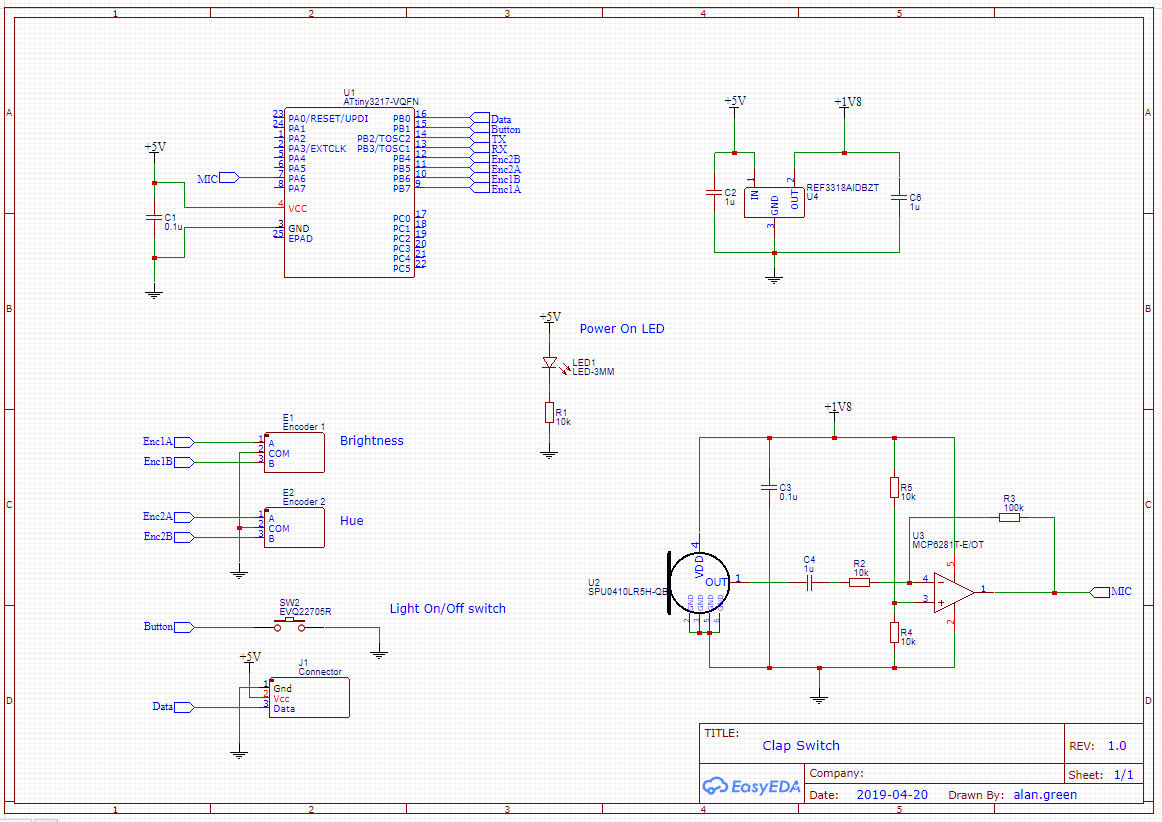

Schematic and Notes

05/21/2019 at 10:04 • 0 commentsHere is my schematic, captured in EasyEDA.

Notes

- Most of these components I chose simply because I had them. They're not necessarily the best for the job, but they're close enough.

- Microcontroller: I chose the ATTiny3217. It is over powered for this application, which is fine.

- Power on LED: I wanted a power indicator to help when I was troubleshooting.

- Microphone: I used the SPU0410LR5H. I'm familiar with it, and it Just Works.

- Op Amp: MCP6281 is a solid low-voltage raill-to-rail amp. It has a 5MHz Gain-Bandwidth Product, which is 500 times what it needs in this application. The trade off for this performance is that it consumes a whole half milliamp of quiescent current, but that is not a problem in this application since it is connected to mains power.

- 1.8 V supply. The WS2812s require a 5V data signal, which means it is convenient to run the microcontroller at 5V. However, the microphone is rated at a maximum of 3.6V. I would have powered it at 3.3V, but I happened to have a large number of Texas Instruments REF3318, and no 3v3 regulators. The REF3318 is a reference rather than a voltage regulator, but it is rated for 5mA output - plenty for the microphone and amplifier.

- Switch: A generic button I found in my cupboard. Ignore the model number in the schematic.

- Encoder: I used a couple of fairly standard rotary encoders that I found in my box. I don't have the exact part number, but they all work pretty much the same.

-

Second Ideas

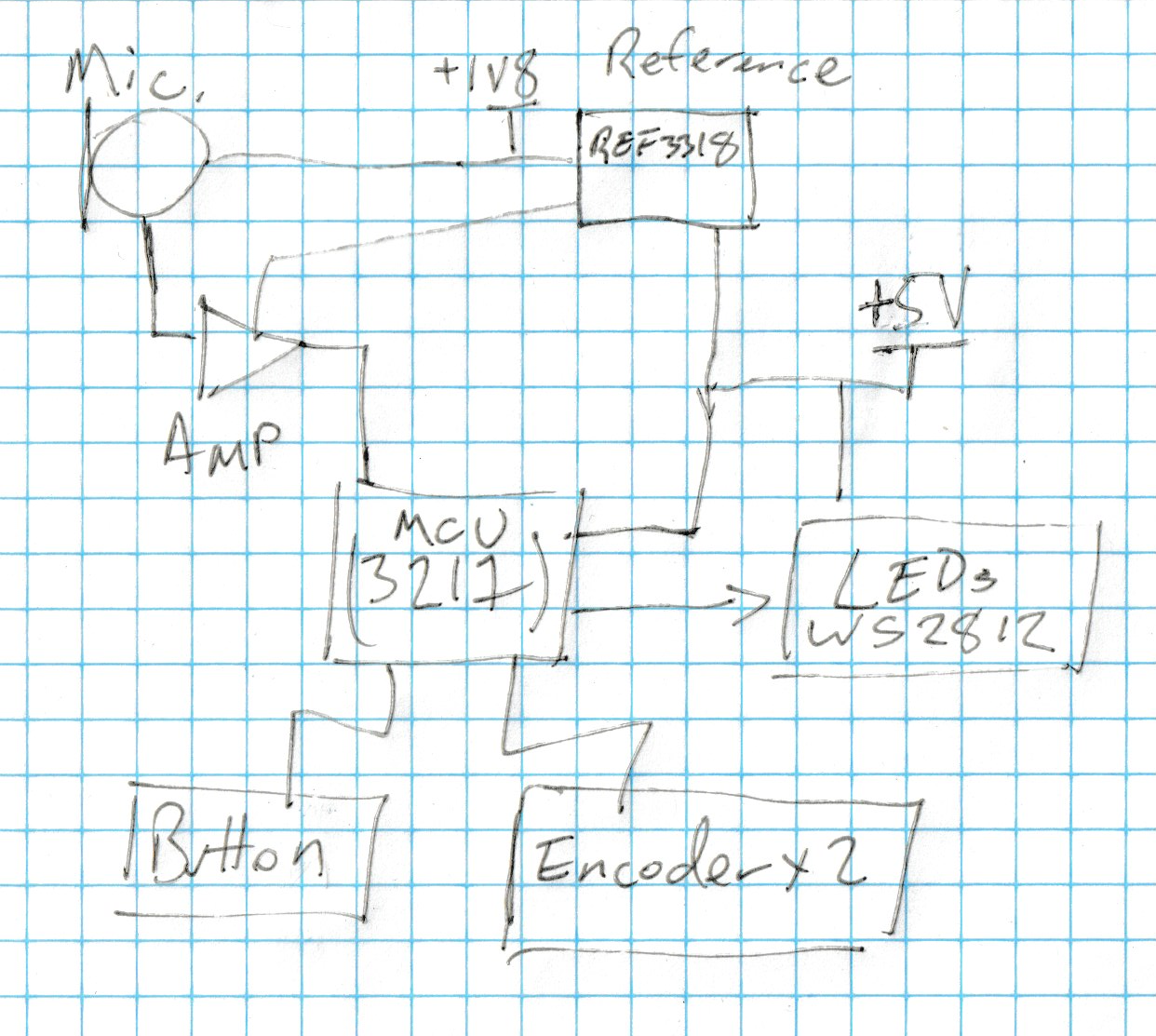

05/12/2019 at 20:28 • 0 commentsMy next plan was bit more involved:

![]()

Design Sketch As you can see, there are a few changes:

WS2812 LEDs from NifteeCircuits Light: The LED lamp and MOSFET are gone, replaced with an 8-element WS2812S stick from NifteeCircuits. It's definitely not a reading lamp, but it will make enough light to be useful.

USB-A to 5V Barrel Jack Power: I found a USB-A to barrel jack cable in my parts cabinet. I also had a compatible barrel jack too. I can't help but feel that this cable is a bad idea because it makes it tempting to plug arbitrary stuff in a a computer's USB port. However it avoids the need for a 7805 regulator, so I'm choosing to use it.

Old encoders and a button Input: It would also be nice to be able to turn the light on and off without clapping, so I added a button. Also, since we are now using fancy WS2812s, I thought it might be nice to be able to dim the lights and control their color, so I added a couple of rotary encoders.

-

How Bad Can an Old LED Lamp Be?

05/12/2019 at 02:06 • 0 commentsMy first ideas were great, but didn't work in practice.

This was the lamp. It has a 240V to 12V transformer, a clamp, a goose neck

![This was the lamp This was the lamp]()

An LED lamp, unplugged I say "this was the lamp" because this lamp went down the garbage chute to be with its friends, the other pieces of garbage.

20V from a 12V supply

The first issue was with the power supply. It was rated at 12V, but I measured 20-and-a-bit volts with the lamp off. This was discouraging because the DMN2004 MOSFET I was planning to use to switch the lamp on and off is rated for a maximum of 20V.

500mA lamp consumes 40mA

The next problem was that the lamp was only consuming 40mA. 12V * 40mA = 600mW, which is far below its rating of 6W. I suppose this is the reason that it was such a terrible reading lamp. This was the final straw.

I wasn't happy working with something so broken, so it went down the garbage chute and I made a new plan.

On Reflection

As I'm writing this up, I can see that perhaps the lamp was fine, but only the power supply was broken. I regret not being more patient. On the other hand, I did like my new design (see next post) and it's not like these things are expensive.

-

First Ideas

05/11/2019 at 23:02 • 0 commentsI wanted a clap switch to make my life easier. My bedroom light switch is at the doorway, but bedlamp switch is at the bed. A clap switch saves me from choosing between fumbling for the bedlamp switch after turning off the room lights, or having to walk to the bed and turn on the lamp before going back to the door to turn off the room lights.

An inspiration here was DIYODE magazine's Three Stage Clap Switch project. I built that project on a breadboard, using a BoldPort Cuttle instead of an Arduino. It worked mostly OK. However, I had bigger plans.

First Plan

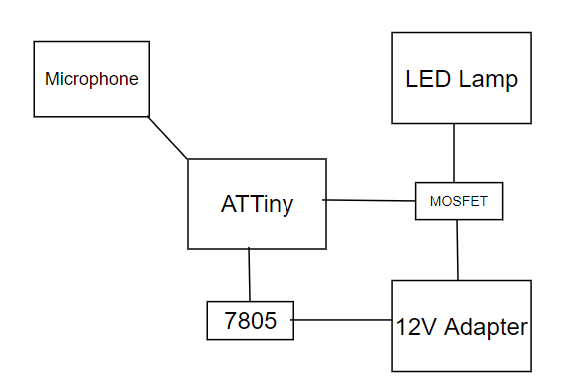

My first plan was pretty simple: take my existing bedlamp, use its power supply to power an ATTiny microcontroller. When the ATTiny detected a clap, it would switch a MOSFET to turn the lamp on and off.

![]()

I was keen to use parts I had in my cupboard, without buying more. I tend to buy components in fives or tens, and this has led to me having, well, a cupboard full. This leads to choices such as:

- ATTiny3217: way overpowered for this project, but I have plenty

- 7805 because I have a tube full.

- Knowles SPU0410LR5H-QB-7 MEMS microphone, because, again, I have many spare.

I also wanted to use my new prototyping board, BlueBoard#01. By no coincidence at all, I have a microcontroller and microphone that fit it perfectly.

Happy Clap Switch

Clap-clap, light goes on. Clap-clap, light goes off. This makes me happy.

Alan Green

Alan Green