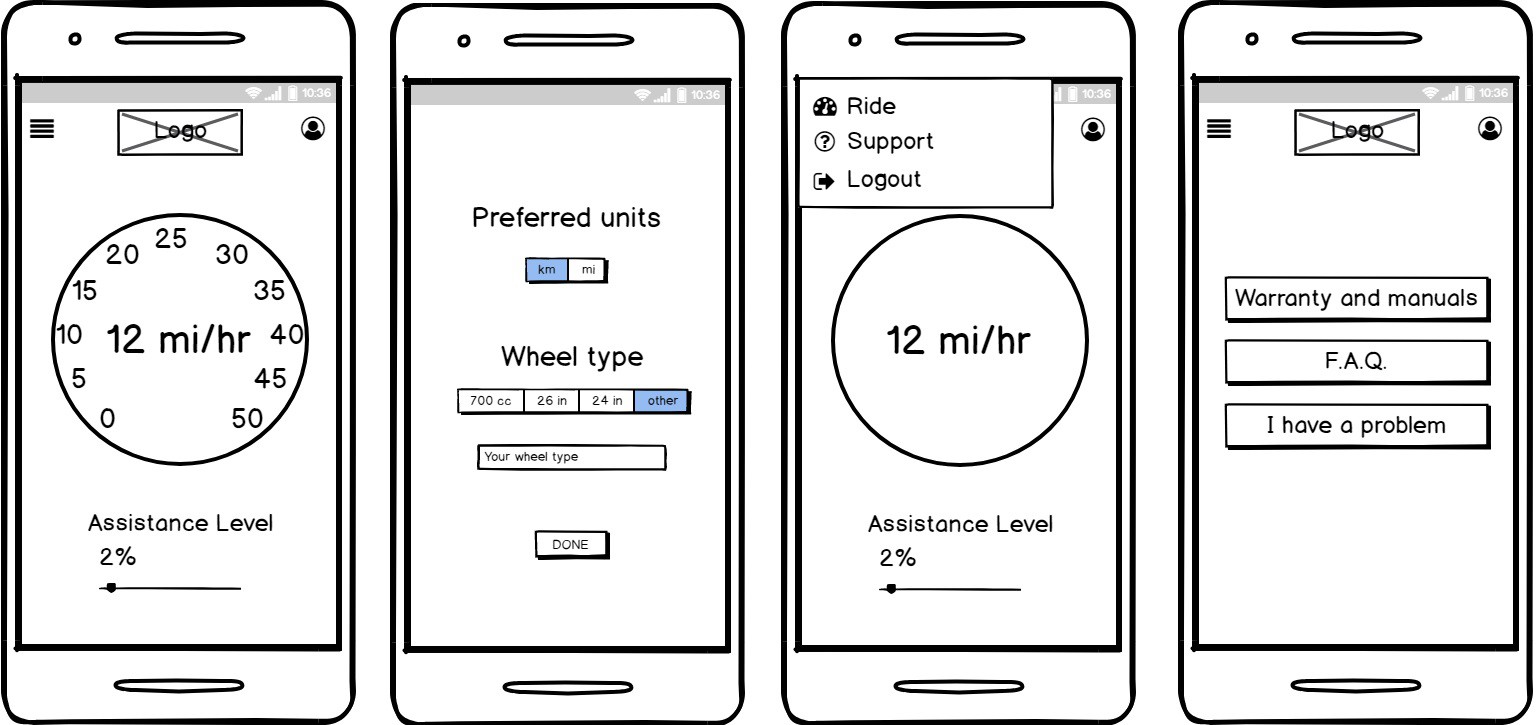

BikeOn is a device that converts any bicycle to electric and back in seconds. No tools or skills required. Just attach the device to the wheel of your bicycle and it becomes an electric assist.

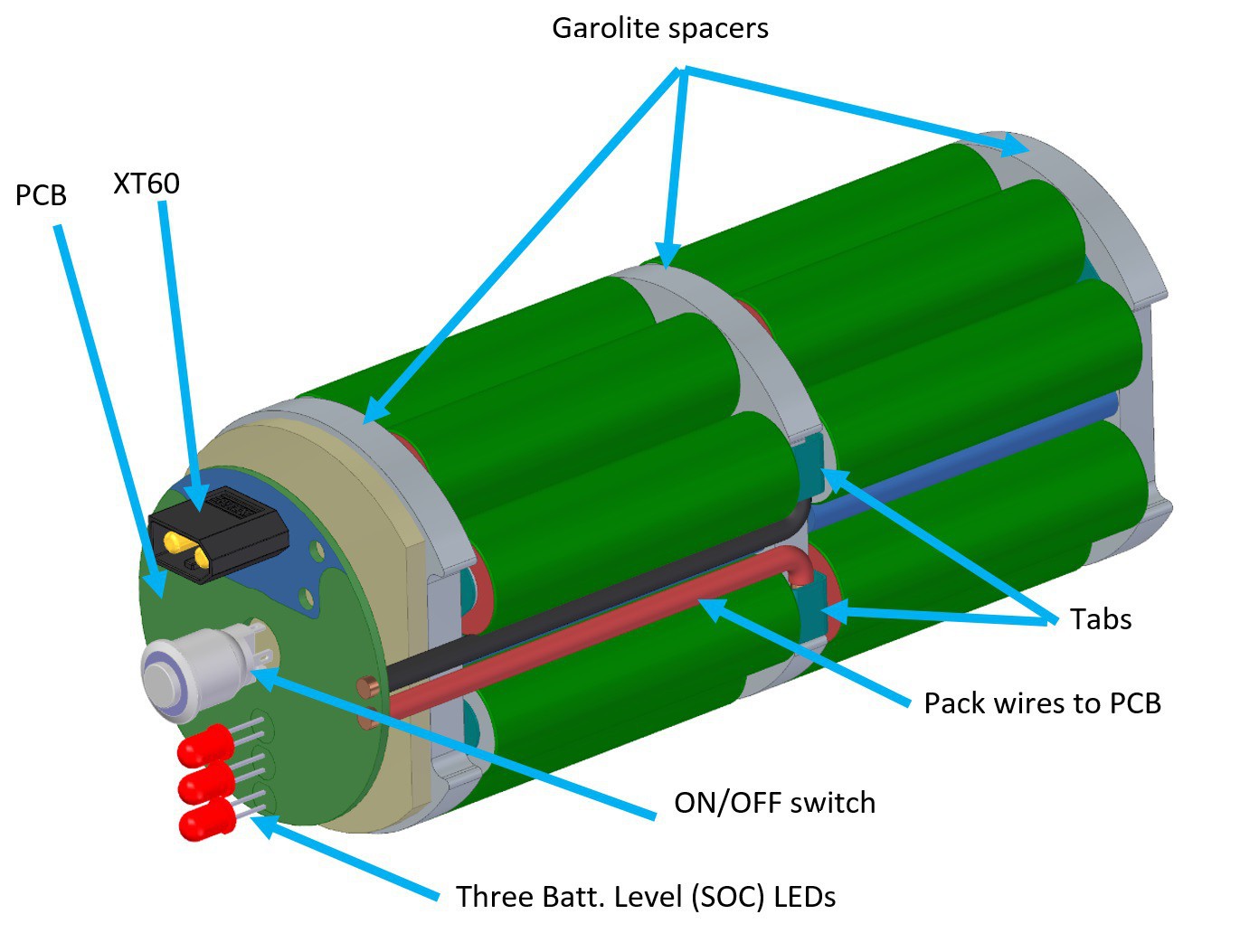

Creating a product that is useful, practical, aesthetically pleasing and stylish was very challenging. It had to be practical in several areas which included:

Aesthetically pleasing and stylish products are often a key to successful brands (along with other aspects, such as usefulness and practicality, for instance). In our view that is especially important for digitally native vertical brand, which we are building.

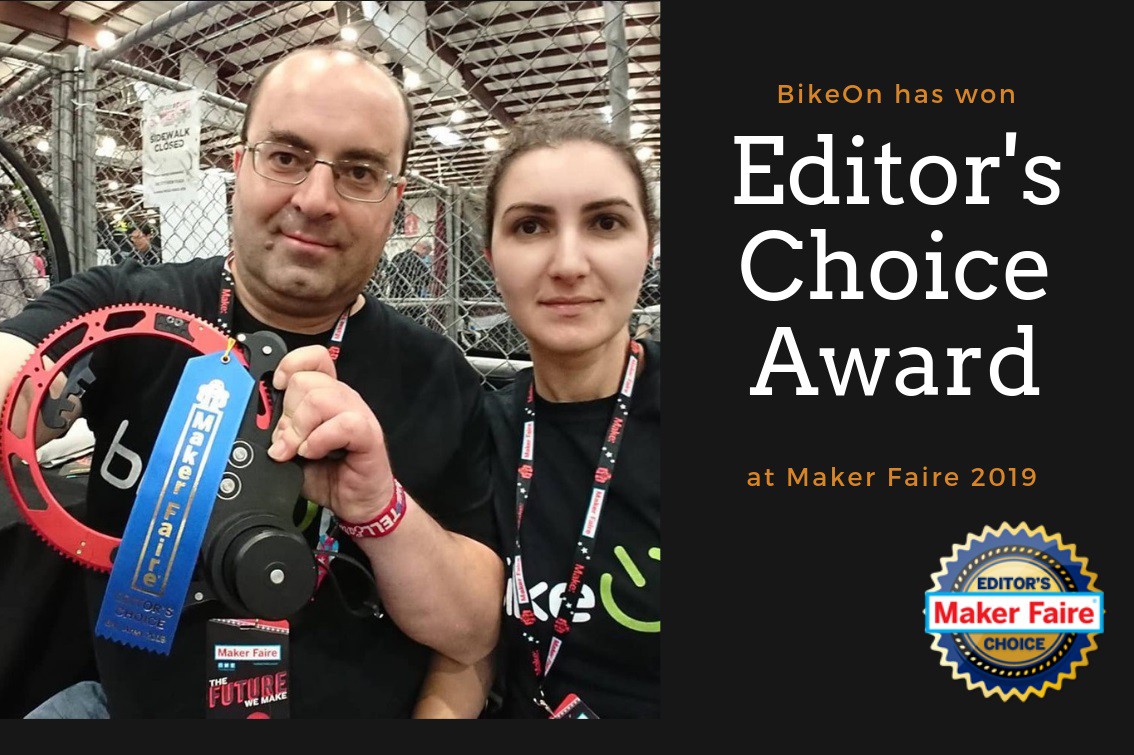

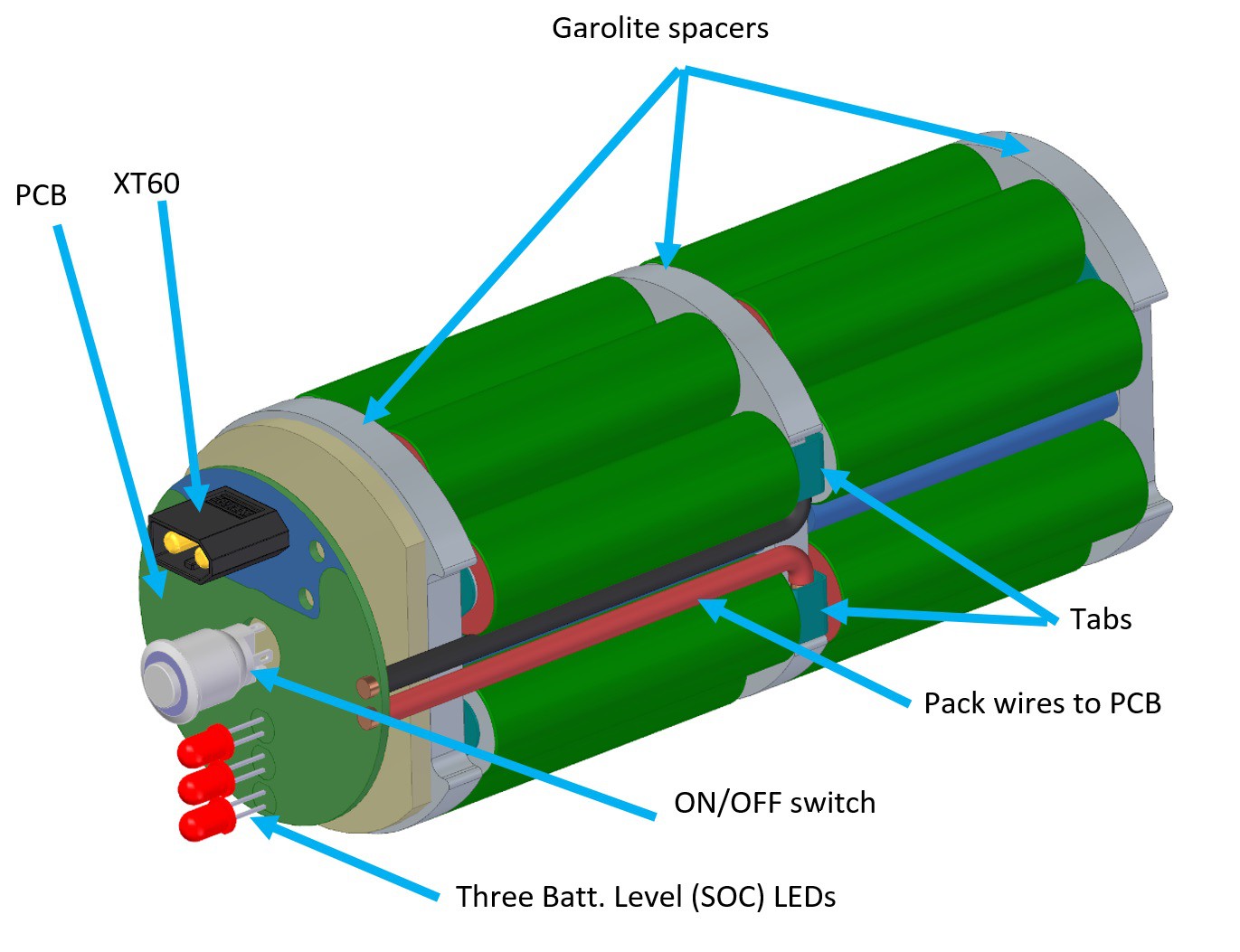

BikeOn is the only device on the market that combines ease of installation and removal (in seconds, with no tools), compact size, and low weight (below 2.5 lbs). Our algorithms ensure the smoothness and ease of ride. Because it powers up the rear wheel, it also provides very natural feel and handling of the bicycle.

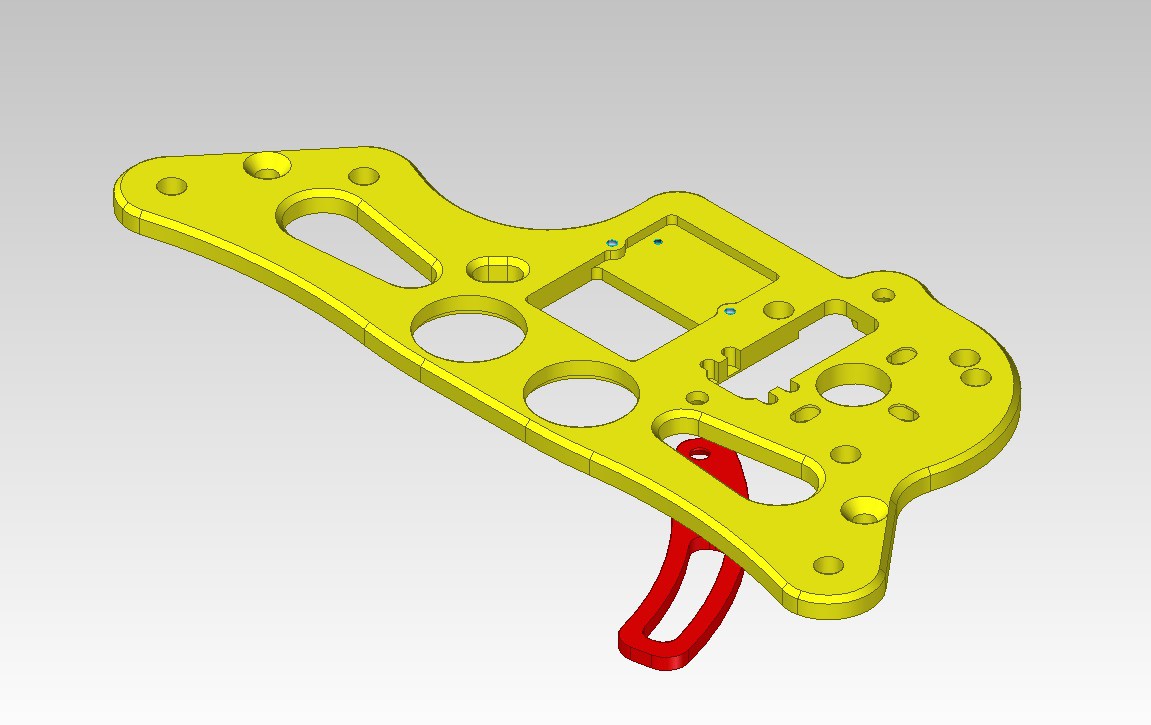

One of the challenges on the technical side was to find a concept and a form factor that would physically fit most of the bicycles. Bicycles of different brands and builds (and even different production year) have very little in common. Frames, wheels, wheel lacings, cranksets and all other bicycle components vary greatly in size and often shapes. There are some common dimensions agreed upon by manufacturers, but not many. We have managed to find a way to bypass most of the constraints yet keeping the design within desired specs and parameters

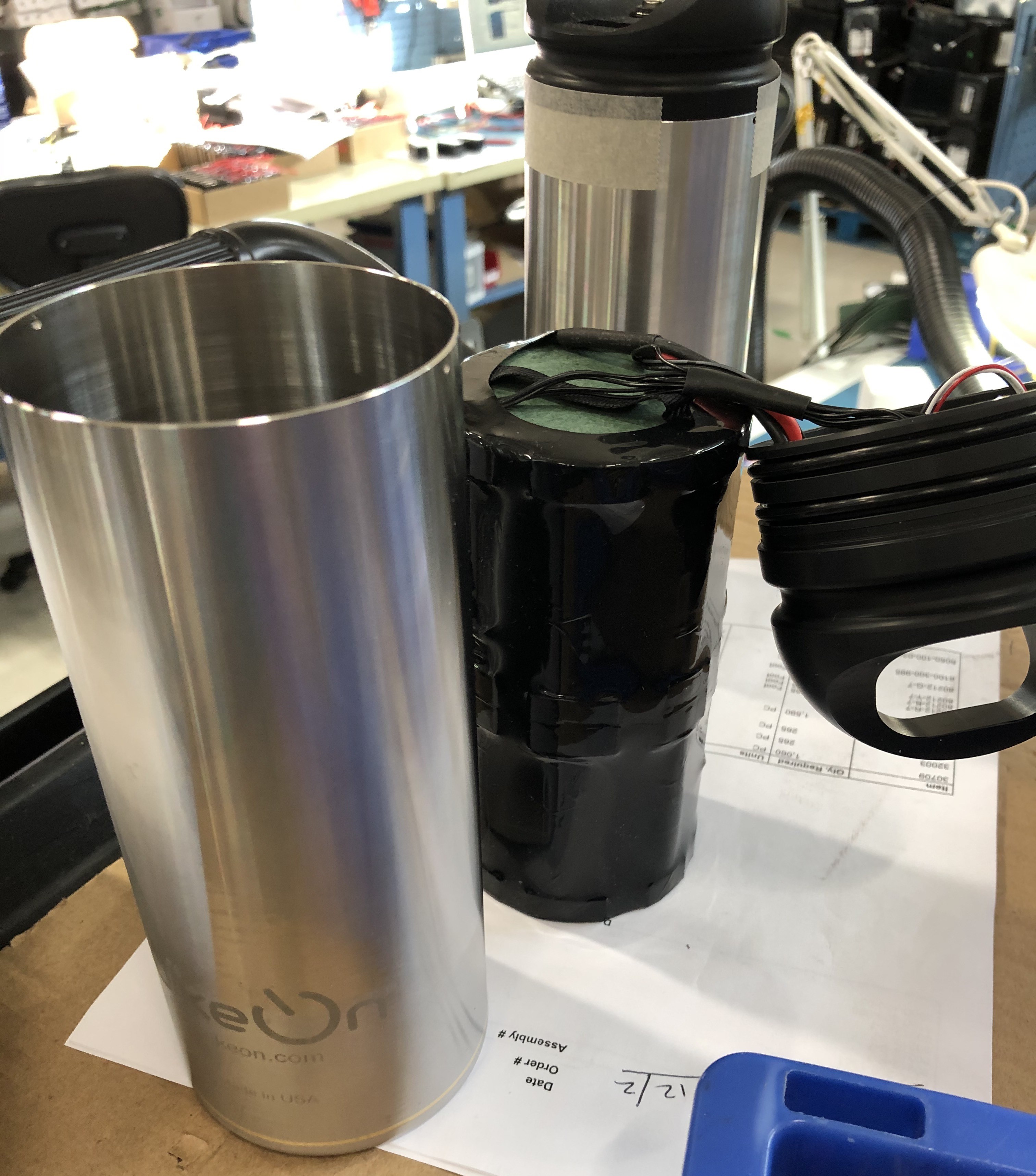

We have been developing BikeOn for over 5 years. In the course of the development, we have made over 70 different prototypes. Each of them led to a different set of decisions and changes. We have tried to compress that 5+ year process in this submission and highlight the most significant choices and decisions we have made. Those decisions can be partially seen in our logs and project details section (see Design portion below)

BikeOn is set to solve two major issues:

When we first started working on BikeOn, there were 5 things we would not compromise on:

- easily attachable and removable, with no tools and skills;

- universal (works on most bicycles);

- nice looking;

- lightweight;

- reasonable cost for the end user.

It was pretty ambitious, no wonder it took us more than 5 years of research and development :)

First, we started developing our own electric motor concept, because at the time, we...

Read more » Shushanik Khachaturian

Shushanik Khachaturian

Hello. I like your project a lot a lot!

What is noise level of a working device? Some electric bicycles buzz like a bee herd, I wonder how it is with your motor/device.

When a new batch will become available for purchase?