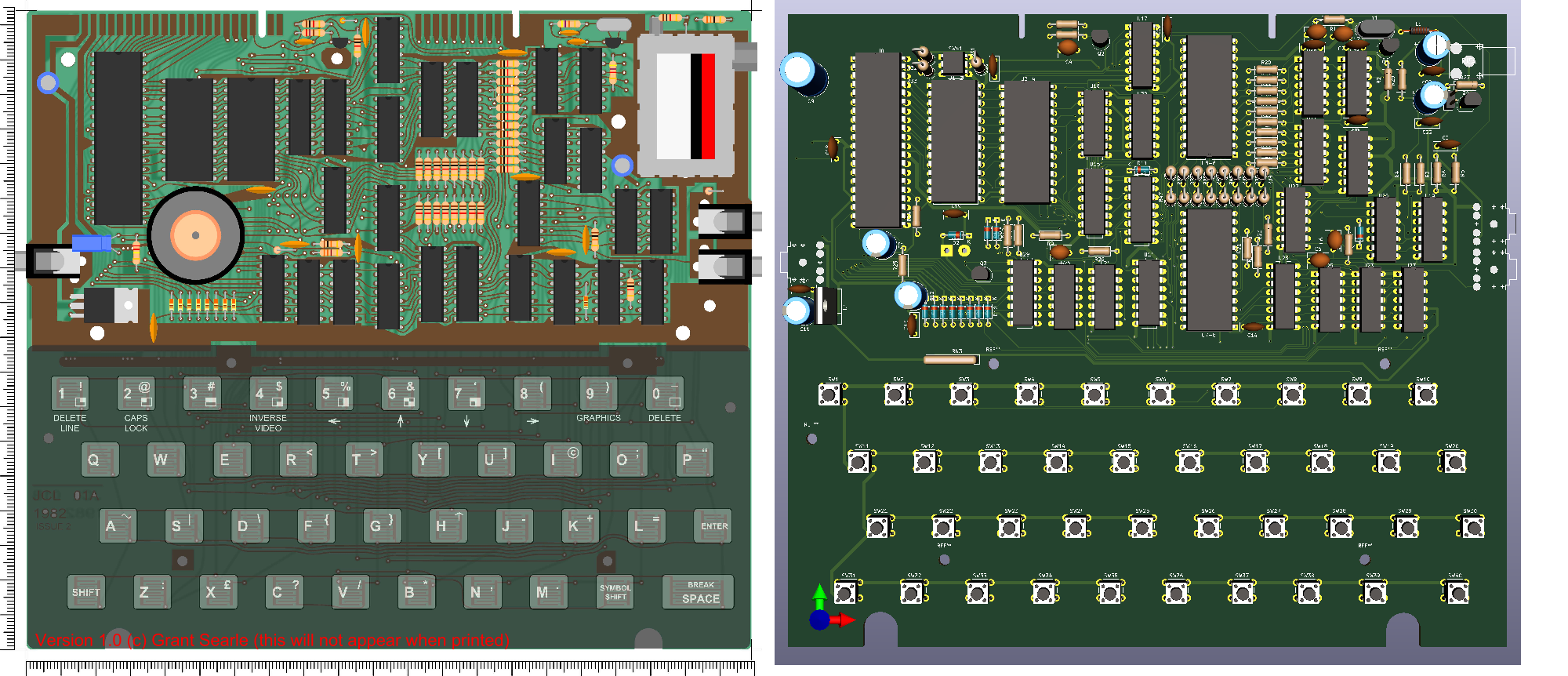

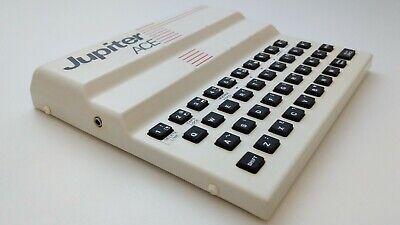

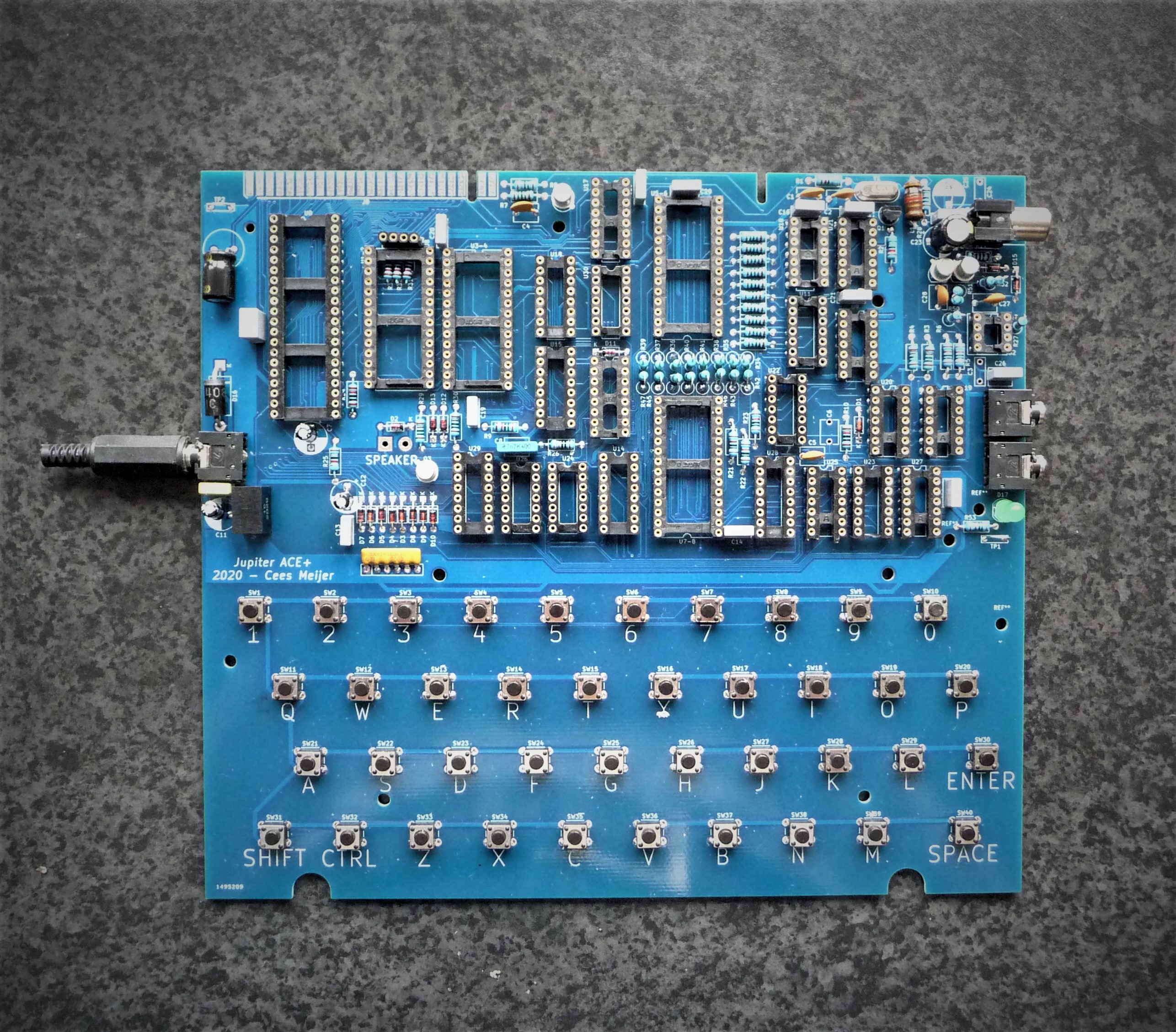

Building a replica of the Jupiter ACE has been done before, and the super accurate replication of the PCB by Grant Searle is probably the best example. The schematics were redrawn later by Bodo Wenzel in ORCAD, and a modified version was made by Isidro Nuñez Blanco De Arenas. Both builds were done 2003-2006 ( which shows if you look at the design of their websites), and things have changed a bit since then. PCB manufacturing is much cheaper now, and it's also easier to create custom plastic parts. Because what's lacking in all these rebuilds is the actual housing, which to me is a huge part of the charm of this machine. And using a 3D printer it cannot be too hard to replicate this.

Actually, since I started creating this, some others have popped up (or I just did not find them at the time). There used to be a kit sold from Bulgaria by 'oricfan' but that one is hard to find these days. The most recent 'ACE' compatible kit is called the 'Minstrel 4th' by Tynemouth Software. Which is probably good, but (as mentioned on the site) is just a board, and will not fit the original Jupiter ACE housing.

There is the Jupiter-II, a beautiful version consisting of two separate PCBs. Which (as far as I can see) was created somewhere 2019-2020.

And of course I recently discovered that people on the Jupiter ACE section of the K? Forum have created an almost identical board, in about the same time-span (2019/2020). They chose to use Cherry keys for the keyboard, which definitely will be a huge improvement in usability, but does not really add to the authentic look and feel.

Update 2024:

Scott Baker made a really nice video on building the unit:

He actually explains the whole thing better than me, and is worth watching if you run into problems with the video or character generator.

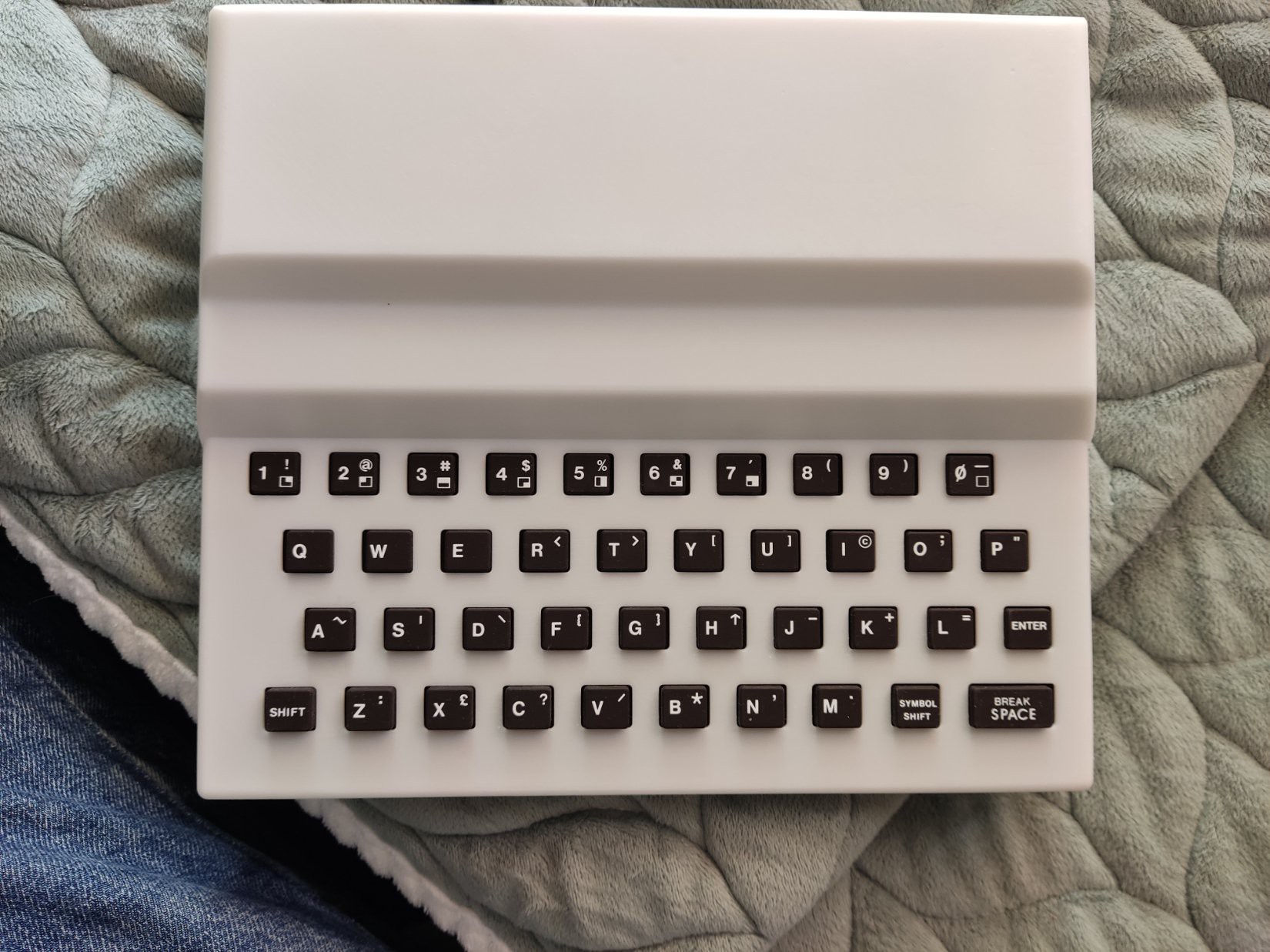

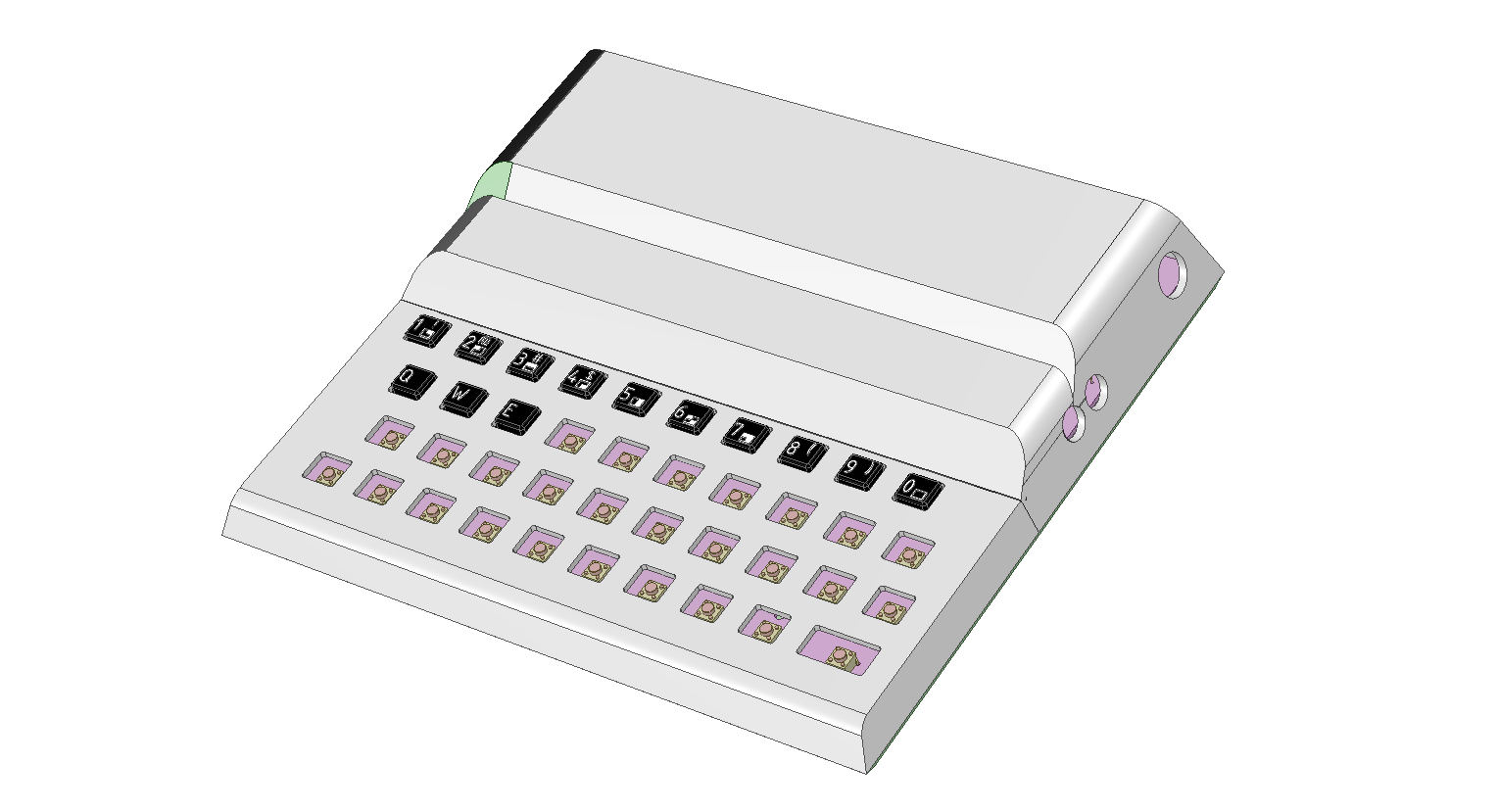

The Housing

To my surprise there were also no 3D models available , apart from the 'mini Jupiter ACE', which obviously is too inaccurate to use as a basis for a real housing.

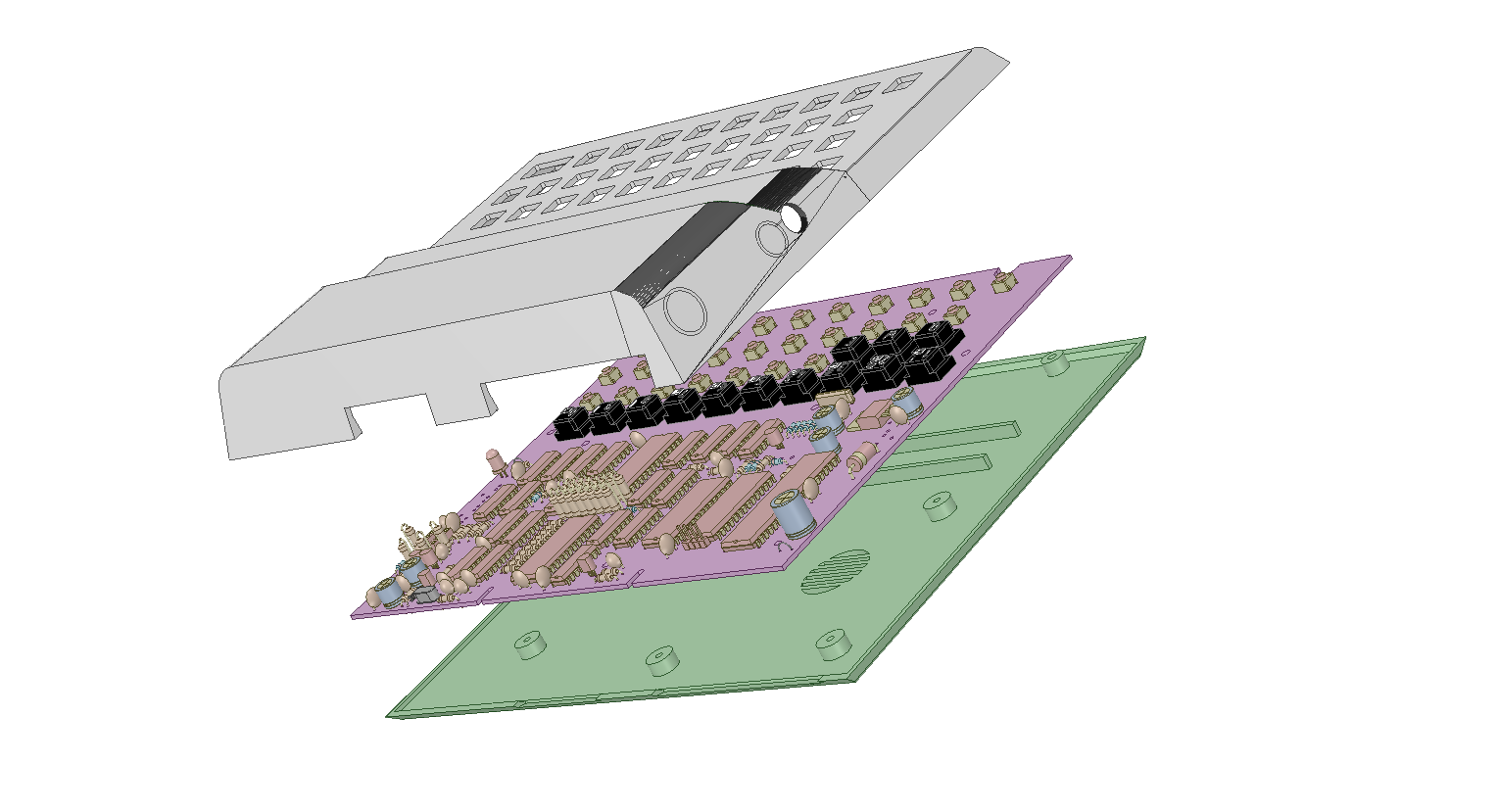

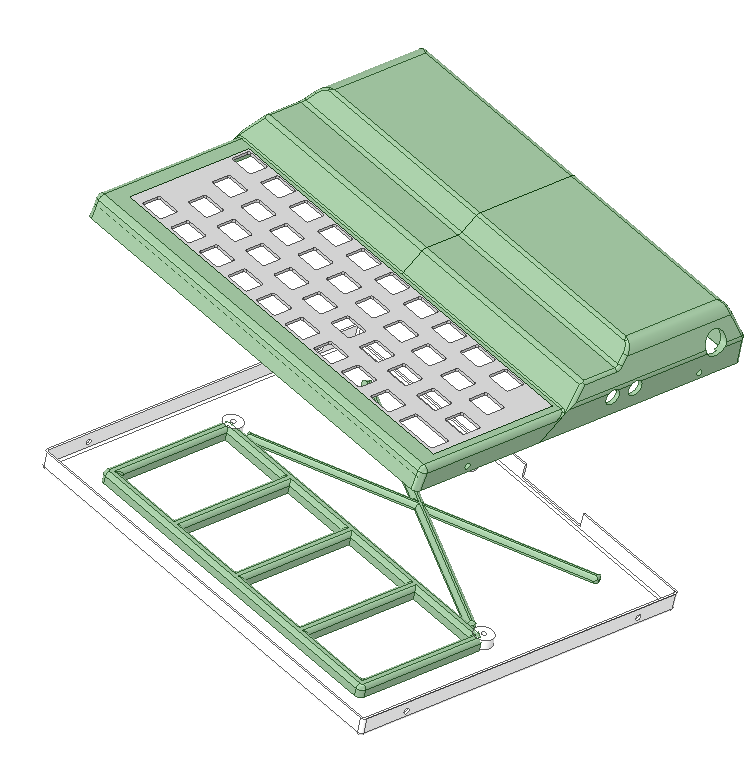

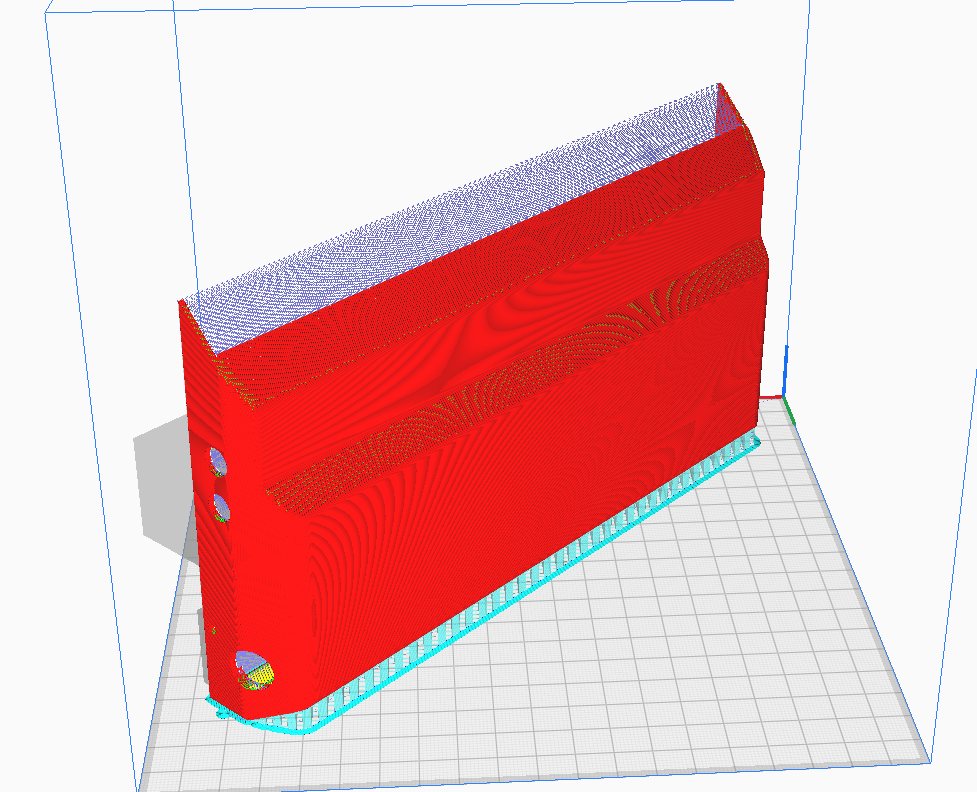

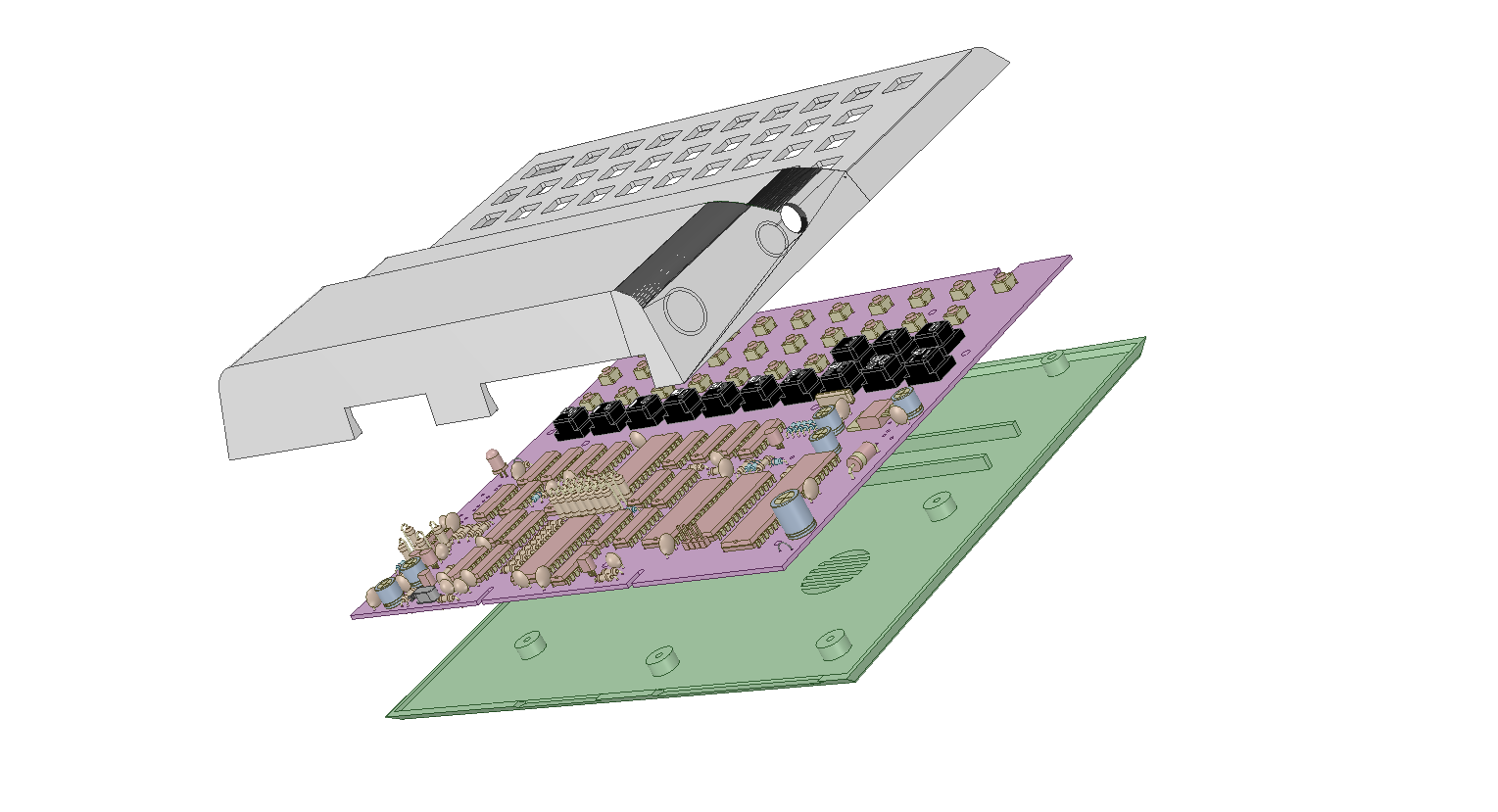

So I started out to do this myself, using my favorite 3D modelling software: 'DesignSpark Mechanical' (DSM). I used Grant's PCB layout, made it into a .png image and imported that into

DSM. Since the drawing includes millimeter marks on the edge it was easy to scale it to exactly 100%.

The final design is now available on PrusaPrinters:

https://www.prusaprinters.org/prints/62264-jupiter-ace-replica

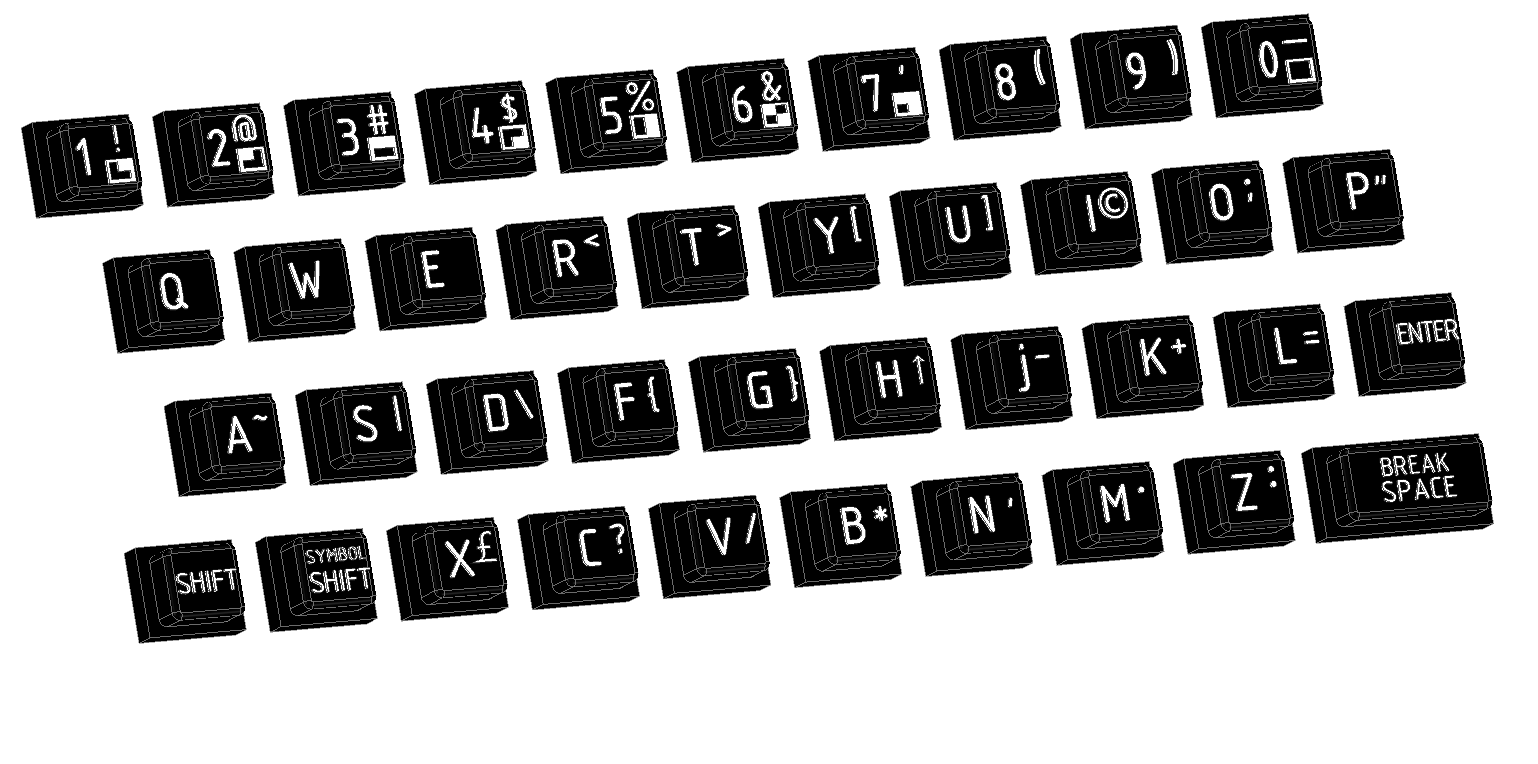

The Keys

That's a hard one. Getting a custom made rubber key-mat is beyond my financial capacity so that's not an option. I'll try to make them using my 3D printer. The main problem here is to get the text on the keys. I considered printing this on adhesive film and just stick it on top of the key. Then I thought I could also print the keys in white, with the text sticking out. Then if I spray painted them black and sand the top it would reveal the text again.

Which worked fine. Except for the smaller fonts like on the Enter and Shift keys. So for the final design I also created an alternative set with larger font, and the Enter and Shift keys as symbols.

Again, all design files for both keys sets available here, or on PrusaPrinters.

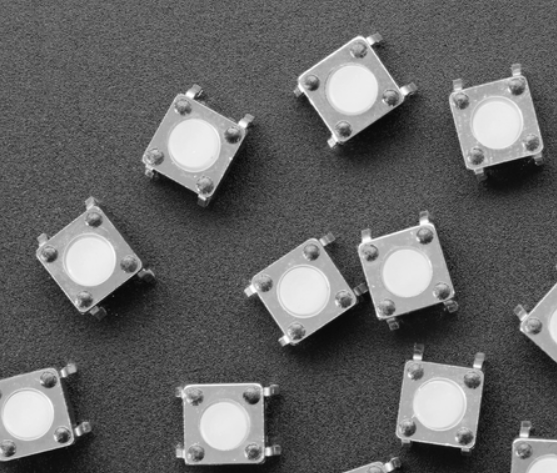

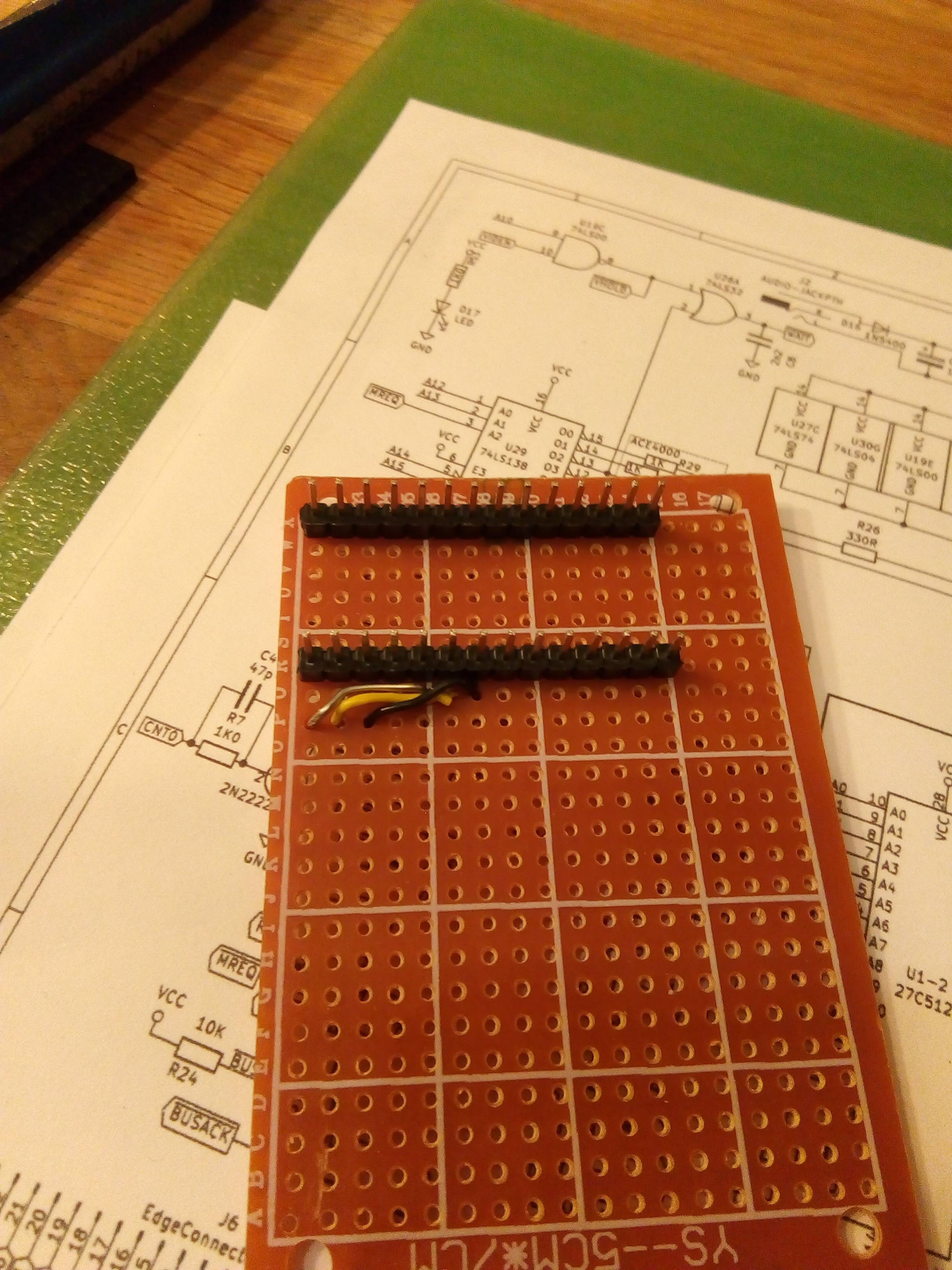

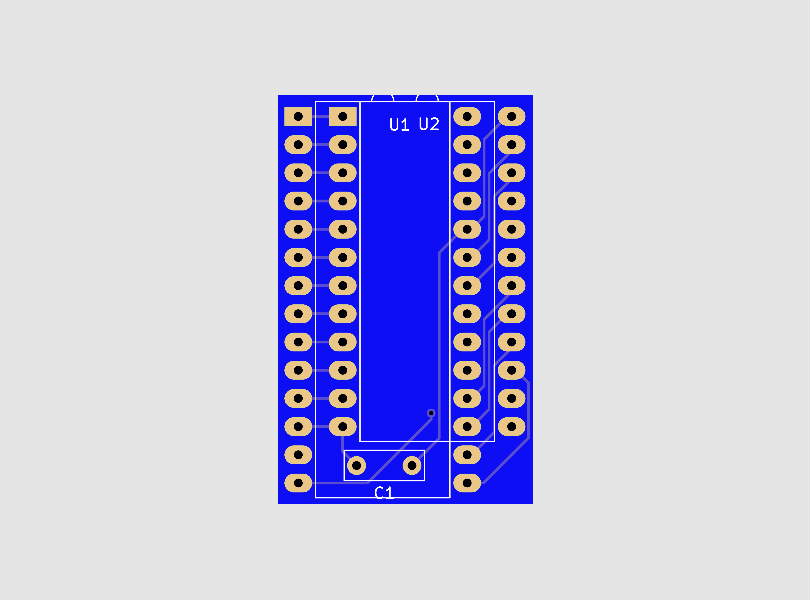

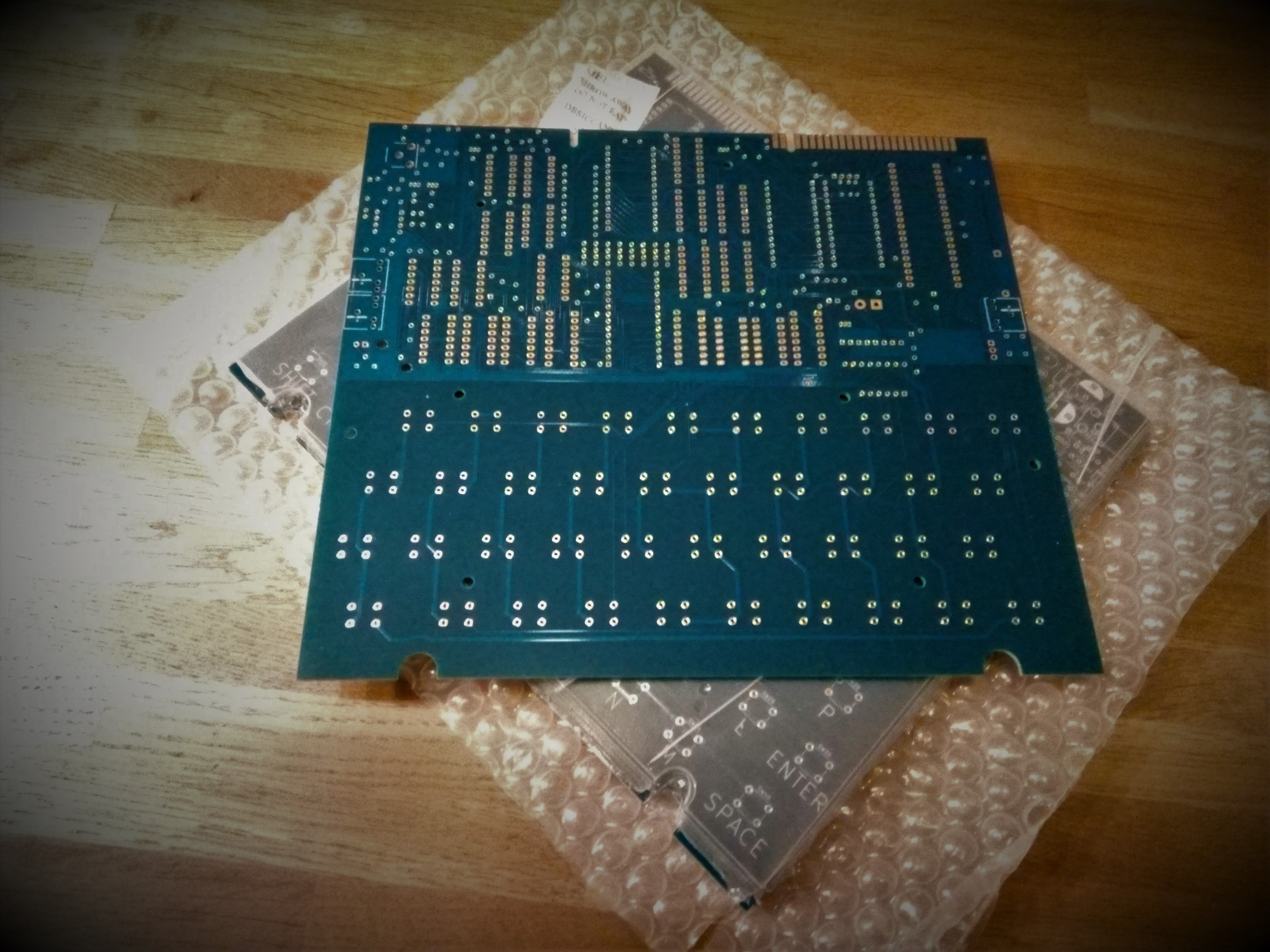

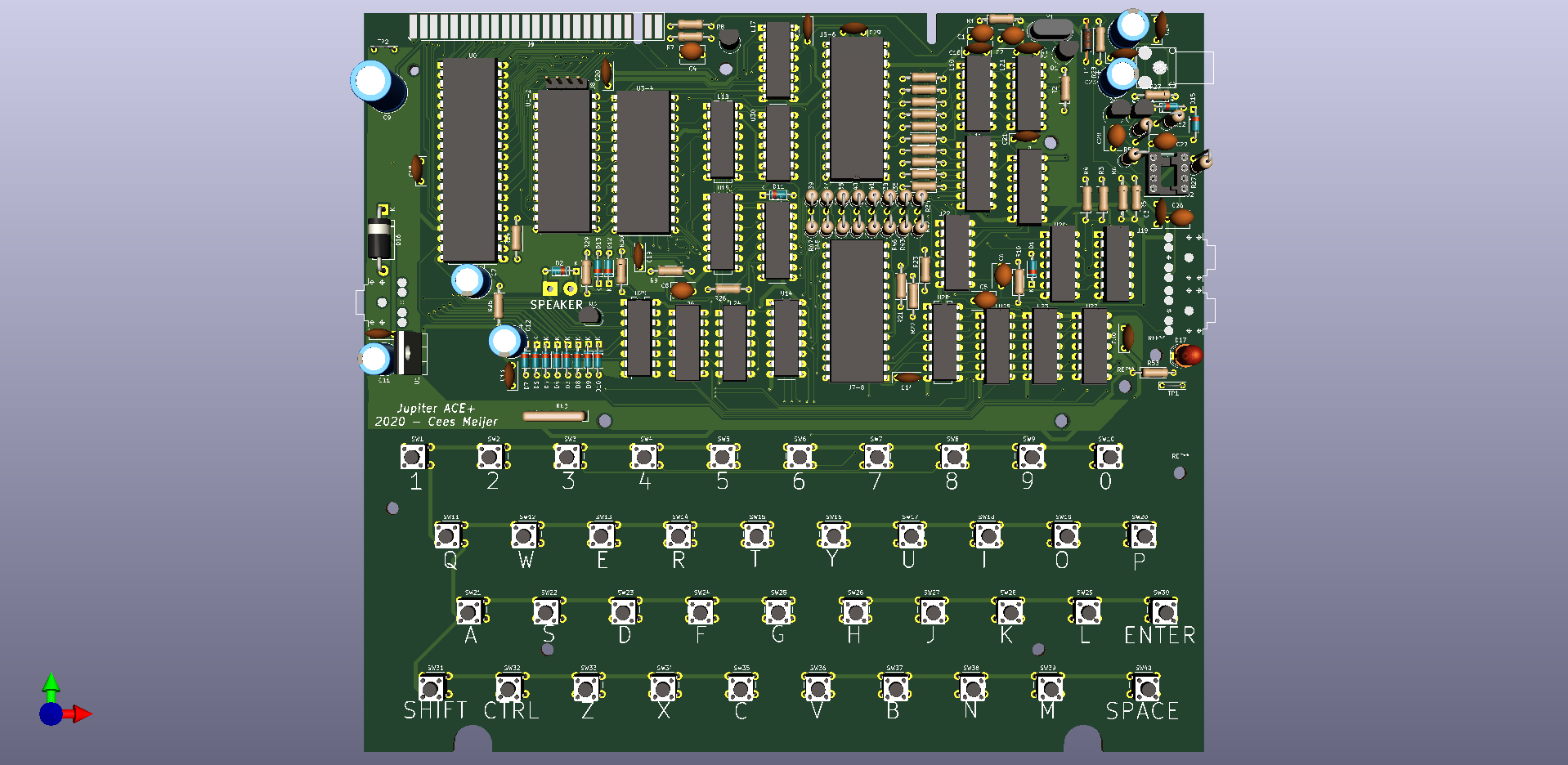

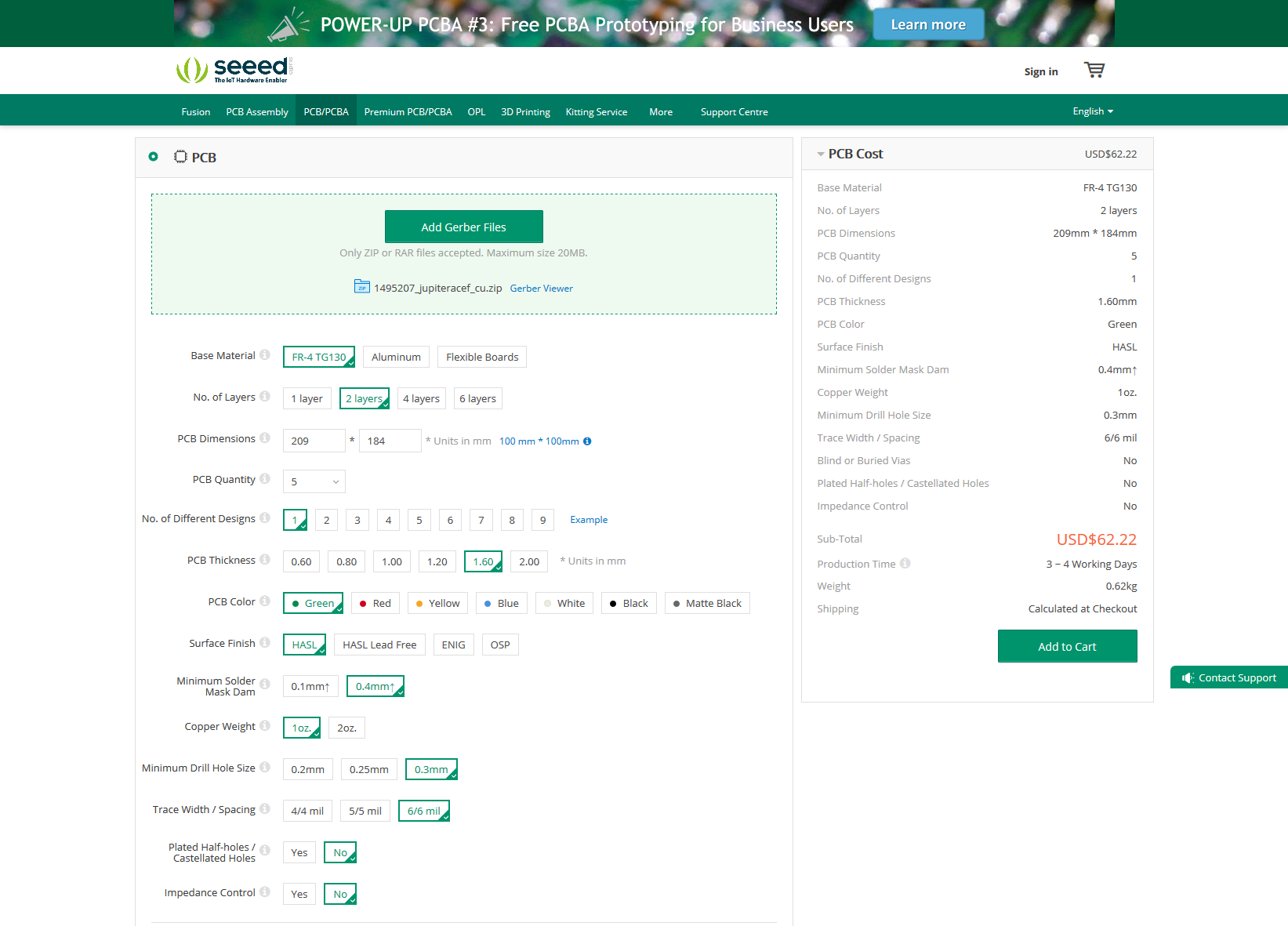

The PCB

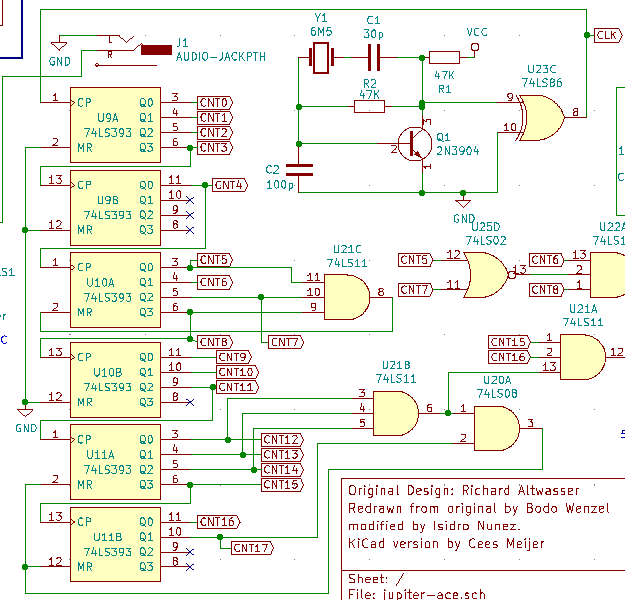

Though it's possible to create the exact PCB replica using Grant Searle's PCB foils, that is not what I wanted. I did want to make some minor changes on the EPROM and RAM connections, and use standard mini switches for the keyboard. Also if the PCBs have to be made by a cheap Chinese shop, it's essential to have Gerber files. So, all in all a good incentive to replicate the schematics again, but now in KiCad. For years KiCad has been a bit troublesome to use, but over the last few years it has improved significantly and is now a serious EDA package. It's free, open source and multi-platform so it is becoming the de-facto standard for all open-source hardware projects.

Cees Meijer

Cees Meijer

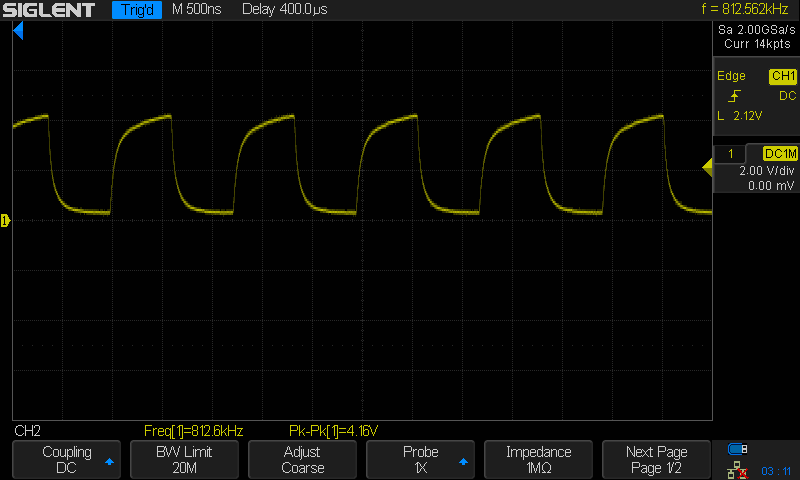

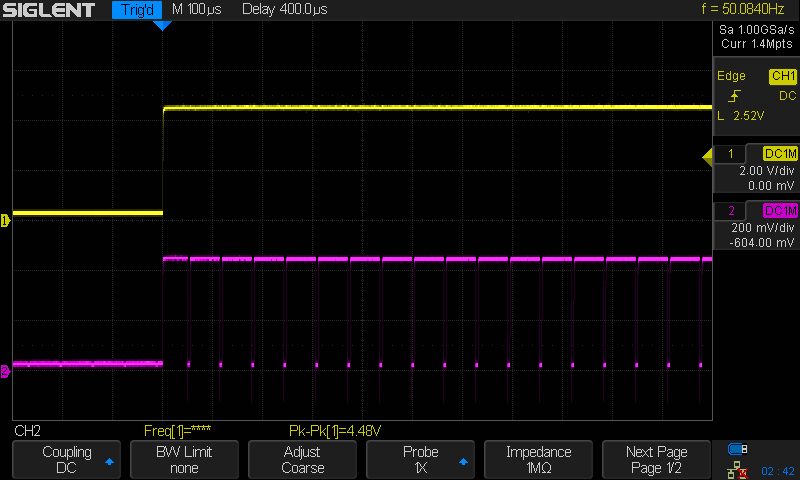

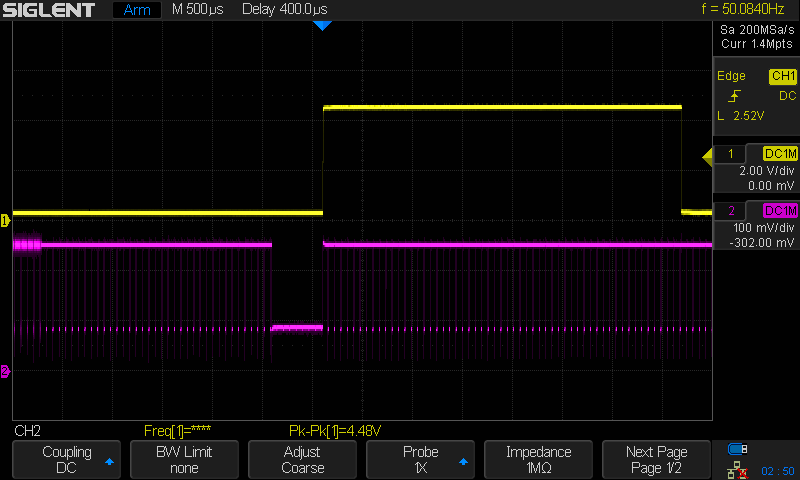

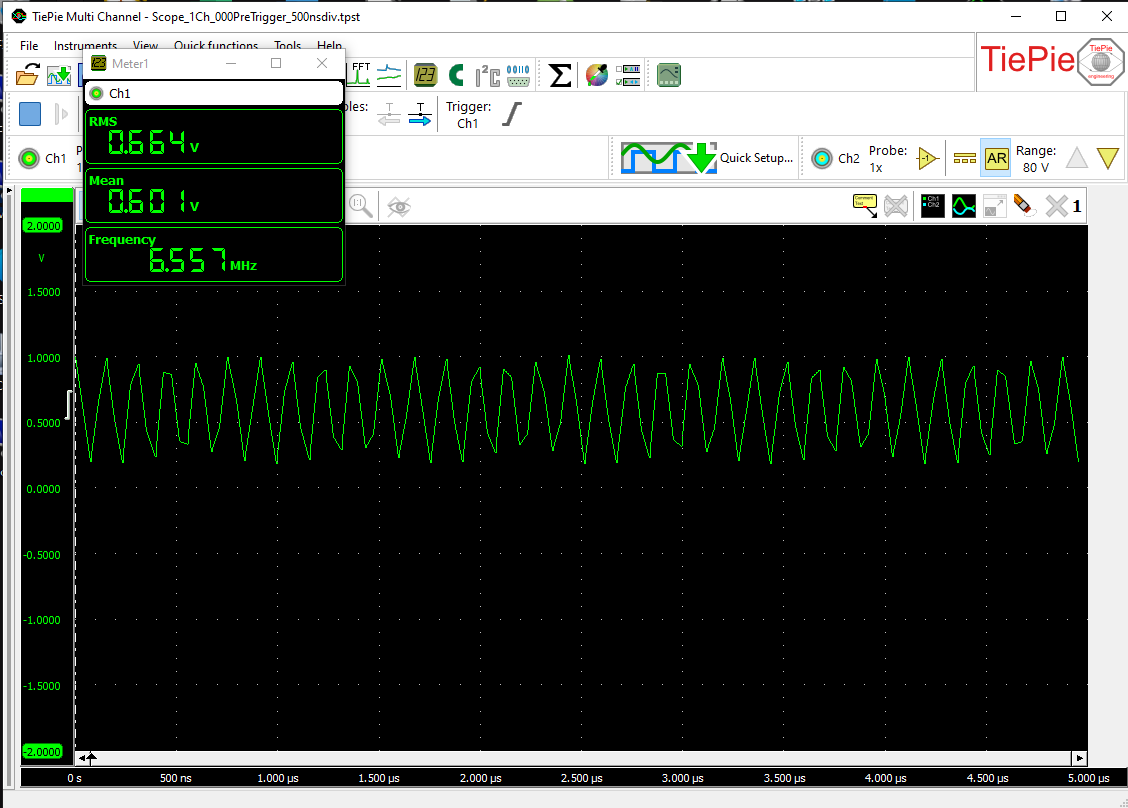

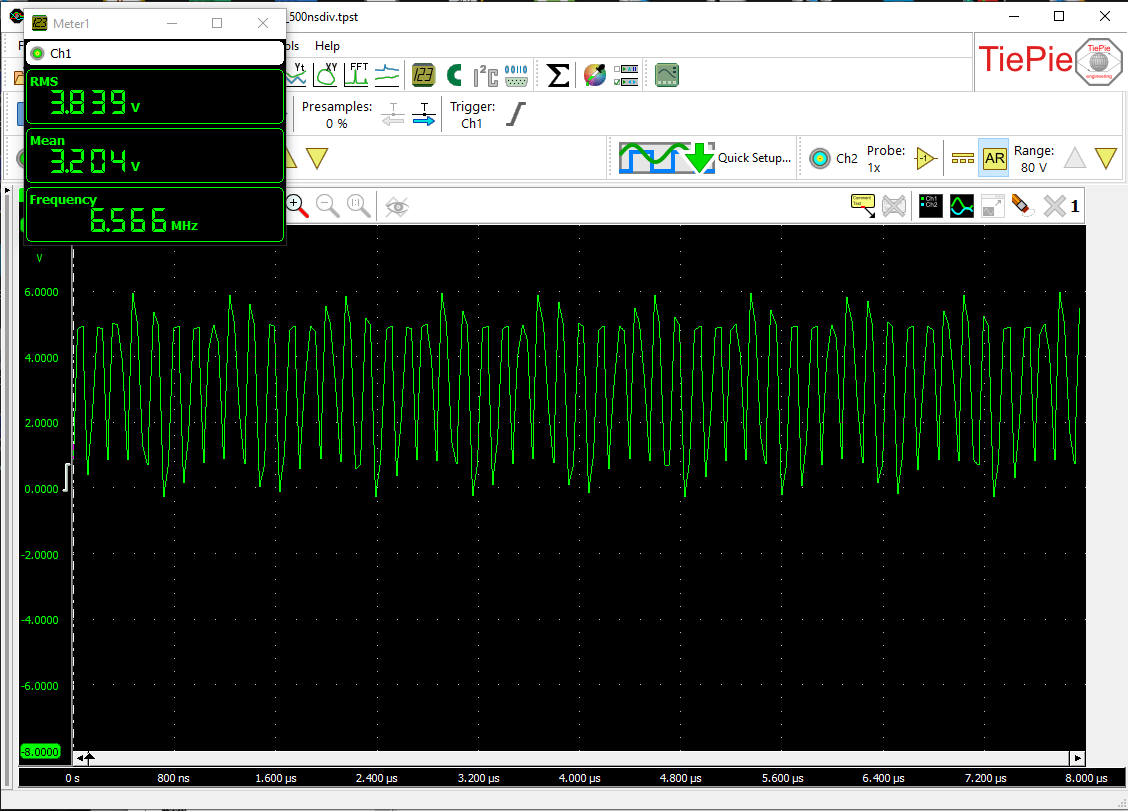

Oscillator output:

Oscillator output:

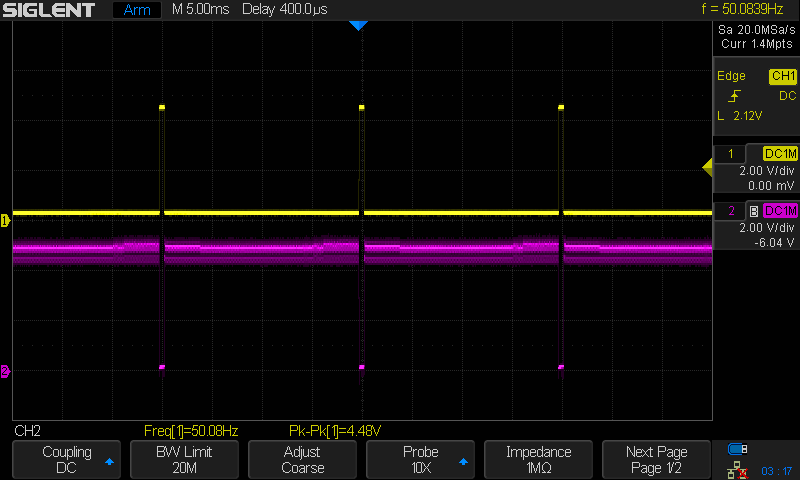

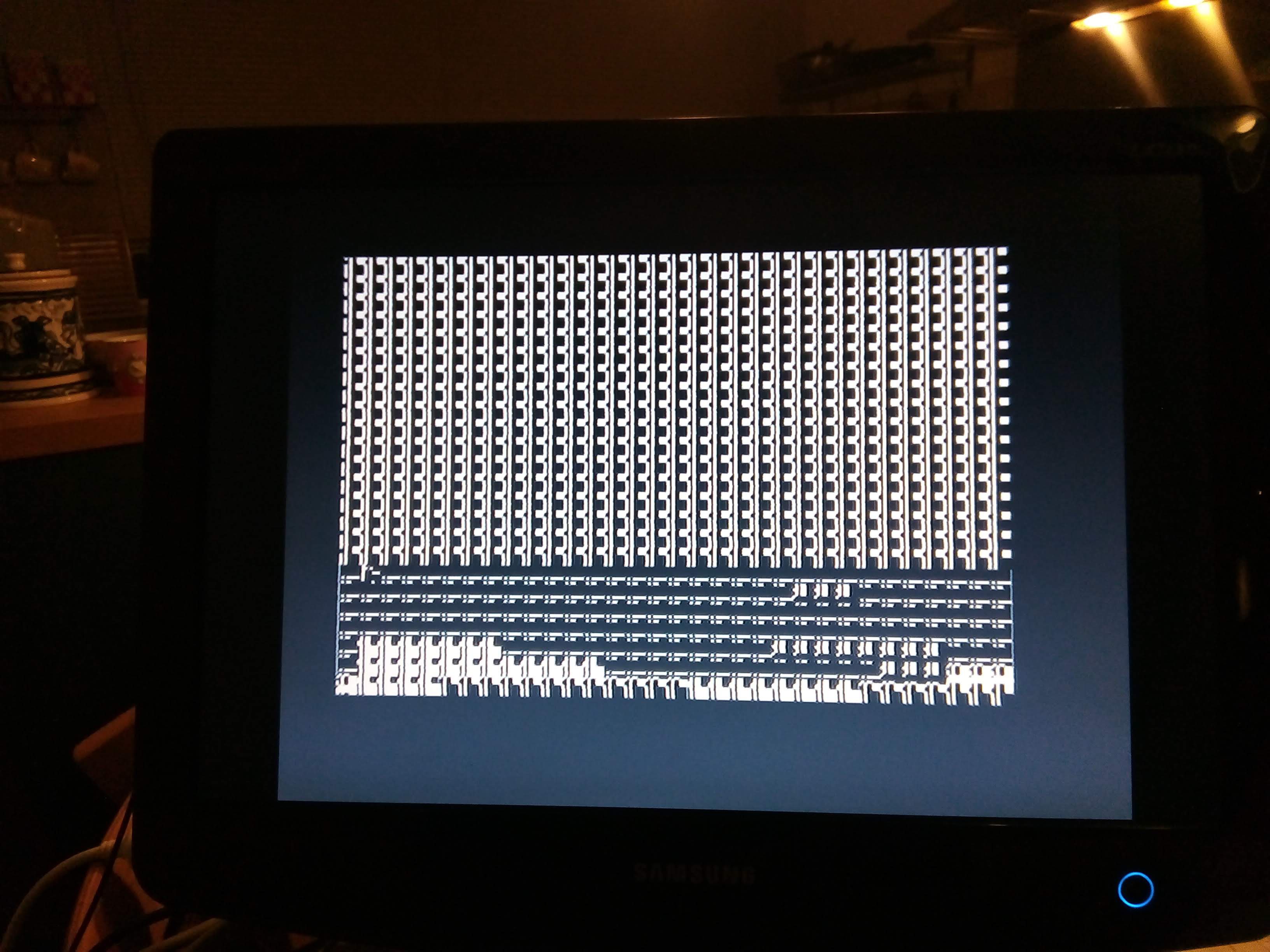

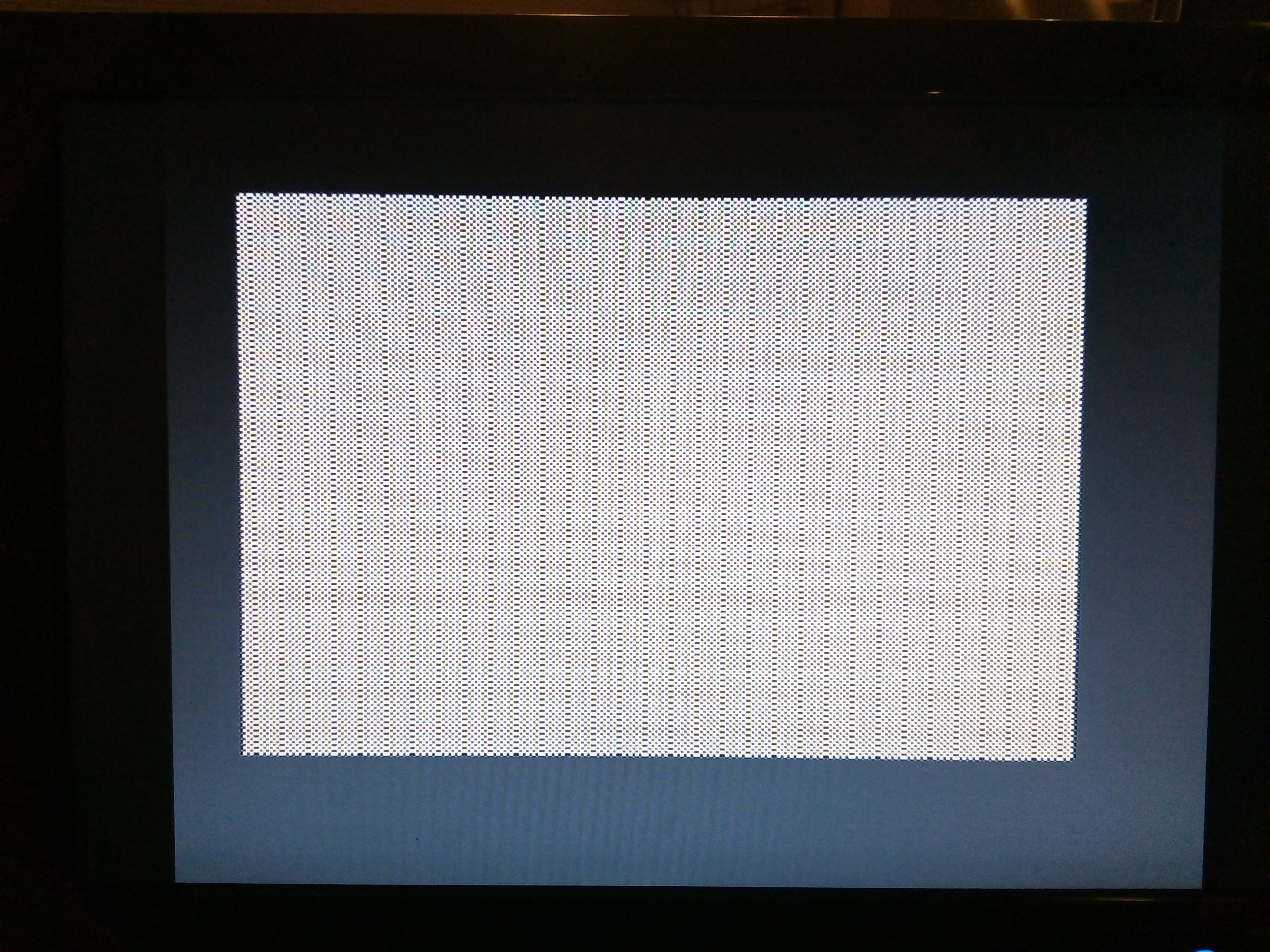

Again: it does react to the keys, so everything seems to be functional, and this confirms my earlier suspicion that the fault must be in the writing or reading of the video memory. Which it was. Another check of the schematics showed that I tied the /CS signals of both video RAM chips together. Obviously not correct. And after fixing this by disconnecting the CS pin on one RAM chip and wiring it to the correct port, the computer showed me this:

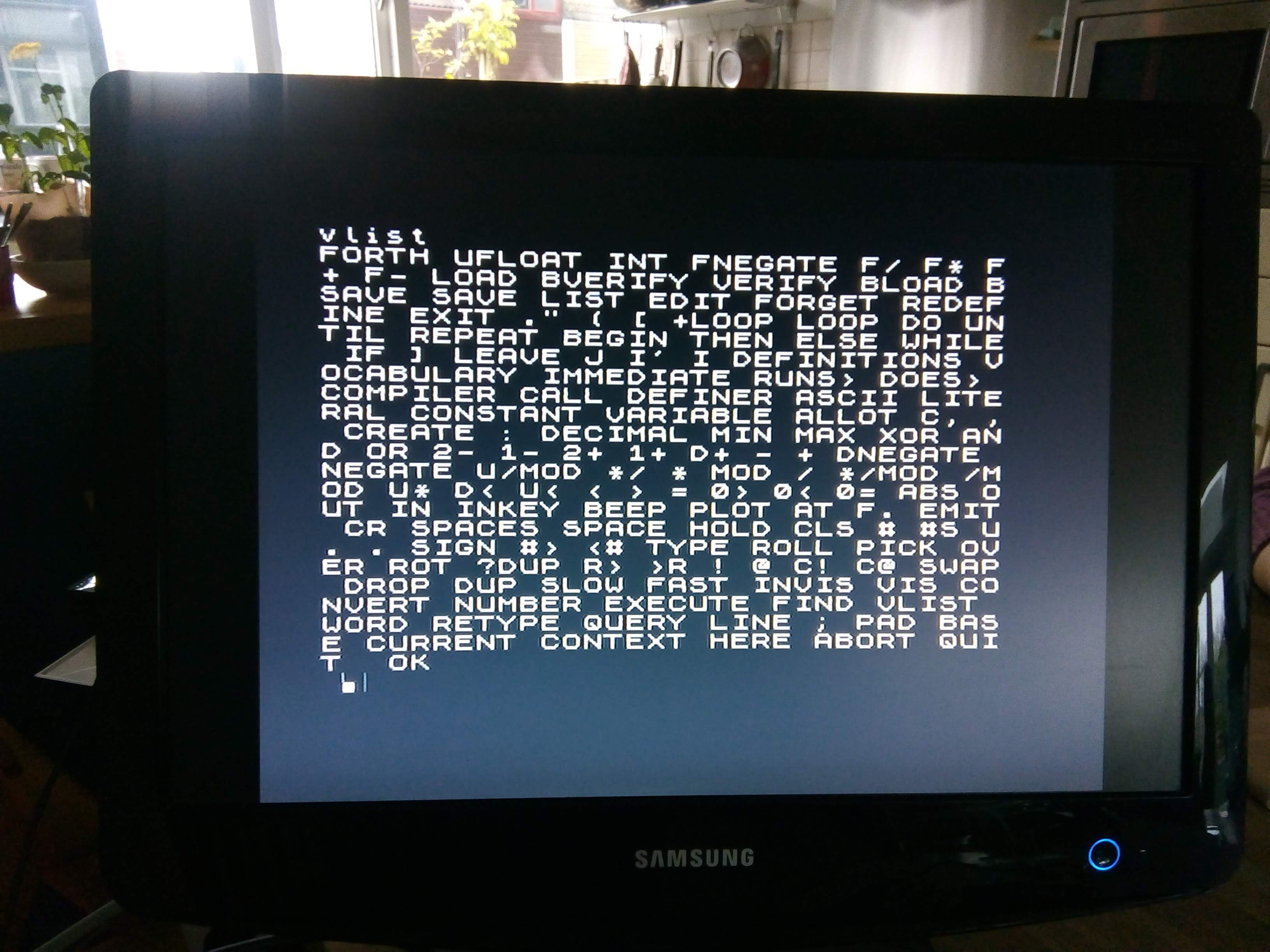

Again: it does react to the keys, so everything seems to be functional, and this confirms my earlier suspicion that the fault must be in the writing or reading of the video memory. Which it was. Another check of the schematics showed that I tied the /CS signals of both video RAM chips together. Obviously not correct. And after fixing this by disconnecting the CS pin on one RAM chip and wiring it to the correct port, the computer showed me this: YES !. That is what I was looking for !. Now let's try the only command I know: VLIST.

YES !. That is what I was looking for !. Now let's try the only command I know: VLIST. EUPHORIA !. Finally, after more than 18 months, it works.

EUPHORIA !. Finally, after more than 18 months, it works.

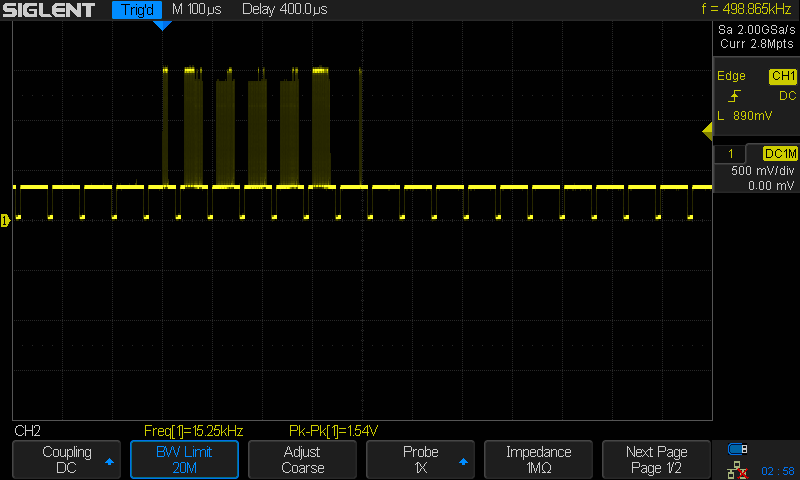

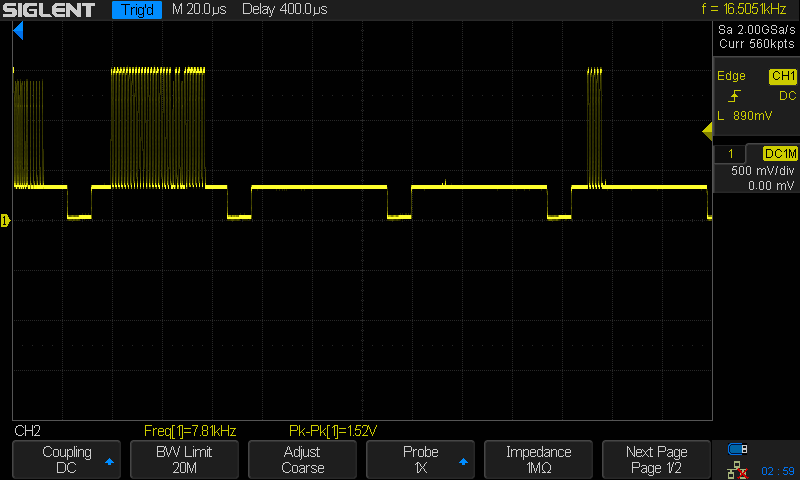

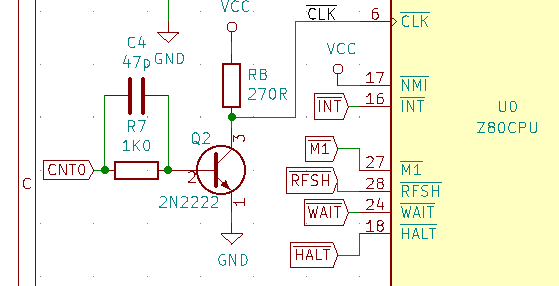

Still looks a bit wacky, but I think that's also a limitation of my oscilloscope which has a maximum sampling rate of 25 MHz so there are only 4 samples per cycle.

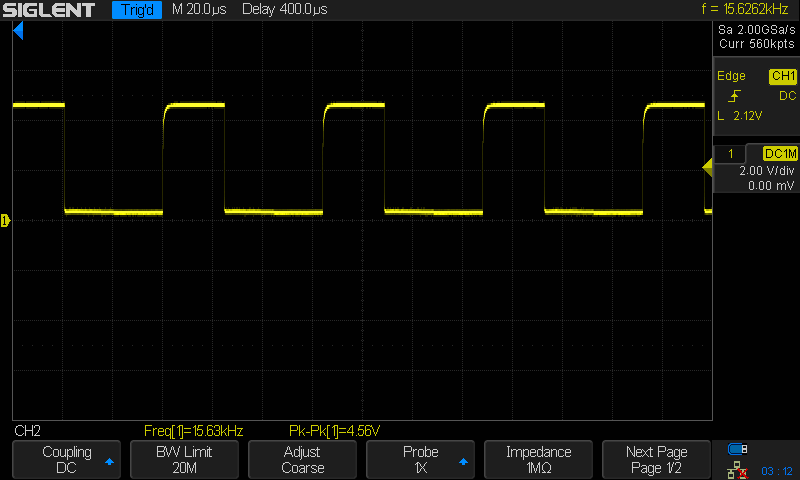

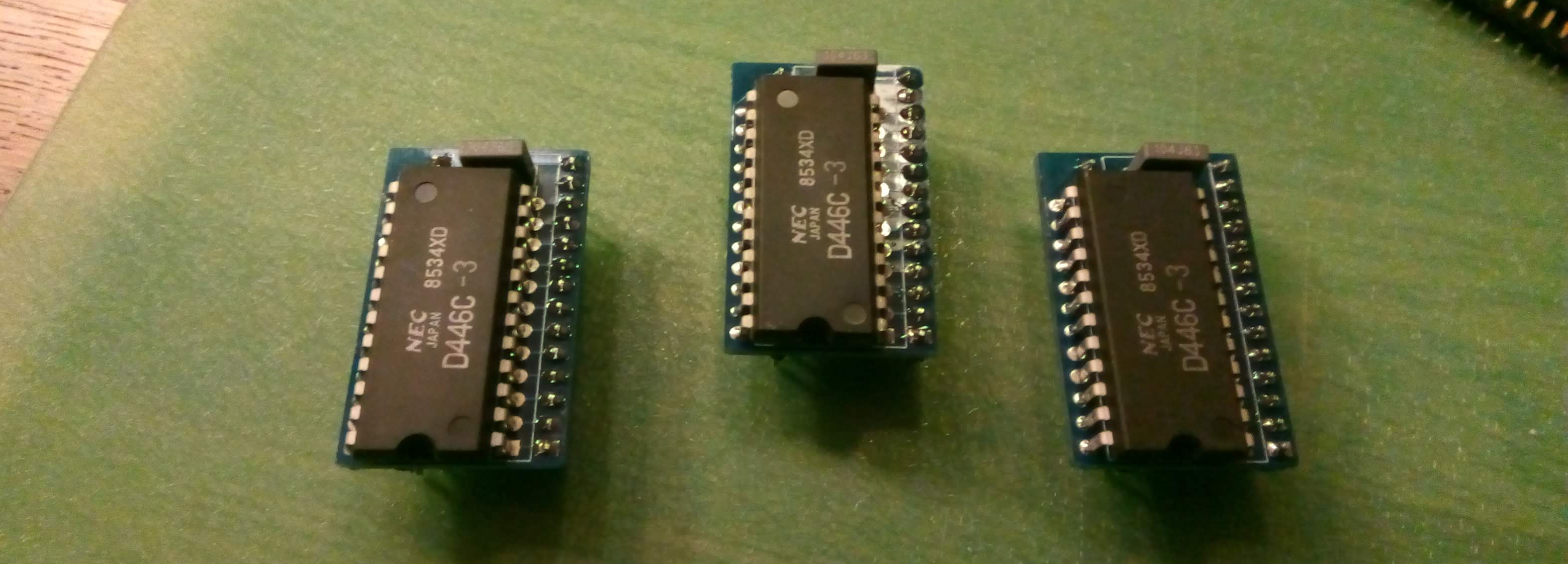

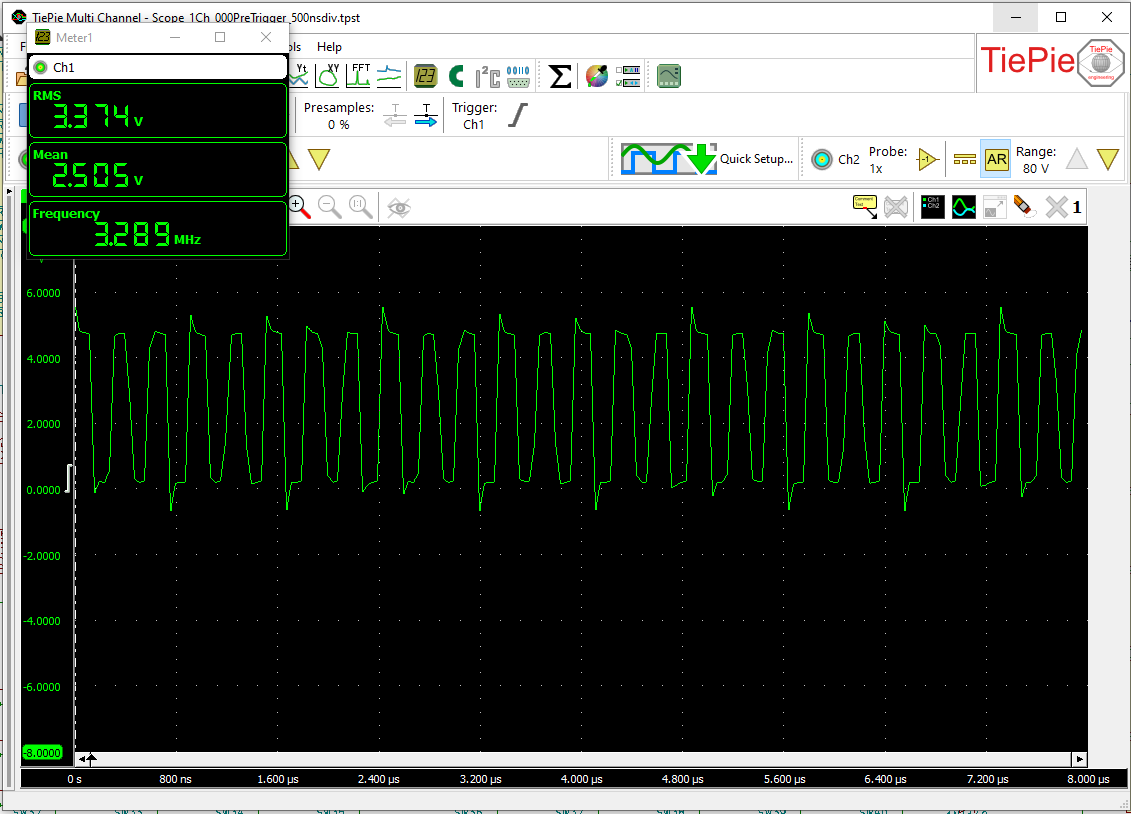

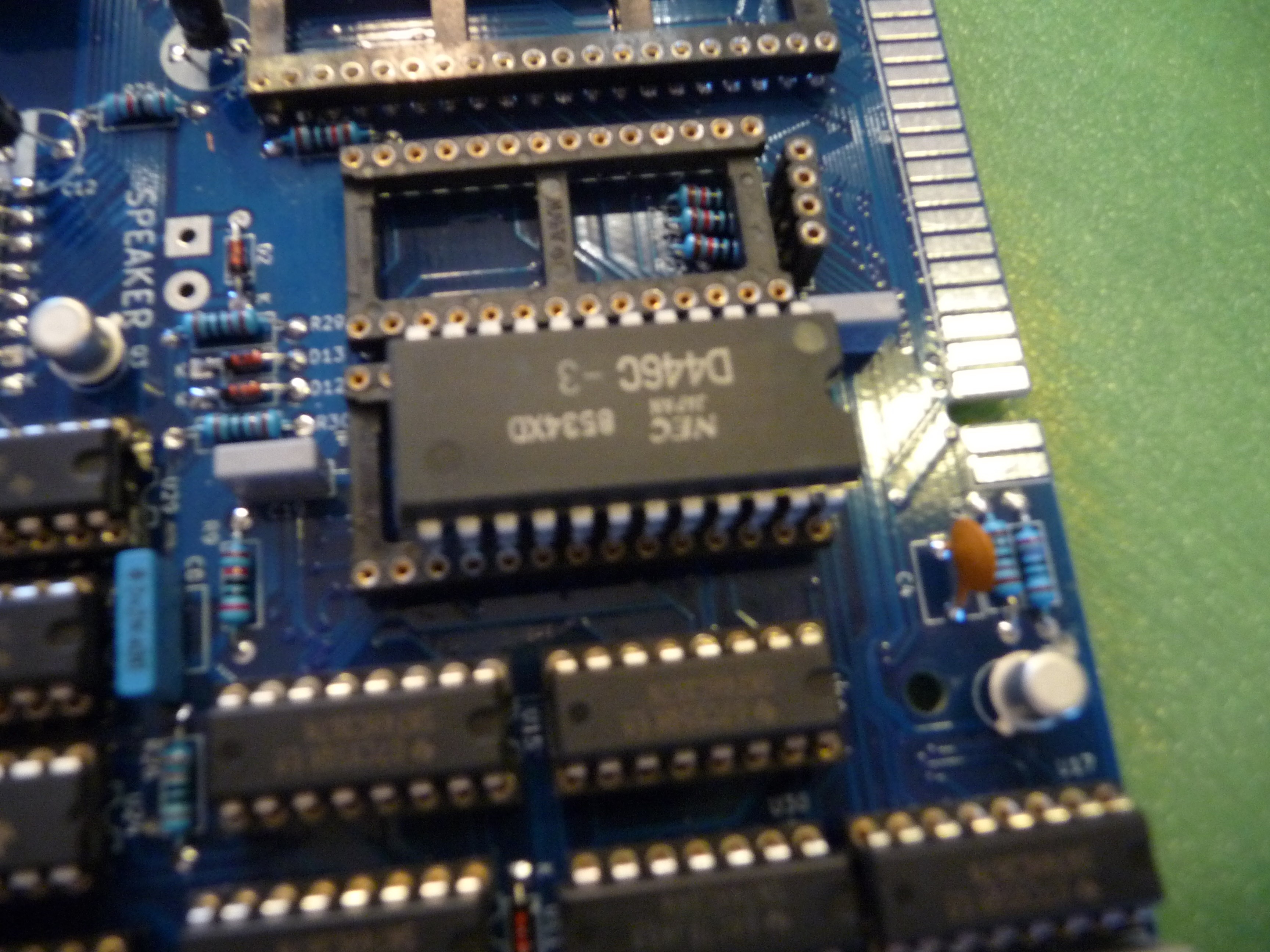

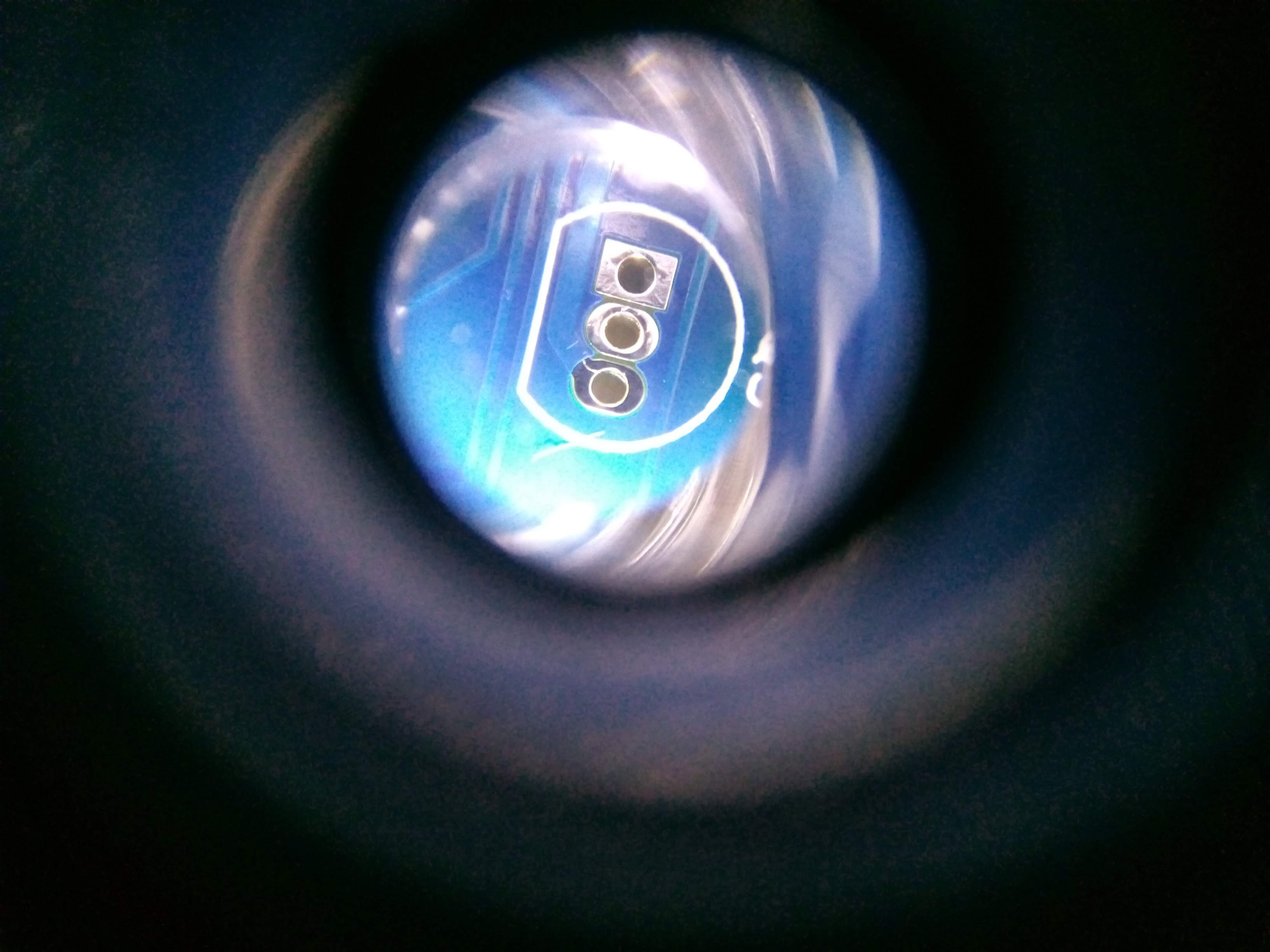

Still looks a bit wacky, but I think that's also a limitation of my oscilloscope which has a maximum sampling rate of 25 MHz so there are only 4 samples per cycle. Well, at least it starts looking like a square wave now. So lets insert the next two counters, U10 and U11. Which seems to work as well, so lets mount all other chips. All good, until I came to inserting the RAM chips:

Well, at least it starts looking like a square wave now. So lets insert the next two counters, U10 and U11. Which seems to work as well, so lets mount all other chips. All good, until I came to inserting the RAM chips:

Hi, I have a question if anyone on this project has come across?

I’m pretty new to all this, but came across your project to recreate the ACE and find it so cool.

I have built up the board and came across the same issue Scott did with the white screen, removing the 555 timer for the back porch made it a black screen with the white cursor.

The issue I have is when I press any keys the cursor moves but not characters are shown.

I suspect a RAM issue, but was posting a comment in the hope you gurus may know the answer. I took some pictures, but can’t see a way of sharing unless I upload them to some cloud drive.

thanks for your time

Jon.