-

PCBs lessons learned

06/16/2021 at 21:53 • 0 commentsThe good:

- PCB shapes turned out to be good. The PCB was scanned then vectorised and then imported to EAGLE. This process worked out fair enough.

The bad:

- The footprint of the salvaged pushbutton is small (damn I have skipped the always verify footprints on a printout before PCB ordering) Using multiple device footprints in these cases usually a positive thing.

- Always add more info on the silkscreen if possible: having the USB coloring present would have been helpful

- When making single boards like the RJ50 side make it universal: I should have broke out all the 10 RJ50 pins to pinheaders, then it could have been repurposed for other things in the future.

- The ESD protection TVS was not at hand instead I populated NUP4302. However that part does not have connection between the in and out pins. Some extra green wiring was necessary.

The lucky:

- There were some DRC errors: the beeper pad overlapped with one connector pad.Luckily the connector pad was not connected to anywhere.

-

PCBs arrived

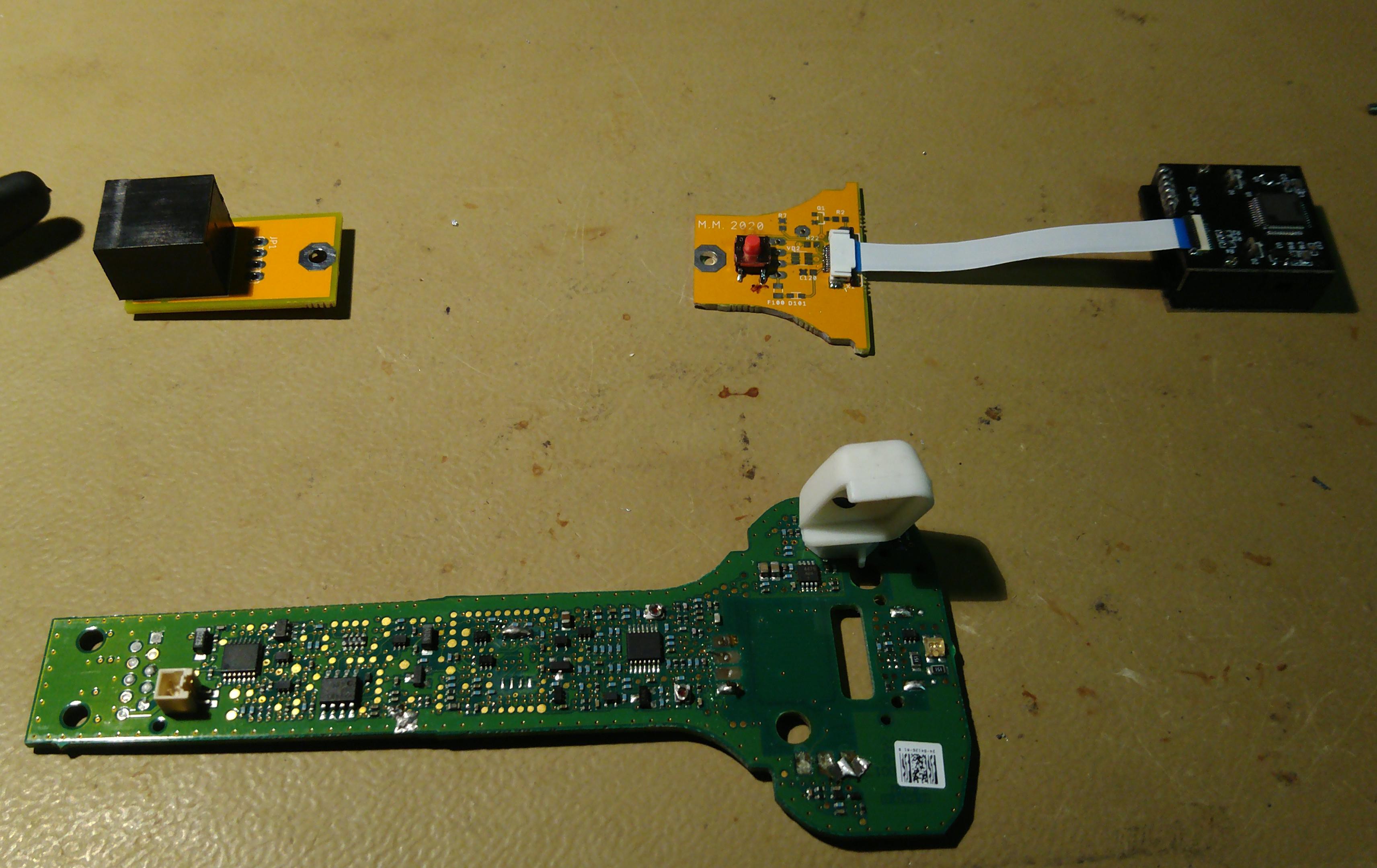

06/16/2021 at 21:41 • 0 commentsI fitted one PCB set to my last dirtyPCBs order, and received them:

![]()

As you see I made two separate PCBs to spare board space.

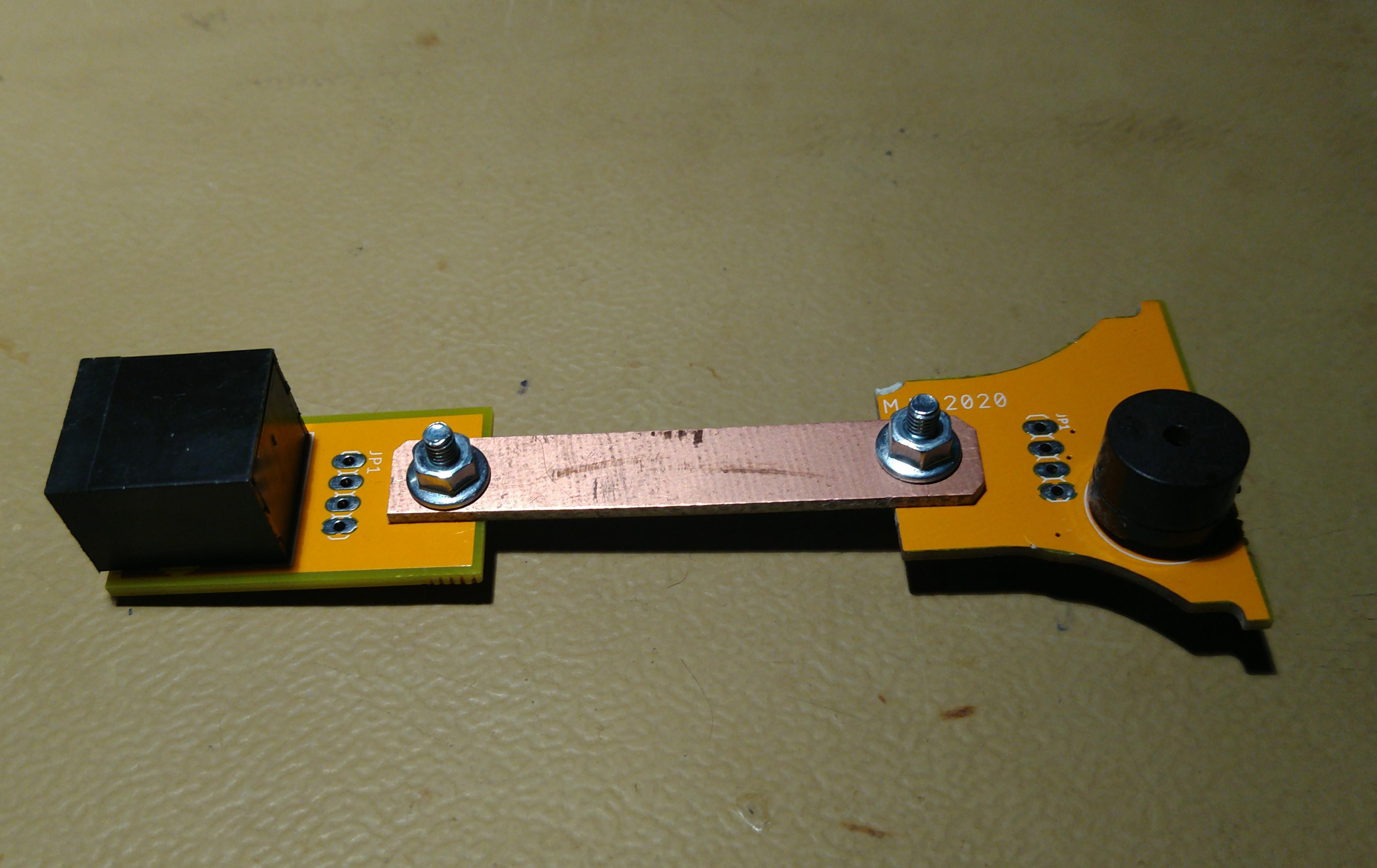

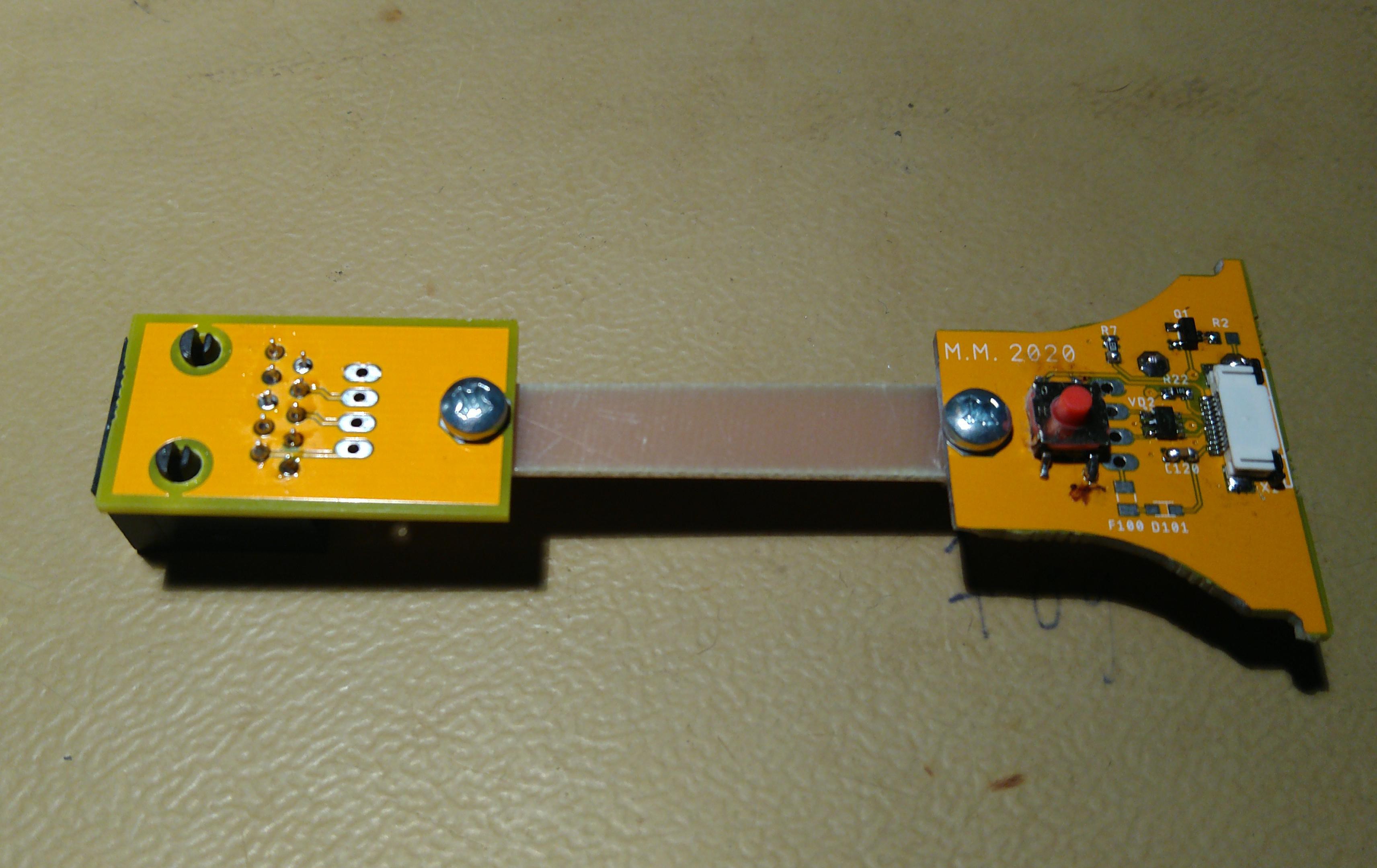

The RJ50 and main boards will be connected with a blank PCB strip:

![]()

![]()

Symbol LS4208 barcode reader retrofit

I have had a broken Symbol LS4208 barcode reader laying around for a while. I decided to give it a new life.

Miklos Marton

Miklos Marton