This badge is a continuation on a theme I started last year with my 'Shitty PIxel' SAO that eventually morphed into something I thought qualified as a full-on badge. I don't think I saw my original idea play out the way I had envisioned so I'm continuing to develop something electronic and interesting based on this design.

Design

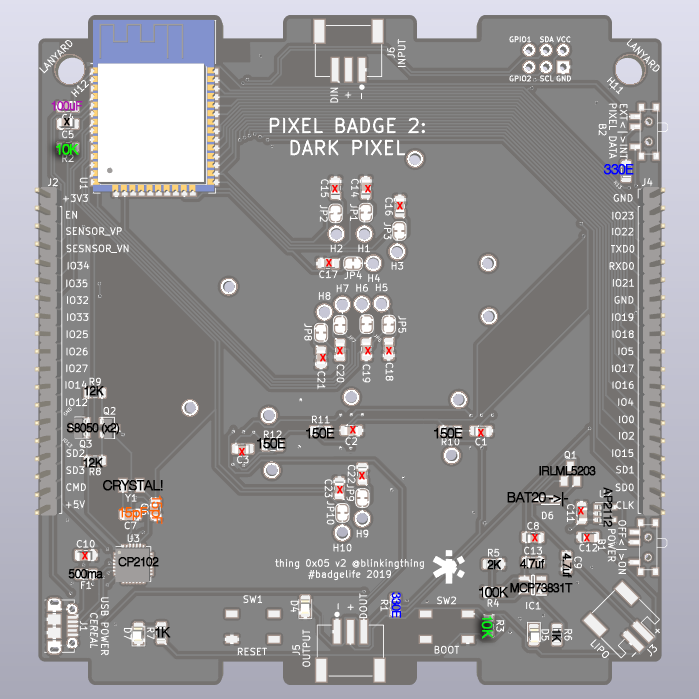

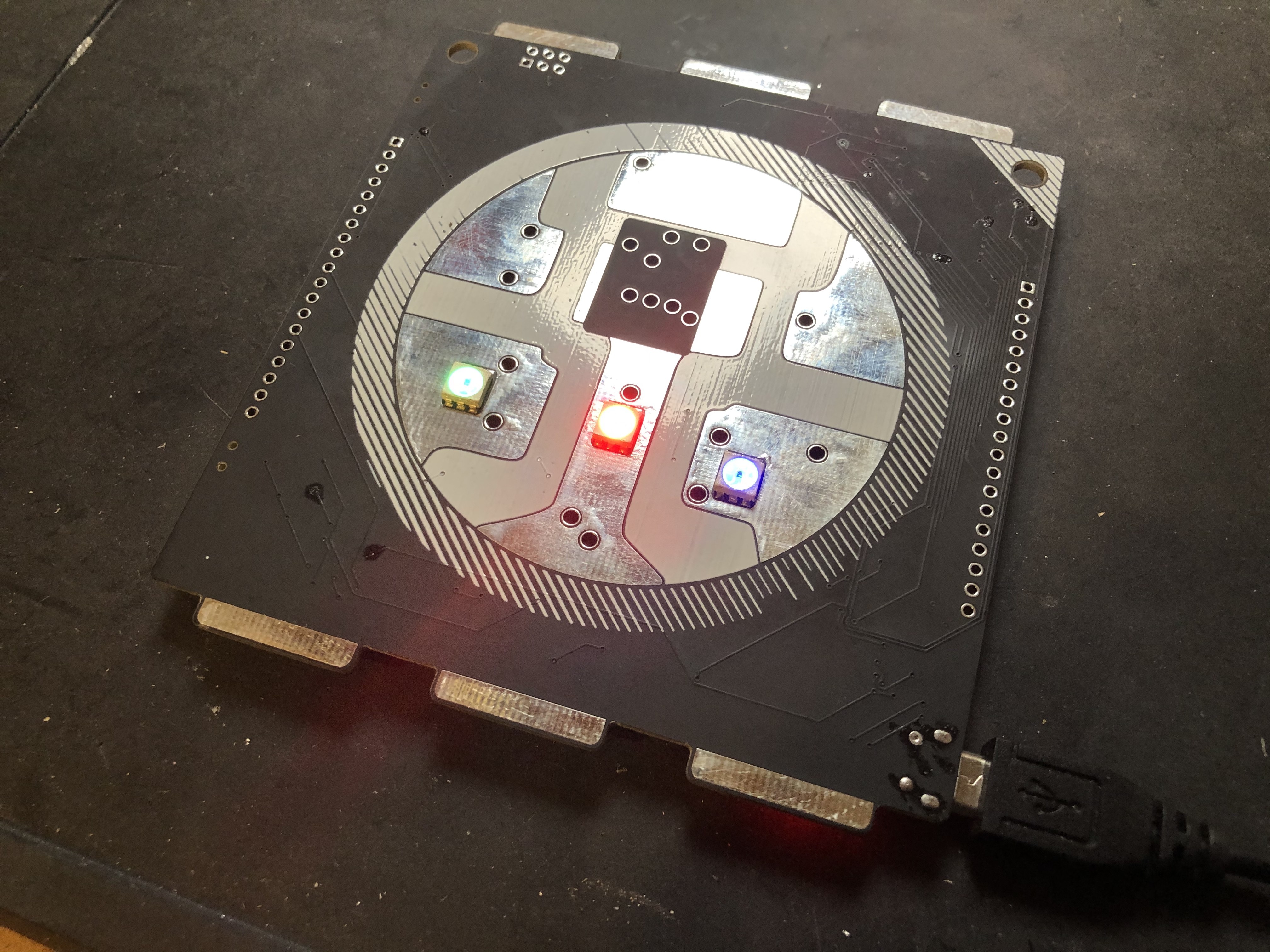

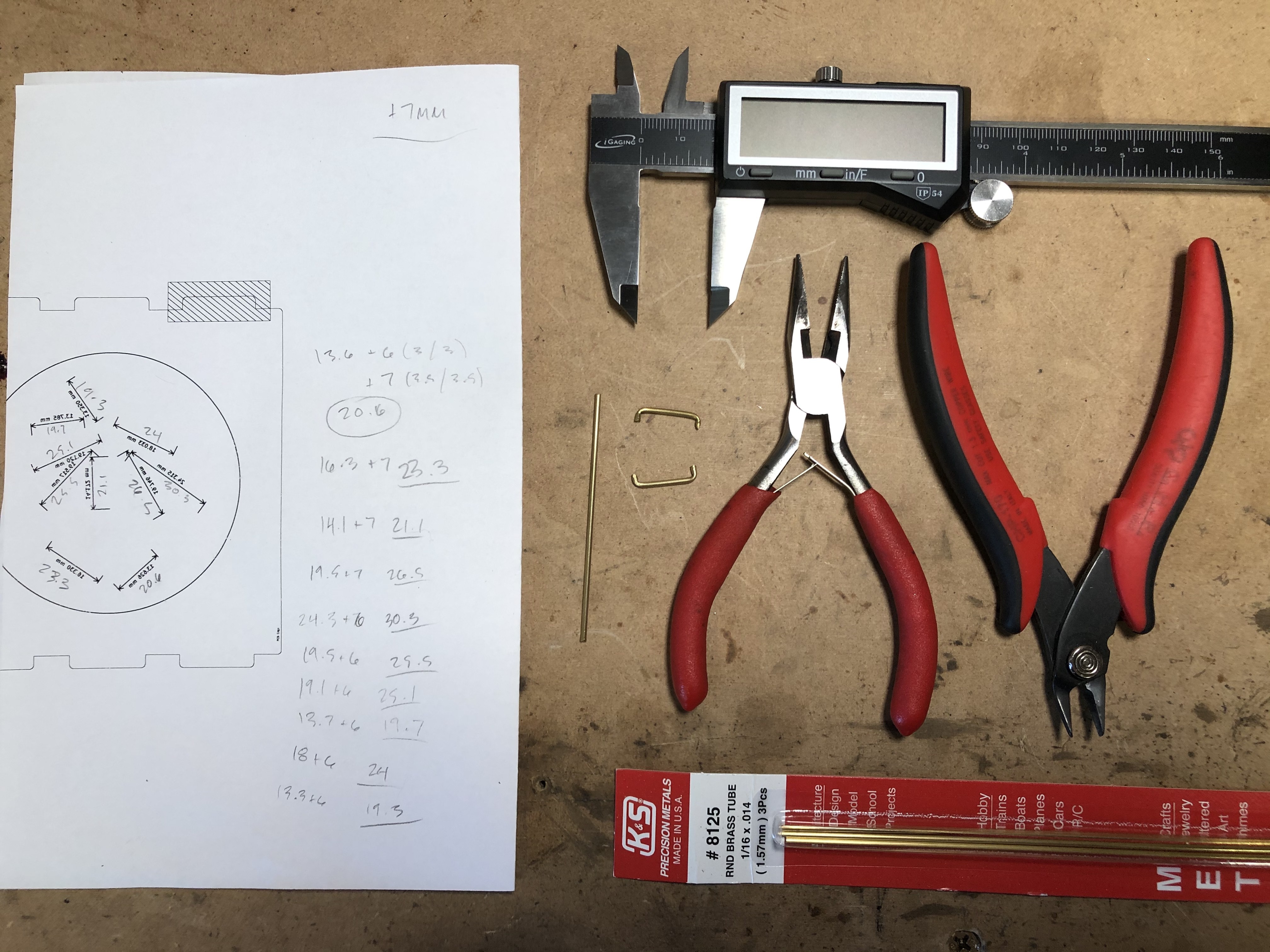

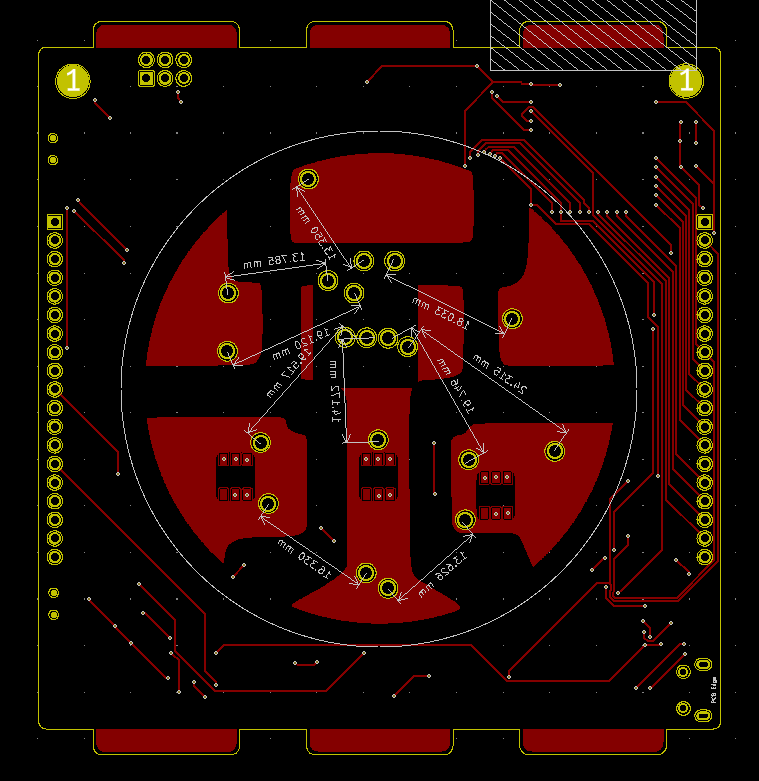

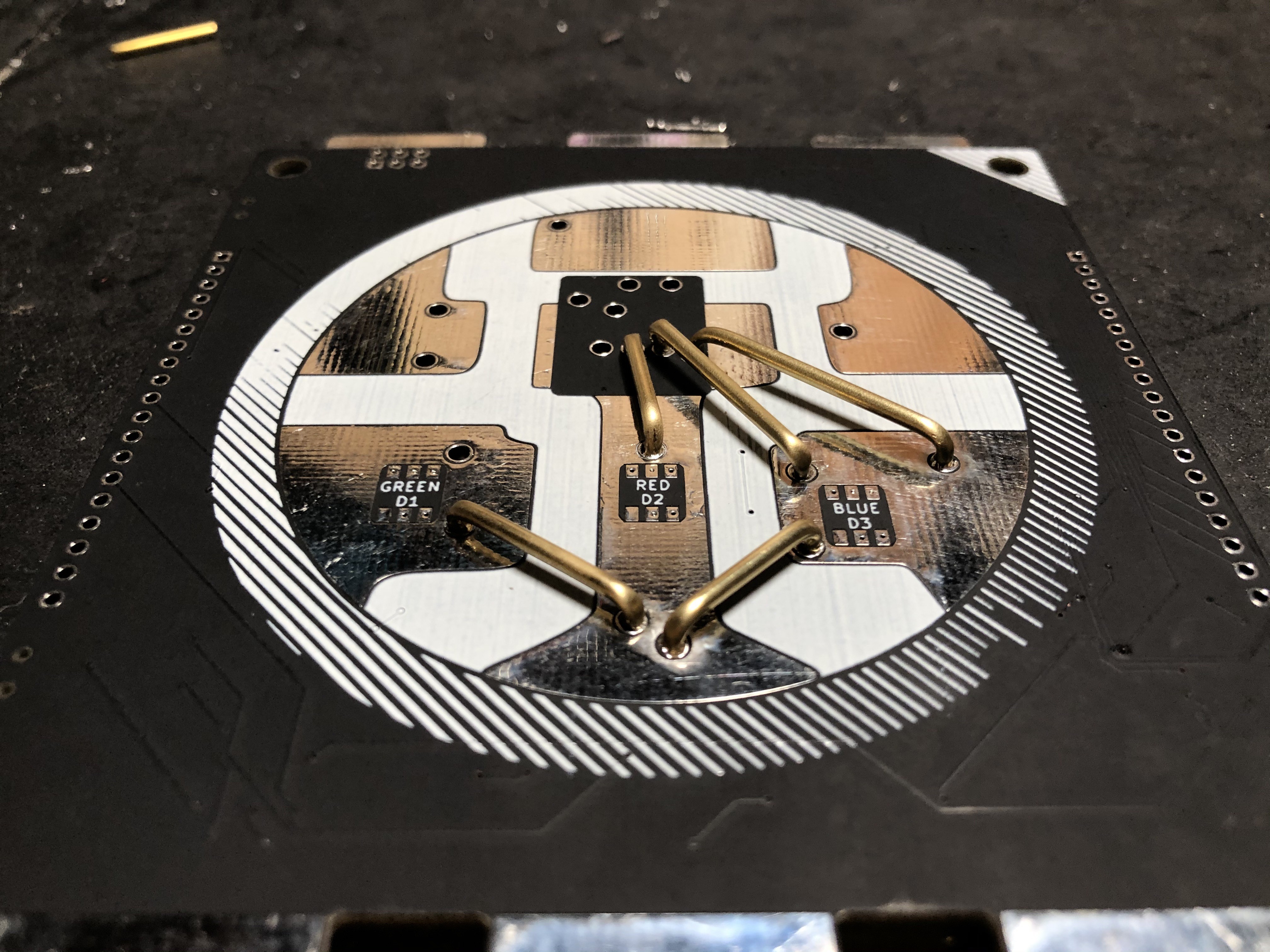

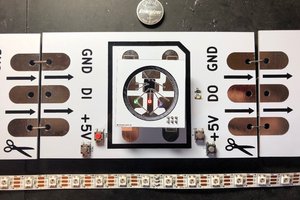

The look of the badge is modeled after the WS2812 series of LEDs by WorldSemi. The shape the copper pads form caught my eye while working on a large neopixel installation a few years back and I thought it would look good on a t-shirt. This came back to me when I started learning about PCB art and I couldn't resist the meta idea of using WS2812's on a giant WS2812. This is one of the key points I missed with the SAO I did last year. I'm making sure to use the appropriate LEDs this year. A large part of the aesthetics this year are the addition of bent brass tubes to emulate the bond wires in the LED. These were inspired by Mohit Bhoite's incredible freeform electronic sculptures.

Features

The feature set isn't fully fleshed out yet, but here's the wishlist so far:

- User controlled animation sequencer.

- Choose between internally generated neopixel data or take external source.

- Output neopixel data (think daisy-chaining badges together)

- Brass tube "bond-wires" cap-touch inputs.

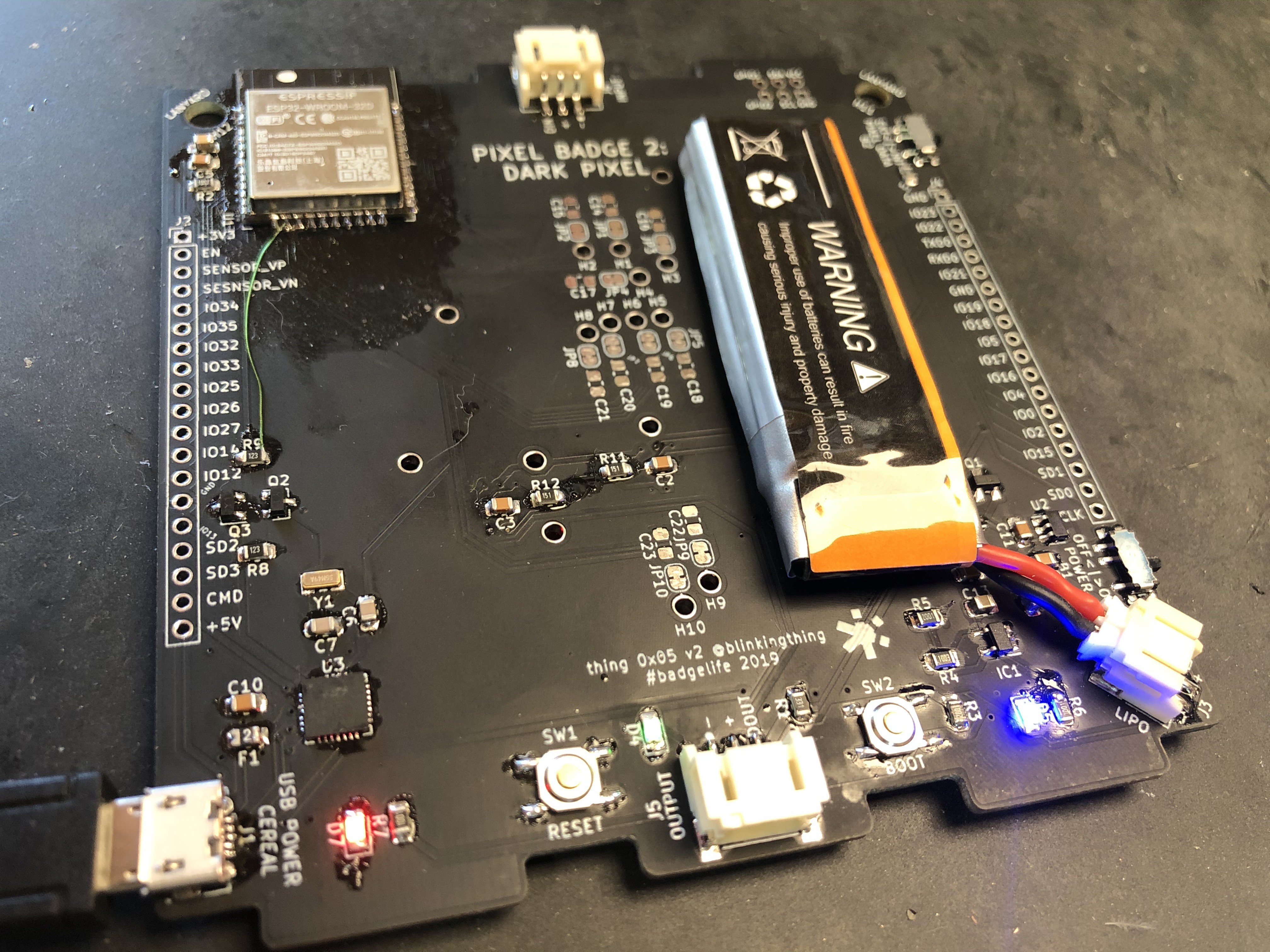

- Lipo rechargeable battery.

- USB Serial interactivity.

*SECOND WAVE Of FEATURE IDEAS*

- Wireless Bluetooth badge to badge color infections

- Battery monitoring mode, led displays red/yellow/green based on battery life

Hardware

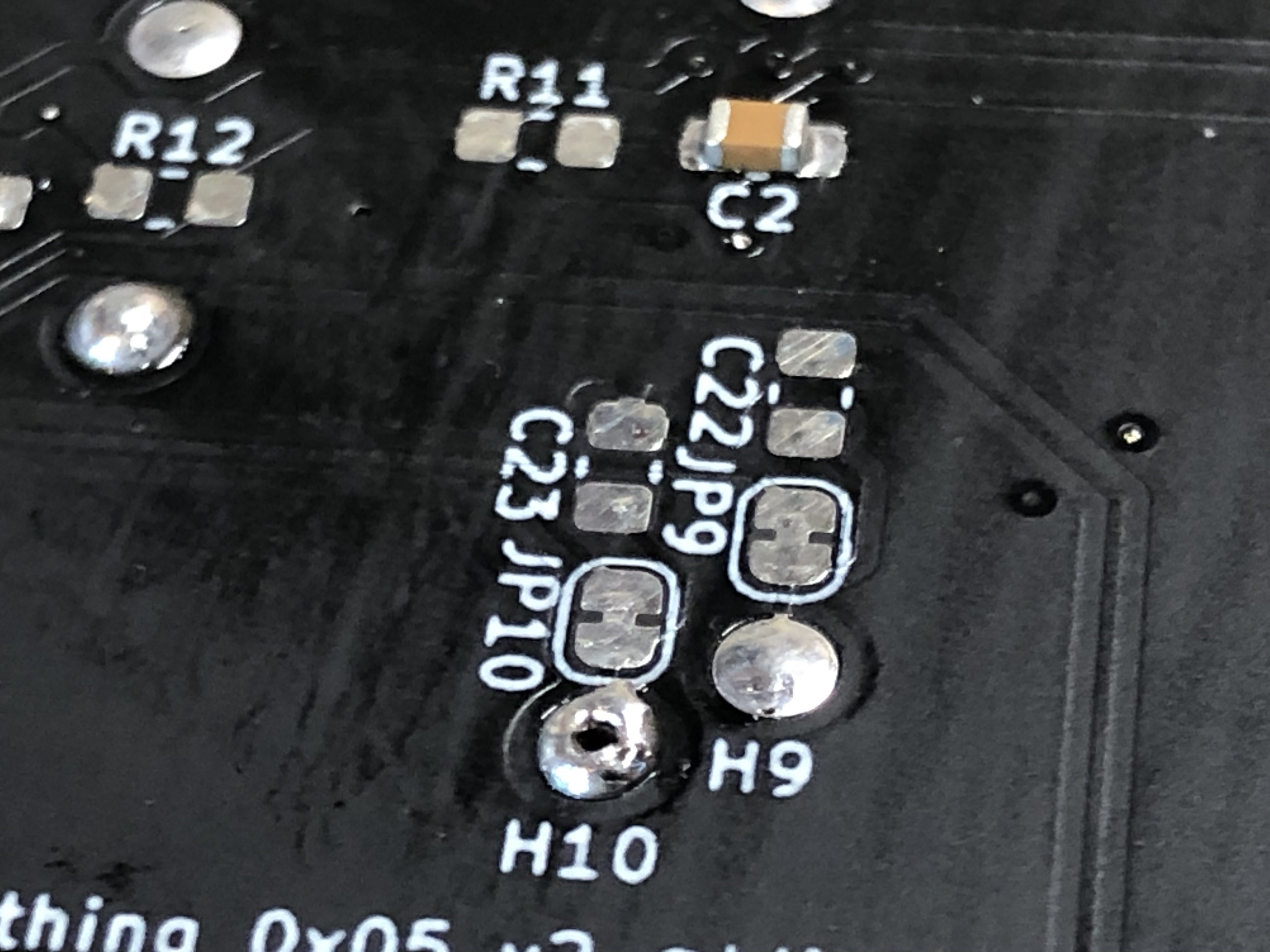

Right now, I'm prototyping using a Hornbill ESP32 dev board and I've essentially copied all of the components from the devboard to the badge design. So the main bits are:

- ESP32 WROOM

- CP2102 for USB/UART

- AP2112 Voltage Regulator

- MCP73831 LIPO Charge

I'm unsure if I'll be making any major hardware change until the features are solidified.

Software

I've only used the Arduino IDE in the past, and this is what I'm sticking with at the moment. From what I understand if I want to use the WiFi/bluetooth capabilities of the ESP32, I may need to switch to native C. We'll cross that bridge when we get to it.

blinkingthing

blinkingthing

Jackson Keating

Jackson Keating

charliex

charliex

Chris

Chris

The K&S cutter does not have guide rollers, and instead uses molded plastic blocks. This can cause thin tubing to deform rather than rotate. An example of an inexpensive cutter is here: https://www.amazon.com/ABN-Mini-Tube-Cutter-3mm-22mm/dp/B01M66AFTY/ref=zg_bs_1232270011_56?_encoding=UTF8&psc=1&refRID=EE4XZ8FJRP489E9MY6J9 this is NOT an endorsement, just an example of a usable tool.