-

In with the new...

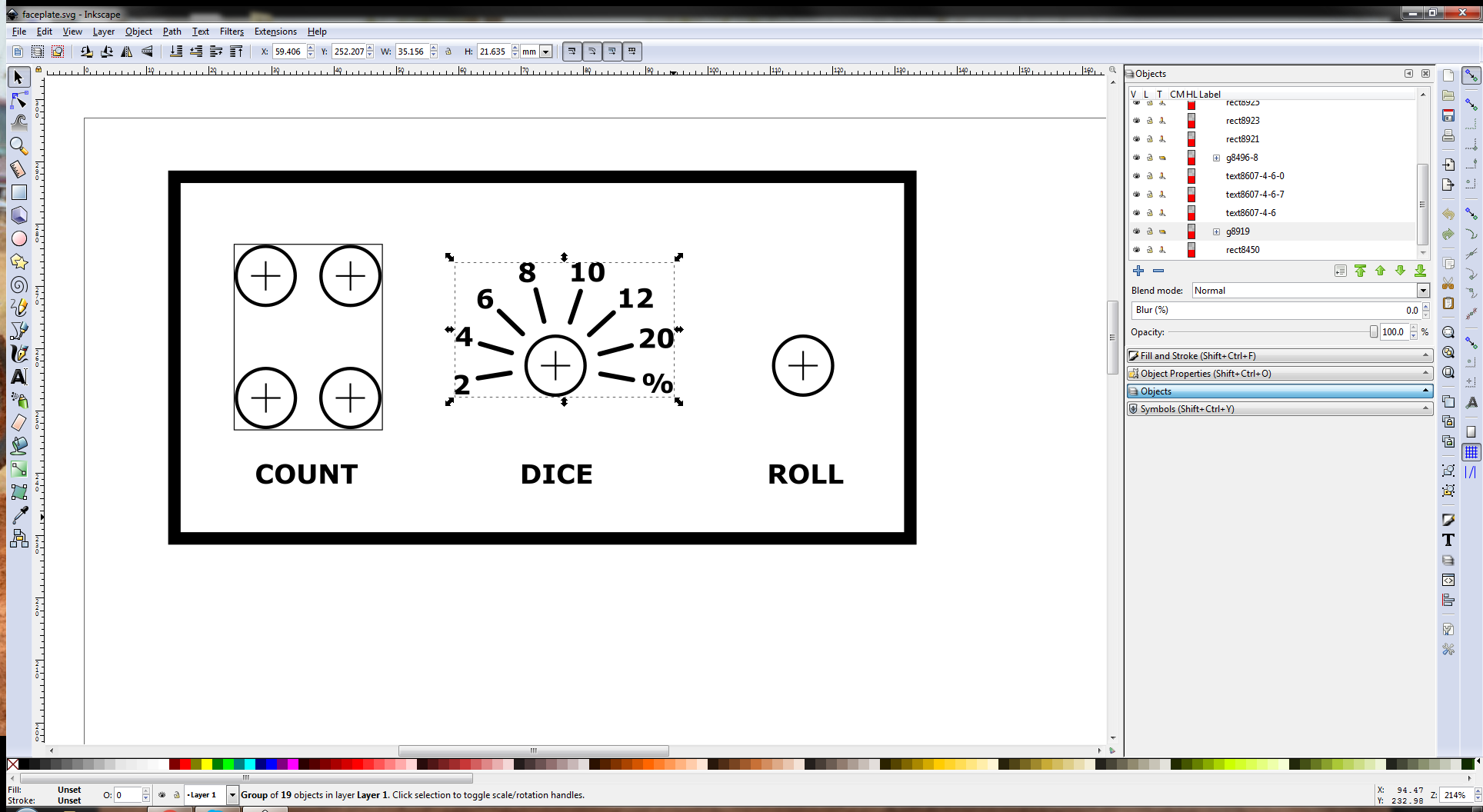

01/12/2020 at 00:43 • 0 commentsNow I needed to figure out how to install the new input switches and button. I started by laying out a faceplate design to scale using the open source drawing software Inkscape on my PC. I set it up to use mm for the scale.

![]()

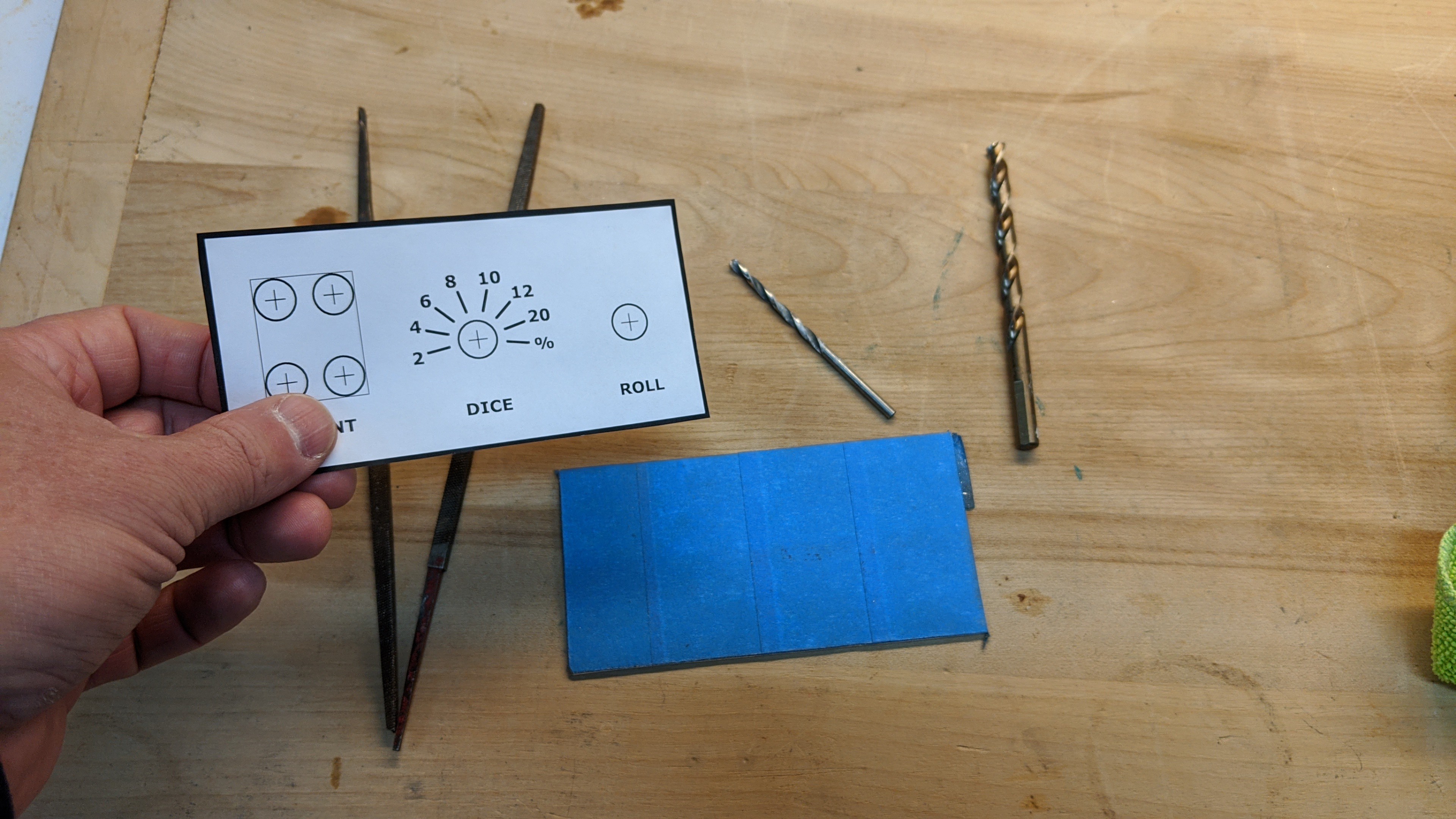

I then printed this to paper and cut it out. Using it as a template, I cut a piece of 1/16th inch aluminum. Note, I put painter's tape on the face of the aluminum plate before working with it. This prevents it from getting scratched up while cutting, filing, and drilling on it.

![]()

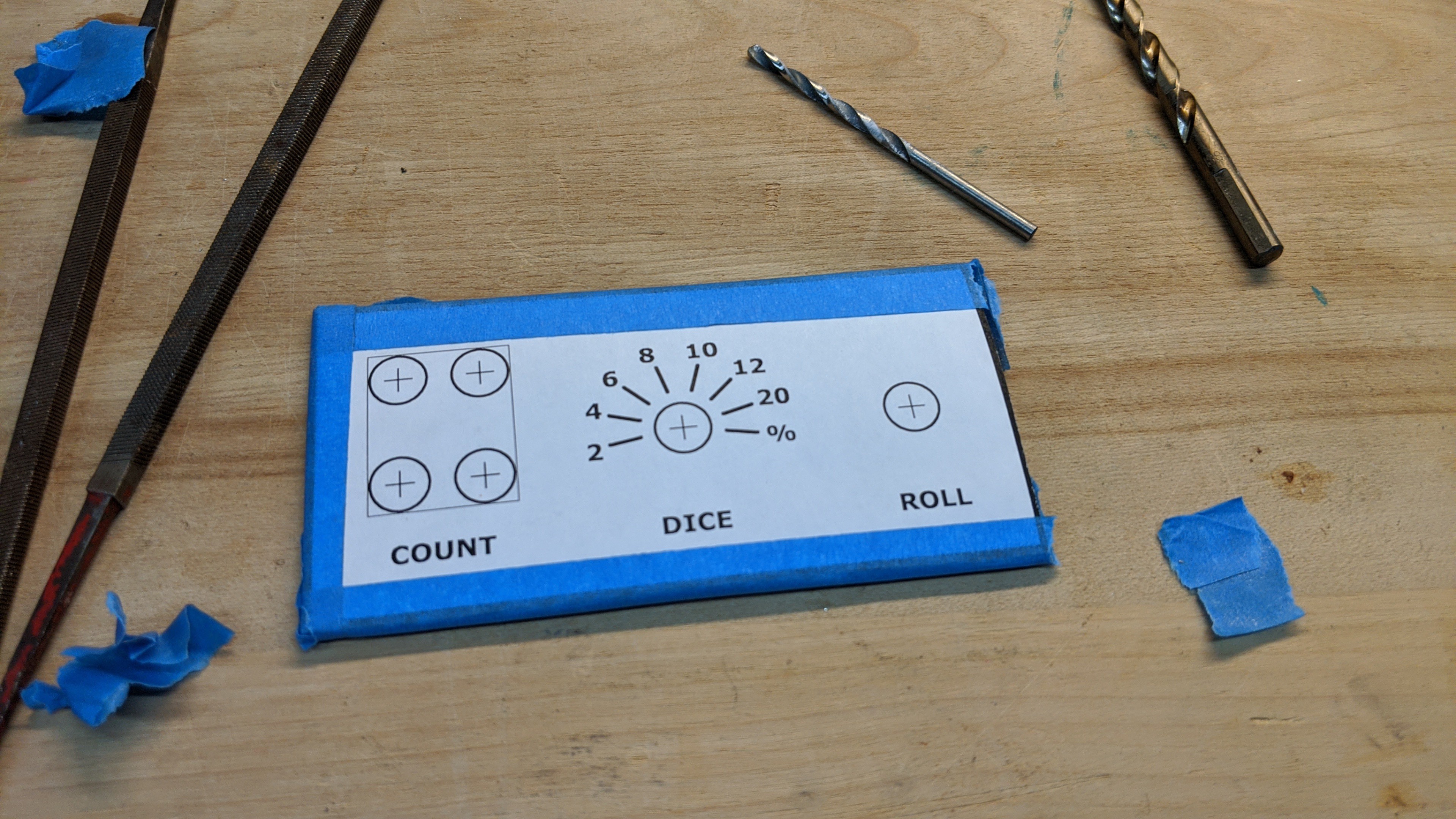

I then taped the paper cutout I printed earlier to the front of the aluminum plate. It'll be the template to drill the holes to mount the button, rotary switch, and thumbwheel.

![]()

Then I drilled the six holes as they were marked in the template. To get the square hole to mount the thumbwheel, I used one of the small square files pictured and squared the sides of the drilled holes. I then took a jigsaw with a metal cutting blade and connected the four holes along the outer lines marked by the template. I was very careful not to cut or file beyond the thin line marking the rectangle. If I didn't cut enough with the jig saw, I cleaned up with the files until the switch fit nicely.

![]()

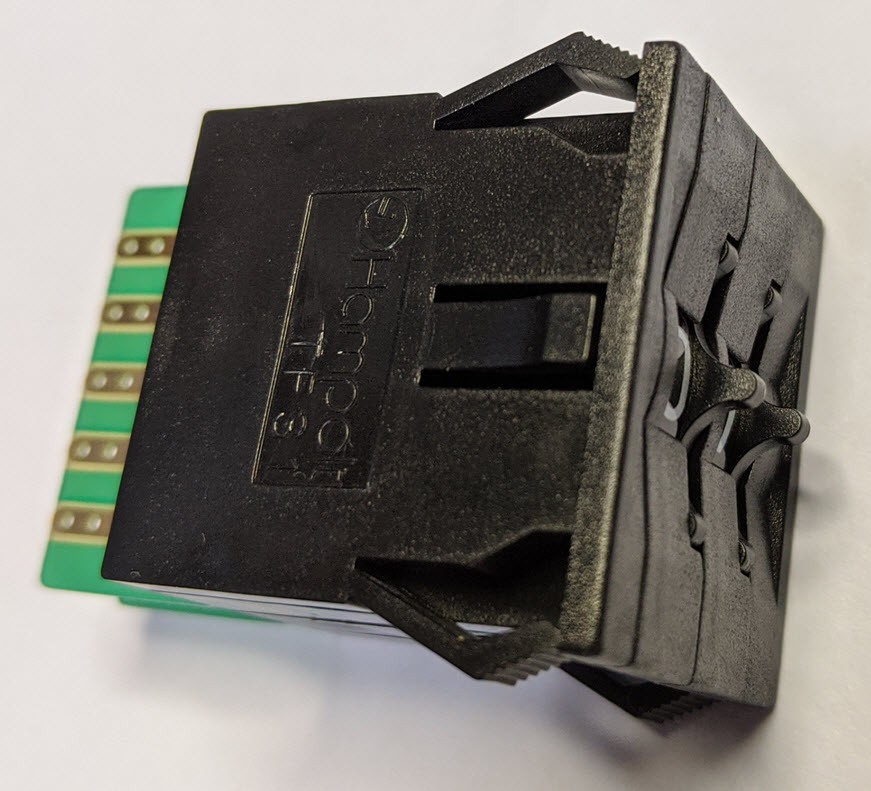

Notice that the switch has a small 1 mm bezel around it. This will hid the small imperfections of the square hole I made with the drill, files, and jigsaw. Unfortunately, I don't have a picture of it.

Lastly, I took the drill and jigsaw and cut the larger rectangular hole in the front faceplate of the case there the original switched and connectors were located. This rectangle was roughly 10 mm smaller than the faceplate I just made. I then positioned the new faceplate on the front of the case and drilled four 1/16" holes in the corners through the case and riveted it to the case. Here's how it looks installed with the new switches.

![]()

-

Out with the old...

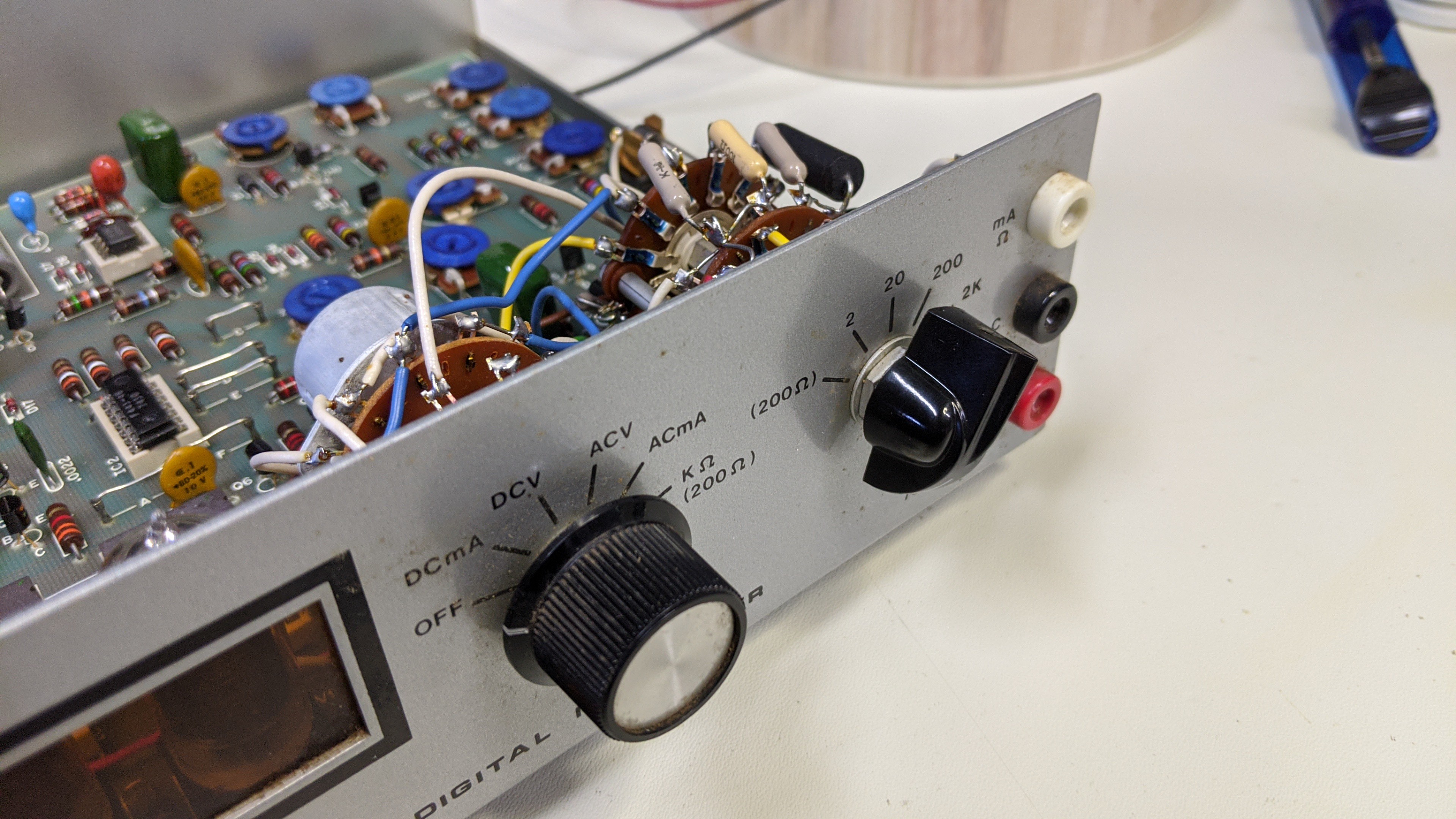

01/11/2020 at 23:54 • 0 commentsNow that I had the control board proven and integrated with the nixie displays and power supply, I needed to figure out how to install the input switches and button required. To do so, I first needed to remove the old rotary switches and banana style connectors.

![]()

The wires connecting these to the PCB are soldered to the board. I cut them at the board so I didn't have loose wires shorting to things they shouldn't. The exception was the two wires that switch the 110V AC on/off. These two wires originate at the power transformer and fuse at the rear of the PCB. They pass under the PCB and pop out under the left rotary switch and connect to the back of it. I clipped the wires there to leave plenty of slack so I could run them to a new on/off switch. The red arrow in the picture below points to these two wires where they connect to the rotary switch. The blue arrow points to a fuse you can remove along with the banana style connectors.

![]()

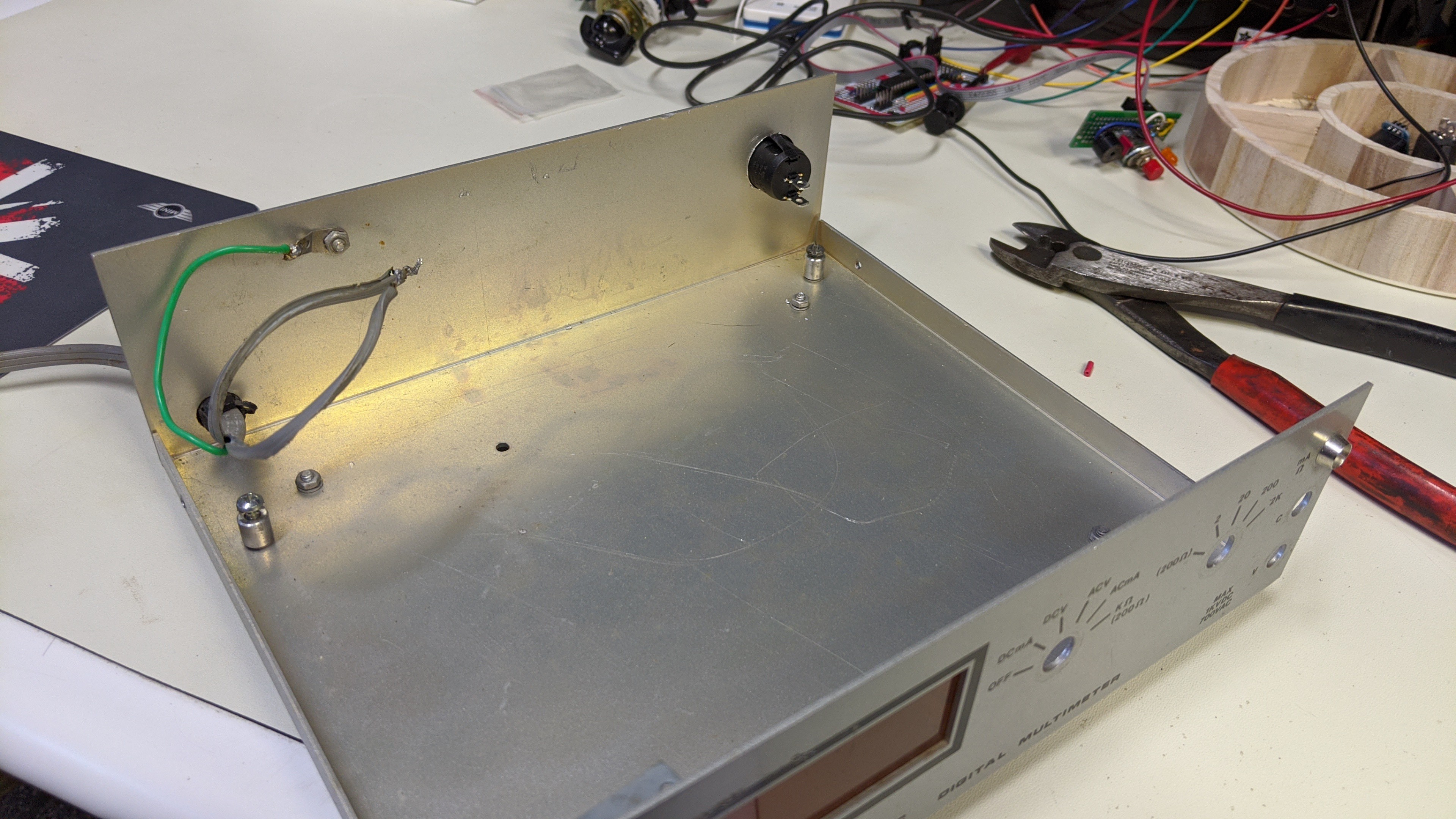

Once the the switches and connectors were removed from the faceplate and the cut from the PCB, I removed the PCB from the case. At this point, it looked like this.

![]()

Next, I drilled out a 3/4" hole in the rear faceplate of the case to mount the power rocker switch. Using a step bit made this easy. Then I used a small square file to notch one side of the hole for the key that prevents the rocker switch from rotating in the hole.

![]()

It looked like this when I pressed the switch into the new hole.

![]()

![]()

Next I crimped a couple blade connectors to the AC on/off wires I trimmed for the rotary switch earlier.

![]()

At this point, I was ready to start laying out the new switch interface and figure out how to make it work with the existing faceplate.

-

Getting started...

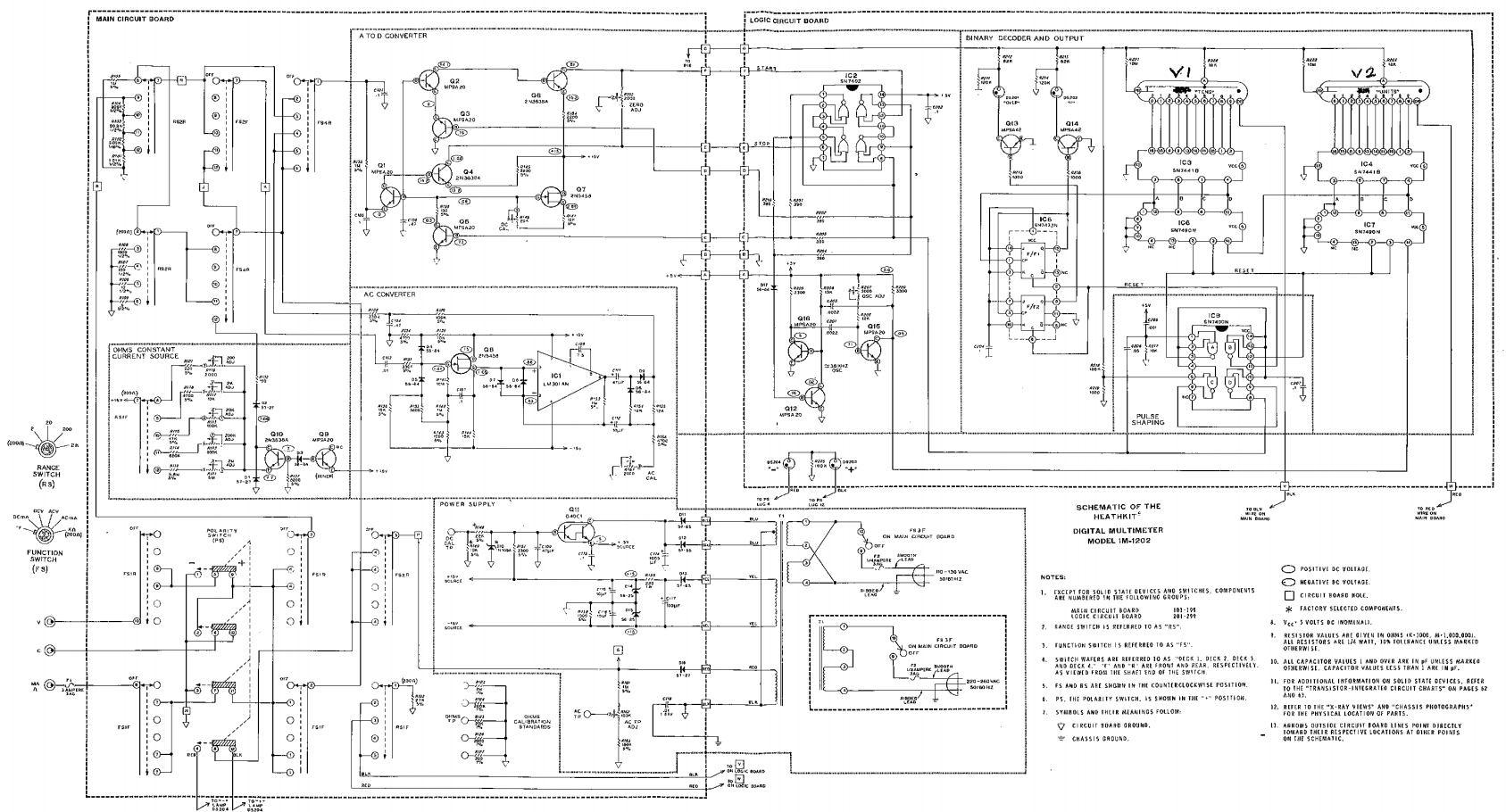

01/09/2020 at 00:50 • 0 commentsAs mentioned in the details of the project, this mutlimeter was originally a kit that DeVry students assembled during their course work. So, there is some design documentation and even a schematic available for it if you do a little searching on the inter-webs. I couldn't find any original Bell & Howell or DeVry documentation of this actual device. But, I quickly discovered it's based on a Heathkit IM-1212 digital multimeter with nixie tube display. A brief search turned up a pdf version of the original Heathkit assembly manual. The same search also turned up some confusion around who owns the Heathkit intellectual property and their intentions. So, I won't post the full assembly manual here. But, I will provide a couple relevant excerpts. If you want more detail, you can easily find the same IM-1212 Assembly Manual. There's also a good overview and description of the circuit design for this meter on Mr ModemHead's blog. You can find it here: http://mrmodemhead.com/blog/nixie-glow/

For dice tower application, I wanted to reuse the case, 7441 decoder/drivers, and nixie tube display. But, after a little research and reverse engineering, I realized it could also reuse the power supply as well. Doing so would require hacking up the single large PCB, or just leaving it in place and adding my simple protoboard with AVR. There's plenty of room, so I left the PCB as it was.

Now I just needed to figure out how to connect the new stuff to the old stuff. Glancing at the schematics, BOM, and part details it quickly became obvious that this could be simple.

![]()

That's the whole schematic. It's not very useful at full view, the scan quality is low. But if you zoom into the upper right quadrant, you can see the detail needed.

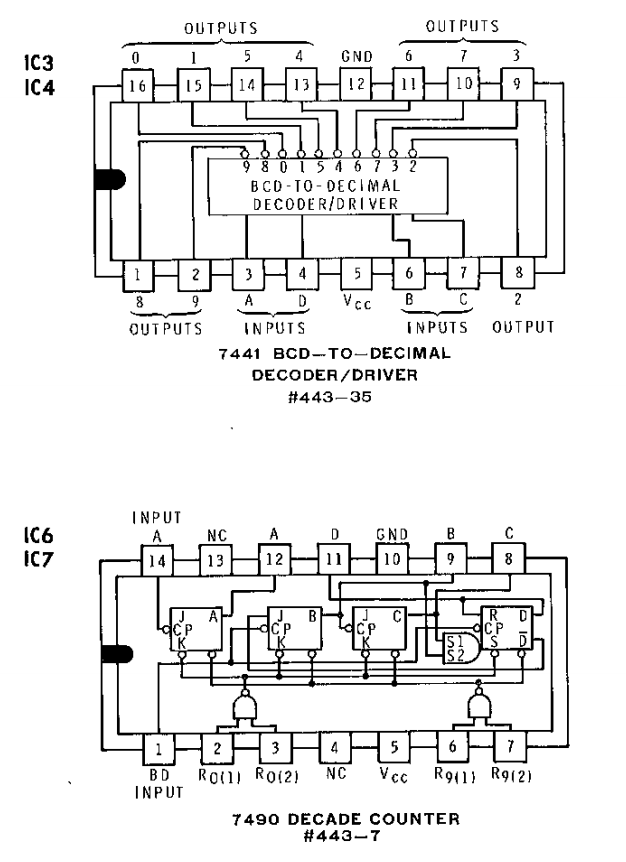

![]()

IC6 and IC7 are 7490 decade counters. They count the clock cycles generated by the single-slope voltage-to-time ADC (see the Theory of Operation as it's described in the link above). Since I'm ditching all the analog multimeter functionality, I don't need those. Conveniently, they are directly connected to the 7441 decoder/drivers that I do want to interface. In addition, the 7490's require Vcc (5V) and GND, and they are socketed on the board. So, those sockets have everything I need to interface my controller board with the nixie displays and power supply.

![]()

I located the parts on the board (labeled 1 and 2).

![]()

Popped them out of the sockets, trimmed a couple socket (female) headers to length, and installed in the sockets to give clearance for the controller board. Note: I also removed the old rotary switches in this picture. I'll document that in another upcoming log.

![]()

I decided to test this approach before warming up the soldering iron. I pulled out my breadboard, jumpers, and ATtiny88 and wired up Vcc, GND, and 4 pins of one of the ports, configured them as outputs, and wrote some values to it. It worked.

![]()

Now confident the approach would work, I trimmed a couple single row headers to fit, placed my empty proto-board on the headers, and positioned it as I wanted it. I soldered the headers right there in place so they lined up with sockets perfectly.

The next step was to pull the proto-board out of the sockets, put it on the workbench, solder down a 28 pin DIP socket for the ATtiny88, wire up/solder Vcc and GND, and then solder the connectors, wire them up, and solder some more.

It looks like this when completed.

![]()

![]()

It's ugly. But, it works :-)

I glossed over some detail there and I'm not going to provide a schematic for the controller board. It's just some wires connecting the processor pins to Vcc, GND, an ISP port, and 5 connectors. I soldered it up looking at a pinout diagram for the ATtiny88. If you need some help wiring up a 6 pin ISP port for the AVR, checkout this Atmel document for more information: AVR ISP User Guide

I'll document which ports connect to which IO functions in the log covering the project software later this week.

1978 "Heathkit" D&D Digital Dice Tower

Resto-Mod Dungeons and Dragons Digital Dice Tower based on a 1975 Bell & Howell IMD-202 Digital Multimeter

John Anderson

John Anderson