-

Being built.....

04/30/2020 at 22:29 • 0 commentsshould be able to show it before today goes up

- April 30th

Think that was a lie. Past week has been confusing.

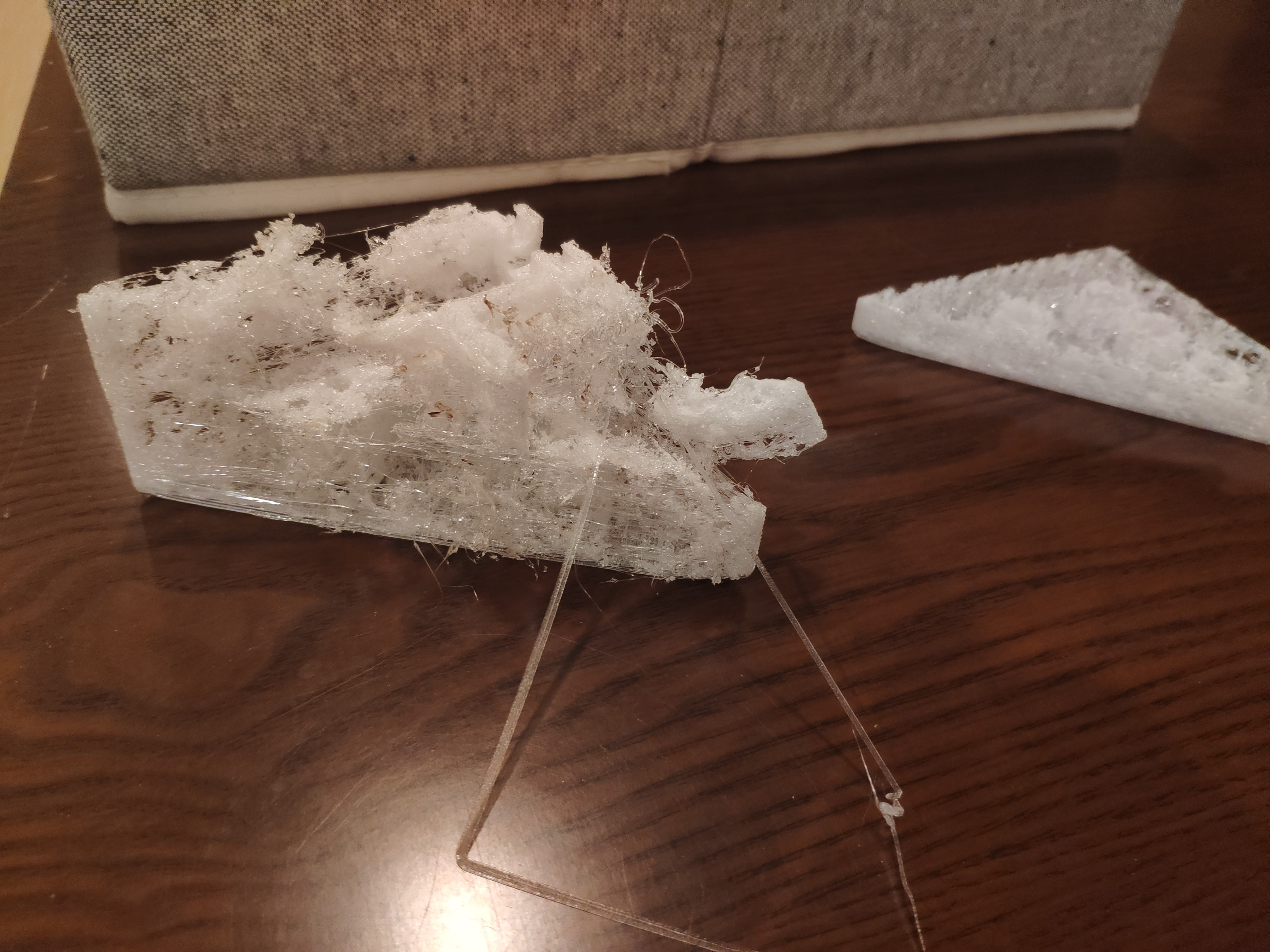

All of the parts are now here, but some parts are ... gone.

![]()

![]()

![]()

![Types of Screws and Bolts - The Nuts and Bolts Blog]()

The main parts, corner and bridge, had pockets for screw head so that various lengths of M5 screws can be used to bolt onto 2020 extrusion and not cause a shortage of a certain length.

I was stupid enough not to differentiate between button and cap screws. (Rather, designing to fit cap screws was a mistake in itself - for M5 screws, button head seems vastly more common.)

In the process, I decided to have a go at PETG since I am finally making something structural this time. It was a mistake.

![]()

What to do if printer underextrudes like crazy and skip steps when you're printing as slow as possible? uh... not buy PETG ever again![]()

The combination of my unstable hotend, which I am afraid is going to burn if I push beyond 240 degrees, and MK7-bowden setup of barely enough grip became the ideal punishment of my complacency in 3D printing.So for now, printing it is... not laser cutting :(

-

Safety

03/30/2020 at 21:59 • 0 commentssafety documentation

-

Electronics & Software

03/30/2020 at 21:58 • 0 commentsSKR v1.3 & Marlin 2.0

Instead of 'proper' laser cutting firmware such as LaserGRBL , I just decided to go for 3D printing hardware & software, predominantly due to their high accessibility and user base, as well as my familiarity with the Marlin firmware. I also chose to use a SKR v1.3 motherboard for the same reasons.

If you have any 3D printing mainboard lying around though, I am confident that the process will be very similar to mine. This guide by Teaching Tech should help anyone else interested.

(BOM for electronics)

-

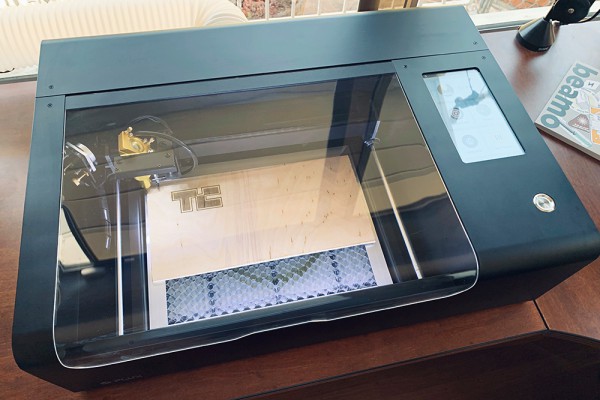

Laser

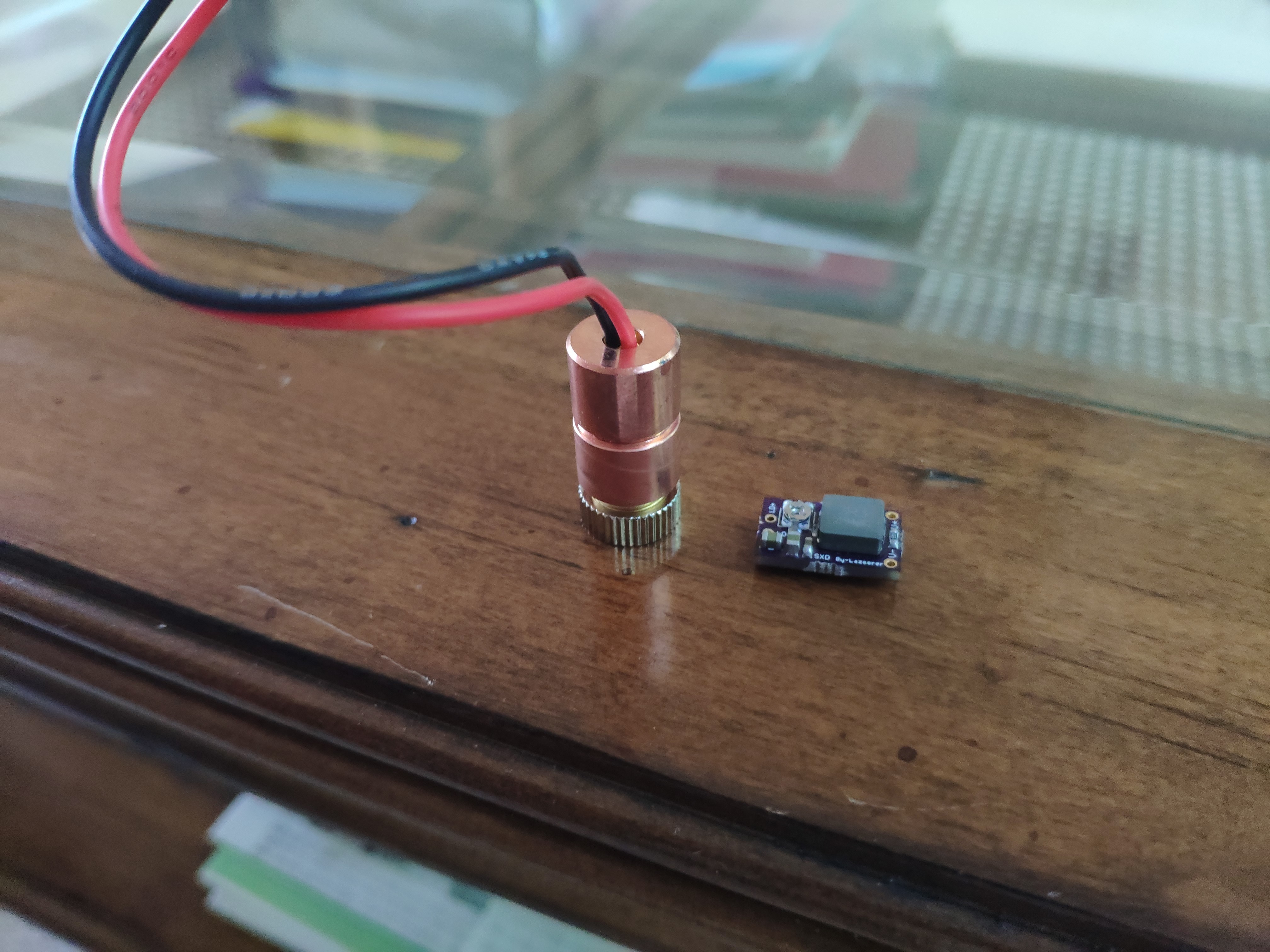

03/30/2020 at 21:24 • 0 commentsDiode Laser

The decision to use a diode laser instead of a CO2 tube is mainly thanks to the diode's superb simplicity.

The challenge with diode lasers, however, is safety. the rays created from a blue diode laser has a wavelength of about 440 nanometers and are not as readily absorbed by common materials. CO2 lasers, in contrast, produces a wavelength of 10.6 micrometers and are blocked by many transparent plastic materials (polycarbonate, polystyrene, acrylic).

After a fair amount of research, I decided to use a combination of laser shield around the diode and an external enclosure around the frame. The intention is that even a very undesirable scenario of someone walking onto the cutter without proper laser glasses does not result in damaged eyes.

Sourcing the Laser Module

I recommend purchasing 440 nm or 445 nm blue lasers, as they have the best absorption characteristics.

Common routes to buy a laser module include:

From what I've found, you most likely want TTL-enabled drivers if you want to do grayscale engraving.... which you probably do.

LCLC is designed around laser modules from DTR's Laser Shop. I trust the shop, as DTR actively participates in Laser Pointer Forum and holds a trusted reputation there. Plus the numerous testings done on DTR's laser drivers on the forum.

The laser comes attached to a copper shaft with diameters of 12 mm, 20 mm, or 25 mm. Then, you would attach it to the laser cutter using a linear rail guide (search "SK12/20/25 CNC" on eBay).

I chose the NUBM08 module and Super X Driver attached to 12 mm shaft, totaling out to around $100. The price is comparable and even cheaper than some laser modules found on Banggood or Amazon.

You should be able to modify one or two parts to support other types of laser modules, although I probably need to redesign the cover before that...

Laser Cover

Air Assist

-

Background

03/30/2020 at 21:00 • 0 commentsI have always wanted to use a laser cutter. But without a makerspace/hackerspace near me, it's difficult to access a real laser cutter.

Like 3D printers, there are cheap laser cutters around the market. Generic "K40" machines can be purchased on eBay/Bangood/AliExpress under $400 and require only minor modifications to get started. However, K40s have a small cutting/engraving area for its price, and its safety remains questionable (with CO2 tubes running at ~20kV, albeit not quite enough amps to kill me or you)

This project tries to inherit the intentions of RepRap project, creating an open design to be used and improved by others, especially individual makers or students without access to laser cutter nor big $.

It is also a design practice for me in experimenting with 3D printing to compress what would conventionally take multiple parts into a smaller number of parts.

All in all, it's just another laser cutter project!

-

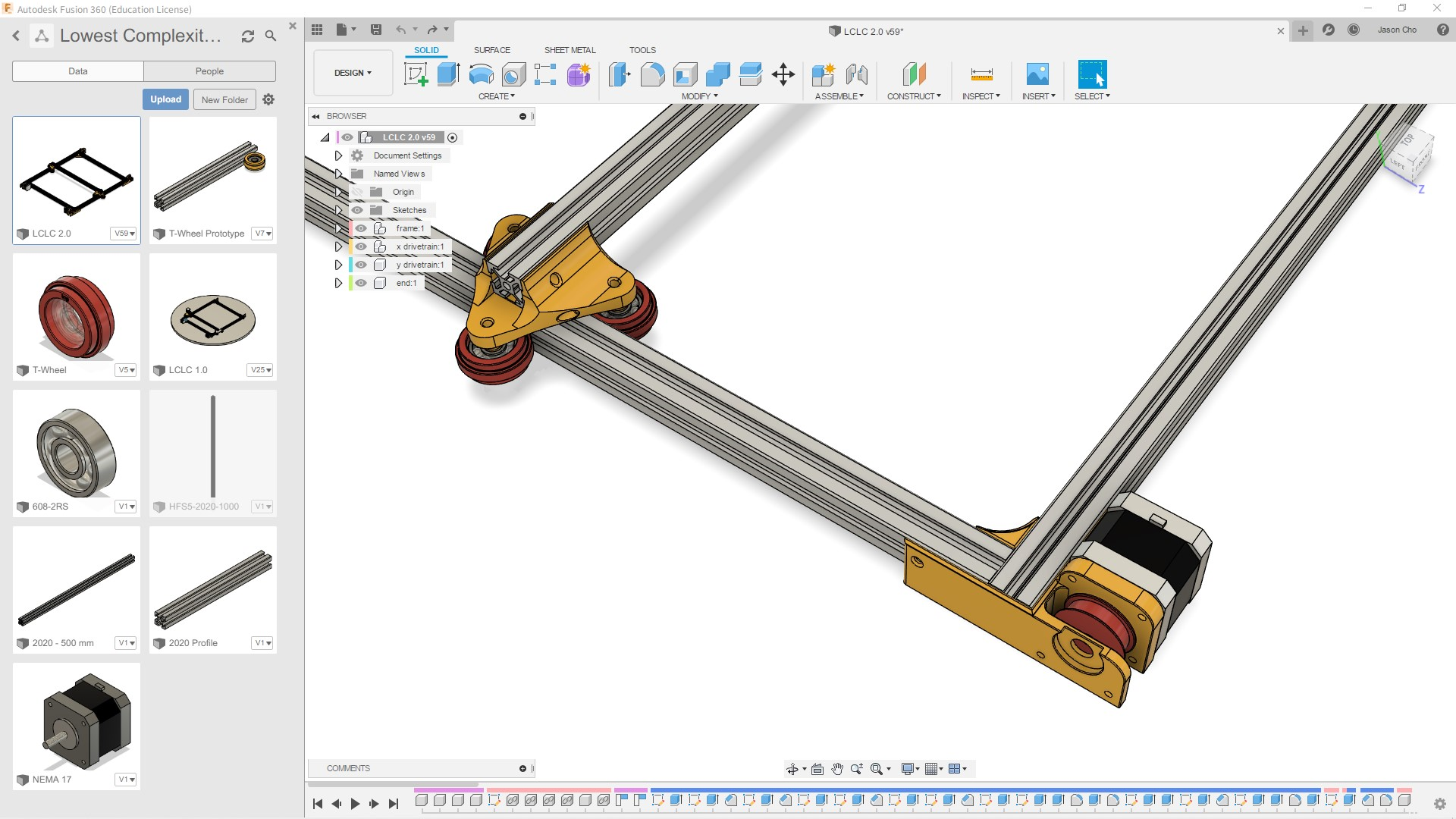

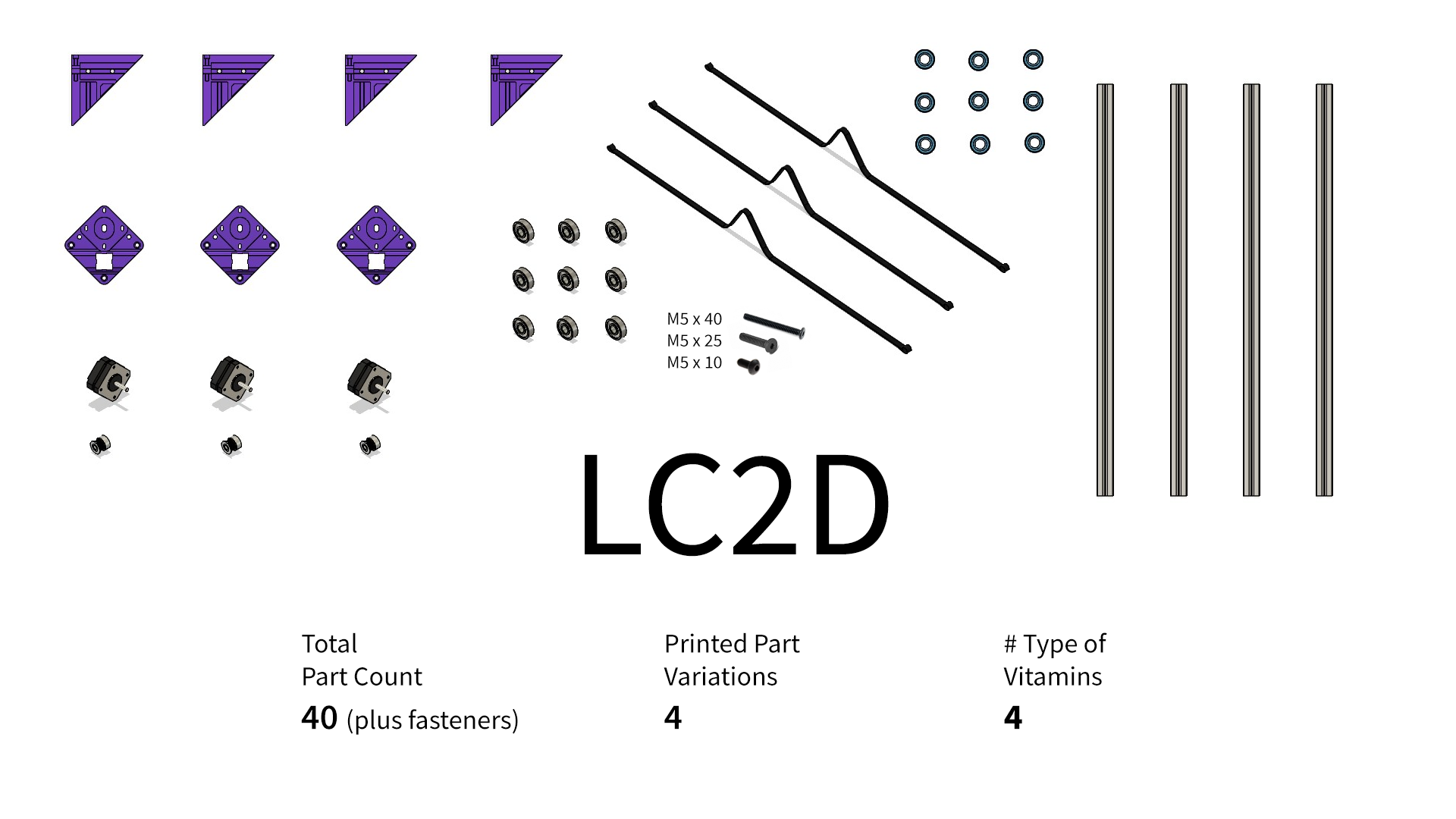

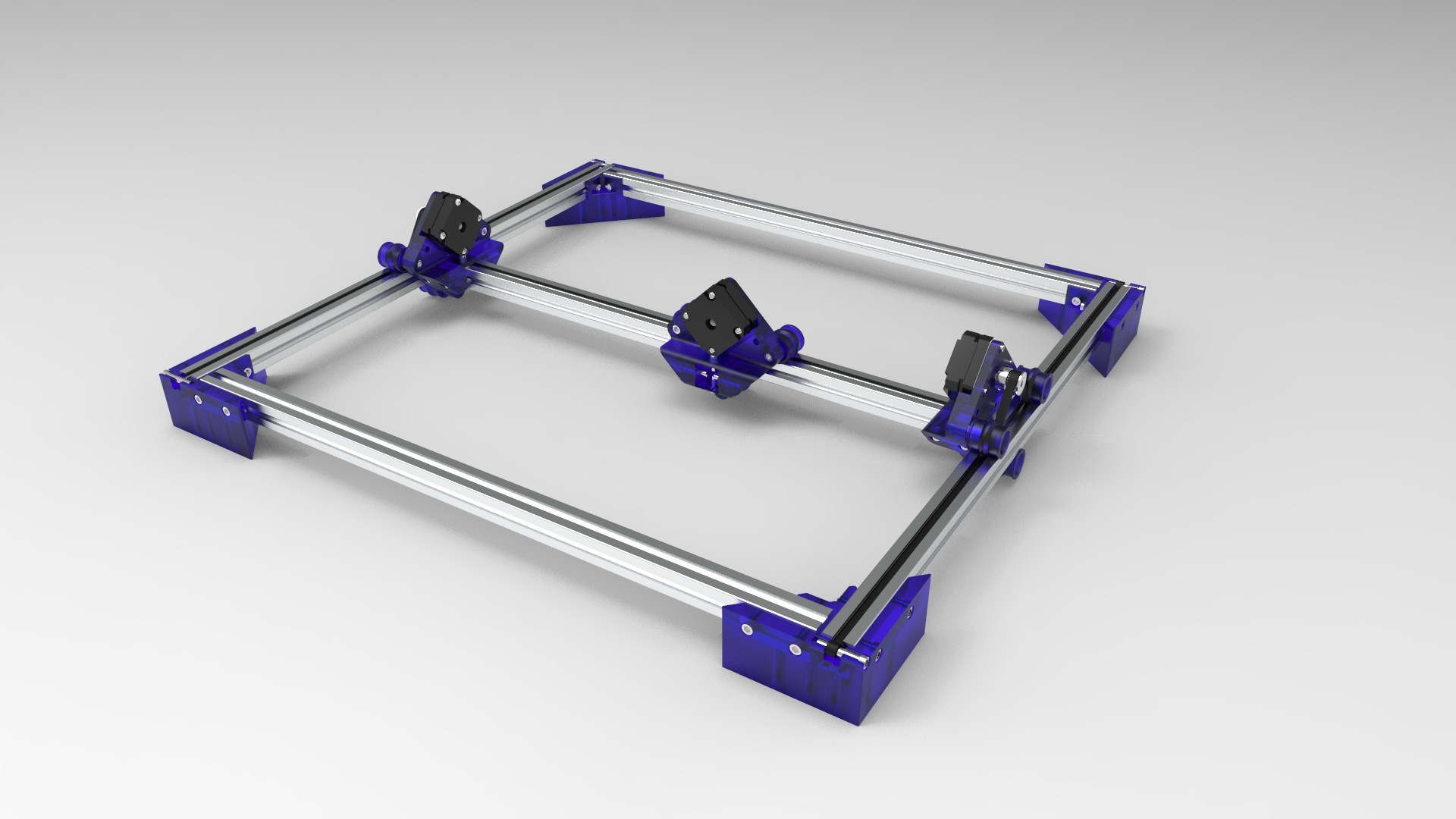

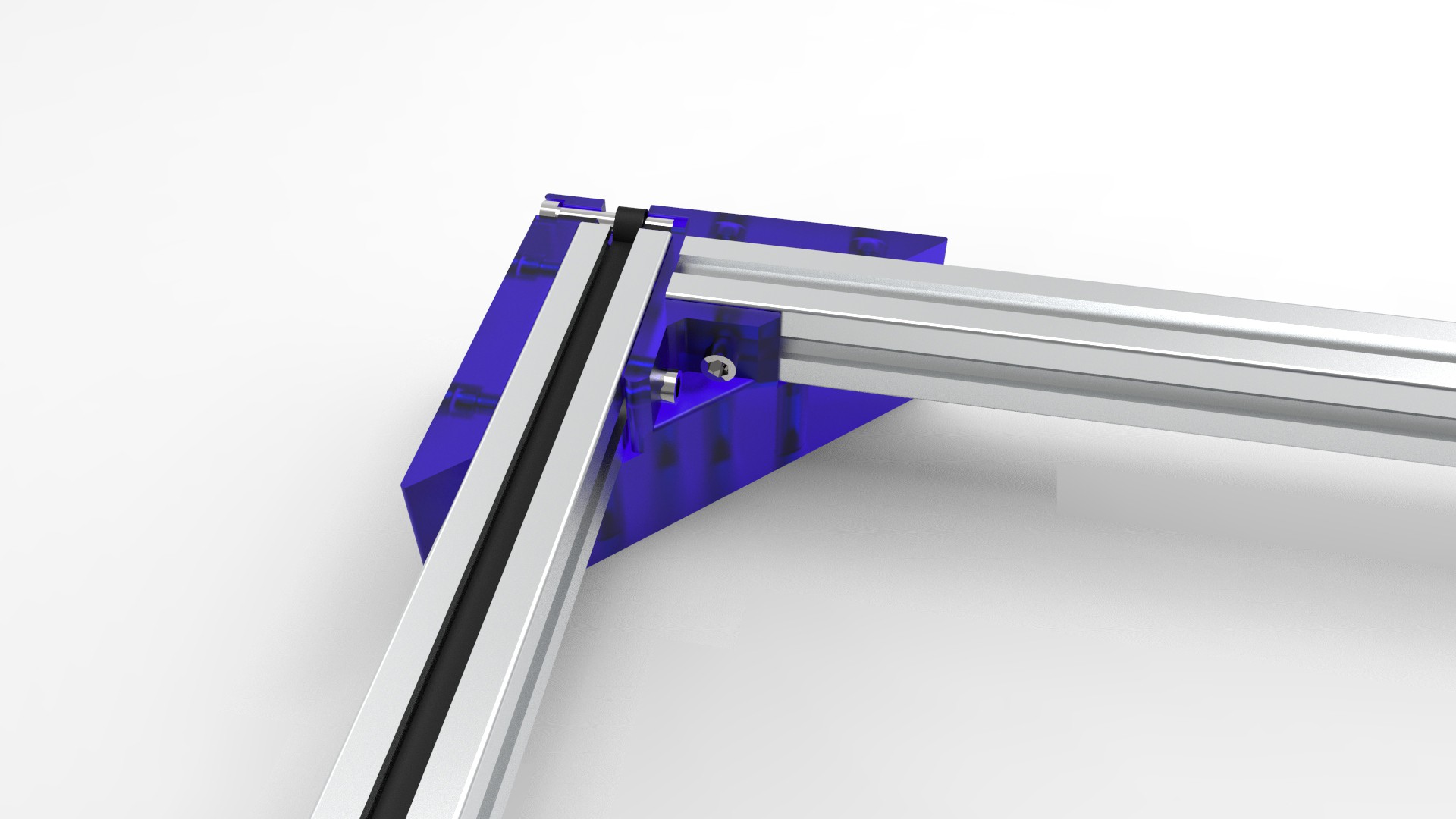

Design: LC2D

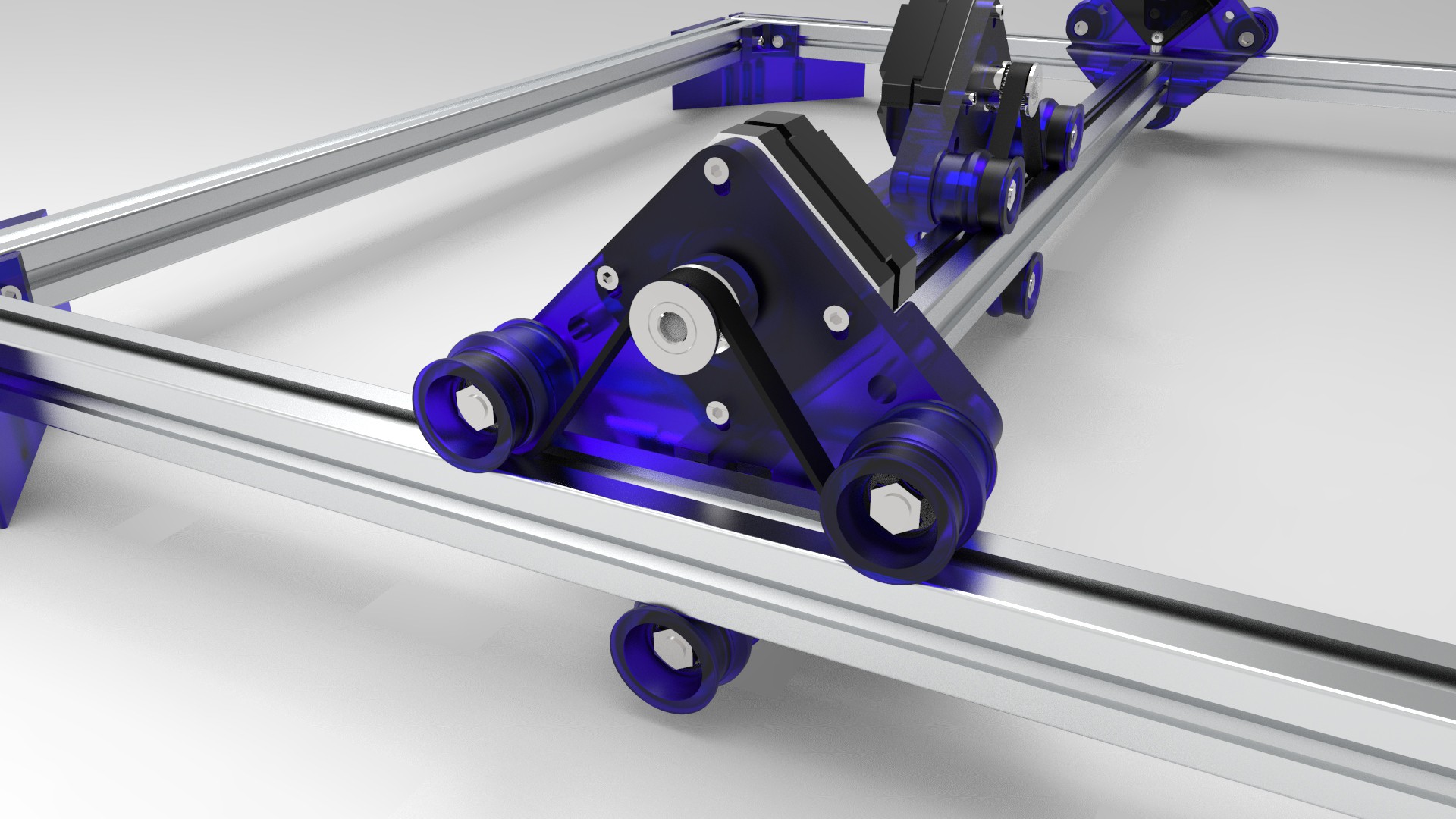

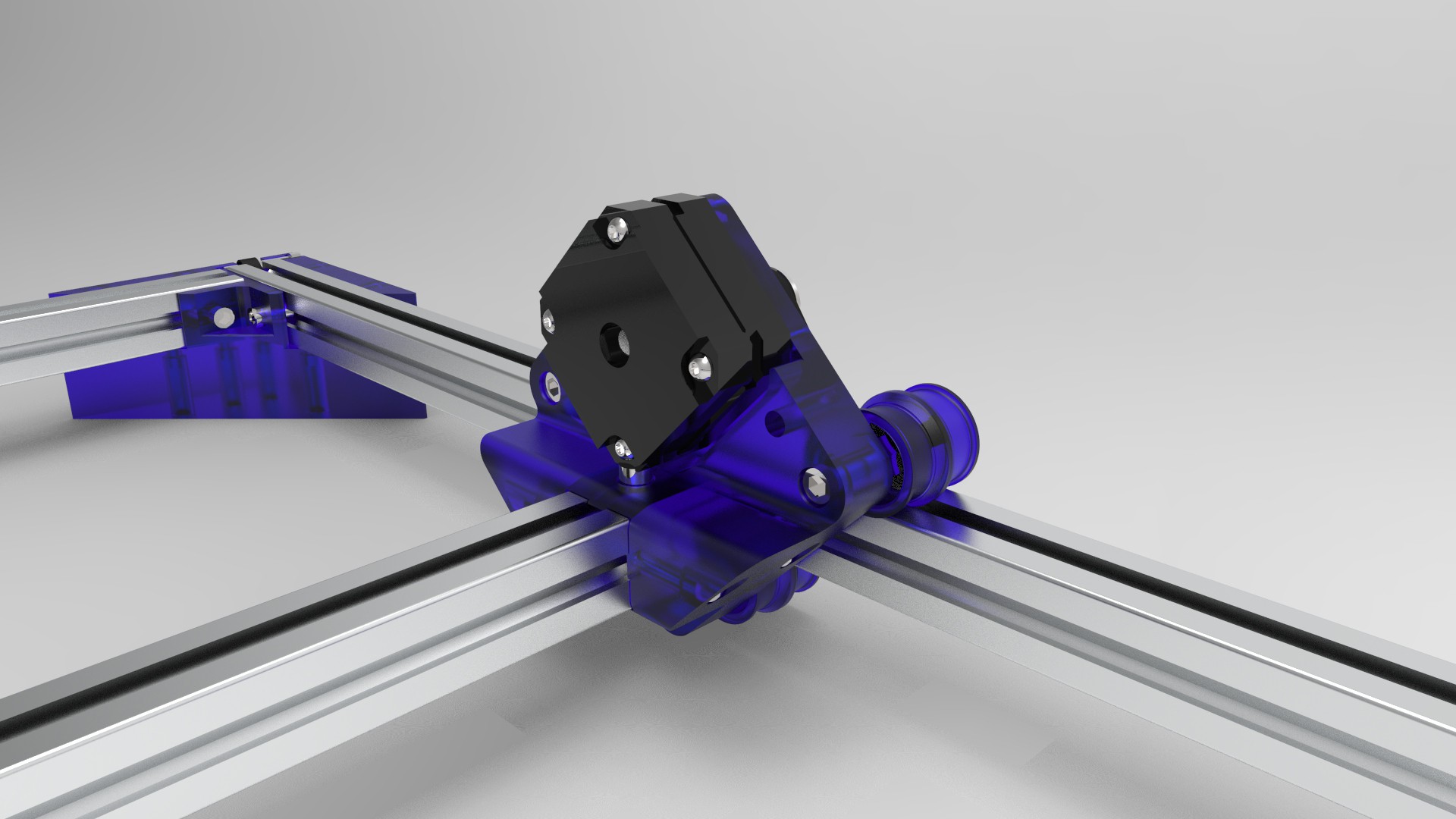

03/21/2020 at 16:20 • 0 commentsLC2D, or Lowest Complexity 2D Gantry, refers to the overall frame & drivetrain of LCLC, not including the laser part. You can use the gantry with other things like a whiteboard marker or a laser pointer (for long-exposure shots) or whatever else you want.

Design Intentions

- Minimal part count

- Minimal number of component variations

- Standardized/Unified "vitamins"

![https://cdn.hackaday.io/images/166001584811572829.png]() So far, it's a success.

So far, it's a success.Renders

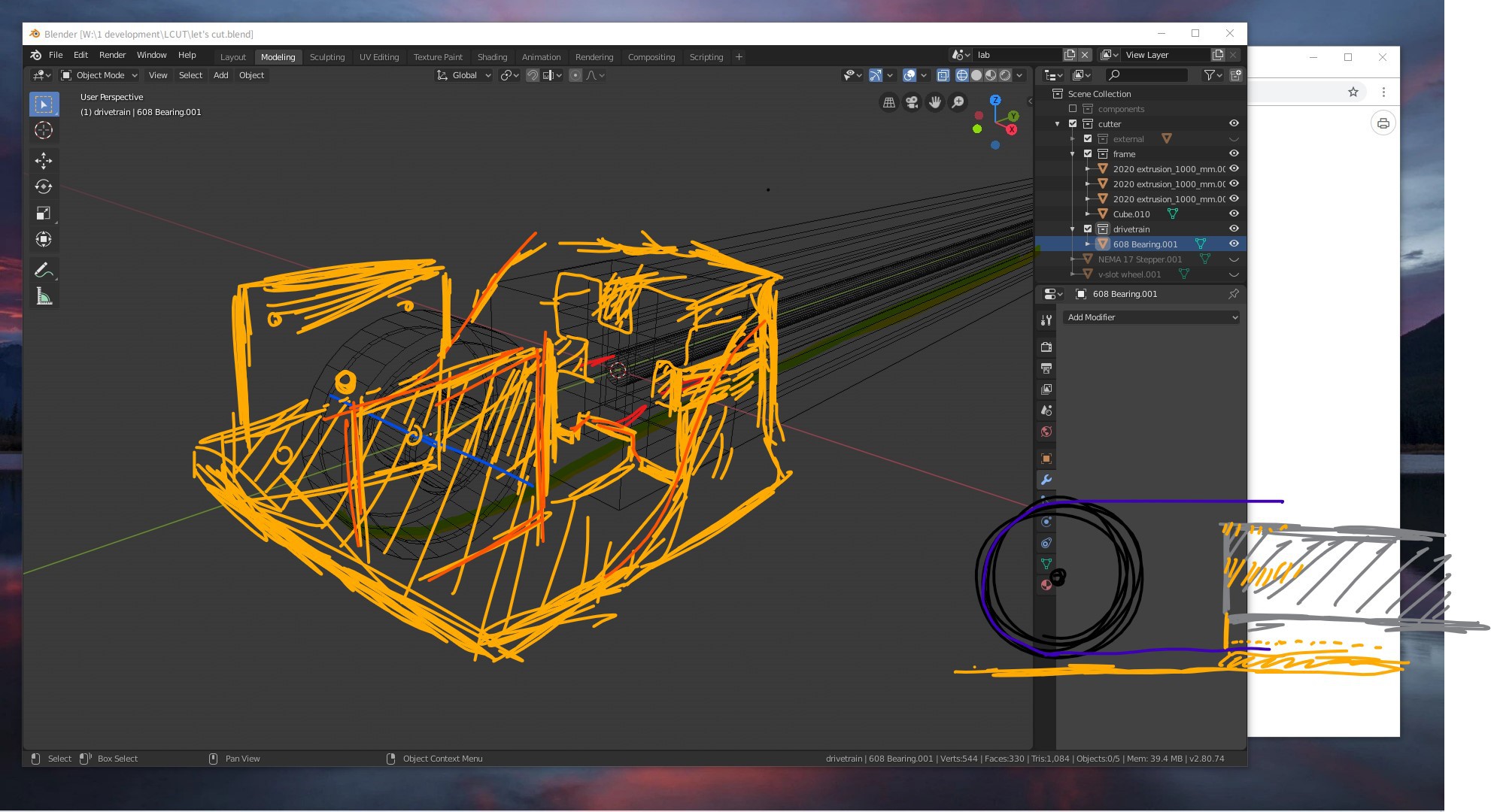

![]()

![]()

![]()

![https://cdn.hackaday.io/images/6629641584810103875.jpg]() Explore the design in here!

Explore the design in here!(You can download the model as well.)

-

Parts are in!

02/11/2020 at 01:38 • 0 commentsSpecifically, the 2020 extrusion from Misumi.

This was my first time ordering aluminum extrusions, and I know I didn't even do anything yet, but it just feels exciting looking at these. I feel so stupid.

-

Design Progress

02/11/2020 at 01:36 • 0 comments![]()

It feels like going very very slow.

I've seen these types of 2D CNC gantries built up in a matter of hours in makerspaces.

Oops, I guess I'm obsessing too much with optimization... And even then it's not that optimized either.

-

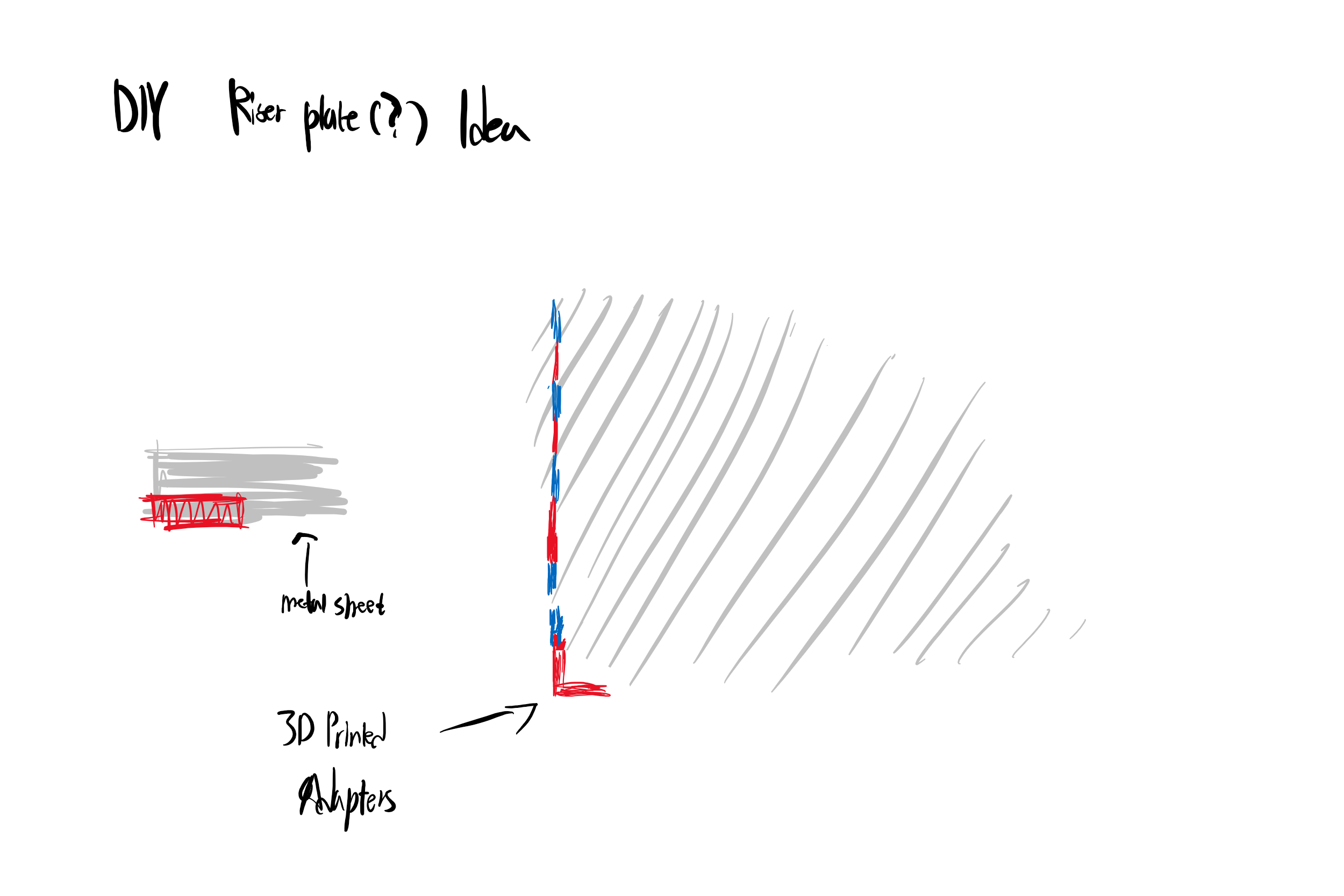

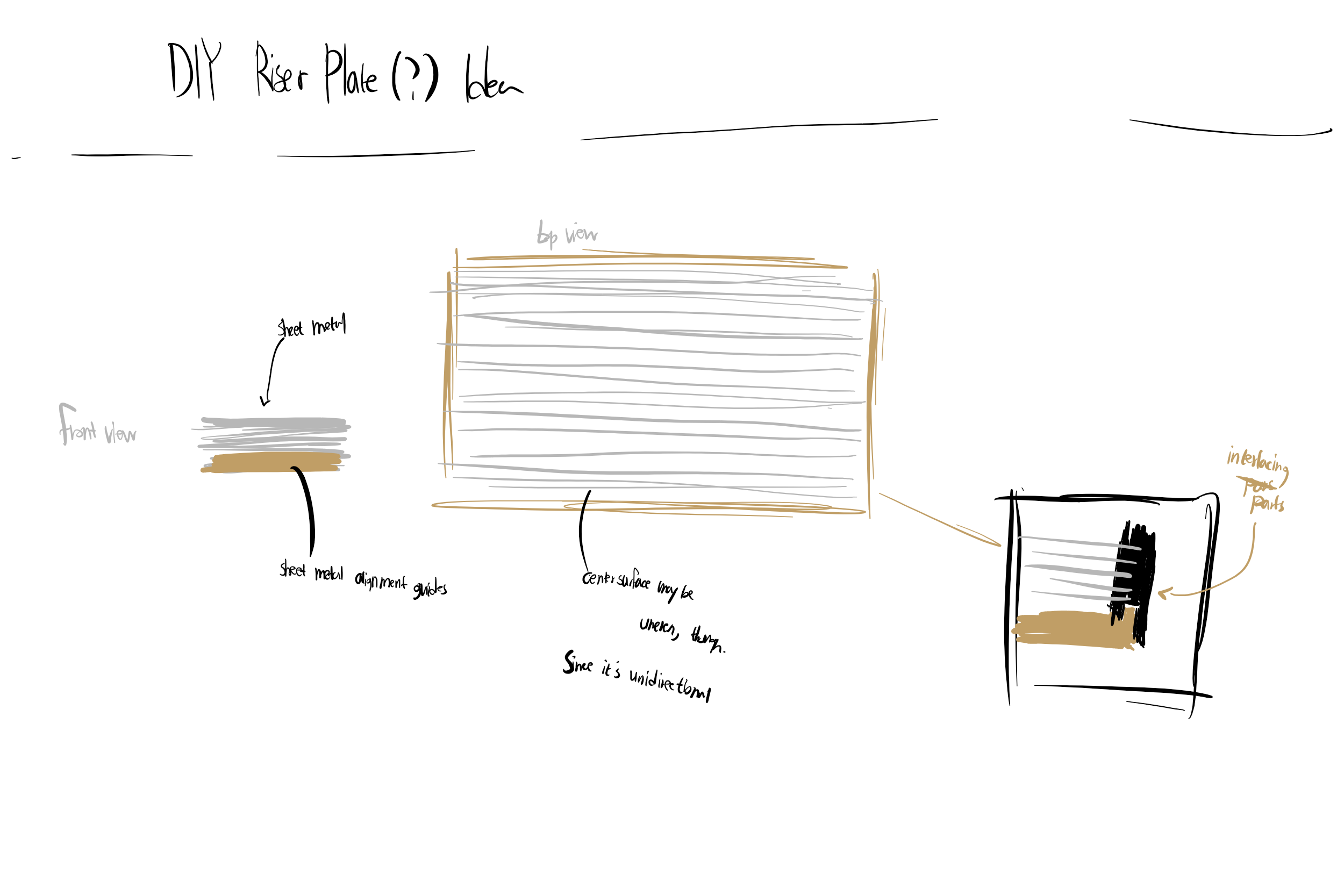

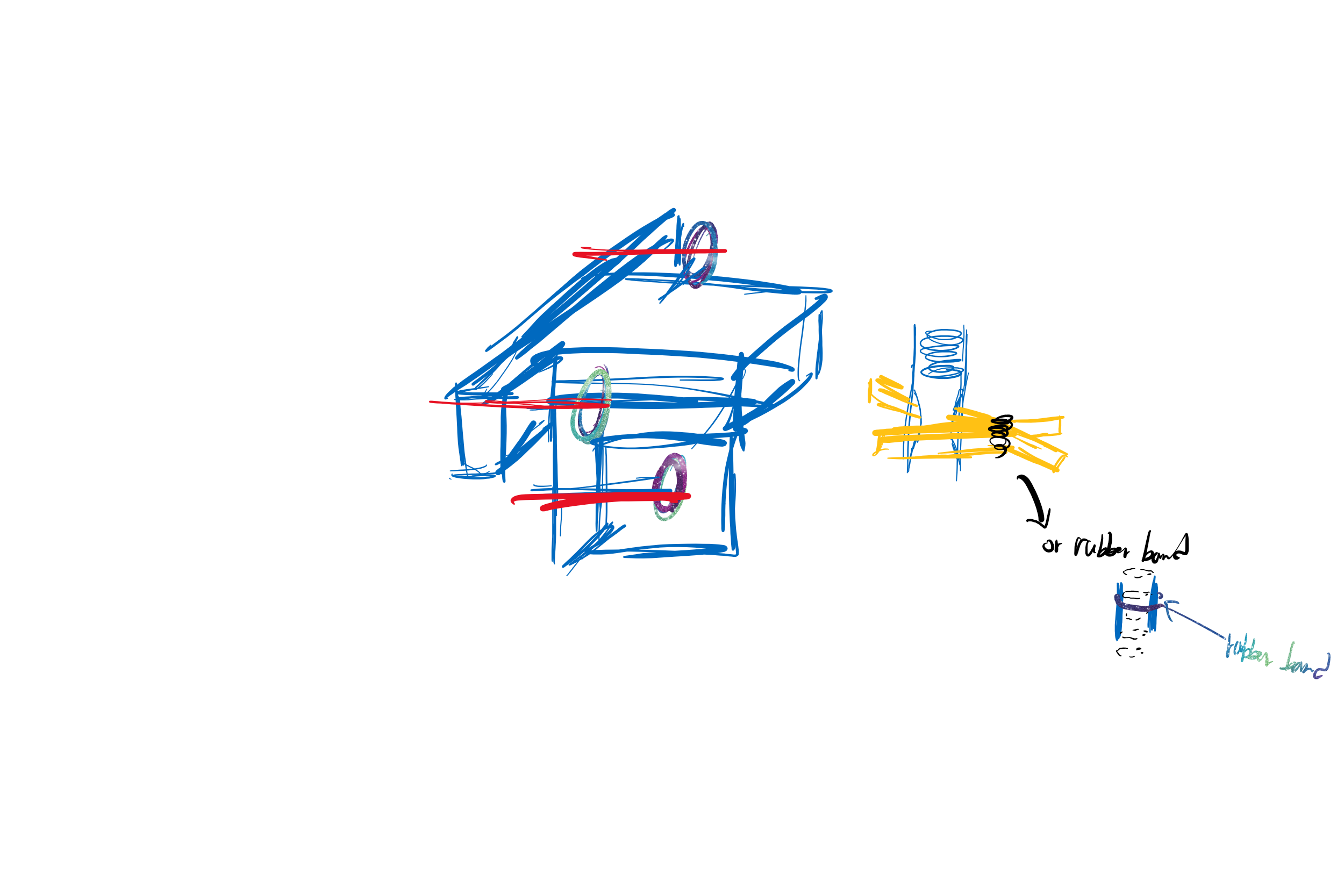

DIY Riser Plate (???) Proposal

01/14/2020 at 00:33 • 0 comments![]()

![]()

It's said that a picture is worth a thousands words, but I am sure my sketches' worth are more like five to six (in an optimistic measure).Anyway, I have been having difficulties thinking about the bottom surface of LCLC.

![]()

See those diamond-shaped grill/web on the bottom? That is the protective piece (I could not find what that is called!), securely holding the workpiece while minimizing any damage from the laser, usually by having a low normal-surface area and offsetting the workpiece from the laser cutter.

Many printers make use of that metal web design, although the (glass) fiber lasers I have seen had triangular spikes holding the piece.

Because the core concept of LCLC is minimizing the scale of the design by having all the parts pinned down on a (wooden) frame, like how Sienci Labs' LongMill) a big conflict was kind of inevitable, especially because I couldn't find the things being sold online.

Constructing these things would be hard as well, since there would need to be cutouts for every intersecting spot on each fin.

However, if the metal fins are unidirectional and have no crossing, it should be easy to construct.

Also, a simple guide with cutouts to align the fins should make it easy to attach it to LCLC.

So that's the idea.

Typing this, I realized that a barbecue grill would prove itself to function well too. We'll have to see.

-

Just Sketches

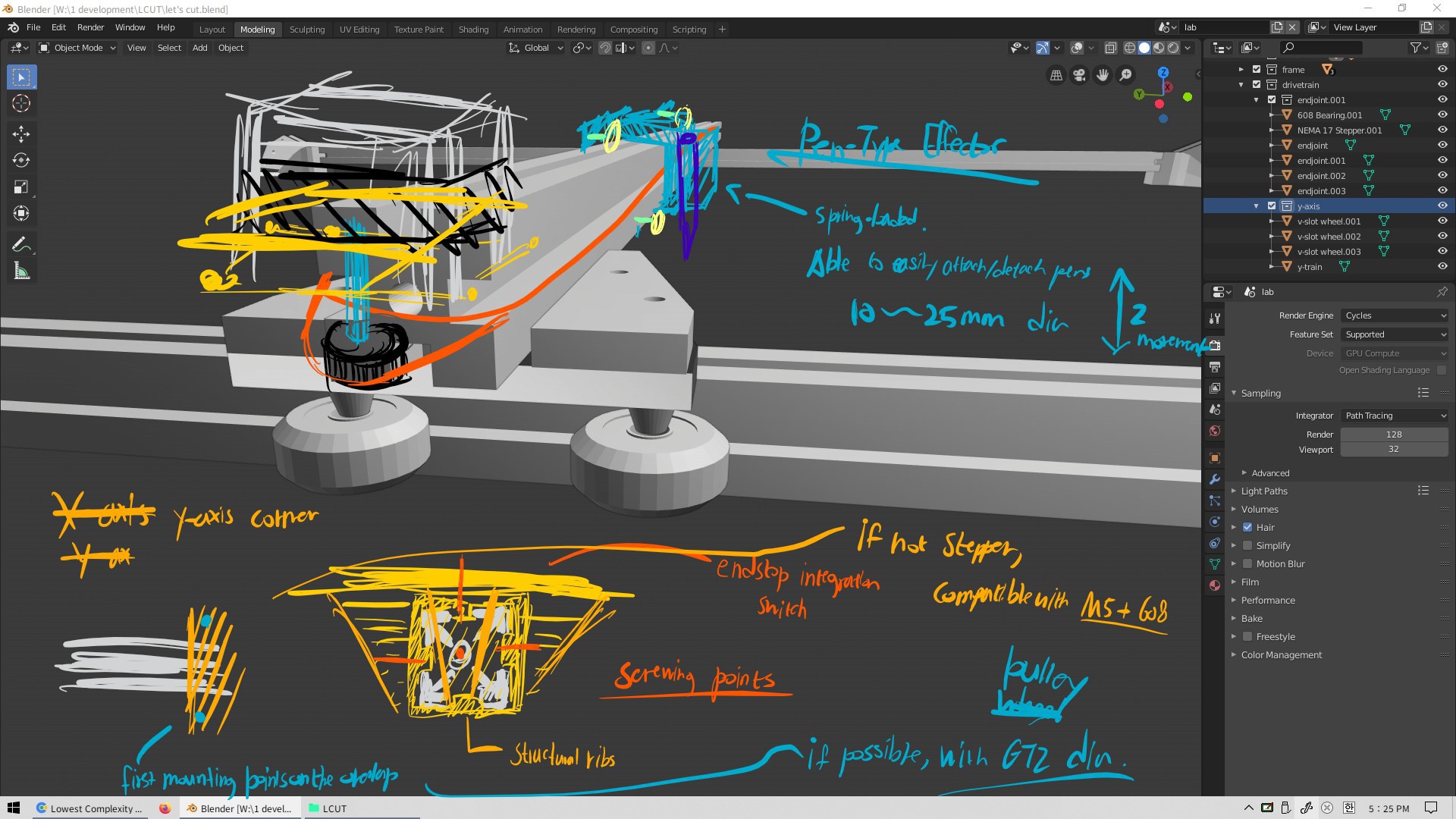

01/14/2020 at 00:22 • 0 commentsI am currently a little bit obsessed with making the construction as simple as possible.

I figured to draw up some sketches and plan out how the parts and functions will be like.

![]()

This is the sketch for the corner bracket(???) thing at the four corners, used to pin down the extrusion into a frame as well as supporting the GT2 idler wheel or pulley (attached with NEMA 17 steppers).

The drawing quality is obviously not that good, and I forgot to include a hole for the GT2 belt to move through. More on this later.

![]()

This is the brainstorming sheet to see how the y-axis (second layer axis? with one rail instead of two) end brackets as well as the effector would look like.

![]()

This is a very bad sketch for the end effector. As you would notice, it's called a pen effector. It's going to hold a pen.

I was inspired by the ODrive demo video drawing the cool pattern, and I think there would be lots of things I could achieve with a pen and paper, especially in school with my math and science teachers.

Some ideas are:

- Drawing mathematical curves (maybe fractals)

- Drawing big graphs, just for fun

- Holding a laser pointer for cool long-exposure shots (long exposure drawings)

Jason Cho

Jason Cho

So far, it's a success.

So far, it's a success.

Explore the design in

Explore the design in