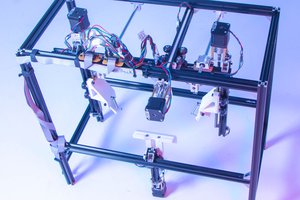

The actuator consists of both bought mechanics and 3D printed parts - printed at 0.2mm layer in PLA with 40% infill. Tested to be strong enough to not break under loads of 12 kg. I haven't really made other high load tests other than lifting the 12 kg NEMA 42 shown in the video - so it may be capable of more. However, 3D printed parts also have their limitations ;)

I have made the design in Fusion 360 and made available both the STEP models and STL packages for both the M8 and the T8x8 version of the beast on GitHub !

M8 vs T8x8 speed

A short video showing the difference in speed for the two versions is given here. The steppers are running at the same speed so it's simply because of the lead screw.

Assembly manual

To get some training in Fusion 360 and since I just think it's easier I made assembly manuals based on renderings which are also available on GitHub...

Second iteration

This design is my second iteration on it and there might come more iterations if I find something that I believe should be changed...

Relation to uStepper

To be clear I will just add a note here that the uStepper and Shield I use here in the video and in my instructions are there because I am one of the creators of uStepper. But for this project it's irrelevant since the actuator is not dependent on the uStepper and can be used with any type of stepper motor controller.

Fabian

Fabian

Enrico

Enrico

Sam Baker

Sam Baker

These have a really nice appearance that just looks professional. Nice job!