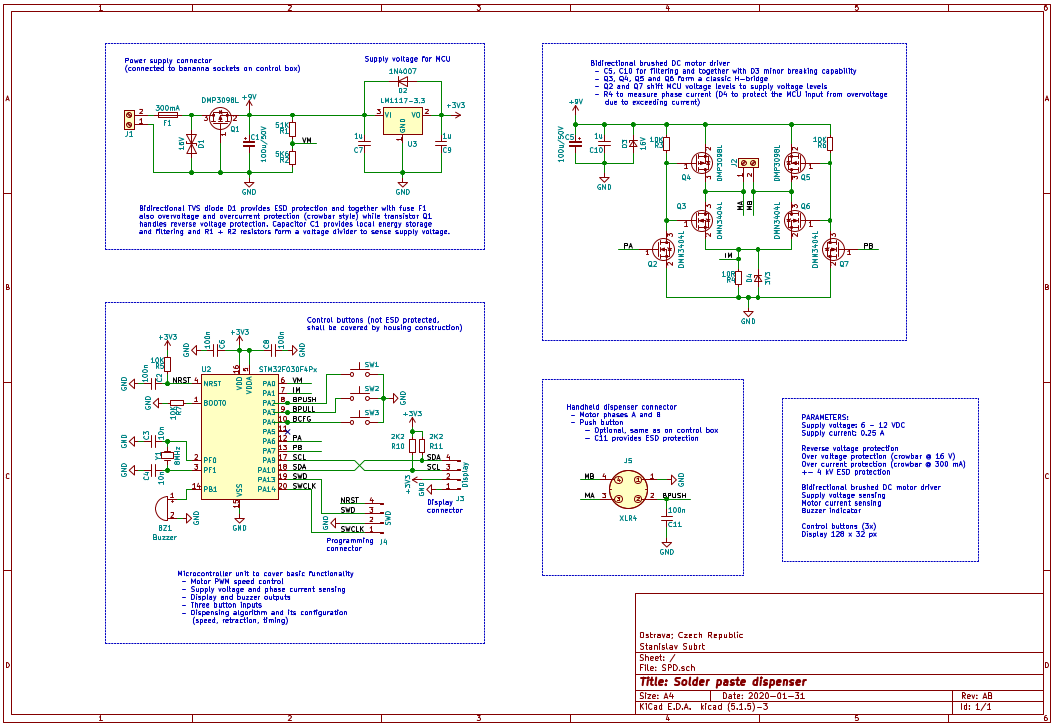

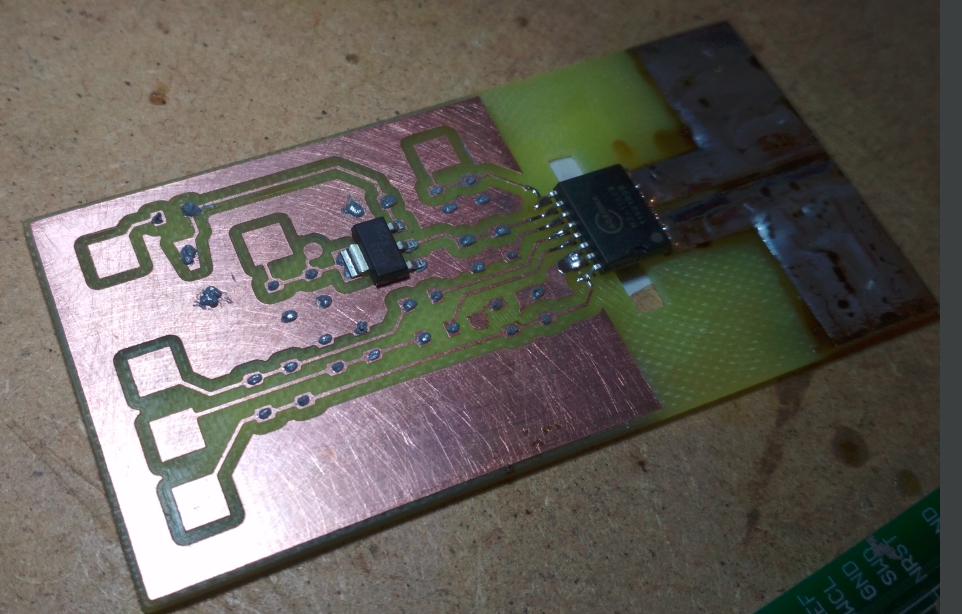

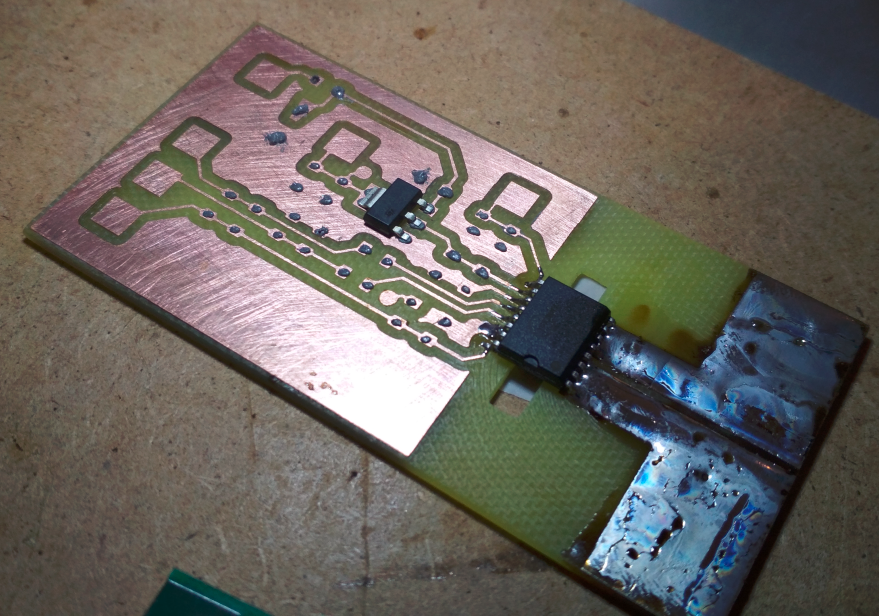

MCU module with 3V3 regulator is bought from ebay, H-bridge and supply protection circuitry is hand soldered on piece of prototype PCB. Layout has not been created.

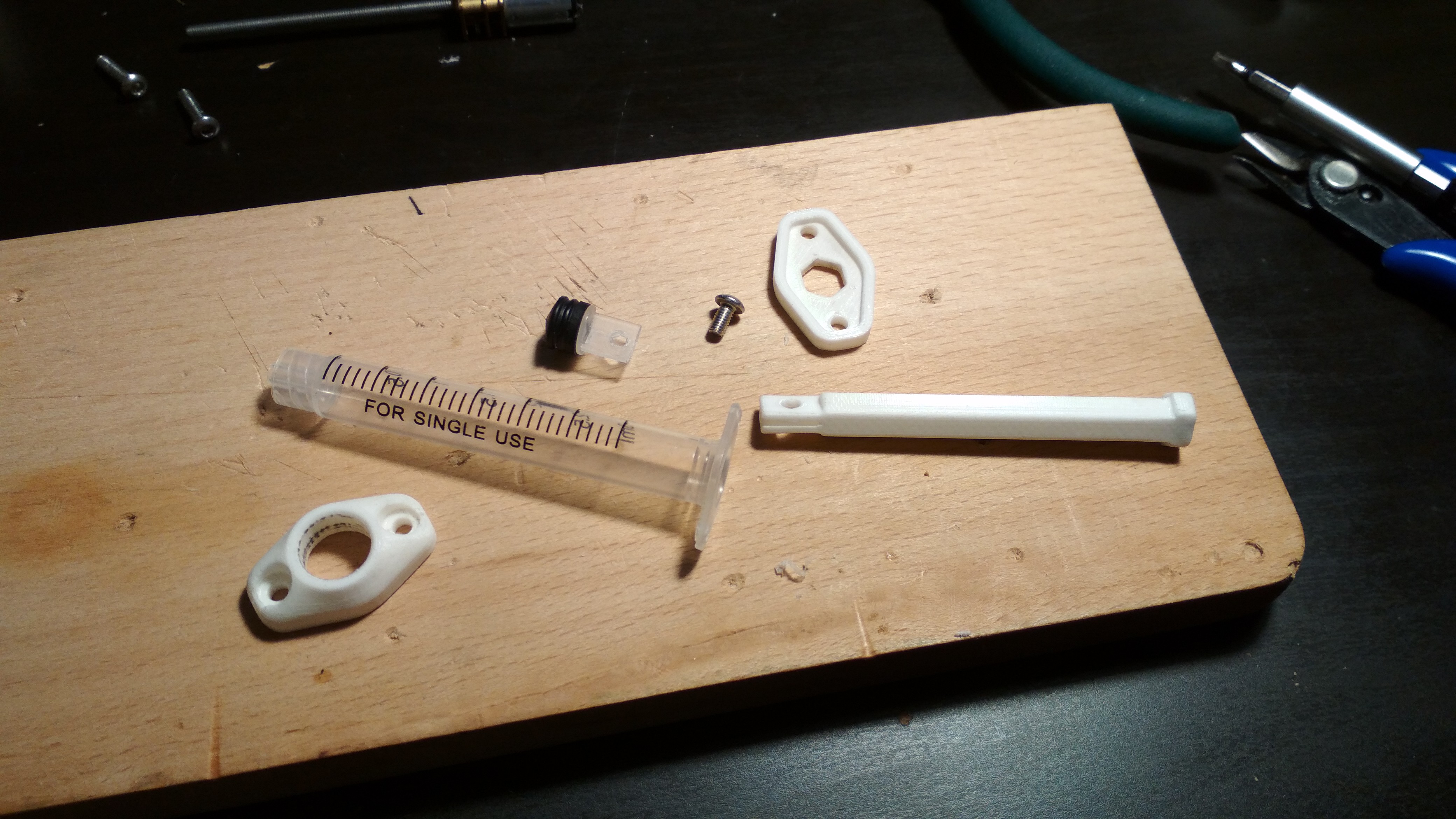

Low cost solder paste dispenser

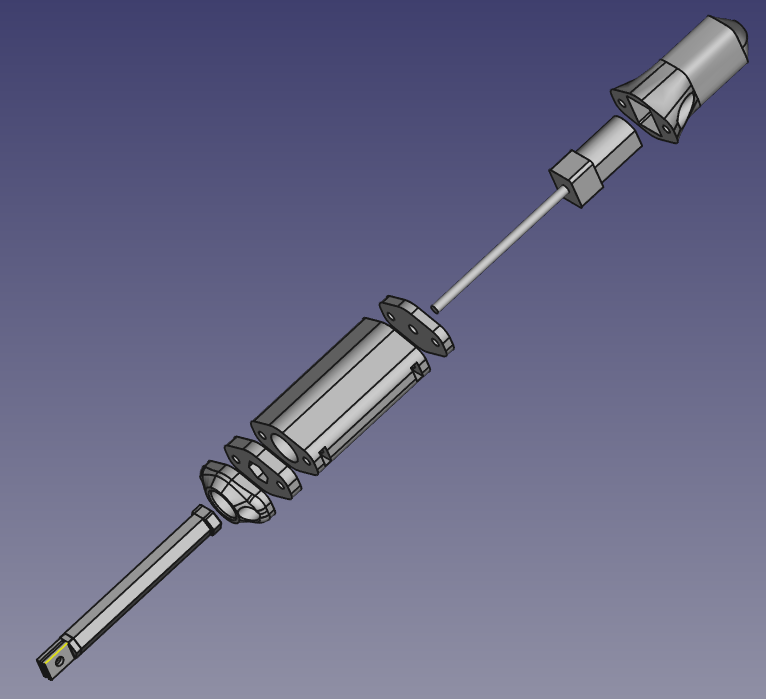

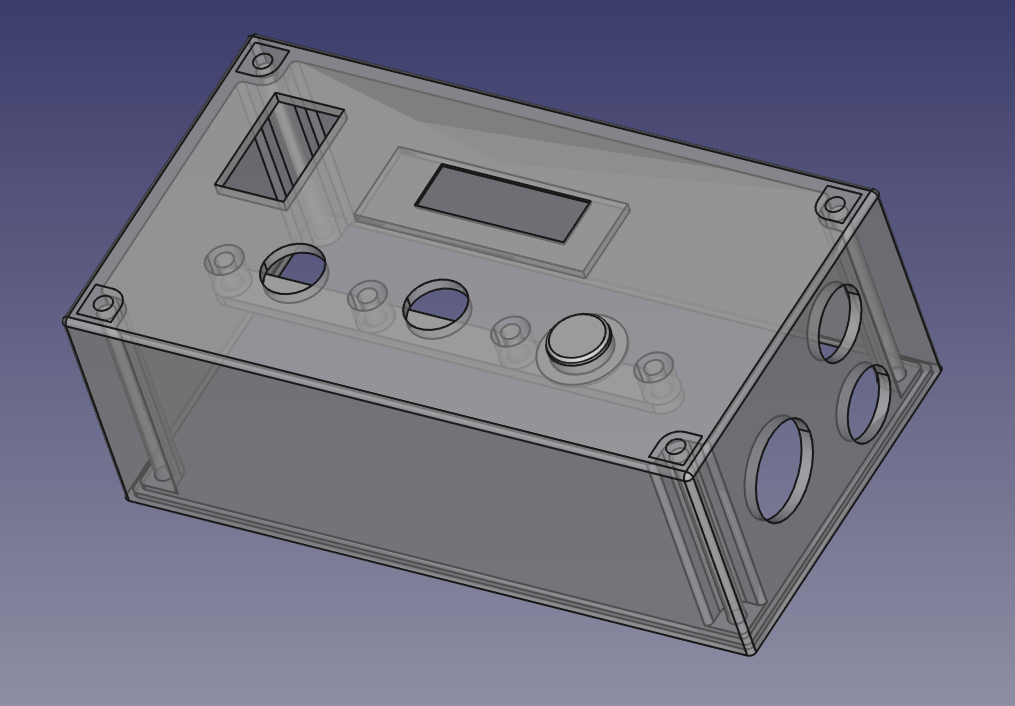

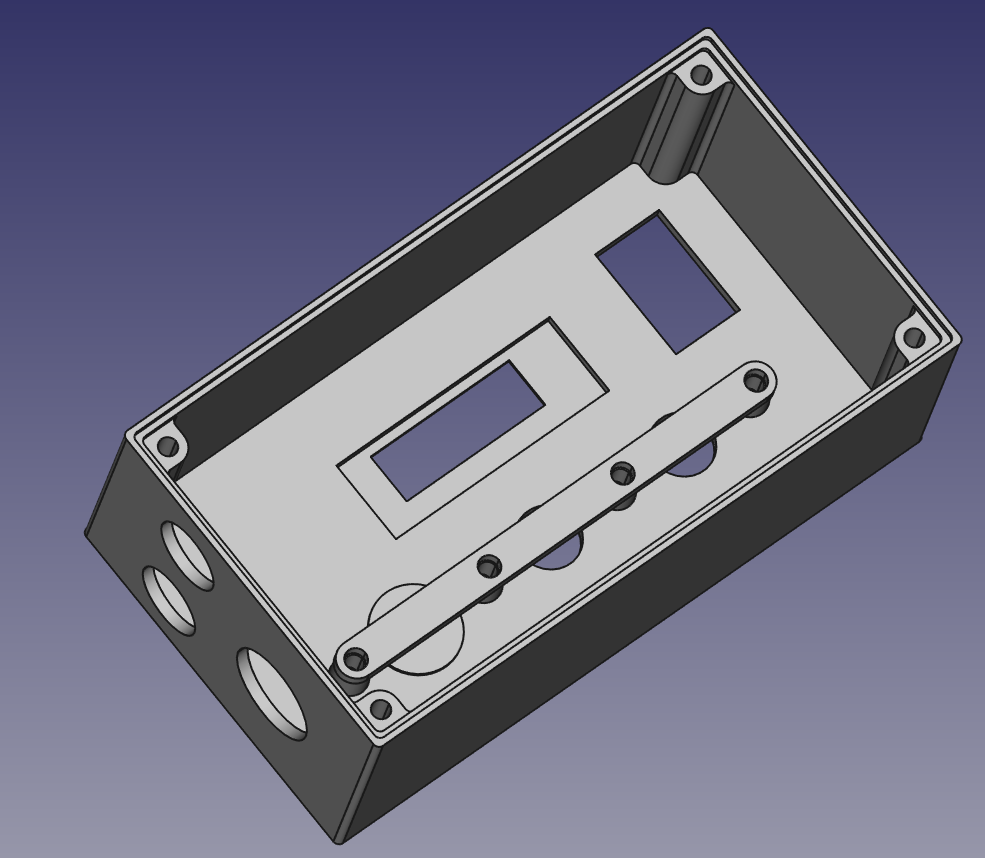

Easy to build but very capable and handy DIY solder paste dispenser built mostly from cheap Ebay components and modules.

kevarek

kevarek

Configuration of push speed

Configuration of push speed and configuration of retraction duration:

and configuration of retraction duration:

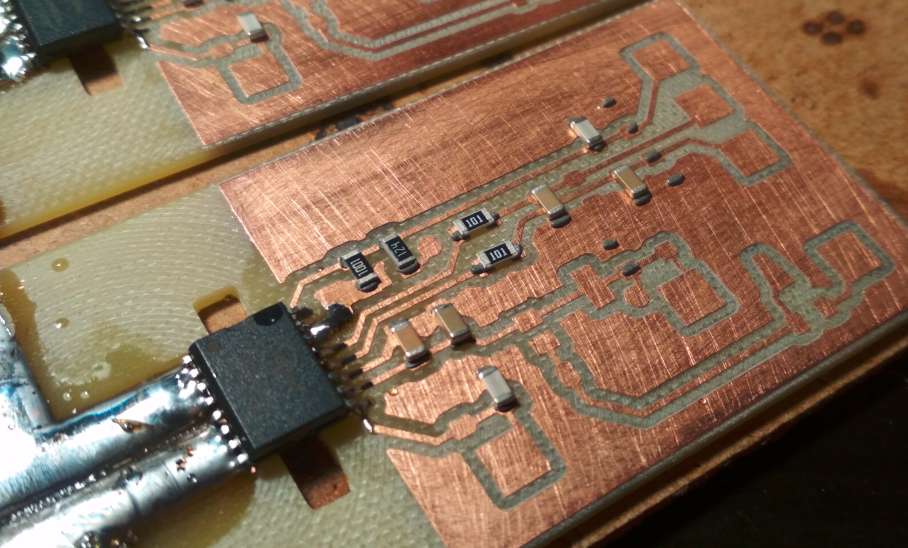

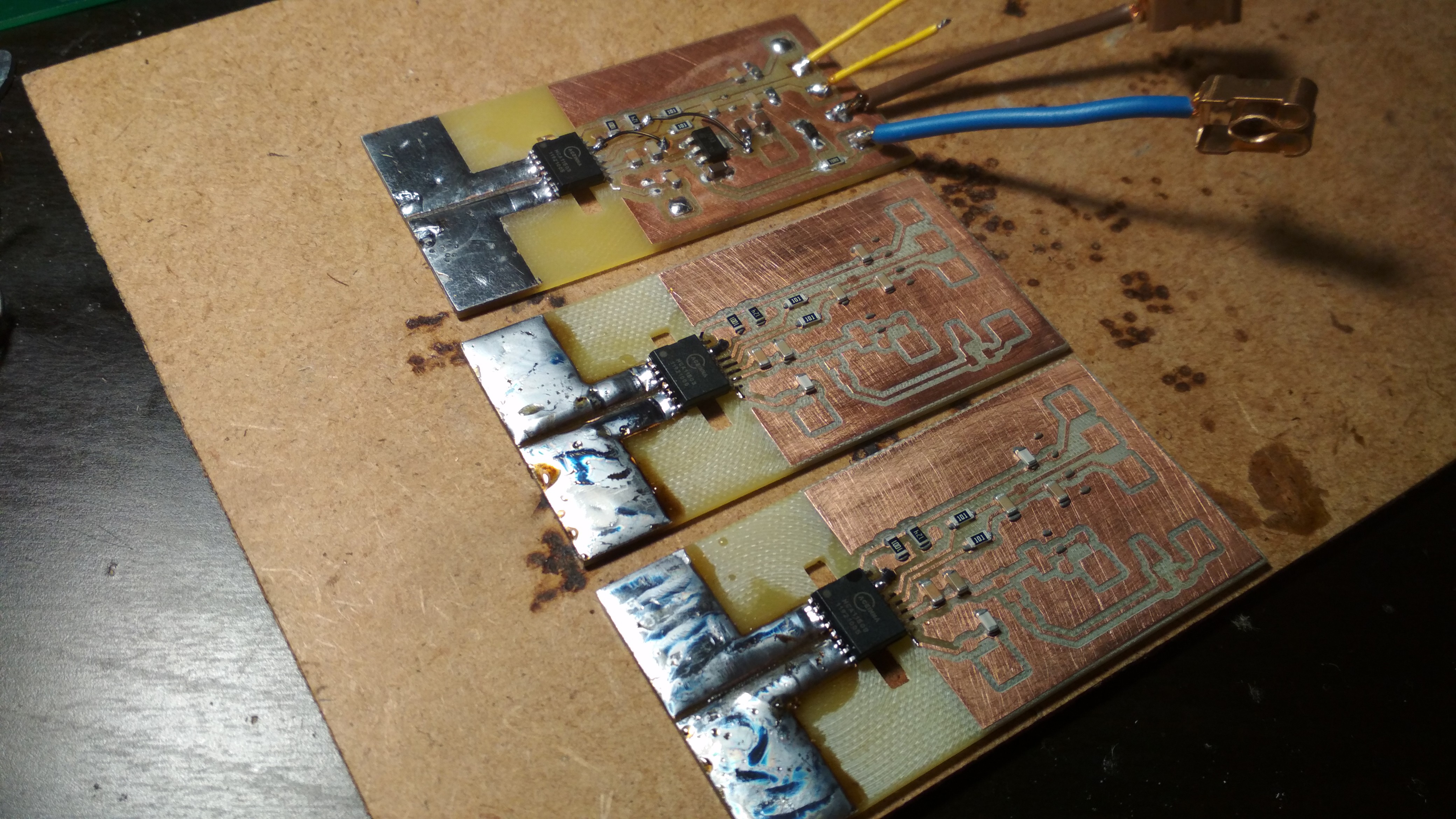

Im very satisfied with the result - the whole process of soldering with solder paste needs a bit of practice but it makes the PCB assembly much more efficient than with solder wire.

Im very satisfied with the result - the whole process of soldering with solder paste needs a bit of practice but it makes the PCB assembly much more efficient than with solder wire.

How can I load the firmware onto the STM32?