350KG RC TANK - PROGRAM : CHAROGNARD

Design and construction of a 350KG (700lbs) RC TANK, from scratch

Design and construction of a 350KG (700lbs) RC TANK, from scratch

To make the experience fit your profile, pick a username and tell us what interests you.

We found and based on your interests.

I wanted to use an IC engine as main power source from the very begining.

I chose a 196cc 4 800W (6.5hp) 4 stroke engine. It includes both manual and electric start. The engine is equipped with a centrifugal clutch, which simplifies my work a lot. It is a "LIFAN 168F-2D-B" engine.

VIDEO

TO BE CONTINUED....

I will be using the torsion bar concept : This is a very compact and low maintainance suspension system.

I wil try to make an adjustable system, since I don't know the exact weight of the finished tank. It can also be useful to modify the initial strain to change the suspension behaviour if needed.

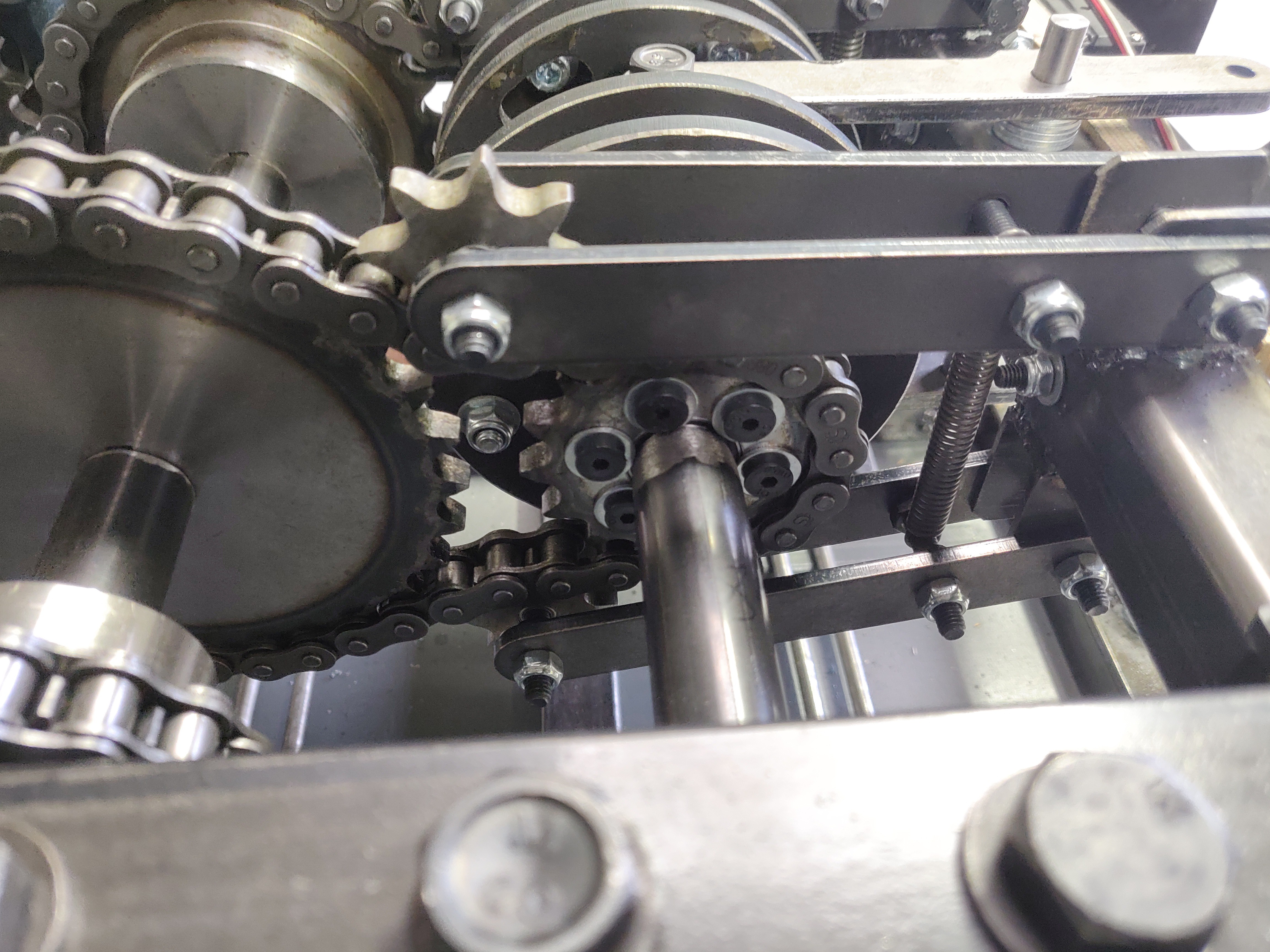

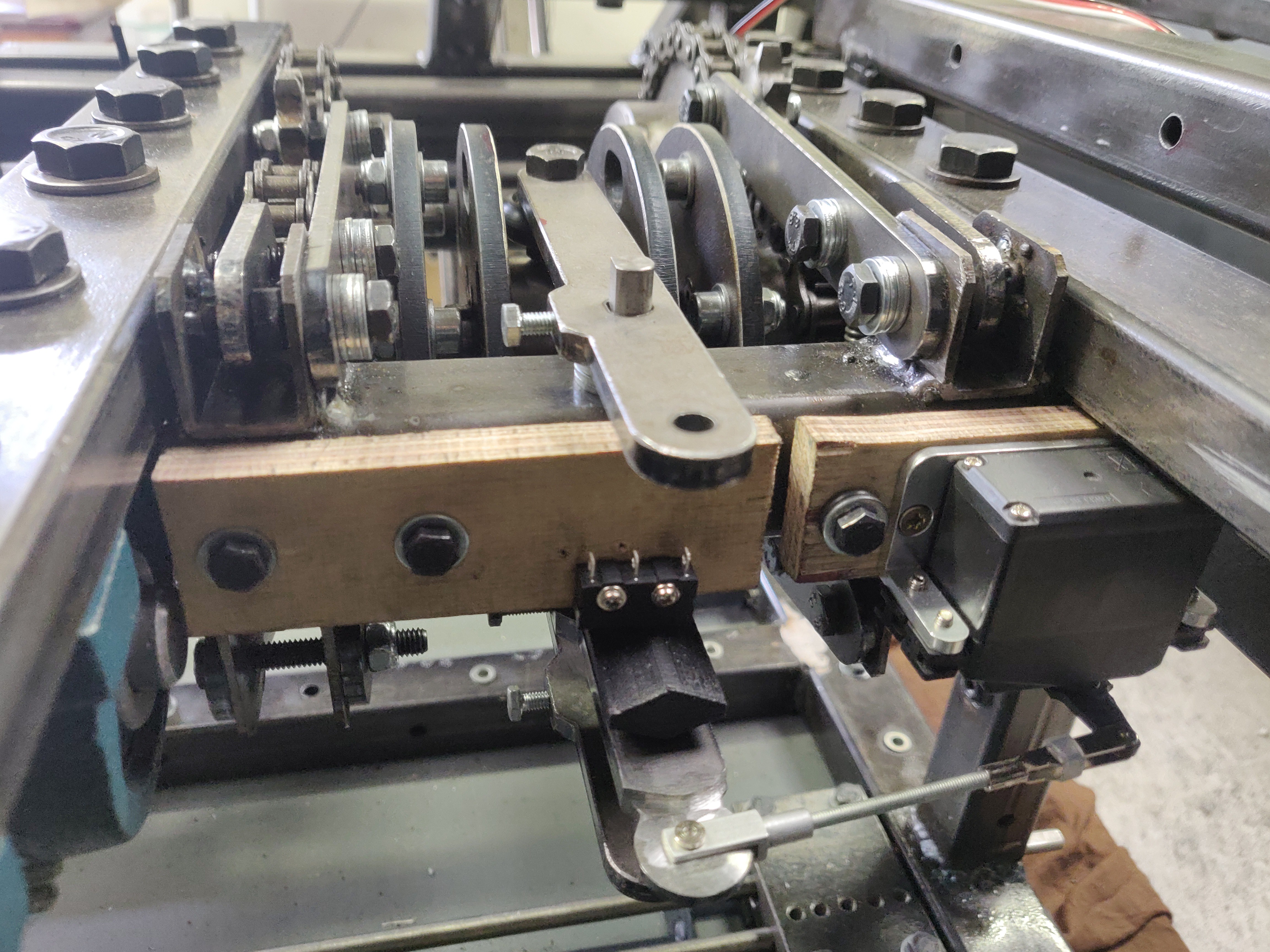

Since I was going to face major problems with the Mk1 gearbox, I anticipated the construction of Mk2, featuring :

-Sprocket tensioners

-Full metal shifting forks

-Additional shaft, allowing to dismount the gearbox more easily.

It features 4 reversible gears.

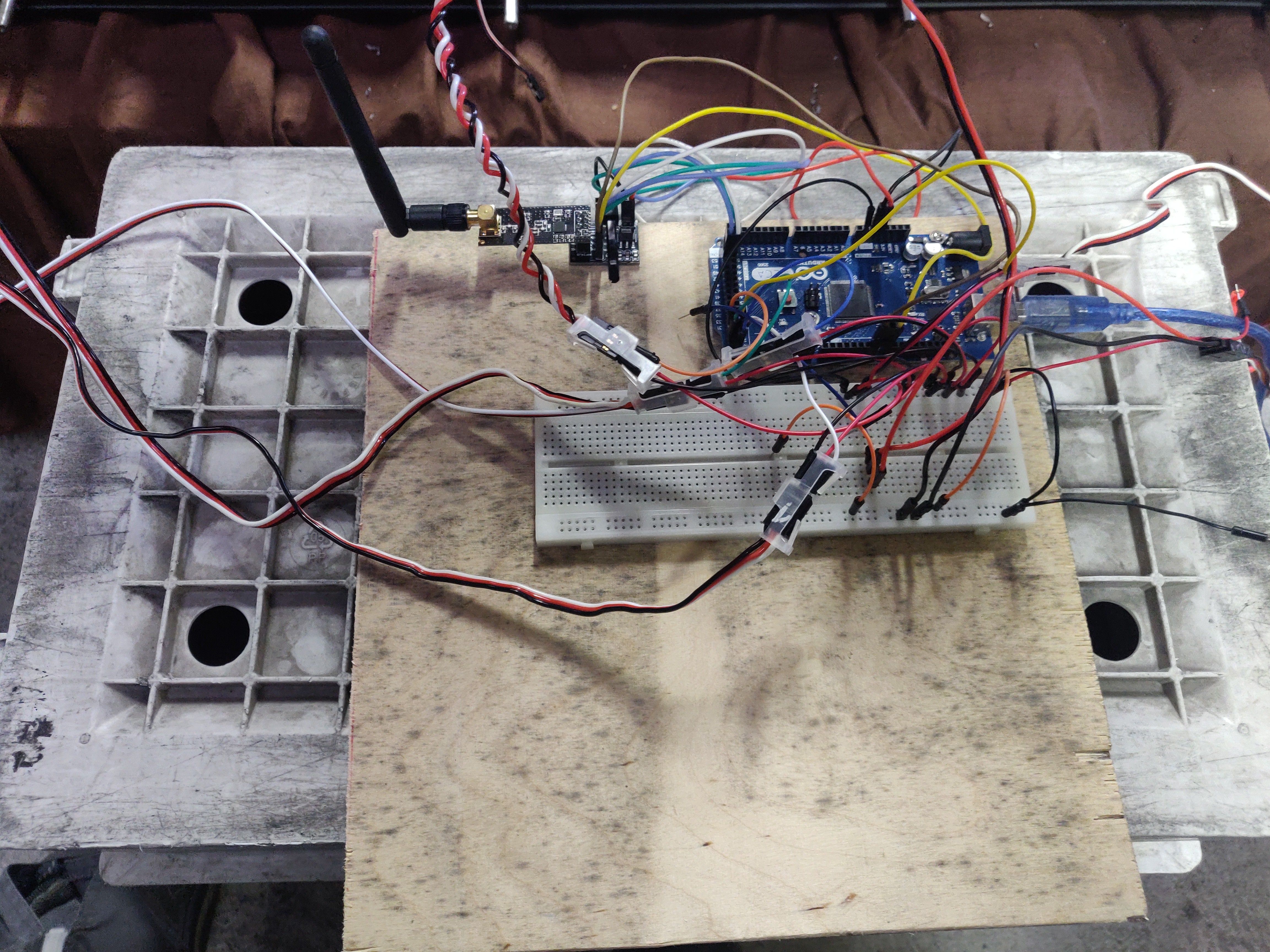

There are no synchronizers, jus basic dog clutches. The dog clutches are motioned by 9kg RC servos, from an arduino.

It is a semi-automated gearbox : when pushing "shift up" or "shift down", the algorithm does all the necessary steps to change gear.

It is a semi-intelligent gearbox that detects when errors occure (e.g. blocked mechanism) and acts accordingly.

The first trial turned to be pretty succesful and quite promissing :

Cfqdfdqfgf

ALL WE HEAR IS RADIO GAGA

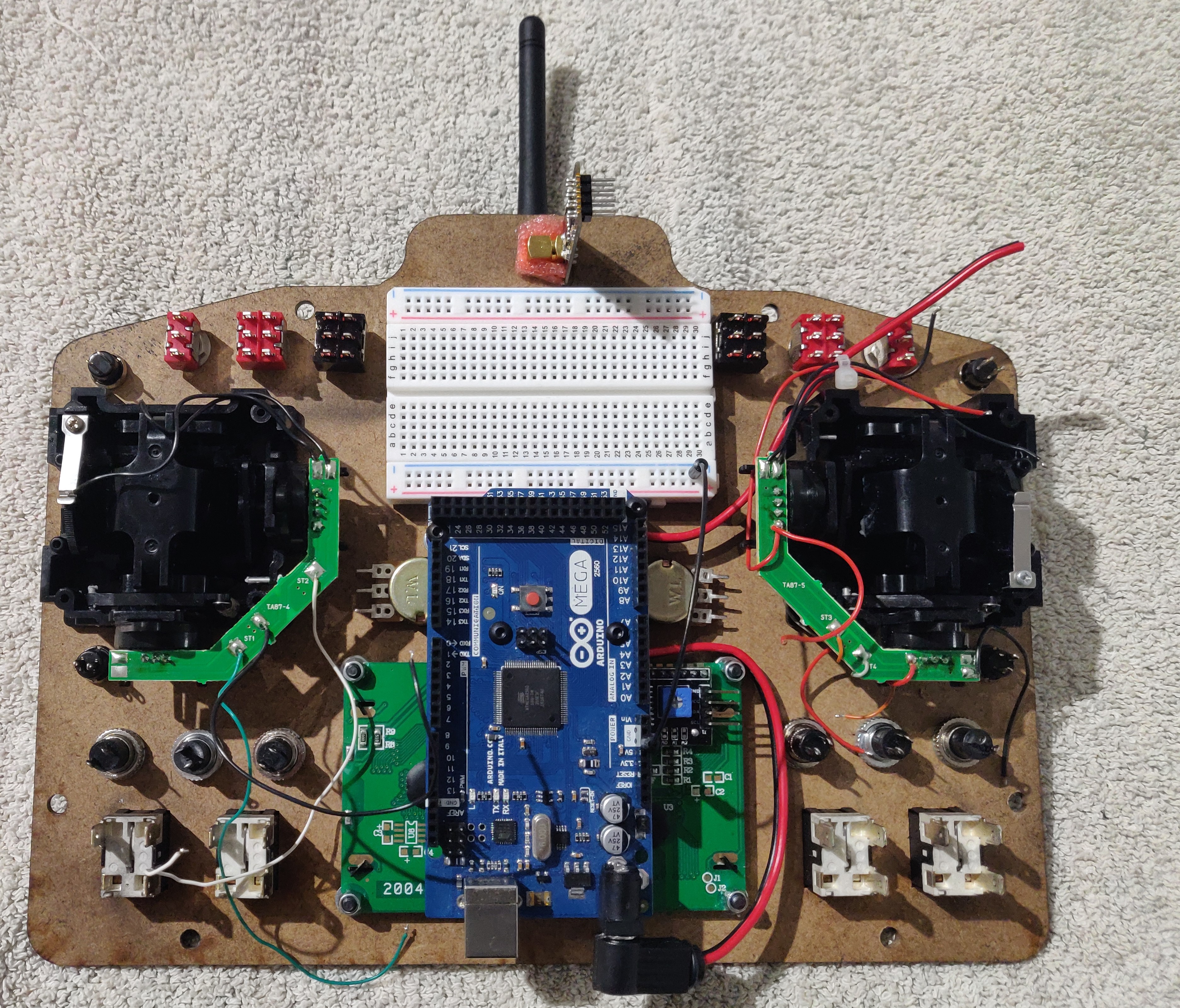

Since I didnt really learn electronics at school, I expectef the radio to be quite difficult to build. but it turned out easier than I thought, it's just a basic button box, with an Adruino, a screen, a 2.4GHz module and a battery of course. The box is 3D printed (SLA) and the pannel is made out of wod, laser cut.

GETTING THE RIGHT FRAME OF MIND

SUMMARY

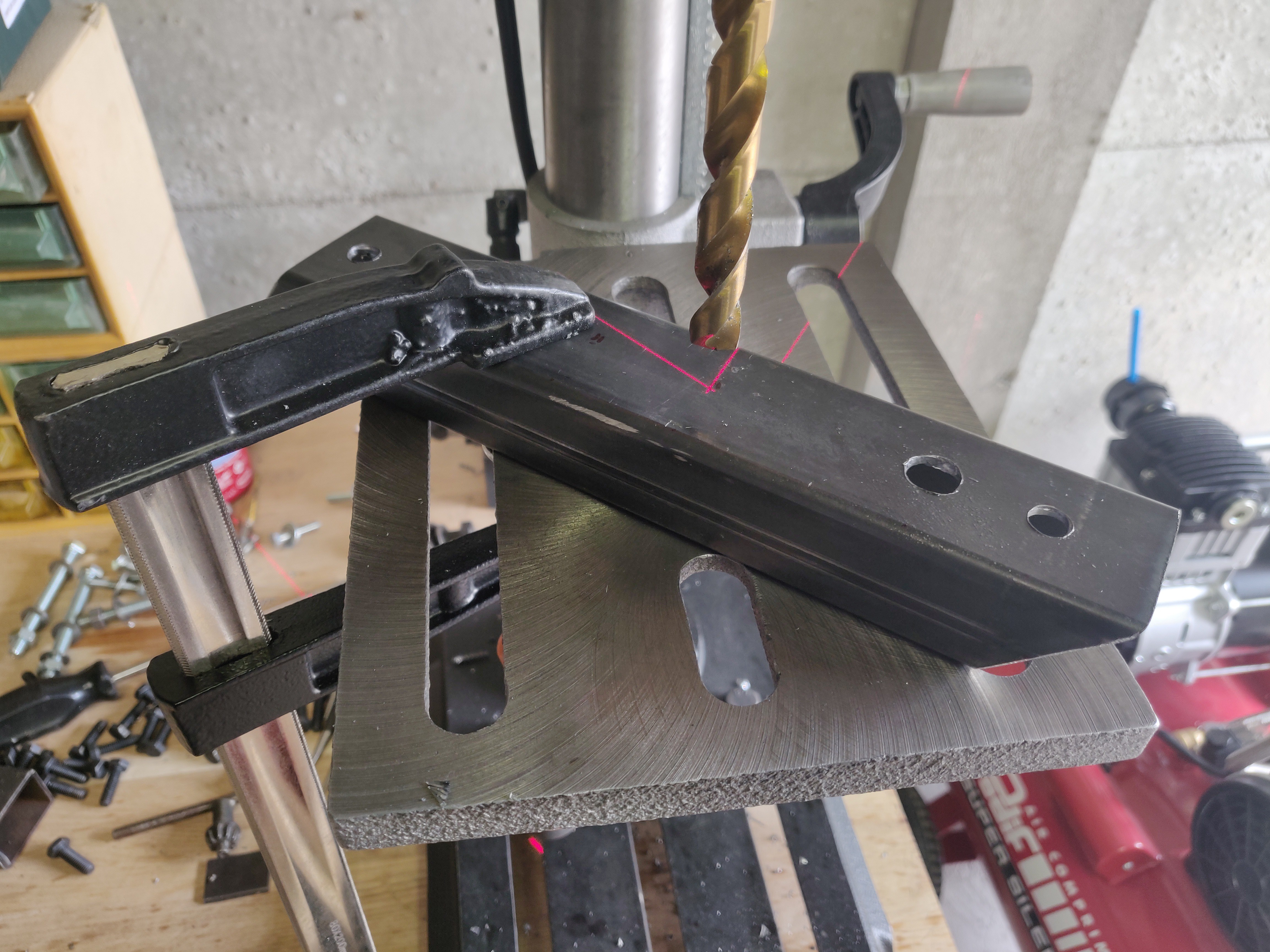

Building the frame wasn't that hard, but much, much longer than I expected. I had to drill several hundreds of holes. I also had to be very patient and very cautious with positioning and maintaining the profils while welding. Since I am no professional welder, I had to improve some weldings after the polishing step revealed weaknesses. The most difficult part was to cut and weld the angled profiles properly.

CONSTRUCTION

And it was a bad idea :

welding of the screws for engine mounts

welding of the screws for engine mounts

Then i welded the left and right wings + turret mounting + rear section :

After a few improvements on the fly, the frame is now complete. I then added a rust protection coating on every single surfaces. Just like real tanks, this one will have a long, and rough life. Let's protect it from the start.

FULL SPEED AHEAD !

The gearbox design has been quite a challenge : I have a lot of mechanical power to transmit (4.8kW) with a high speed on one side and high torque on the other. Not to mention that the gearbox had to be as compact as possible to fit in the tank. I used roller chains instead of gears to make it easier to assemble run and maintain, as is it my first gearbox project.

MATH TIME

Because history matters

Create an account to leave a comment. Already have an account? Log In.

Become a member to follow this project and never miss any updates

By using our website and services, you expressly agree to the placement of our performance, functionality, and advertising cookies. Learn More