The spindle motor supplied with the machine is not great, the control electronics is installed directly on top of it and its randomly failing (due false contact I believe), for this reason I decided to change it.

First I was planning to buy a more pro spindle motor such as the Kress 800. However such motors are (in my opinion) way to big for the size of such small machine.

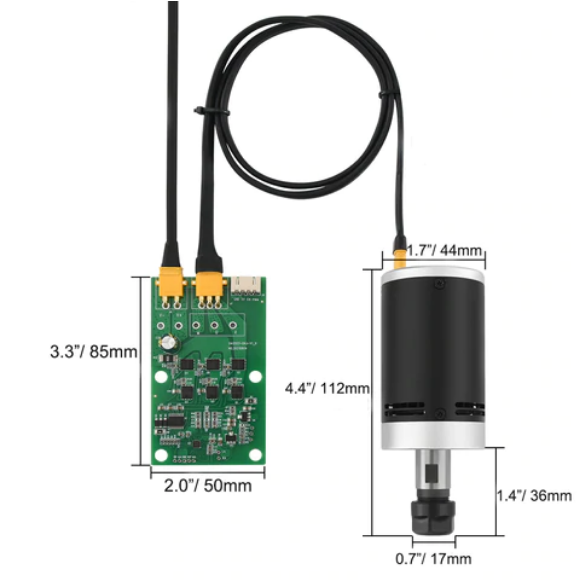

For this reason I finally choose for a small and cheap upgrade: the Brushless Motor Spindle Kit 24V 12000rpm (link, note that I bought on aliexpress for around 65 eur link)

This is a drop in replacement for 44mm spindle motor such as the one on the CNC1419.

The motor has a much neater finishing, it has bearing to decrease the run-out and it comes with its control board and a nice metal enclosure.

The cabling is straight forward:

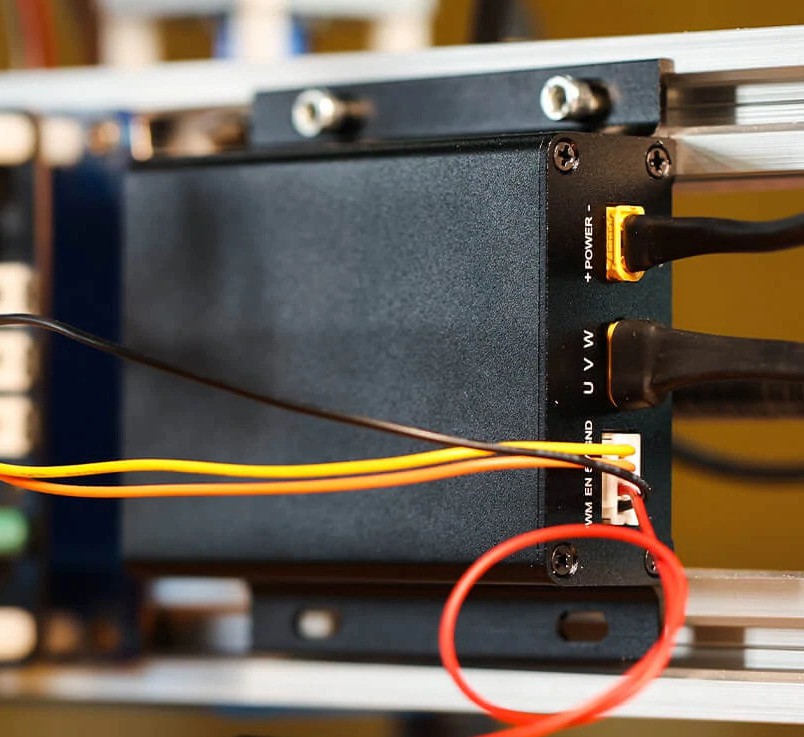

- Connect the power to the GRBL board spindle output (be careful with the polarity)

- Connect the tree-phase (UVW) cable to the motor (not the connector is unidirectional, you can not connect it wrongly)

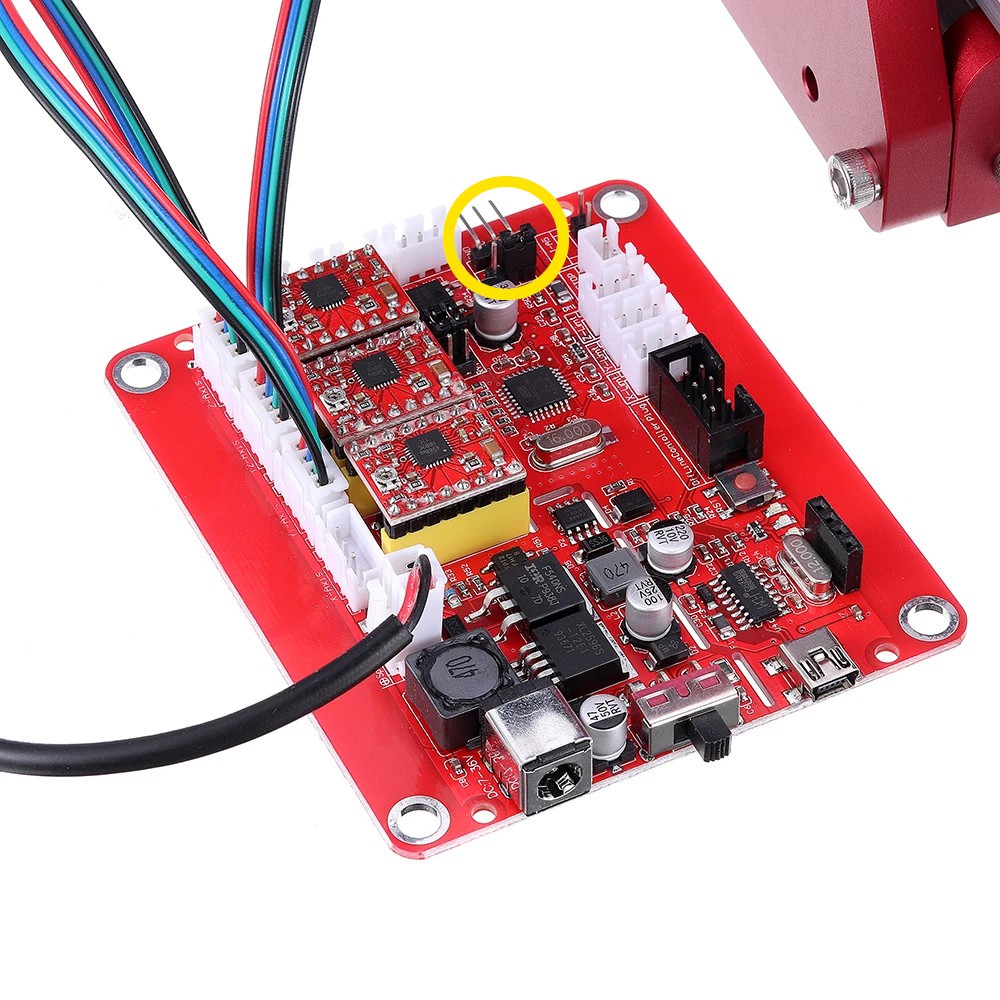

- Connect PWM, 5V and GND to the proper connector on the GRBL board (for my board look the picture below)

- Left the enable unconnected

The motor so far seems good, is much more silent and it seems reliable, it worked straight away with the board firmware (without requiring any change).

The only negative is the impossibility to change the rotation direction of the spindle via gcode (there is a switch on the back of the control board)..

Martino Ferrari

Martino Ferrari

Discussions

Become a Hackaday.io Member

Create an account to leave a comment. Already have an account? Log In.