At the end of March 2020, we were thinking about whether we could do something for the world to help in the COVID-19 crisis.

After some discussion we quickly got to a point where we agreed.

We believe that a usable ventilator could certainly make a small contribution to the fight against COVID-19.

Globally, the shortage of ventilation equipment was growing noticeably. We knew that it would not be an easy task to develop a device that can be used in a medical situation.

Searching for the right mechanical design and concept, a few weeks passed… After a lot of trial and error, some light began to shine at the end of the tunnel.

Our mechanical concept slowly got better and better, which gave us courage to continue working until we reach our goal.

At the moment we are very close to the point where we can start producing our device. We are very happy and proud that we have reached the point where we are now.

At this point the cost of the whole project becomes more difficult to bear and additional financial support in the format of crowdfunding would be more than welcome.

dannyvandenheuvel

dannyvandenheuvel

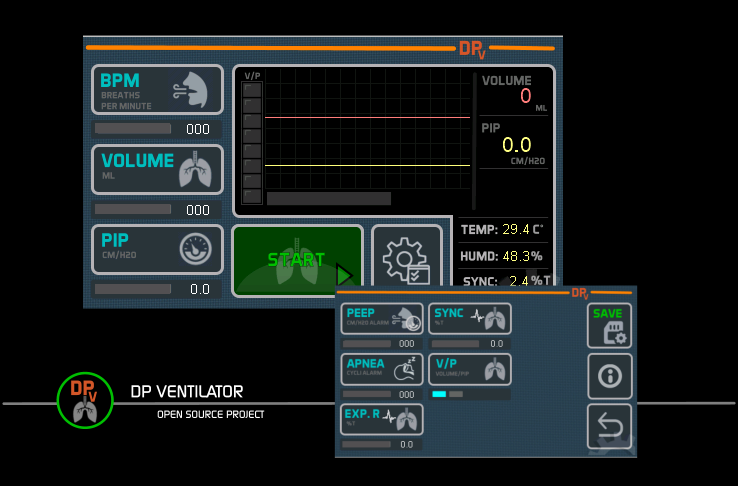

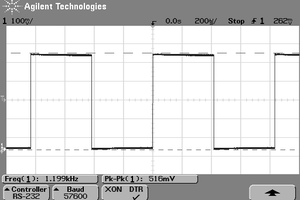

I am transferring all source from Arduino to Atmel Studio 7, many more possibilities to debug and stabilizing the software.

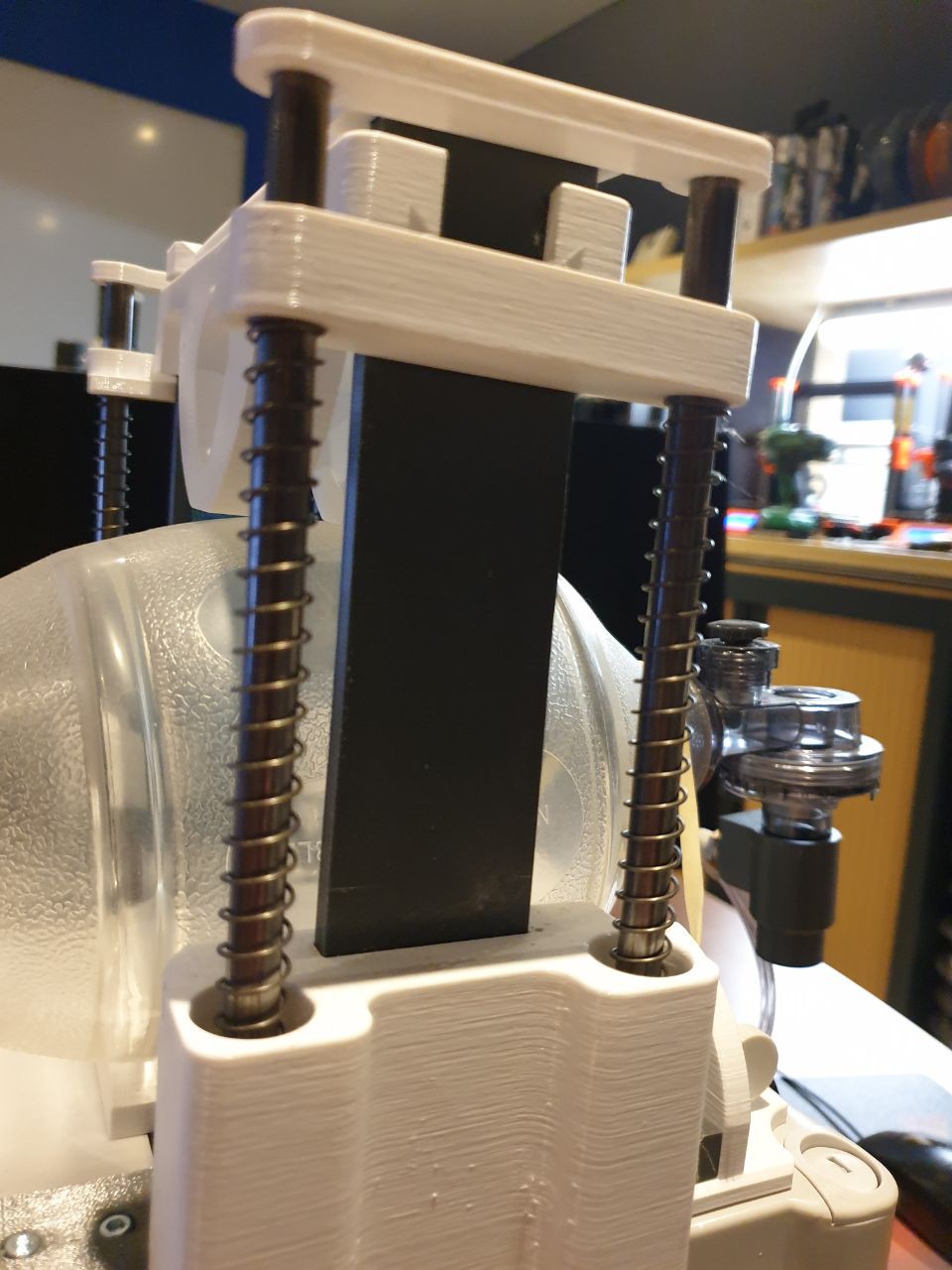

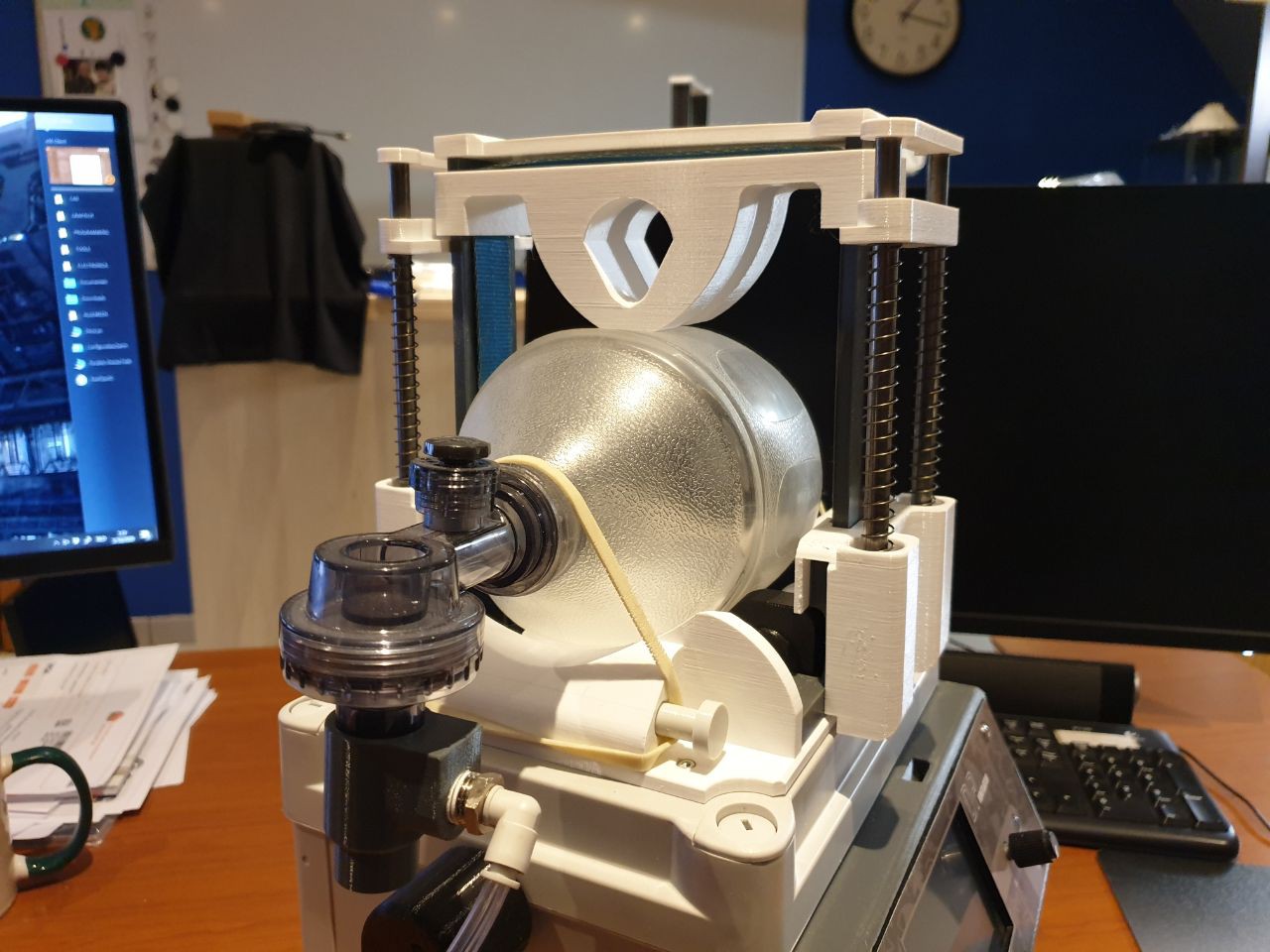

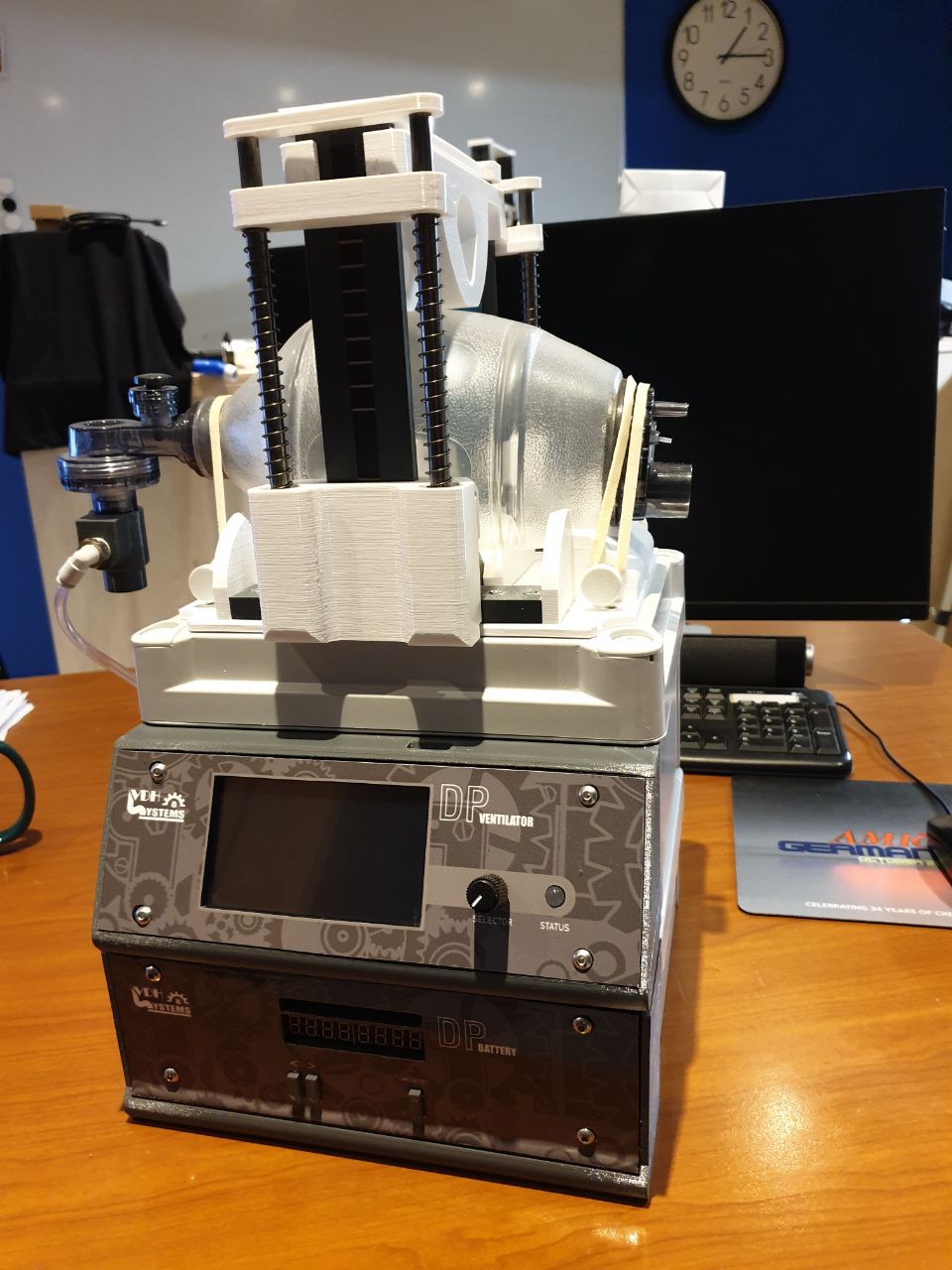

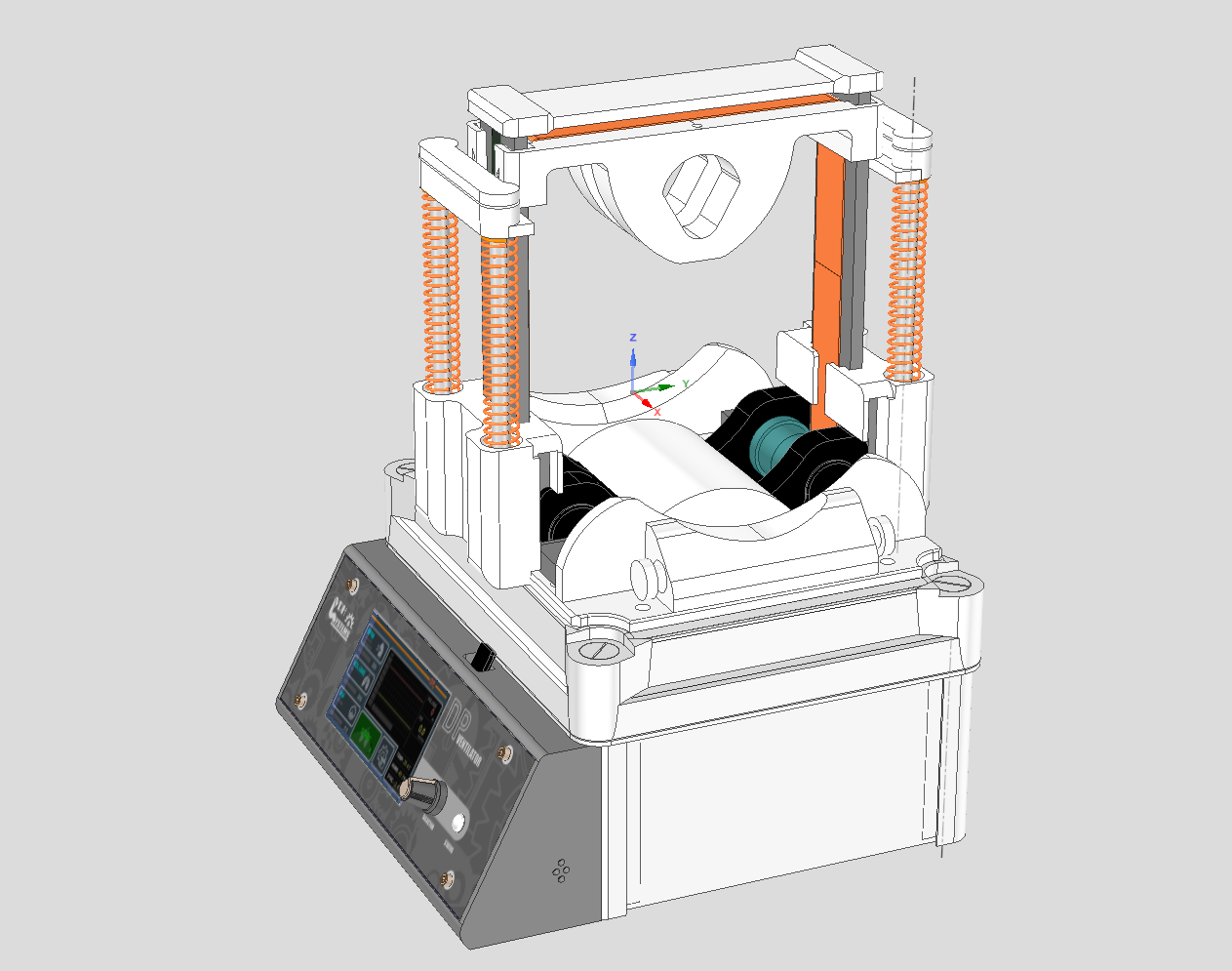

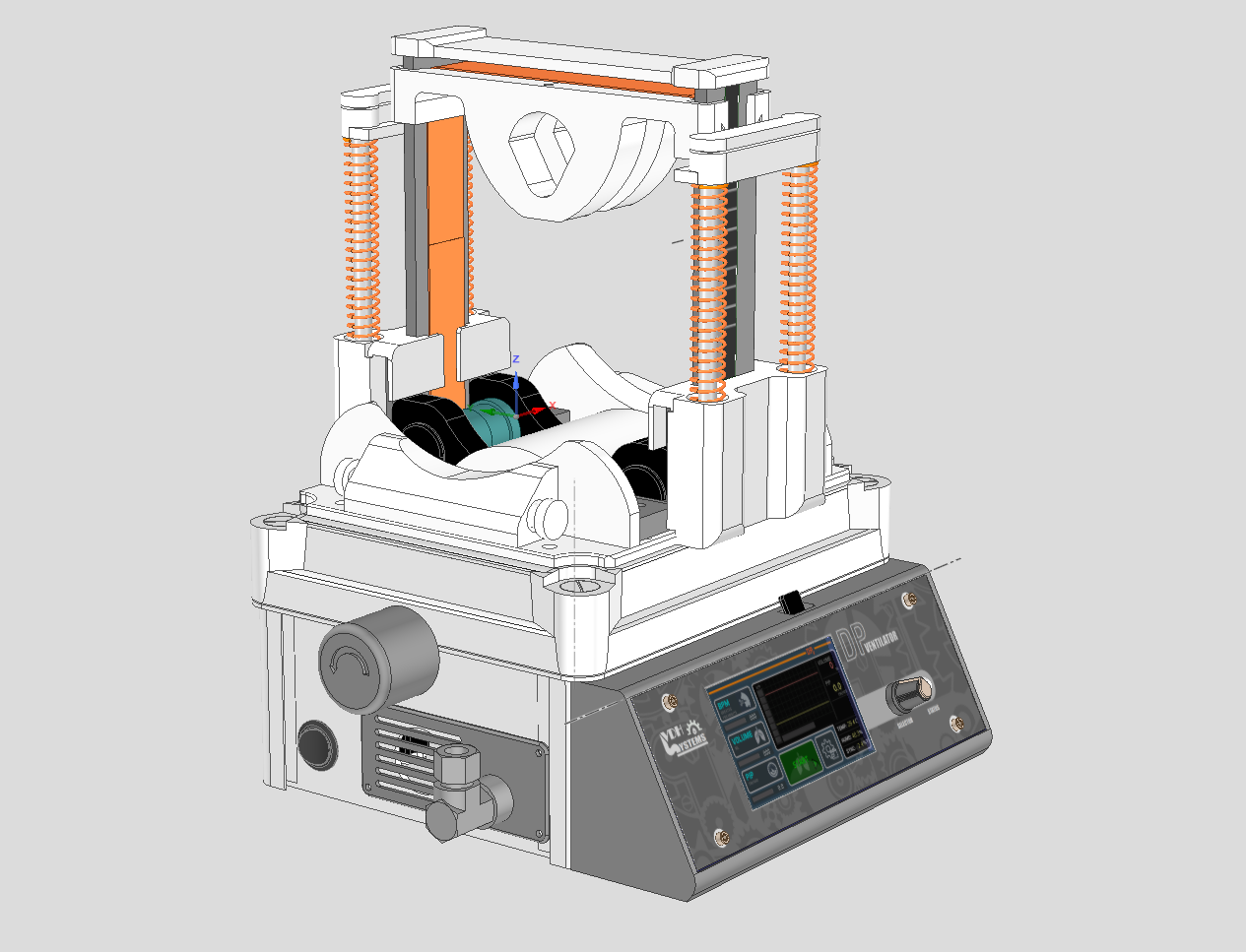

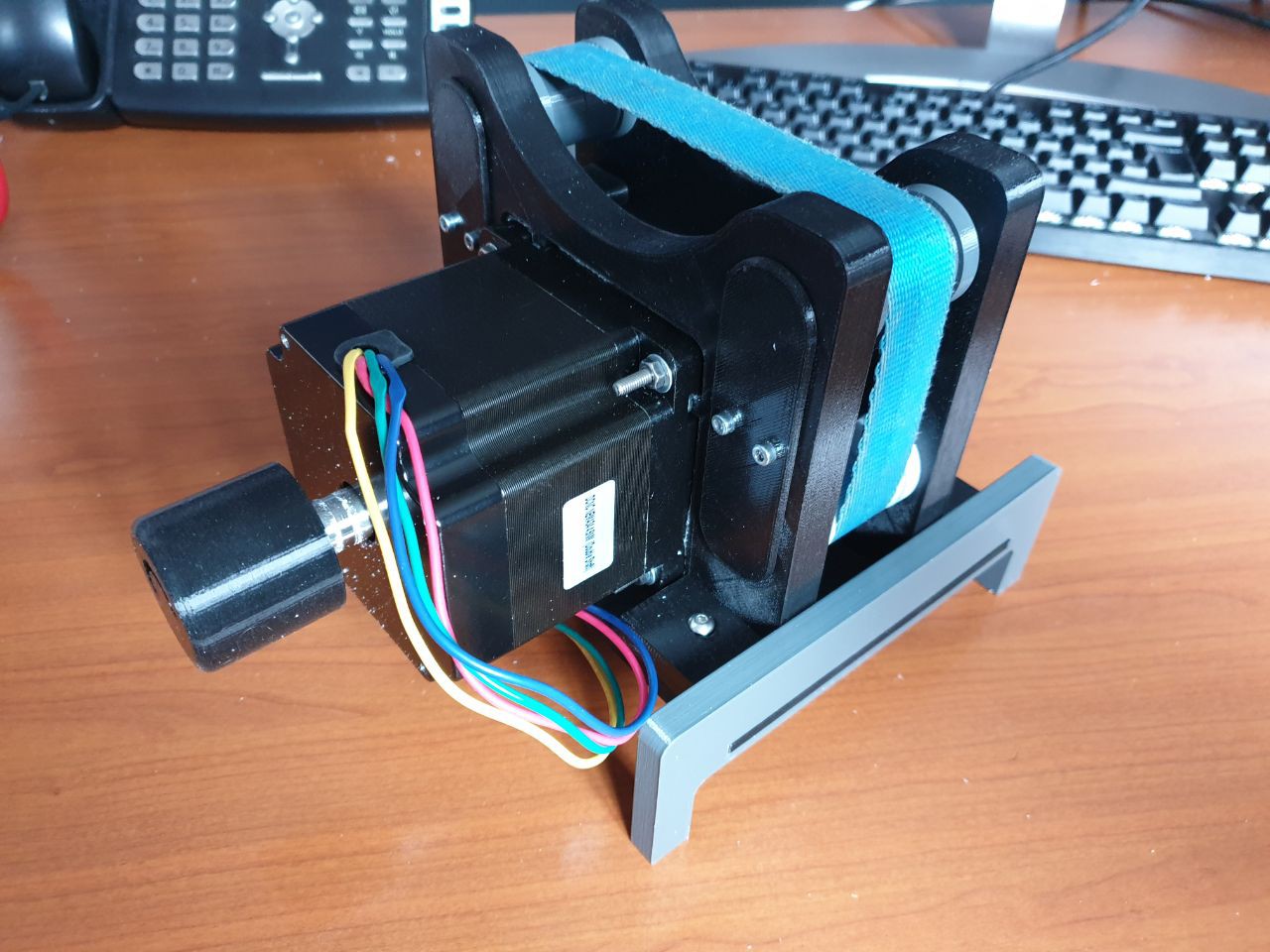

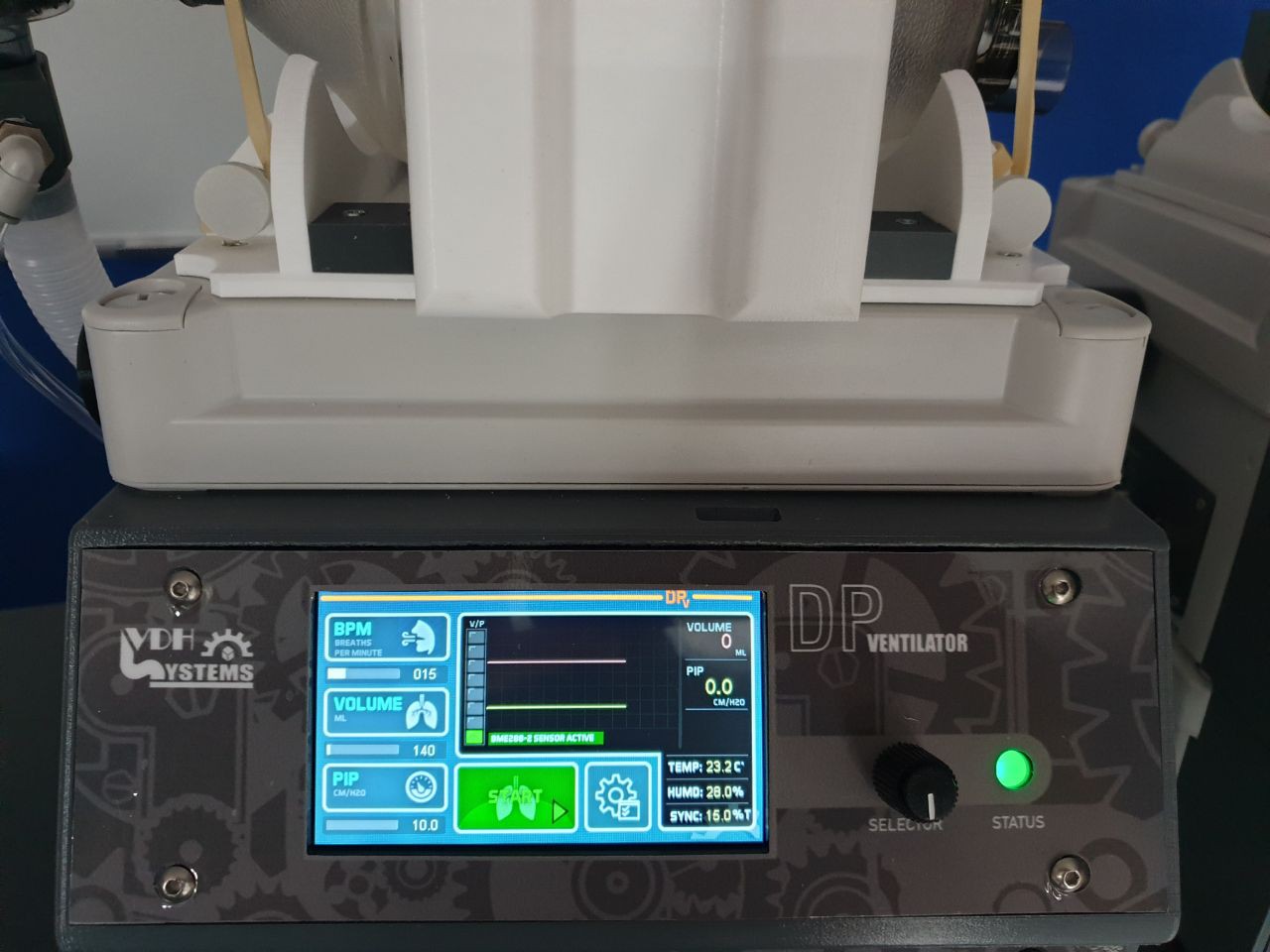

I am transferring all source from Arduino to Atmel Studio 7, many more possibilities to debug and stabilizing the software. To move controlled in both directions Up and Down we used springs, this way we are fully guiding the press system on the amu-bag.

To move controlled in both directions Up and Down we used springs, this way we are fully guiding the press system on the amu-bag.

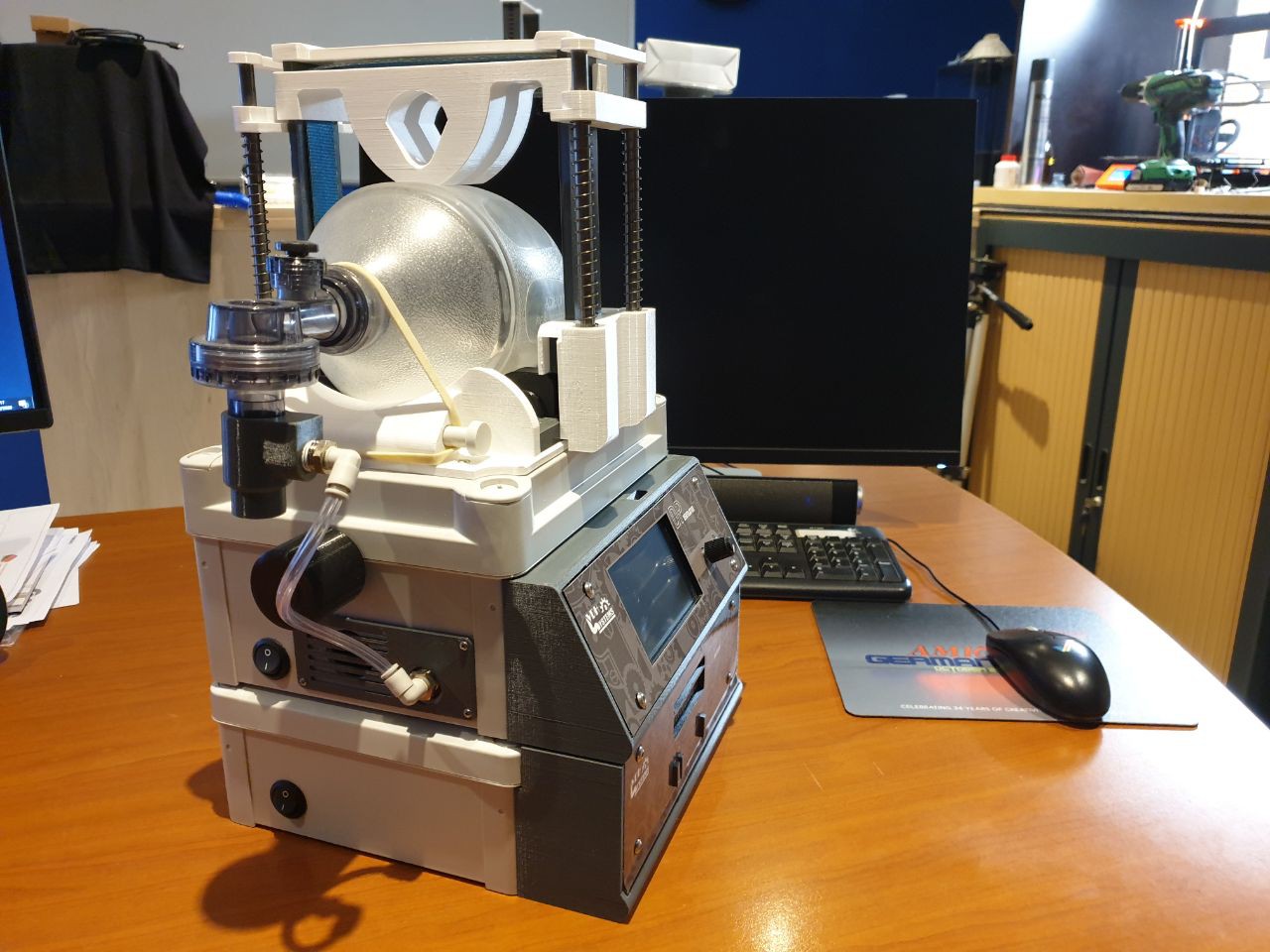

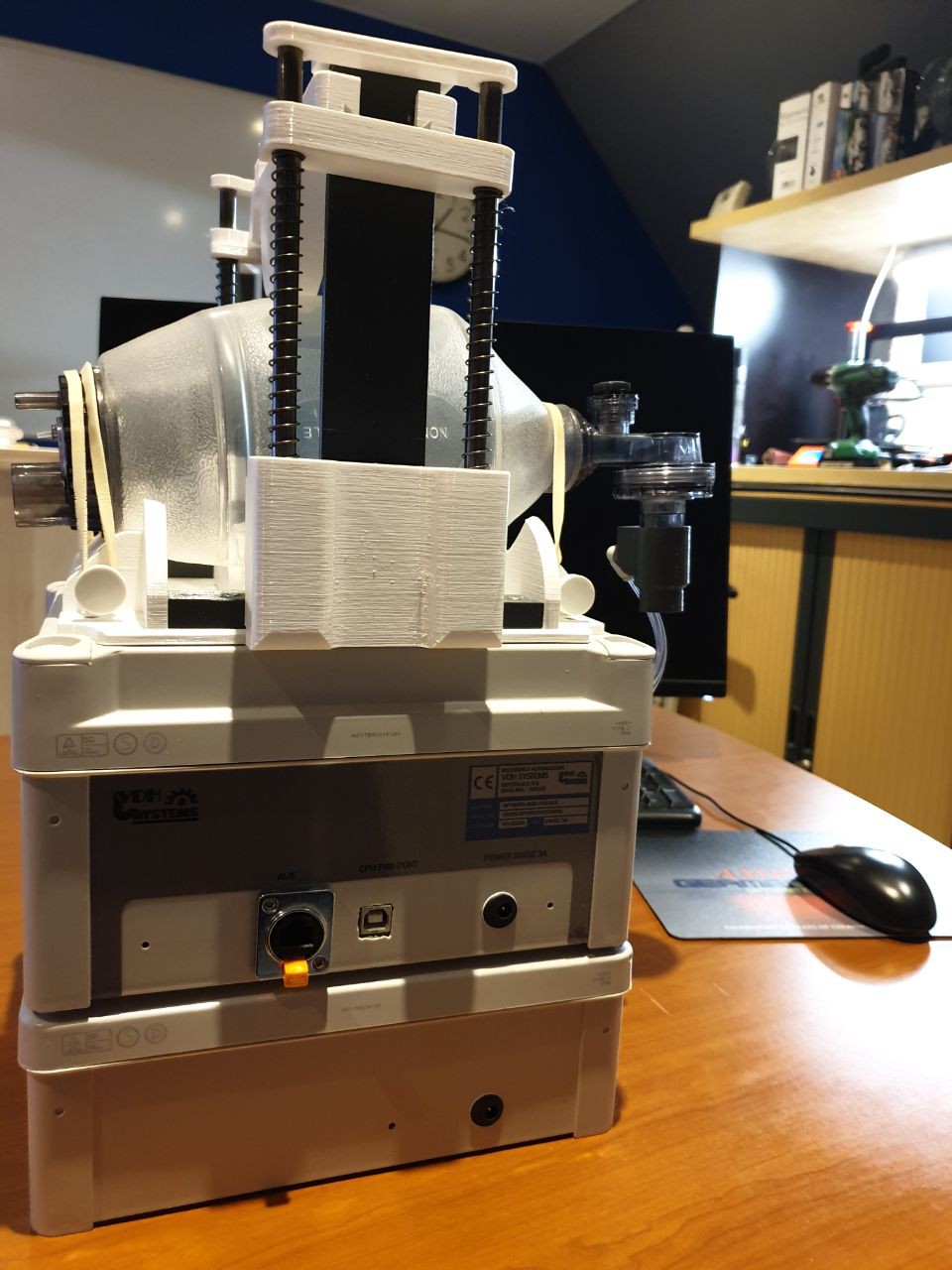

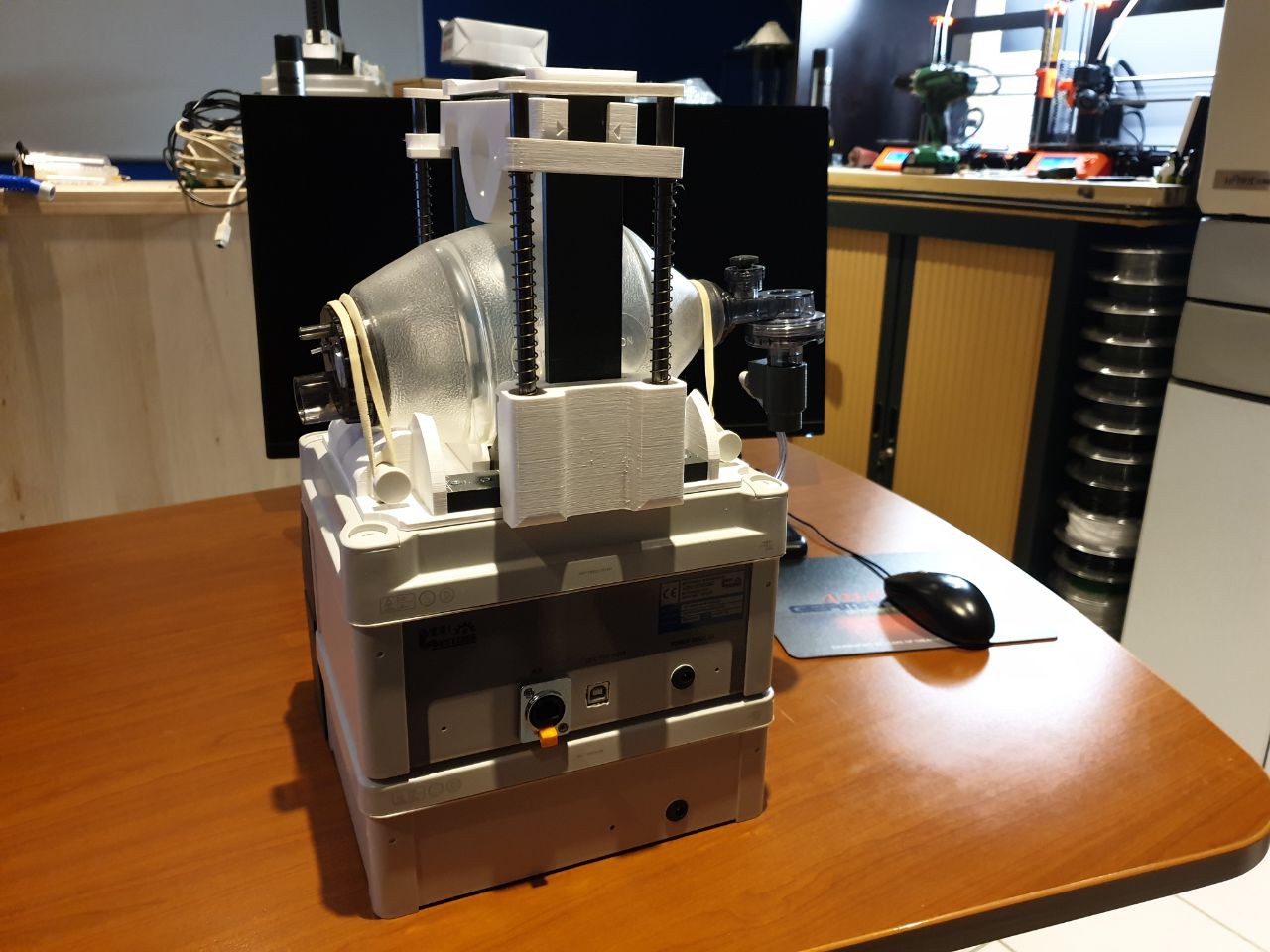

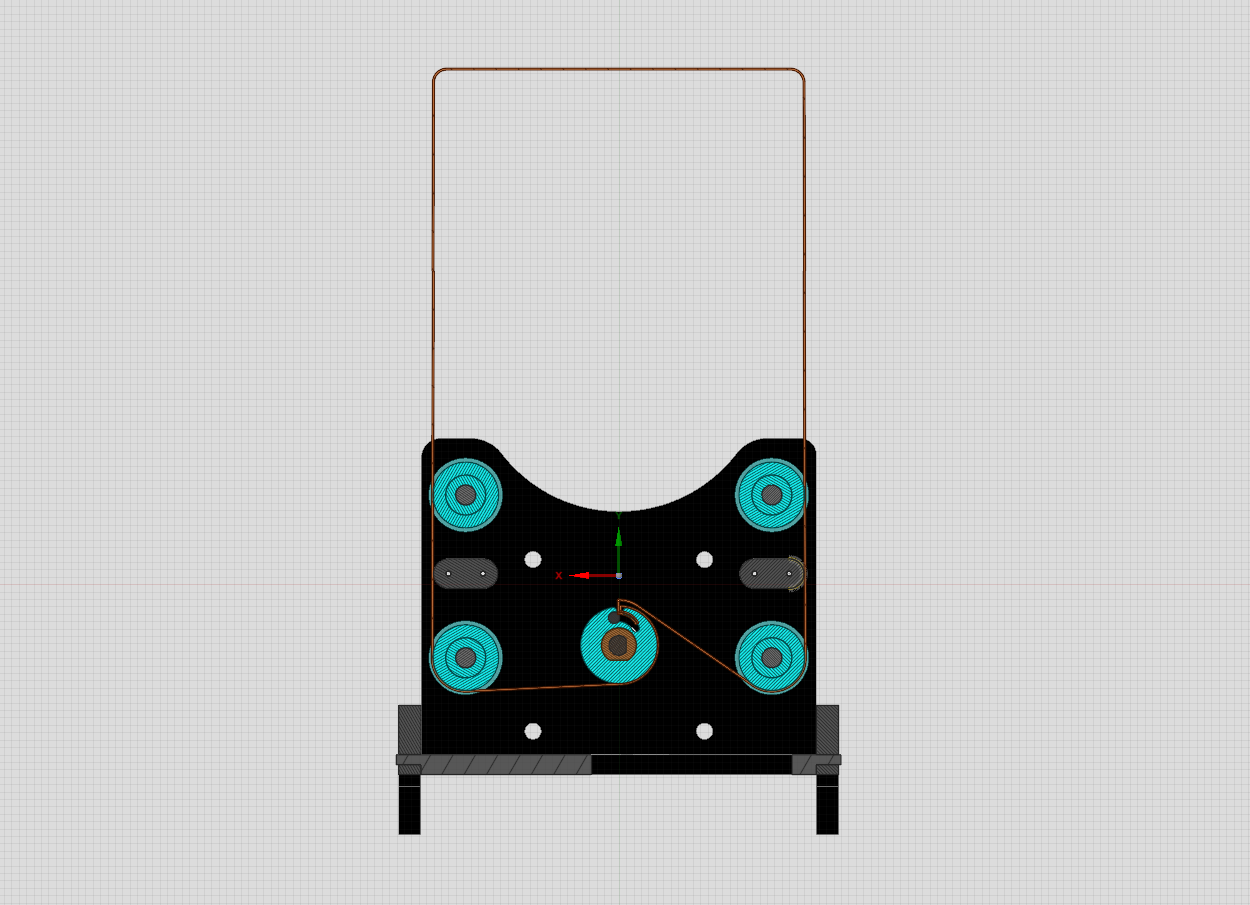

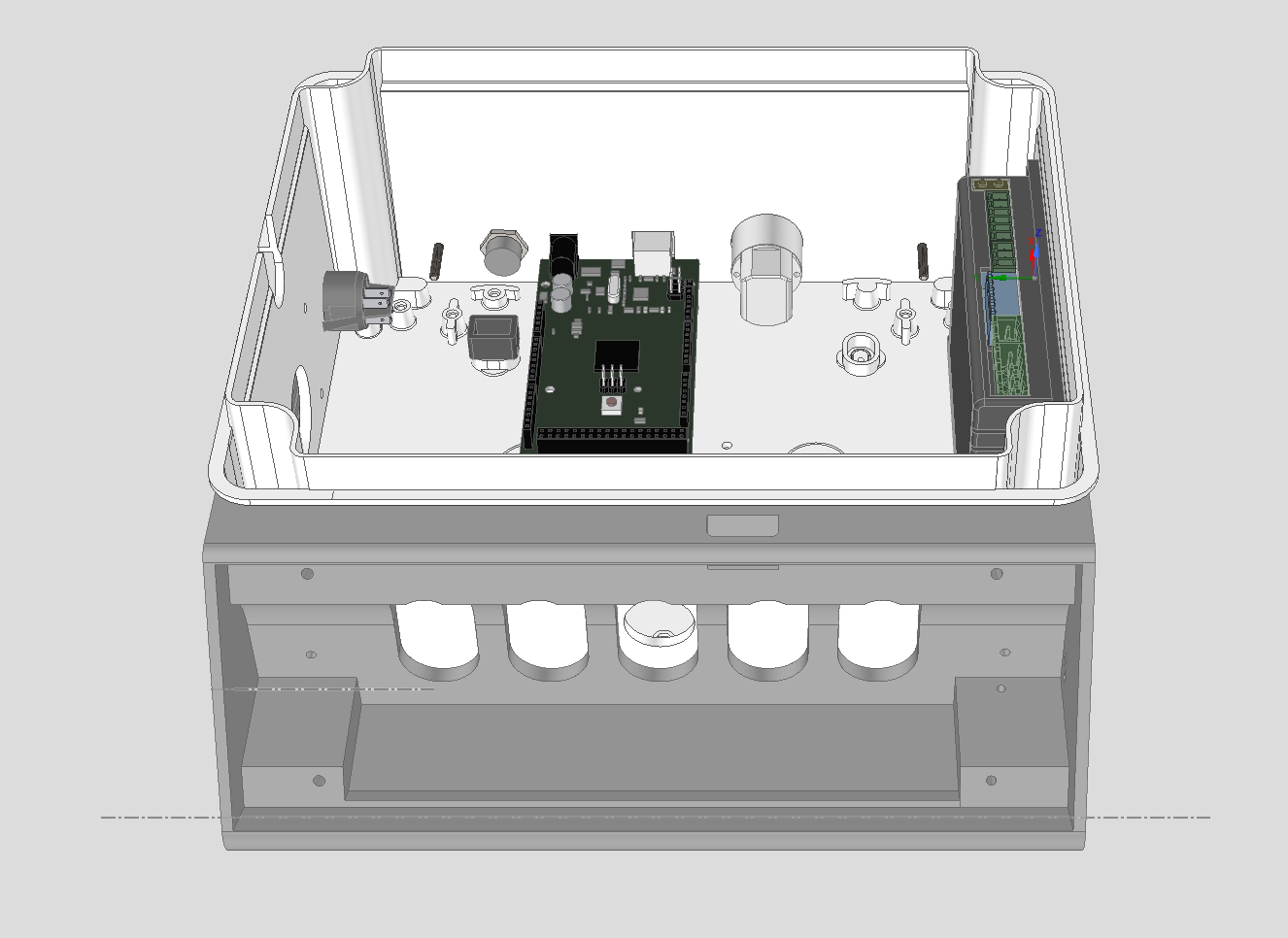

The mechanical table exists out of a strap belt, the whole mechanics has to be build into the enclosure on a easy way to get removed or inserted.

The mechanical table exists out of a strap belt, the whole mechanics has to be build into the enclosure on a easy way to get removed or inserted.

It's been build around a very strong stepper motor Nema 34 with 4.5Nm torck. The driver must be very silent so we needed to work in micro steps with enough power. After several tests with different motors this was the best result. It also needed to be double shafted because we wanted to work with a motor that we manually wanted to move to bring in the ambu-bag.

It's been build around a very strong stepper motor Nema 34 with 4.5Nm torck. The driver must be very silent so we needed to work in micro steps with enough power. After several tests with different motors this was the best result. It also needed to be double shafted because we wanted to work with a motor that we manually wanted to move to bring in the ambu-bag.

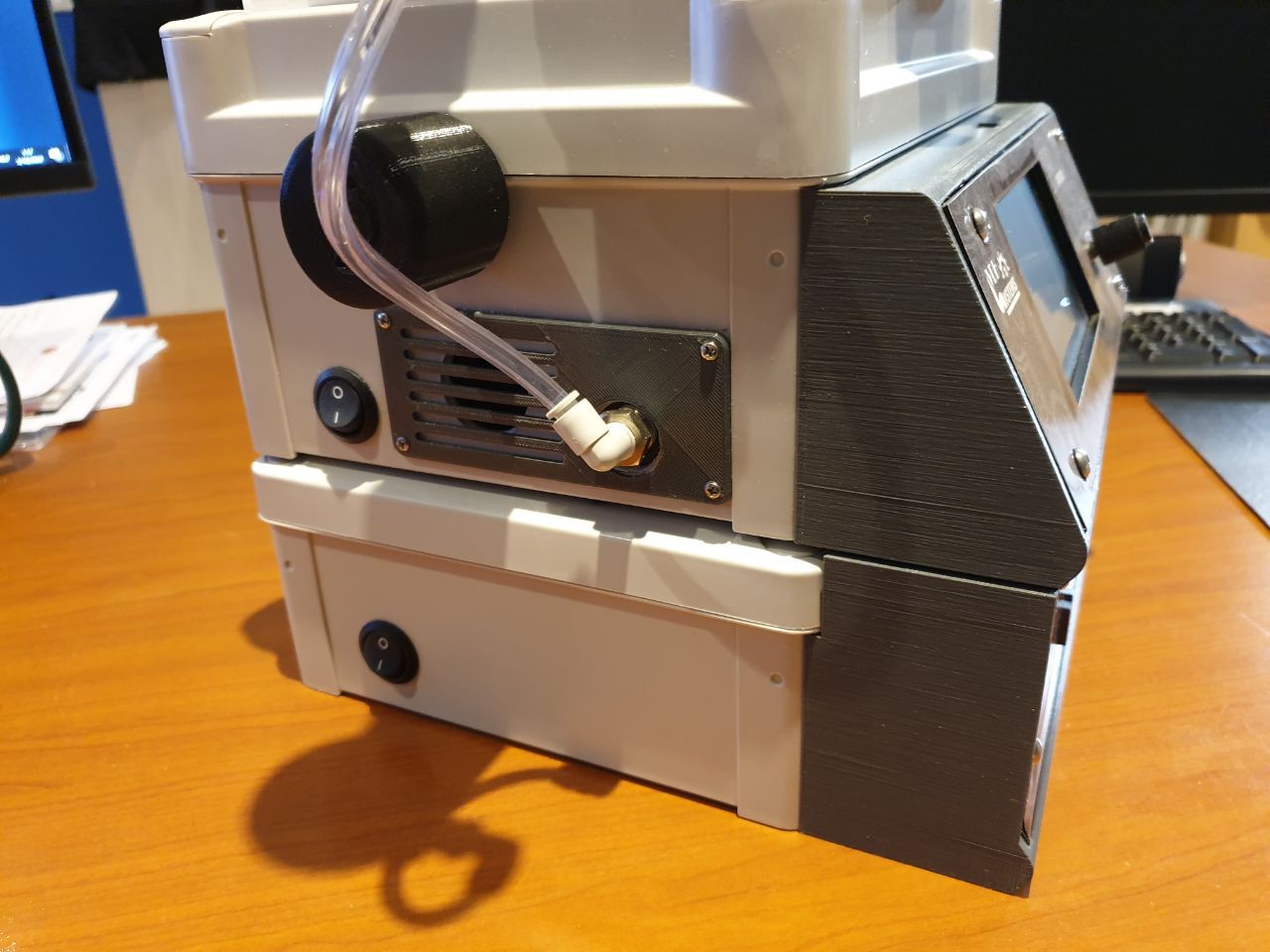

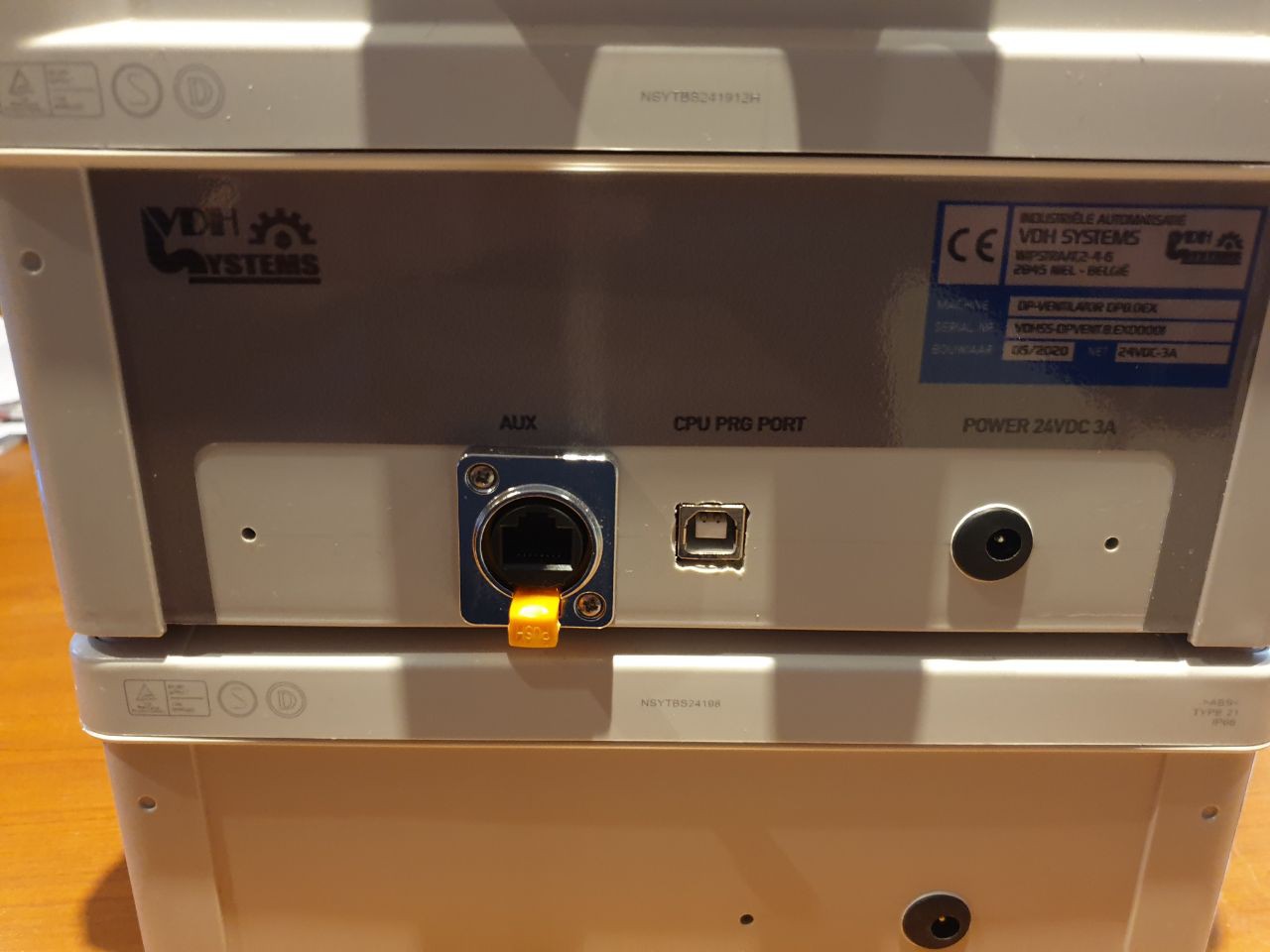

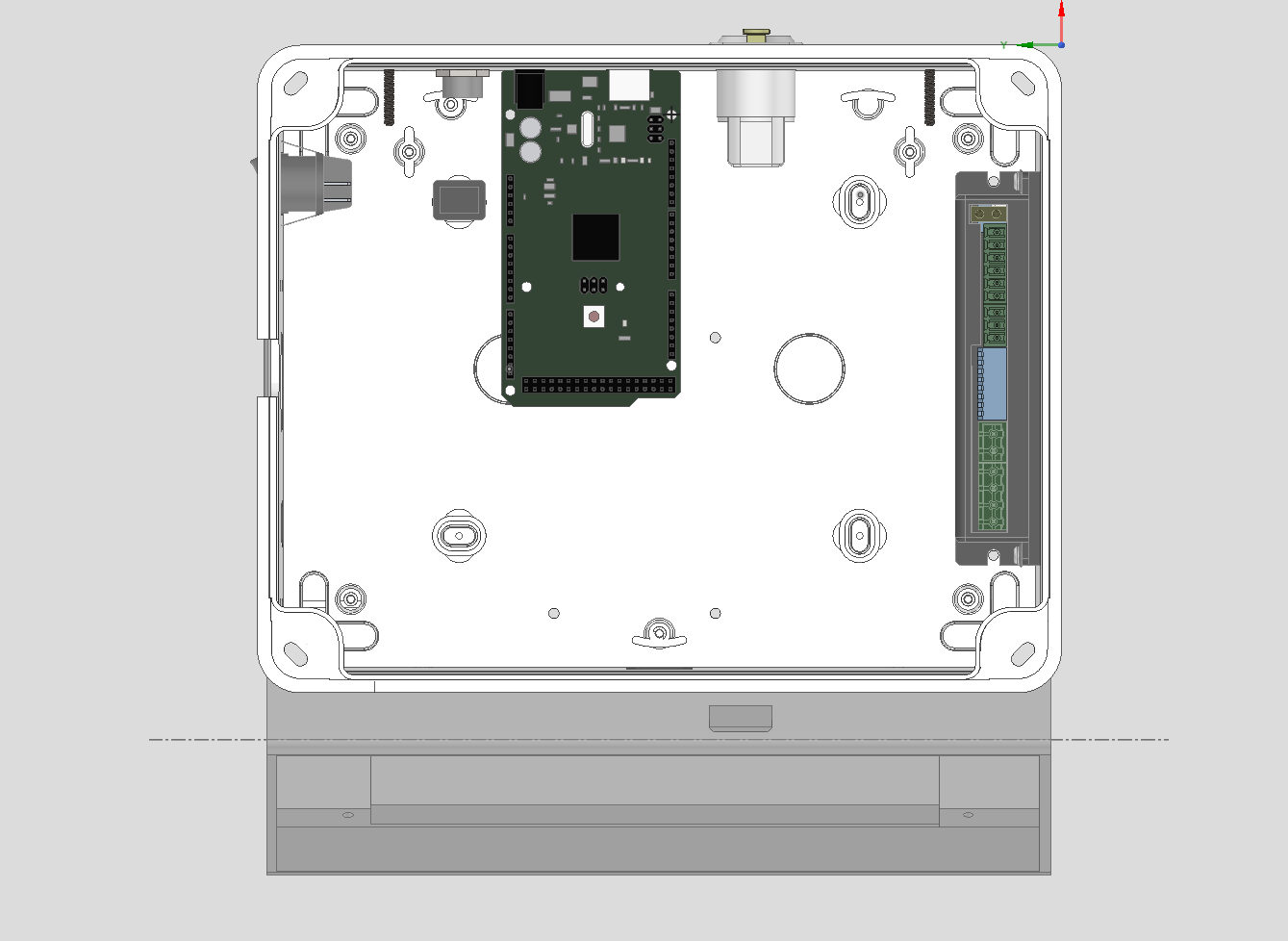

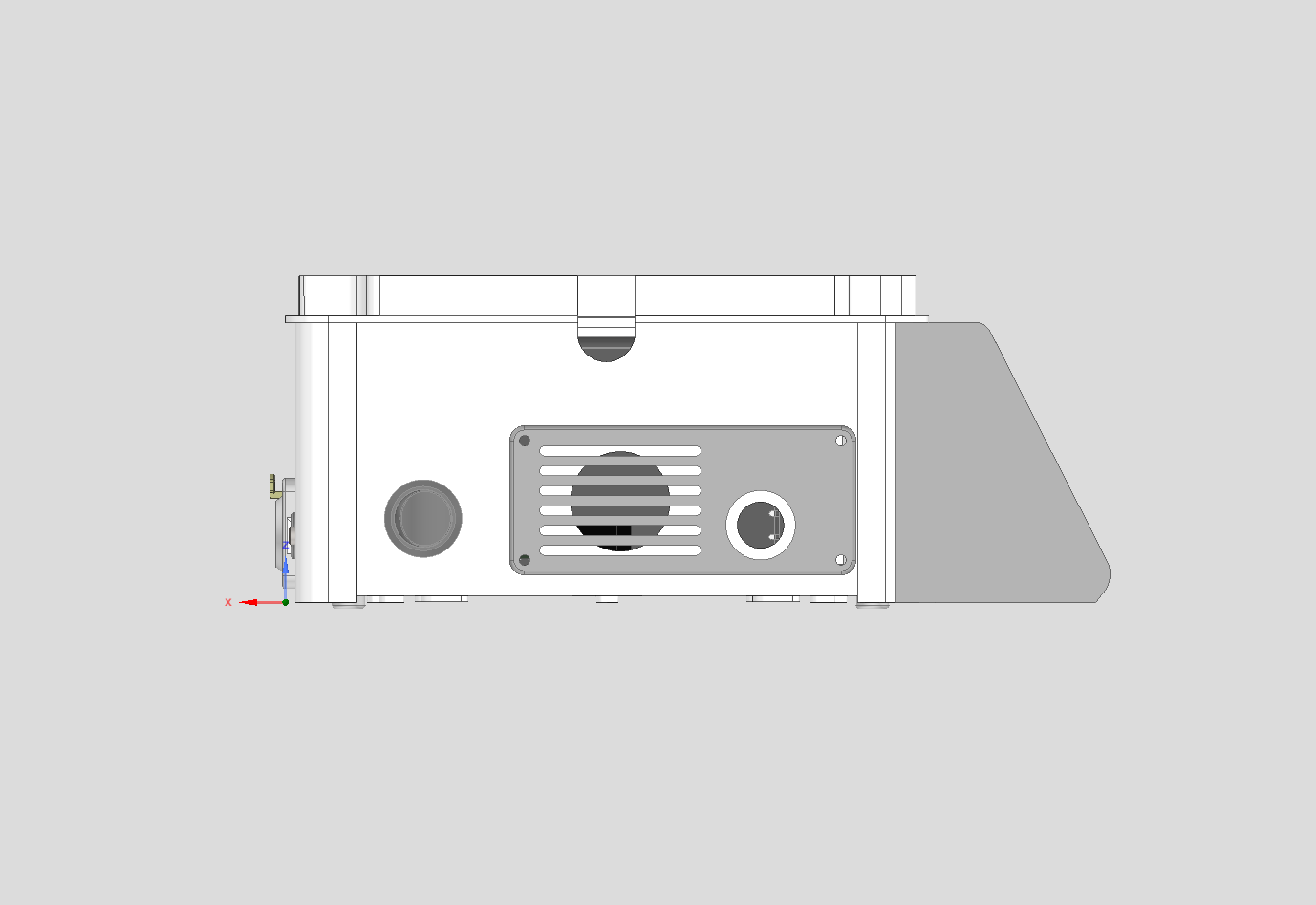

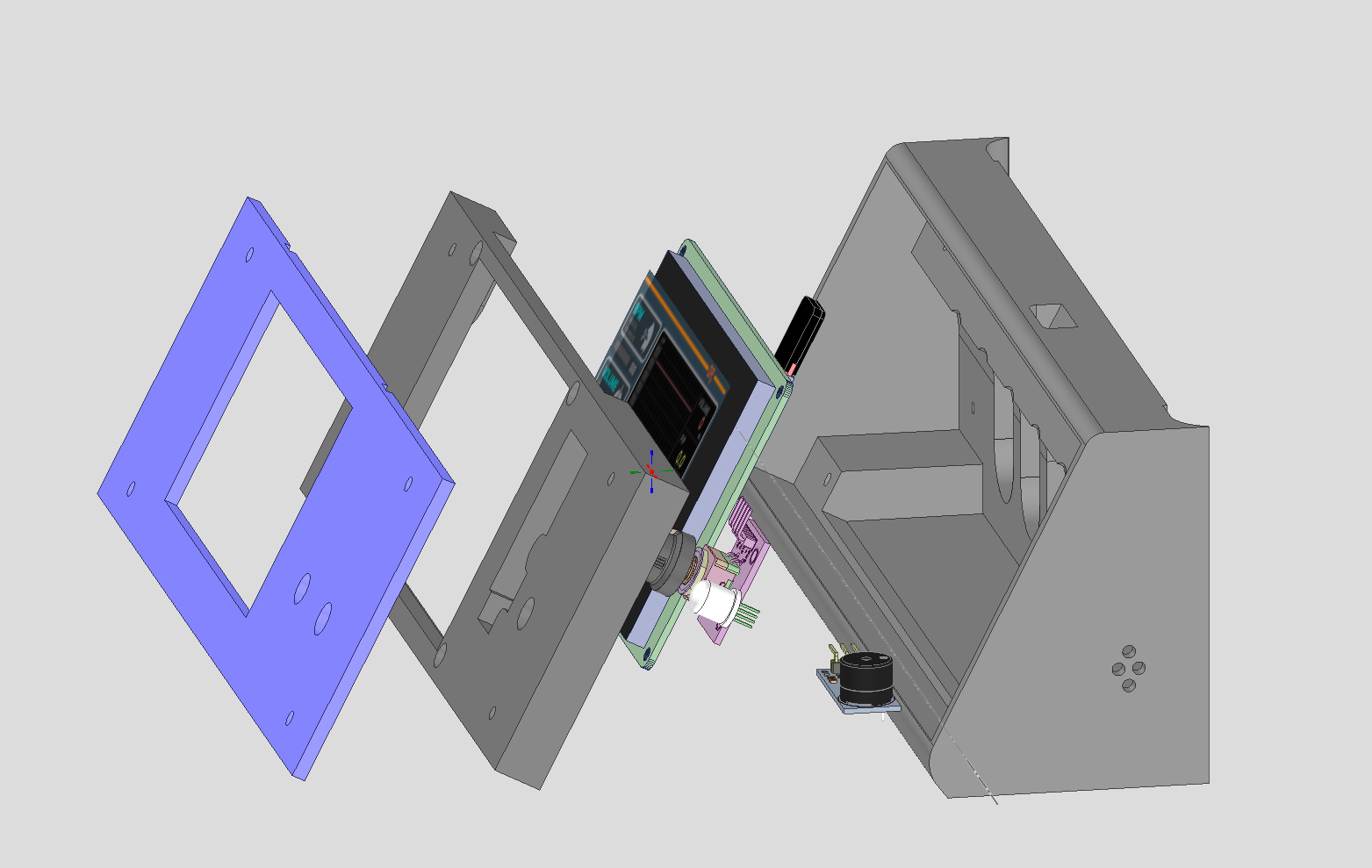

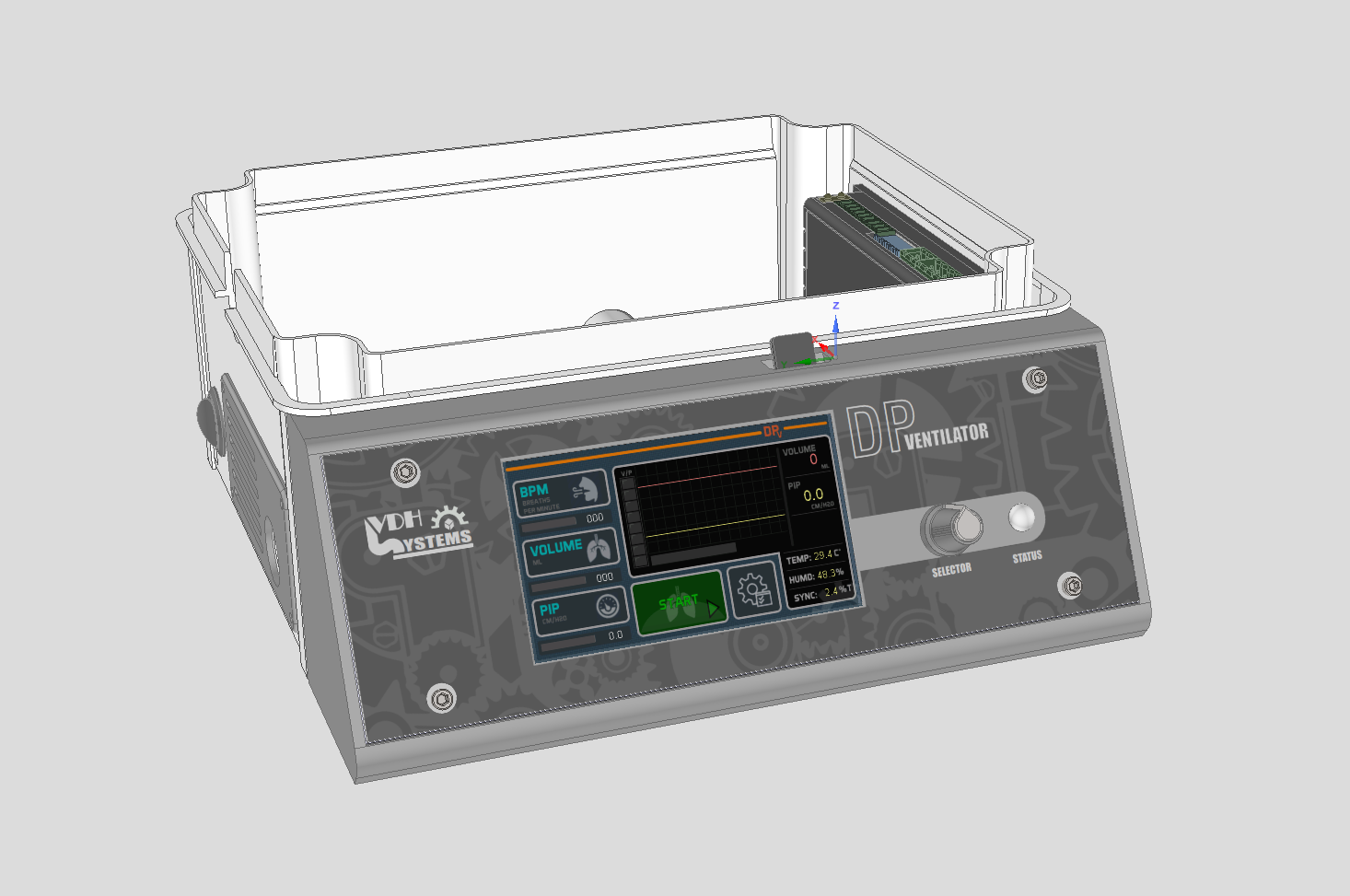

This was one of my first questions, how I going to build it? Everything started with this enclosure.

This was one of my first questions, how I going to build it? Everything started with this enclosure.

ACROBOTIC Industries

ACROBOTIC Industries

Vedran

Vedran

Hello Daren,

Thanks for the comments,

We did a lot of things about one month ago, the reason why we not have been progressed so far is the lack on support and financial help. We wanted to move forward and take the necessary steps to improve our machine. We also know the problems and missing things, stability wasn't the problem, measuring only with BME280 isn't enough, we know, also for this we had some solutions worked out. But like I said we are out of money at the moment, we are still searching for a solution to get this project up and running again like it should be.

Also the need for respirators has decreased sharply, many larger companies have even stopped making them.

I saw yours, looking good, do you believe in the possibility you can put them up and running and certified by the medical organizations all over the globe?

Not that easy.

See ya