-

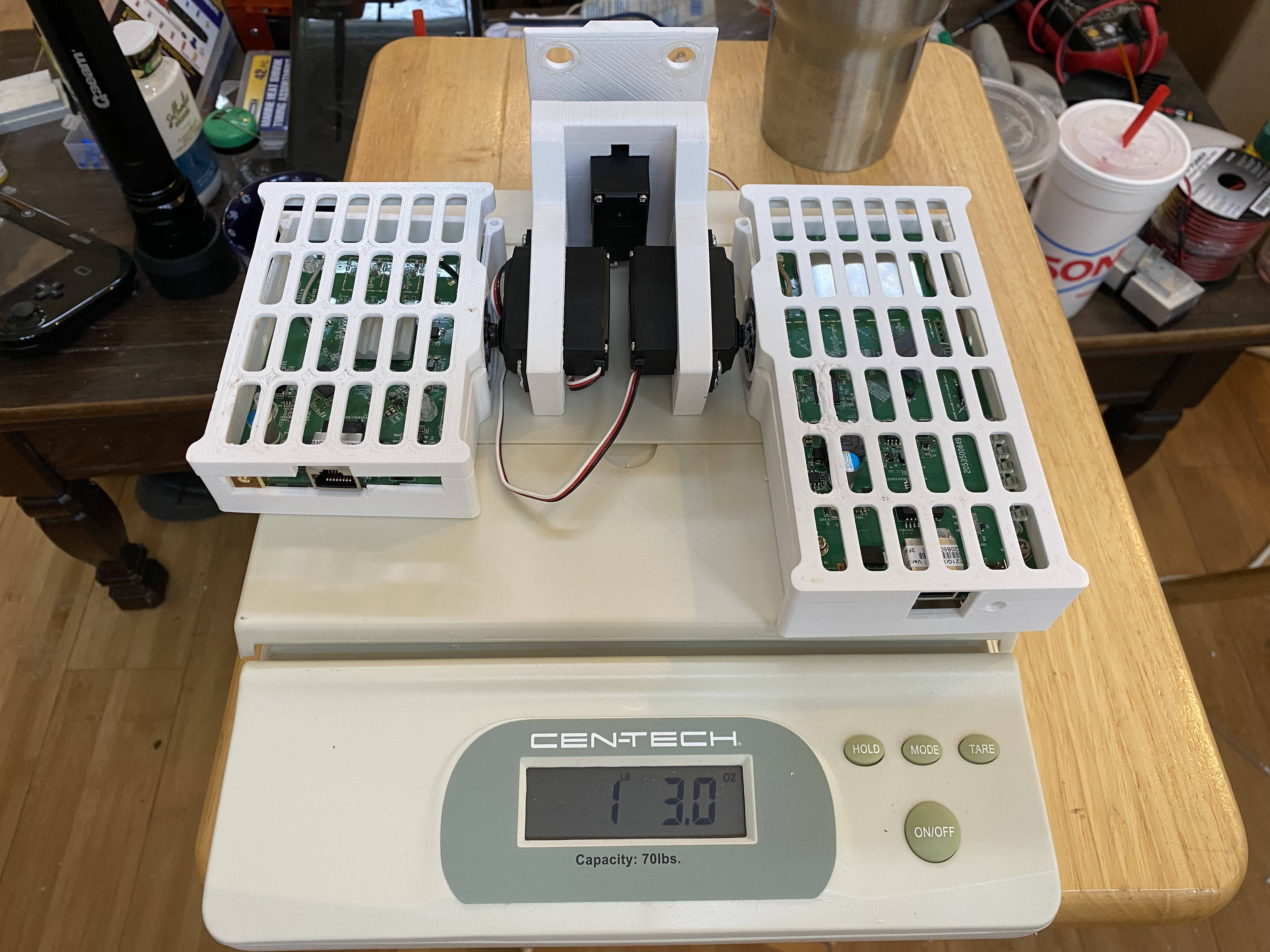

Weigh in of the WiFi Array and pan / tilt

09/09/2020 at 13:13 • 0 comments![]()

Here is the total unit assembled with both 5G and 2.4G load outs with Pan /Tilt functions for each antenna.

![]()

Here is the dual 2.4G and 5G units together in their cases as currently designed.

![]()

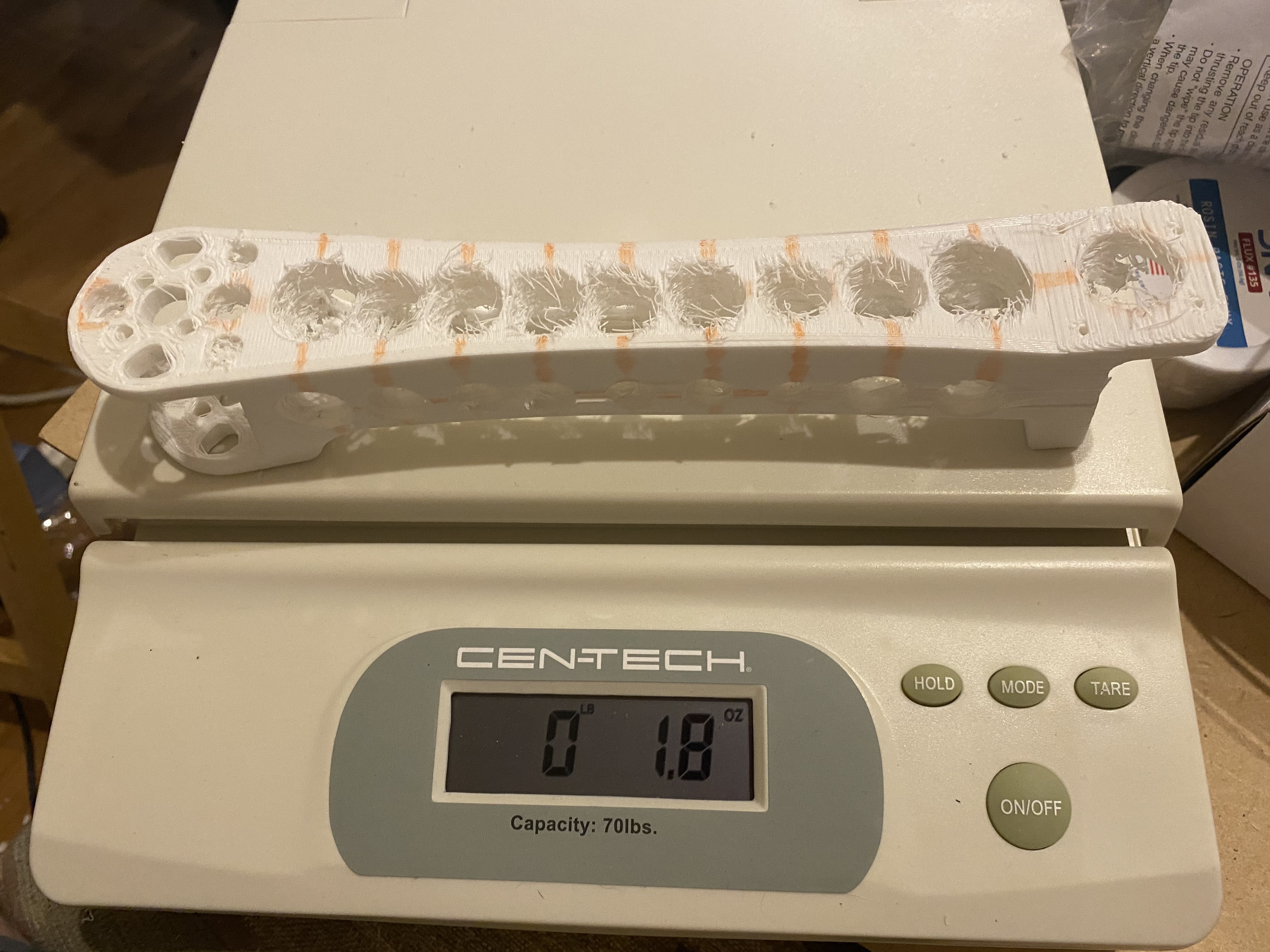

The 2.4G long range antenna weights in 3 ounces more than the 5G at 6.8 ounces. This is mostly because of the two layers of plates that make up the directional antenna in addition to a larger PCB.

![]()

Here is the 5G antenna and Transceiver package , 3.8 ounces. I am kinda surprised it is so light.

-

Weight reduction of the frame design

09/09/2020 at 05:19 • 0 comments![]()

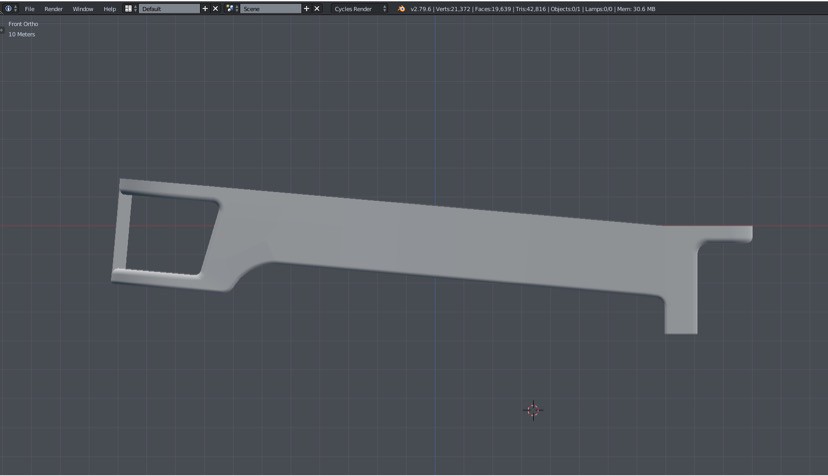

![]()

Ok so we are at the point where we need to shave off every ounce we can to make room for a good thrust to weight ratio and allow plenty of ceiling space for additional electronics. I manually drilled out the prototype and found it reduces it all the way down to the original oem part weight, however drilling manually is impractical and makes a mess. So everywhere I have drilled out I am transferring those holes back into the 3D model for efficient weight reduction right off the print bed. The top level with additional frame plate and anti vibration spacers may also be removed for another few ounces dropped off the frame. My challenge at the moment is to make a frame with parts lighter than the originals. Every ounce of weight dropped is equal to gaining another ounce of thrust and flight weight capacity. After some calculations I have found with some weight reduction I can manage to keep the overall power budget below 1000 watts and therefore reduce the requirement of three power supplies down to two power supplies. Only having two power supplies onboard further reduces the weight 1 - 1.4 pounds lighter by itself.

-

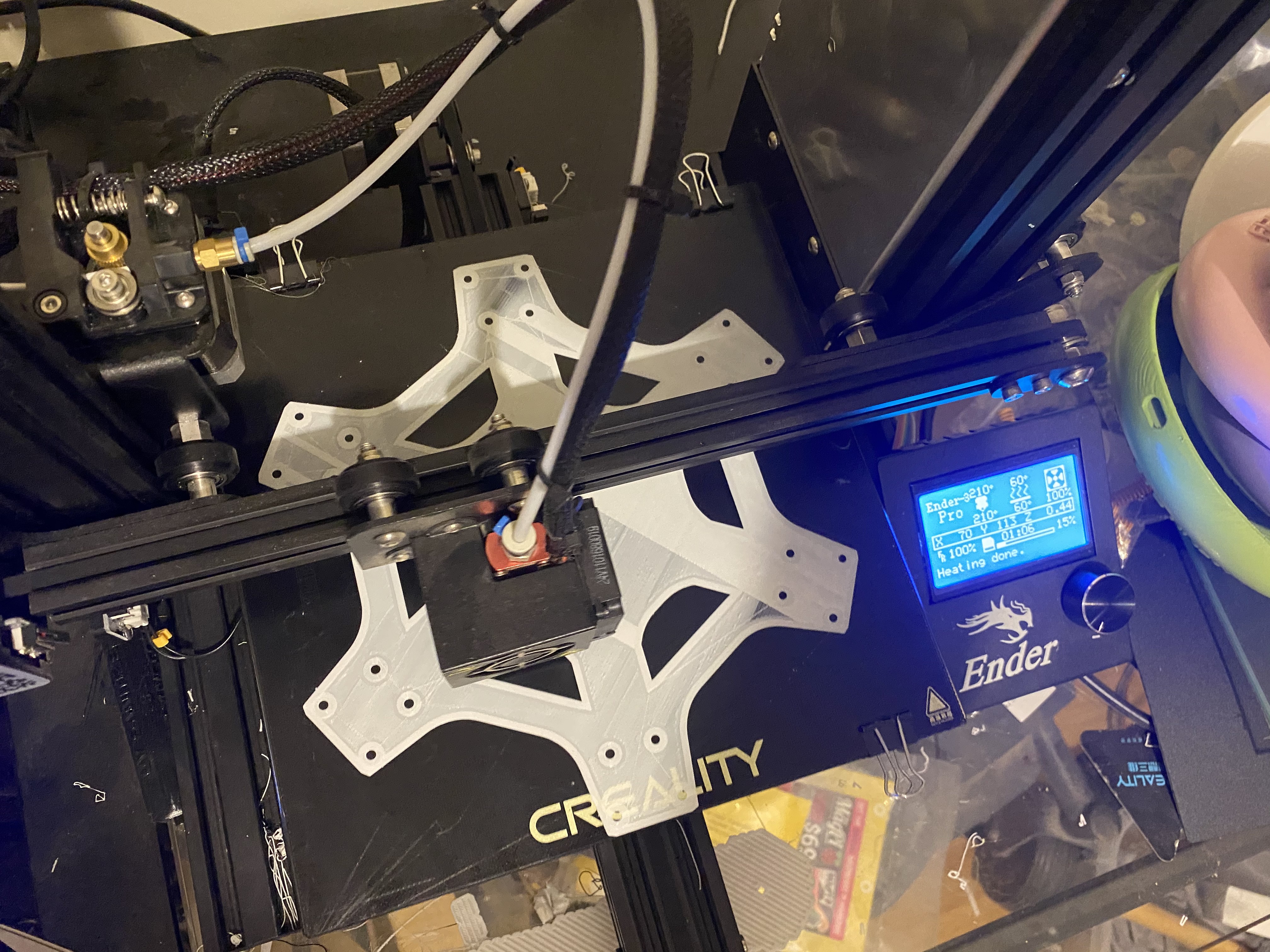

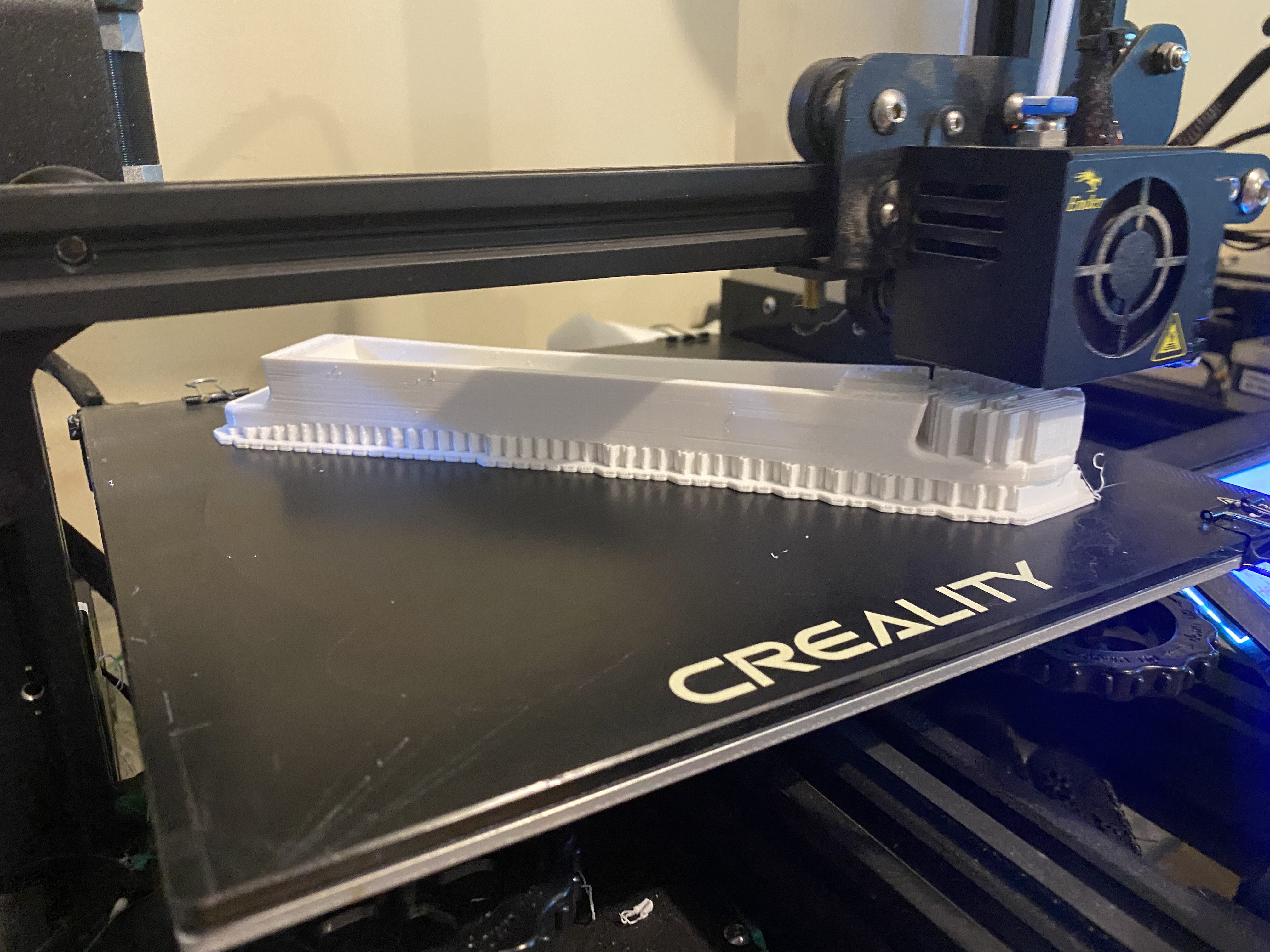

New 3D Printed F550 Style Top Plate

09/09/2020 at 01:06 • 0 comments![]()

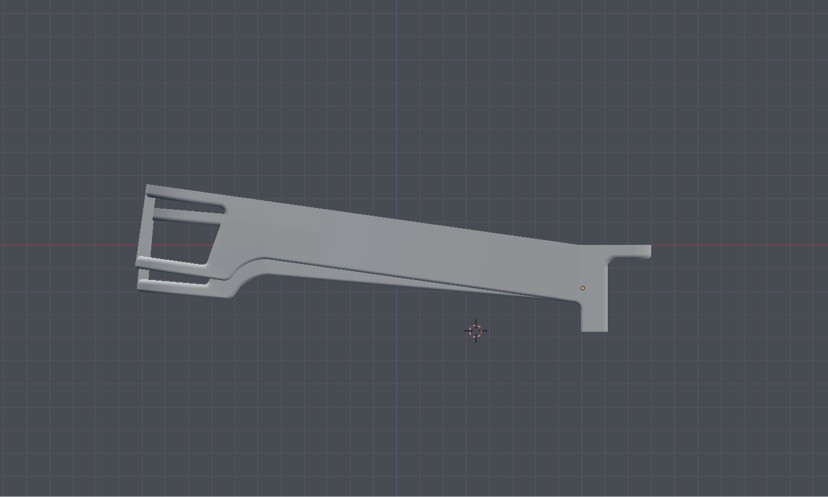

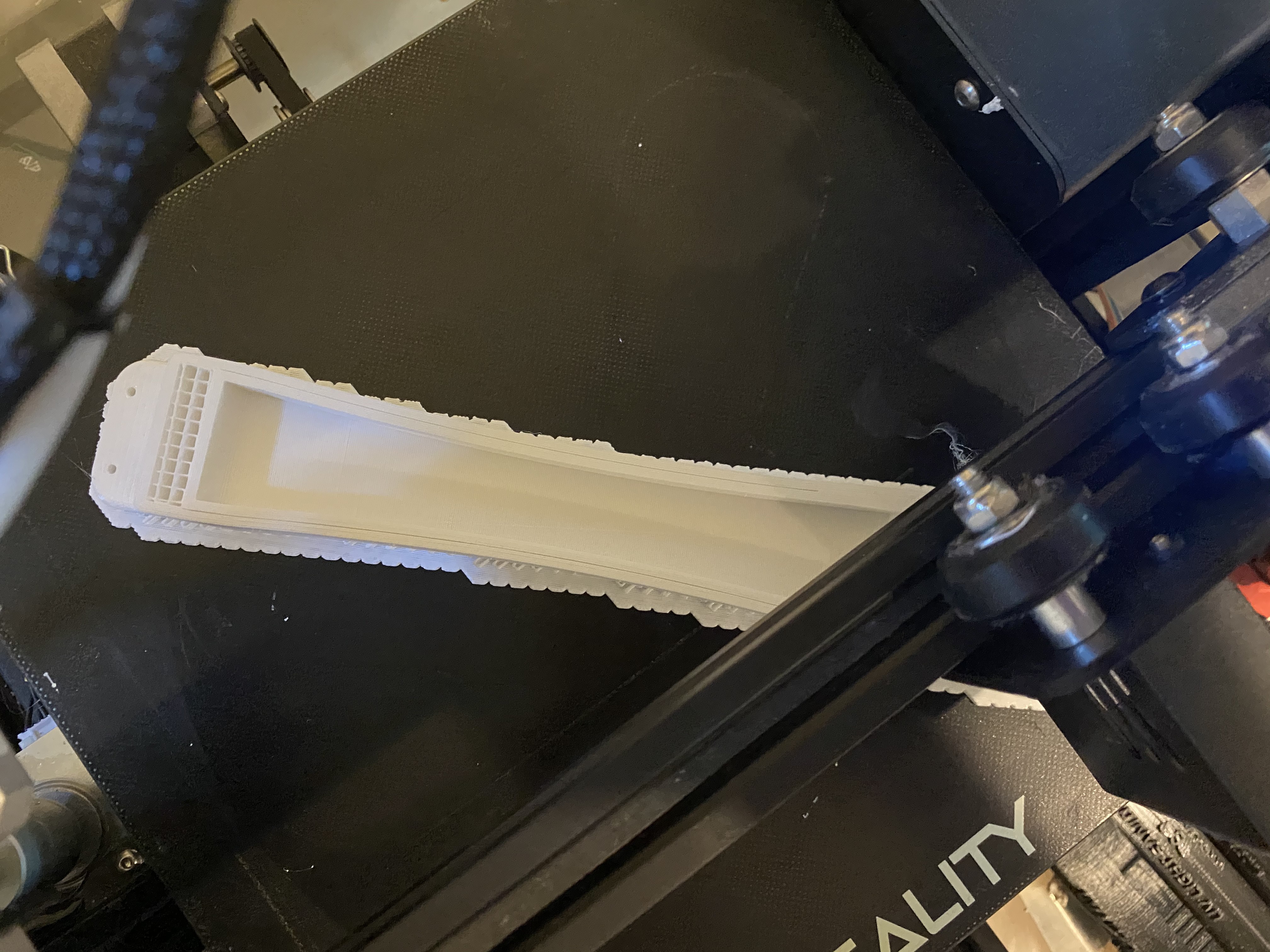

One of the goals in this project is versatile options for construction. Using a prebuilt frame works fine however a F550 frame to work with is not always available and tensions with China make getting cheap clones or even genuine parts harder and harder. At times taking weeks to get here in the USA and even more difficult in other parts of the world. Also I am taking into consideration that other places in the world like Sri Lanka for example may have trouble getting parts imported in, so 3D printing has become even more popular as an alternative. I have included a Top Plate F550 replacement where the holes line up. I am testing a 1mm thick and 2mm thick part. They are printing right now. I have not modeled a lower plate for the frame yet, but it will be coming.

-

Ver 3 8 degree arm weight in

09/08/2020 at 03:56 • 0 comments![]()

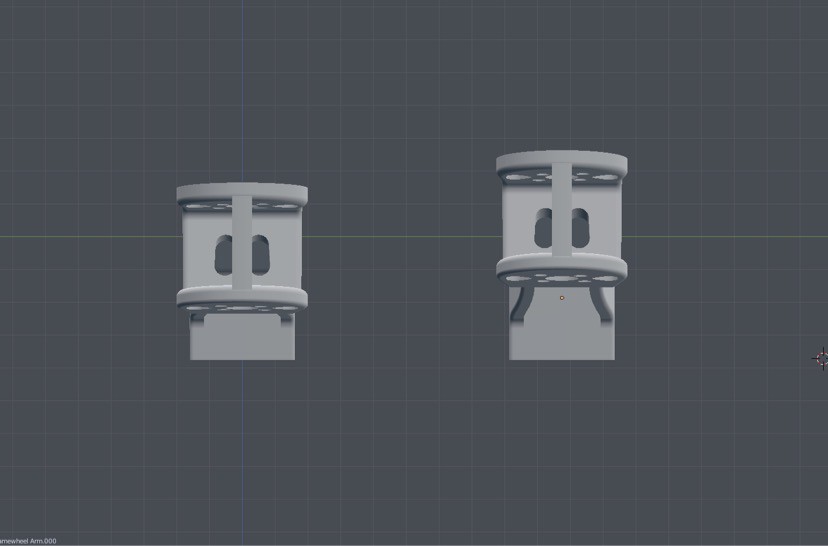

![]()

![]()

![]()

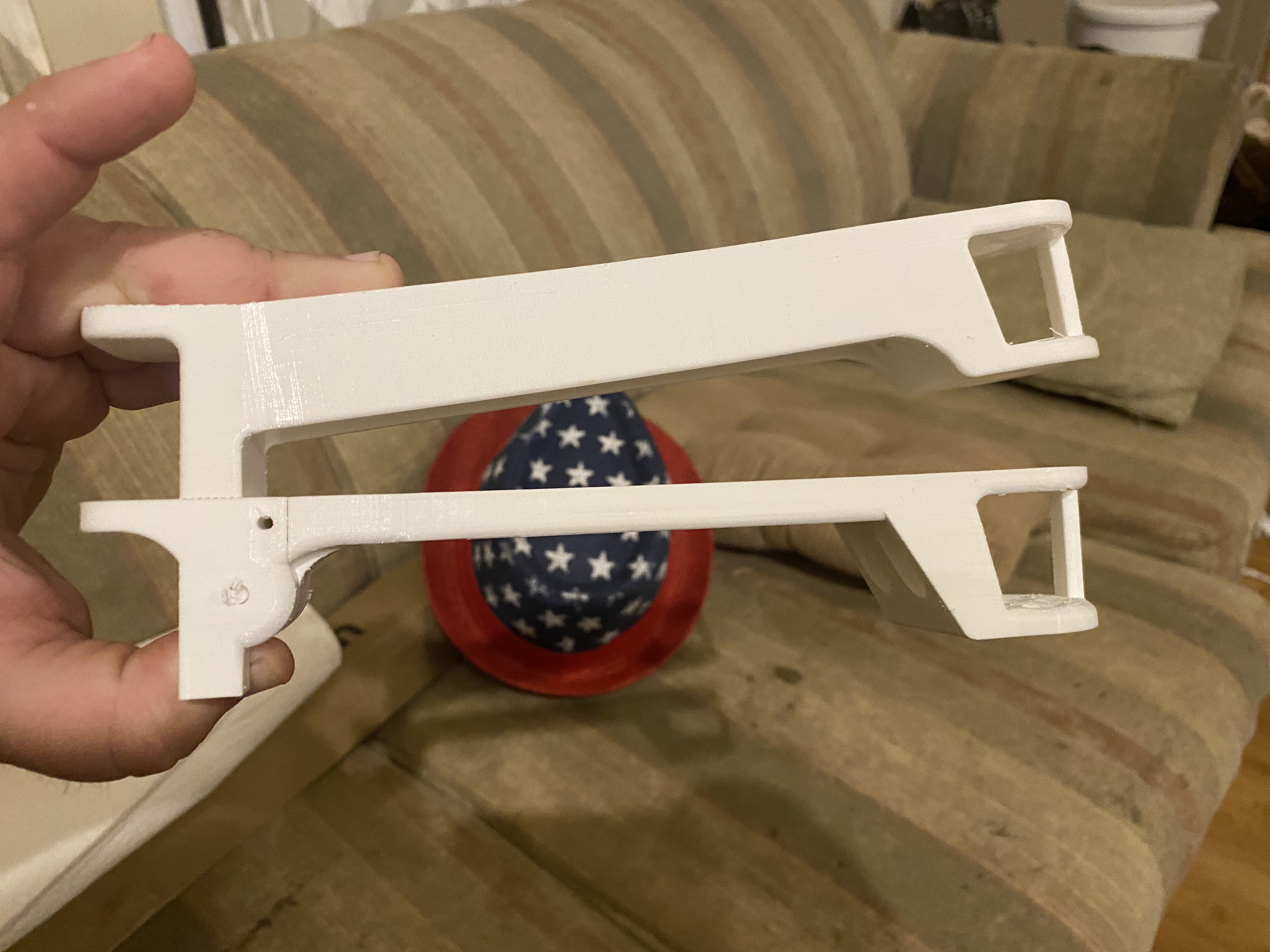

only a .4 ounce increases for a significantly stronger arm, I am considering drilling holes in strategic locations to shave off the other .4 ounces ,but keep the increase rigidity. Of course there is not need for the two bolts that were the hinges on the folding arm so that weight is lost as well. I will start measuring for the ESC and wire feed locations in the morning as the other two arms are printing of the total 6 needed for the upgrade.

![]()

Just for point of comparison this is a normal original equipment ABS molded arm that has no tilt for stability and no dual motor mount option. -

Ver 3 , 8 Degree Arm Dihedral Motor Mounts

09/07/2020 at 19:28 • 0 comments![]()

![]()

![]()

![]()

![]()

![]()

![]()

-

Ver 2 PSU parts arrive from Digikey

09/06/2020 at 05:10 • 0 comments![]()

![]()

This is a quick comparison of the ver 1 power supply and the custom components we ordered from Digikey, take in mind I ordered one extra of every component in case of duds. So I should be able to be a more powerful power supply and still stay within the same or less weight range. I will start assembly on the custom PSU tomorrow I believe. In addition to more power I am including one Lipo battery as a power reservoir on the output of each power supply. I will spread out the components and take pictures as well as weight them individually as I go.

The first power supplies will be on a prototype board with jumper wires .

I am not in any way sponsored by any company, I just happen to shop there based on the price. -

Sky Anchor Flies for the First Time

09/05/2020 at 05:12 • 0 commentsAfter a hard landing refusing throttle too quickly I surveyed the damaged. Luckily everything is 3D printed and I can print spares in a few hours.

-

BOM for the 1st ( of three) 500 watt power supplies

09/01/2020 at 20:30 • 0 comments941-1792-ND PACSR12042S AC/DC CONVERTER 12V 504W 1 Immediate 187.87000 $187.87 2 1189-2033-ND 450VXH220MEFCSN25X35 CAP ALUM 220UF 20% 450V SNAP 3 Immediate 3.86000 $11.58 3 490-9555-1-ND DE2E3KY222MN2AM01F CAP CER 2200PF 250VAC RADIAL 1 Immediate 0.46000 $0.46 4 P122323CT-ND EEU-FS1C821LB CAP ALUM 820UF 20% 16V THRU HOLE 6 Immediate 0.66000 $3.96 5 490-9555-1-ND DE2E3KY222MN2AM01F CAP CER 2200PF 250VAC RADIAL 1 Immediate 0.46000 $0.46 6 1189-2033-ND 450VXH220MEFCSN25X35 CAP ALUM 220UF 20% 450V SNAP 1 Immediate 3.86000 $3.86 7 490-9531-1-ND DE2B3KY101KN2AM01F CAP CER 100PF 250VAC RADIAL 3 Immediate 0.41000 $1.23 8 490-9561-1-ND DE2E3KY472MN2AM01F CAP CER 4700PF 250VAC RADIAL 10 Immediate 0.39600 $3.96 9 1572-1784-ND MPX104K305D CAP FILM 0.1UF 10% 305VAC RAD 2 Immediate 0.41000 $0.82 10 P14783-ND ECQ-UAAF474M CAP FILM 0.47UF 20% 275VAC RAD 3 Immediate 0.64000 $1.92 11 490-9463-ND DE2E3KY152MA3BM02F CAP CER 1500PF 250VAC RADIAL 2 Immediate 0.45000 $0.90 12 RNV14FAL820KCT-ND RNV14FAL820K RES MF HV .25W 820K OHM 1% AXIAL 3 Immediate 0.26000 $0.78 13 553-3963-ND PH9455.705NL CMC 6.5MH 9A 2LN 6.4 KOHM TH 2 Immediate 7.61000 $15.22 -

Current Strategy for Power Tether updated

09/01/2020 at 16:40 • 0 commentsThough I do not post every test as boring as it would be, I am coming to the conclusion I need to alter the power distribution strategy. First is that peak wattage should come to about 1200-1300 watts with an average below 1000 in total. That being said only two power supplies are hard pressed to handle this for hours on end. Reducing the load below 80 percent of the maximum of a power supply is really a requirement at this point. At this time the top 6 motors and bottom 6 are on their own circuit. This would mean 500-600 watts each surpassing that 80 percent goal. The second improvement that needs to be made aligns with a lighter power to weight ratio. The need to custom build a power supply is here, and for the purpose of both efficiency and redundancy these 12 motors will move from two groups of 6 to either 3 groups of 4 or 4 groups of 3. I am using two DJI power distribution plates which will no longer be used in the new power distribution grouping which may reduce weight if removed, but they are also part of the frame at the moment. The power tether weight can be halved by running 220 volts instead of 110v which was already in the works. We also may 3D print a new power supply frame that doubles as landing gear because the ones I have are very flimsy and flex out of shape with the slightest twist when landing.

-

2nd test after rewire, throttle up 25 percent

08/28/2020 at 04:45 • 2 commentsThis is the second test after removing the bad PSU from the loop to test equipment. It is raining outside now so we will have to wait till we can get it outside. There are many goals to this project and we are tackling them one at a time. This test is only with one 6000 mah battery, however we are upgrading that to four tomorrow I believe. Power tether may be swapped around to having Any PSU on the ground and then fed by power wire and Ethernet.

Open Sky Anchor WiFi Drone Brings The GIG

Mission "Wifi" Impossible > Bring Long Range 5G and 2.4 G WiFi Backed By A 1 Gigabit Fiber To The East Brainerd EF-3 Tornado Disaster area.

Josh Starnes

Josh Starnes