Short overview:

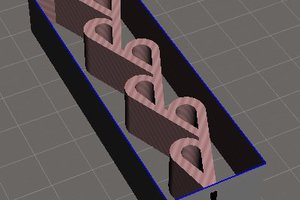

- Vacuum chamber built from a plexiglass tube, 3D printed parts and aluminum profile

- The inner framework supports the chamber from the inside

- Pressure sensor is designed to keep the pressure in the chamber regulated using a pump

- Connection using pneumatic connections

- This is a tool to assist at building the "Nerdiskerator" (a 3D printed disk-generator): https://hackaday.io/project/172445 and therefore also WinDIY (a 3D printable HAWT Wind turbine): https://hackaday.io/project/172328-windiy-hawt-wind-turbine

For what?

Admittedly, a vacuum chamber is really not often needed. (At least not for me) But with one of my projects the Nerdiskerator - a 3D printed disk generator - I had the problem that air was trapped in the epoxy when casting components.

If you are interested you can read the details about it here in the relevant project log: https://hackaday.io/project/172445/log/179551-the-actual-state-issues-and-how-to-solve-them-hopefully

Unfortunately my search for a suitable and not too expensive vacuum chamber was unsuccessful. That's why I decided to just build my own. :)

ToDO:

- Set up test circuit to test reading of the pressure sensor and control of the pump: pending

- Implement and test PID control of the air pressure in the chamber: pending

- Design circuit board for control electronics: pending

Fabian

Fabian

Sohum Desai MD

Sohum Desai MD

Nasser

Nasser

Cole B

Cole B

I want to repurpose the pressure sensor and scale this up for a personal hovercraft. I have no idea why that was the first thing that came to mind. Thanks for sharing this as a standalone effort (the project deserves it).