Adaptive wireless switch

Adaptive switches are often used by people with limited hand function. This switch looks like a game controller and uses a low cost keyfob.

Adaptive switches are often used by people with limited hand function. This switch looks like a game controller and uses a low cost keyfob.

To make the experience fit your profile, pick a username and tell us what interests you.

We found and based on your interests.

1 Controller body top v8 (final).stlFinal 3D print file for controller body, top component.Standard Tesselated Geometry - 2.10 MB - 08/01/2020 at 12:35 |

|

|

2 Controller body bottom v9 (final).stlFinal 3D print file for controller body, bottom componentStandard Tesselated Geometry - 923.13 kB - 08/01/2020 at 12:35 |

|

|

3 Battery clamp v2 (final).stlBattery clampStandard Tesselated Geometry - 22.93 kB - 08/01/2020 at 12:35 |

|

|

4 Pushbutton Short v7 (final).stlShorter pushbutton for nearer the user's hand. See note for Tall pushbutton.Standard Tesselated Geometry - 148.81 kB - 08/01/2020 at 12:36 |

|

|

5 Pushbutton Tall v7 (final).stlTaller pushbutton for further from the user's hand. The difference between short and long is small. Usually the buttons are printed as different colors.Standard Tesselated Geometry - 147.25 kB - 08/01/2020 at 12:36 |

|

Since the start of this project I have assembled 5 of these wireless switches. The latest version is rugged and reliable. The range of operation is only about 4 to 6 feet, but that works well for my application. As the battery runs down, the range reduces.

I use 500 mAh batteries, but the controller will fit 1000 mAh batteries with no problem. I purchase fresh batteries every 4 years or so, but I actually do not know how long a battery will last.

Assembly is somewhat tedious. The detailed instructions are very helpful.

One weakness of the existing design is that the mounting posts can break when being tapped, or the threads can be stripped during assembly. The best way to protect the plastic mounting posts is to use heat-set thread inserts. Note, this only works with thermoplastics. There is an expansion-type insert that can be used on other plastics.

I use McMaster-Carr part 93365A230. Carefully drill out the 4-40 thread holes in the mounting posts with larger and larger drill bits until you reach 9/64". Try to hit this size exactly (that is, buy a 9/64" bit). If you use other heat-set threads, drill to the specifications of those threads. Make sure the bottom of the heat-set thread just fits into the top of the hole. With a soldering iron (with a very clean tip), poke the tip into the heat-set thread and hold until the plastic gets soft. With a little push from the iron, the thread will advance smoothly into the hole. Lift the soldering iron off when the insert is completely inside the post. Have a small flat screwdriver handy to keep the thread from lifting up while you lift the soldering iron. There are some good demos in the Internet, so you can see how it works.

The project is complete. A tiny tweak to the lower body case lip helps the case fit together without endangering any of the alignment posts. The USB charger board is held in place by the rear pins and the adjacent wall. The front pins (nearest the micro USB connector) are not used. Final STL files have been uploaded to print your own case.

Bill of materials file deleted and replaced by listing of all components. Draft step-by-step file replace by full set of instructions.

I found two controllers that did not properly trigger the receiver. I saw a similar problem with a non-rechargeable controller I built earlier (see photo). The keyfob board is designed to work with coin cells. When you use a separate power source it lacks a low impedance RF pathway across the battery terminals. To solve this, I added a 1.0 uF ceramic capacitor across the keyfob battery terminals. The picture shows a capacitor with a 5.6 ohm resistor. You don't need the resistor. (The resistor was needed in that earlier design because I ran it on 6 volts, which was too high.) The capacitor solves the problem in the new controller. Some controllers will operate without the capacitor, but why take chances? The instructions have been updated to include the capacitor.

Files now have preliminary assembly instructions and bill of materials.

Basic operation.

In the chrg position, the controller is off and can be charged using a standard cell phone charger and a micro-USB cable. The charger LEDs will go from red to green when the battery is fully charged. In ON position, the battery is in use. The LEDs from the PowerBoost board should be visible: green when ON, but turns to red when the battery is low. The keyfob LED should light red when a button is pressed.

The intended receiver is an Adafruit

1096 Simple RF M4 Receiver - 315MHz Momentary Type

It is built into my Raspberry Pi PlayVideo system

https://wordpress.com/page/arm22q13.wordpress.com/3369

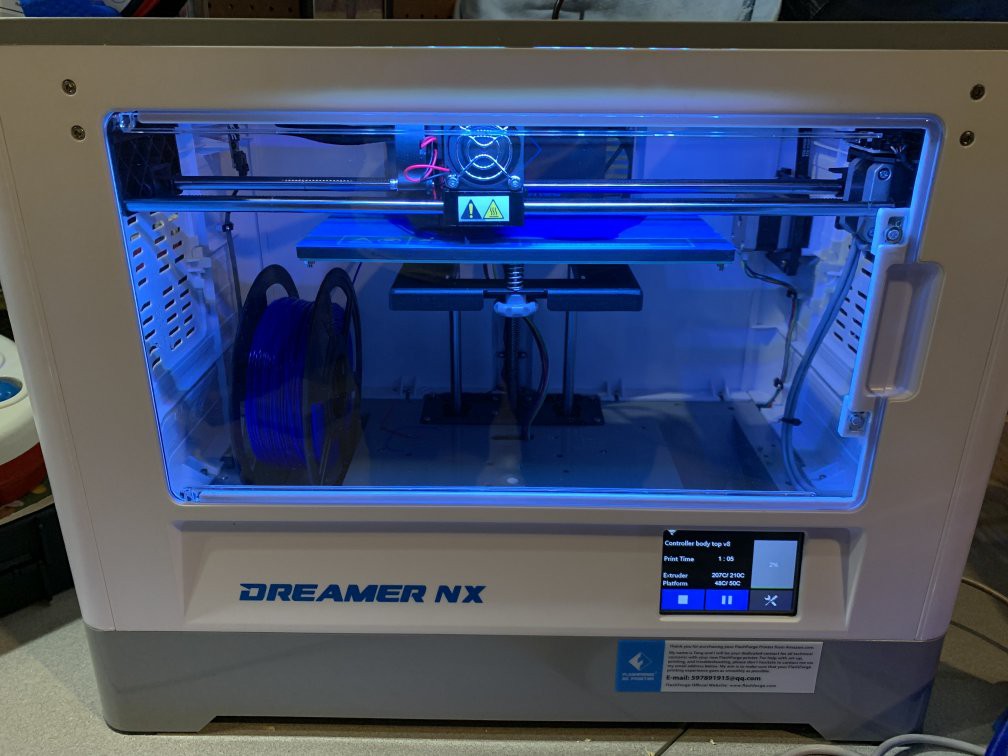

The 3D printer used for all the prototypes and production adaptive switches is the Flashforge Dreamer NX. Because the project was to aid disabilities, the use of the printer and materials were donated by two wonderful supporters of this project.

Bottom half of case. Clear out battery hold-down holes with a #50 drill bit and pin vise. Carefully tap the hole with 2-56 tap.

Top half of case. Very carefully drill the 7 thick round mounting posts using a #42 drill bit and pin vise. Go slowly and clear out waste a couple of times while drilling holes.

Stop here. See Log file: "Using heat-set threads for mounting posts". The heat-set threads work much better than tapping the plastic directly. Optionally, you can continue with this step and tap the plastic directly. Step 7, below, shows heat-set inserts in three of the mounting posts.

Tap these holes with a 4-40 tap. Tap the holes even more carefully than drilling. Keep the tap clean. Do not drive the tap too deep. The posts can snap off.

[Warning: This step has risks. The battery is very powerful. Do not let the two battery leads touch each other.] See Step 11 for a picture. Cut the connector off the battery keeping 2 to 2.5 inches attached to the battery. Do not cut the two wires at the same time with a metal tool. Cut each lead separately to avoid shorting them. Cut the JST-PH battery extension cable so that the female connector (the connector that has no exposed metal) has about 2 inches of wire on it. Save the other end of the extension cable, you will need it. Strip (that is, remove the insulation and expose the wire inside) the wires on the female connector.

Note that the RED wire of the battery must be connected to the RED wire of the connector. Decide if you will be using epoxy or heat shrink tubing to insulate the connections. For heat shrink tubing, strip one battery wire. Mount a piece of heat shrink tubing on that wire. Twist the battery wire to the matching color wire of the connector. The wires should be twisted in-line with each other to allow the shrink tubing to fit over the connection. Solder wires together. Slide the heat shrink tubing over the soldered connection. Shrink the tubing. Now repeat for the other battery lead. With this method the two battery wires are not exposed at the same time. Now the battery has a cable with the correct connector. and the correct connections.

The other way to insulate the soldered wires is with J-B KwikWeld epoxy. Connect the cable without heat shrink tubing. Me careful to keep the read and black exposed wires separated. Mix the epoxy and coat each connection. Be sure no wire is exposed. Do not handle wires for 20 minutes so the epoxy can set.

Create an account to leave a comment. Already have an account? Log In.

Become a member to follow this project and never miss any updates

JT

JT

Kevin Neubauer

Kevin Neubauer

Solderking

Solderking

3D printing was done on a Flashforge Dreamer NX.