-

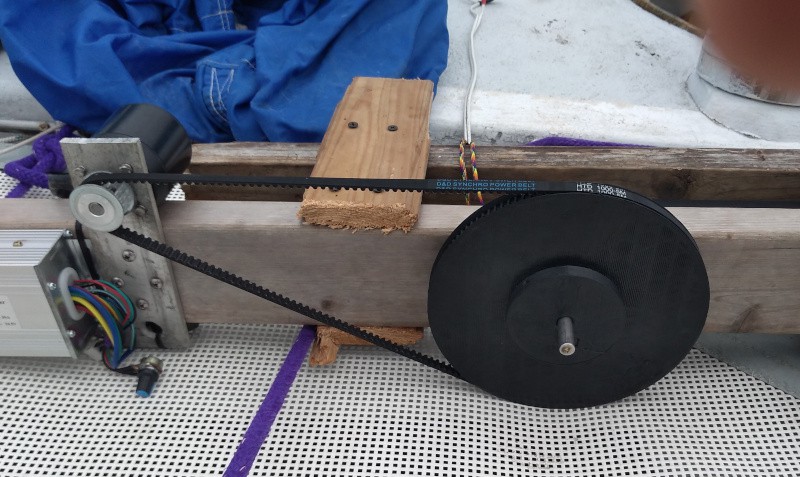

09/07/2020 New pulley test

09/07/2020 at 23:21 • 0 commentsI printed a 90 tooth pulley, improved the alignment, and the motor spins faster with the 11.25:1

ratio down from 15:1 previously.The power consumption increased to 120 watts which is barely more than a single solar panel. The boat speed 2 knots. It will be interesting to try higher voltages and power levels but the efficiency is currently around 50% vs 20% for a typical electric trolling motor.

-

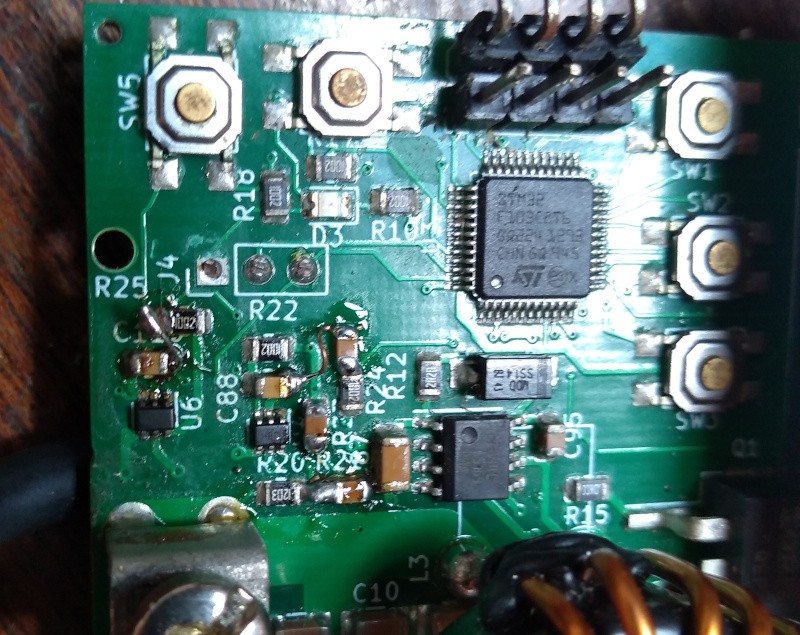

08/31/2020 rework MPPT circuitboard

09/01/2020 at 03:15 • 0 commentsI have improved the MPPT by adding 5 filter capacitors.

![]()

These capacitors greatly stabilize the voltage and current readings. This allows for quicker peak power tracking, although the algorithm sometimes gets confused if the light level is increasing or decreasing with changing cloud cover and doesn't get back to the optimal setting until the power level stabilizes.

I also reduced the mosfet gate capacitors from 33 ohms to 6.8 ohms and was able to realize an 18% power increase over a direct battery connection up from 15% previously because of reduced dead time. I was only able to cut the dead time in half from 1.25uS to .625uS I wonder if using a more powerful gate driver or using mosfets with lower gate charge (but higher on resistance) might help allow for a shorter dead time.

I need to try with a parallel schottky diode to the mosfet, as it may conduct during switching and slightly increase performance, it will be interesting to see how significant it is.

I still need to experiment with different inductors as well.

-

8/30/2020 initial test powering boat

08/30/2020 at 17:35 • 0 commentsToday I managed to test the motor after tightening the belts considerably so they wouldn't skip teeth. I had to hammer the pulley on the shaft to get the higher tension, so an adjustable idler pulley on each belt may may more sense in the future. The motor draws only 5.4 amps at 13 volts or about 70 watts of power. The boat speed is similar to sculling cruising speed (less than sprint) at about 1 knot.

This may seem slow, but it's already plenty to maneuver in harbors and to break out of wind holes back into wind again. It is also much less power consumption than I expected. I had hoped to achieve this around 100 watts, so it seems the low friction ceramic bearings, high aspect ratio large diameter carbon propeller have paid off.

The next step is to try a smaller reduction ratio on the initial stage which uses 20 and 120 tooth pulleys. So maybe a 100 tooth or even 80 to boost speed. Another option would be to print a 30 tooth instead of the 20, as a 30:120 should be slightly more efficient and less stressful than a 20:80 even though the ratio is the same.

Another way to increase speed will be to use a higher voltage battery which I eventually hope to obtain.

-

8/28/2020 Greatly improved mppt sketch

08/29/2020 at 19:07 • 0 commentsSuperior filtering and actual maximum power point tracking. Solar panels' maximum power point is usually about the same in widely varying light conditions. Normally the duty cycle should be adjusted so that the voltage of the panel remains at the relatively constant maximum power point. The approach used is to follow the maximum power point voltage using a PD filter. This gives great dynamic response to changing loads. The maximum power point is adjusted by 0.2 volts every 10 seconds or so and the direction reversed if the power decreases. This seems to work reasonably well and is simple. I do not like scanning the entire range because of the lost power during the scan, and a 0.2 adjustment near the peak power point is generally < 1% less power than the maximum.

I am achieving about 15% more power than a direct connection to the battery.

From this experiment, it seems I need to add low pass filters to the voltage and current monitoring to decrease noise before I can increase the rate of tracking.

-

8/27/2020 Improve motor

08/29/2020 at 19:00 • 0 commentsI drilled a hole through the shaft and put a stainless screw through the shaft and pulley, hopefully this will stop it from slipping. I cannot test for a few days because of high winds. I would normally only sail in these conditions, after all, the boat can sail much faster than it will ever go on solar power.

![]()

-

8/26/2020 Initial test of electric outboard.

08/29/2020 at 18:59 • 0 commentsI needed to reprint the bearing holders several times with slight variations in offset to align the shafts and get the right tension on the belts. This is much easier than reprinting the pulleys. The shafts need slight angles (1 or 2 degrees) to compensate for the tension of the belt and to ensure the belts walk the right direction. This also determines if the intermediate shaft is pulled in or out and I wanted to get it well balanced to avoid axial loads on the ceramic bearings.

The motor draws 15 watts (friction losses) spinning the propeller in air at full speed. Speed in the water is only .75 knots because pulley slips on shaft. This is using about 65 watts. It is impossible to use a keyed shaft on a plastic pulley, the plastic stretches.

-

8/14/2020 Begin printing toothed pulleys of various sizes

08/29/2020 at 18:59 • 0 commentsEventually printed 15mm 60tooth pulley for prop shaft, and 9mm 120 tooth pulley for intermediate shaft. My printer is limited to 130 tooth size at 5mm pitch in a single piece. If I wish to go with larger pulleys in the future they will have to be screwed together.

These can take 4-5 hours to print at only 12% infill. It would be great to use a much higher infill or solid pulley for durability, but it would take about a week to print this using solar power (can print only 4-5 hours per day). This gives a first stage reduction of 20:120 and second stage of 24:60. The total reduction is 15:1

-

7/22 Initial sketch working on mppt controller.

08/29/2020 at 18:58 • 0 commentsIt uses a fixed duty cycle of 80%. This is a proof of concept that I could get more power from the panels than a regular controller or direct battery connection. The array of ceramic capacitors have a large inrush current, much more than electrolytics. For this reason, the controller must carefully ramp up the duty cycle from zero to avoid resetting the processor.

-

7/18/2020 Ordered parts needed for electric outboard motor

08/29/2020 at 18:57 • 0 commentsfrom mcmaster-carr ($40)

1) 1/2"x12" hardened stainless steel threaded rod with nuts for main propeller shaft. This allows me to clamp the prop, pulley and bearings to the shaft.

2) 10mmx6" nitronic stainless rod for intermediate shaft

3) thrust bearing to support pushing loads on shaft from propeller without wearing out the regular bearingsfrom ebay:

1) 2x fully ceramic ball bearings with 10mm inner diameter. These are very low friction, do not corrode or need lubrication. ($20)

2) 270kv 6350 brushless outrunnder for electric skateboards ($45)

3) motorcycle bearings for main shaft (eventually to be replaced by ceramic) ($10)

4) hdt5m toothed belts 9mm x 1meter and 15mm x 2 meter ($20)

5) 30 amp brushless controller ($25)

6) 20 and 24 tooth hdt5m aluminum pulleys ($10)from hobbyking:

32x10 carbon fiber propeller ($60) this is the largest propeller I could find for a reasonable price.from hardware store:

screws and stainless bolts $5total: $235

-

7/15/2020 Designed MPPT

08/29/2020 at 18:56 • 0 commentsI have designed and built my own working MPPT. A few notable differences:

a) free software and hardware design. <github link>

b) all ceramic capacitors. This slightly increases efficiency as electrolytic capacitors are often a weak link and also eventually fail

c) buck/boost design allow either higher or lower voltage of battery vs panel.

d) components rated for up to 48 volt system (60 volt mosfets)

e) voltage and current monitoring on both input and output. This allows the unit to calculate it's own conversion efficiency and display this information

f) high-efficiency regulators to power the 3.3v logic as well as the 10v needed for gate drive. This keeps quiecent power consumption around 5 milliamps even powering the backlight of the lcd.![]()

![]()

I had not used the stm32 series microprocessors before, so this seemed like a good opportunity to learn. I can use floating point calculations with no noticeable performance penalty even running at only 8mhz. I have used the stm32duino environment as working with registers directly on this processor is very complex compared to the avr I am more familiar with. Despite this I needed to anyway for the pwm output to achieve the variable deadtime needed in driving the mosfets. I have achieved variable deadtime in the past using timer interrupts on avr series, but this limits the overal maximum frequency to around 20khz.

The design uses a basic buck converter, however it can be reversed and act as a boost converter as well. So there is not a solar or battery specific side, but a high and low voltage side. The parts cost approximately $12 in small quantities.

sean d'epagnier

sean d'epagnier