-

Epoxy coating failure

03/15/2021 at 09:56 • 0 commentsI finally managed to try coating the PCB with epoxy resin. I wanted the circuit to be visible and, at the same time, protected so I thought epoxy would be a good idea.

The test wasn't a great success.

First of all, I expected a shiny smooth over but ended up being rough and not visually appetible. This is probably the result of my little experience handling the epoxy.

And I also lost the button in the process. Despite paying attention not to cover the push-button, the resin still managed to sneak in, making it unusable. I had to remove it and fix it.However, the coating adds some weight and gives a nice solid feeling. I will try again and maybe with a different material. If someone has any suggestion I'll be happy to know it.

-

Boards are complete

11/08/2020 at 21:56 • 4 comments![]()

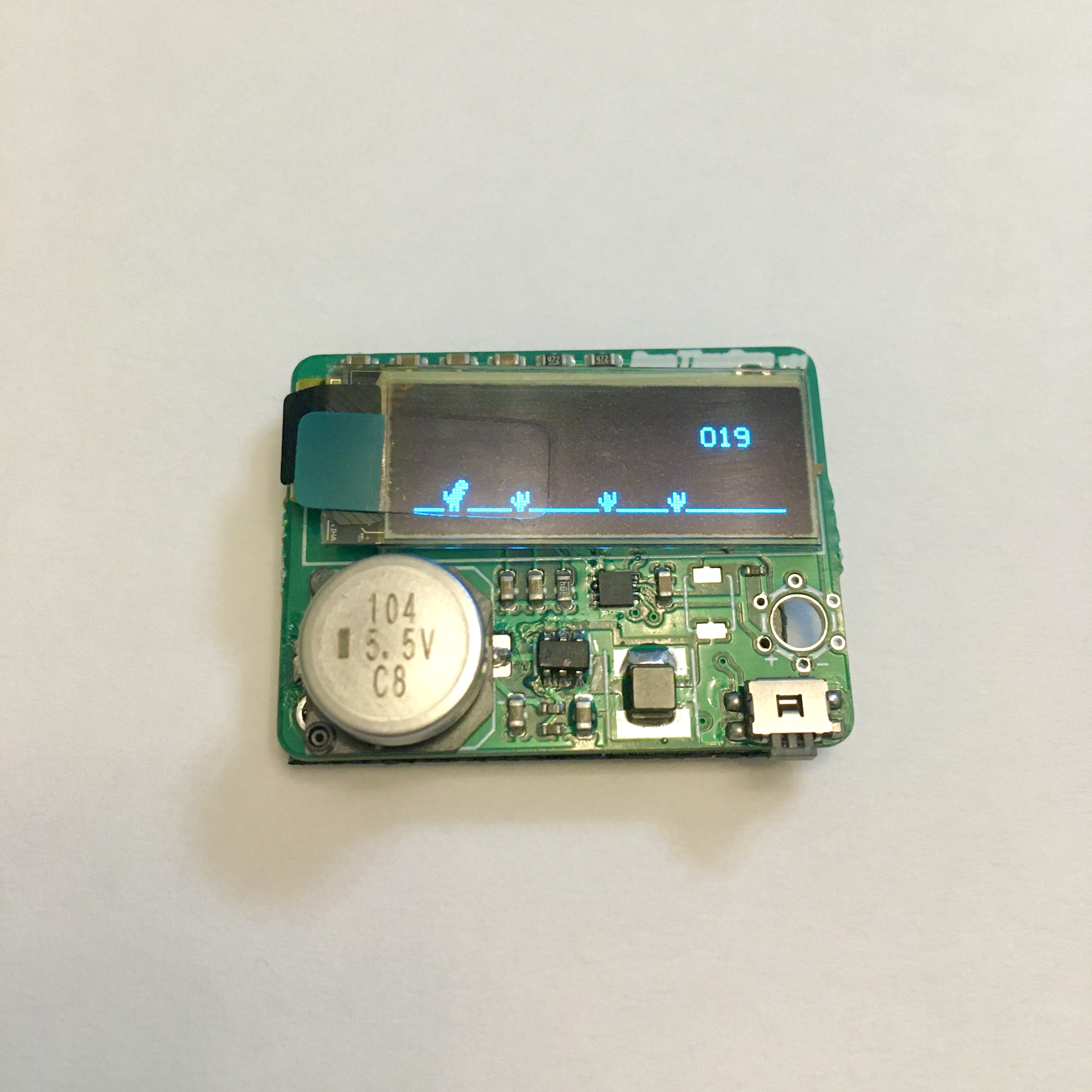

The components are all soldered and the boards are ready.

I first soldered all the smaller components leaving display, supercapacitor and solar panels for later. For these, I used solder paste and a hot surface.

Then I programmed the ATtiny10. This way, if the chip was not correctly soldered I could reflow it without removing other components.

As always happen when I successfully solder DFN packages, I've been surprised to see the program being uploaded correctly.

Next, I soldered the display. This seemed daunting at first but ended up being not really troublesome: just use a little solder and a lot of flux.

Supercapacitor and solar panels followed.I built four boards out of the 10 ordered and all of them work. In the process, I had to throw away a step-up converter: if you solder it reversed you get some magic smoke...

The only missing part is a reset button but this not strictly necessary. I will add it later.

As expected, the board with the IXOLAR panels takes longer to charge the capacitor.

The one with the larger panel can run an indefinite time when directly exposed to sunlight.

I also found out that a 10uH inductor helps lowering the boost converter start-up voltage.

In future, I'm going to replace the MCP1640 with an IC specific for solar energy harvesting. Another improvement will be replacing the pushbutton with a capacitive pad and dedicated IC -

Boards Arrived

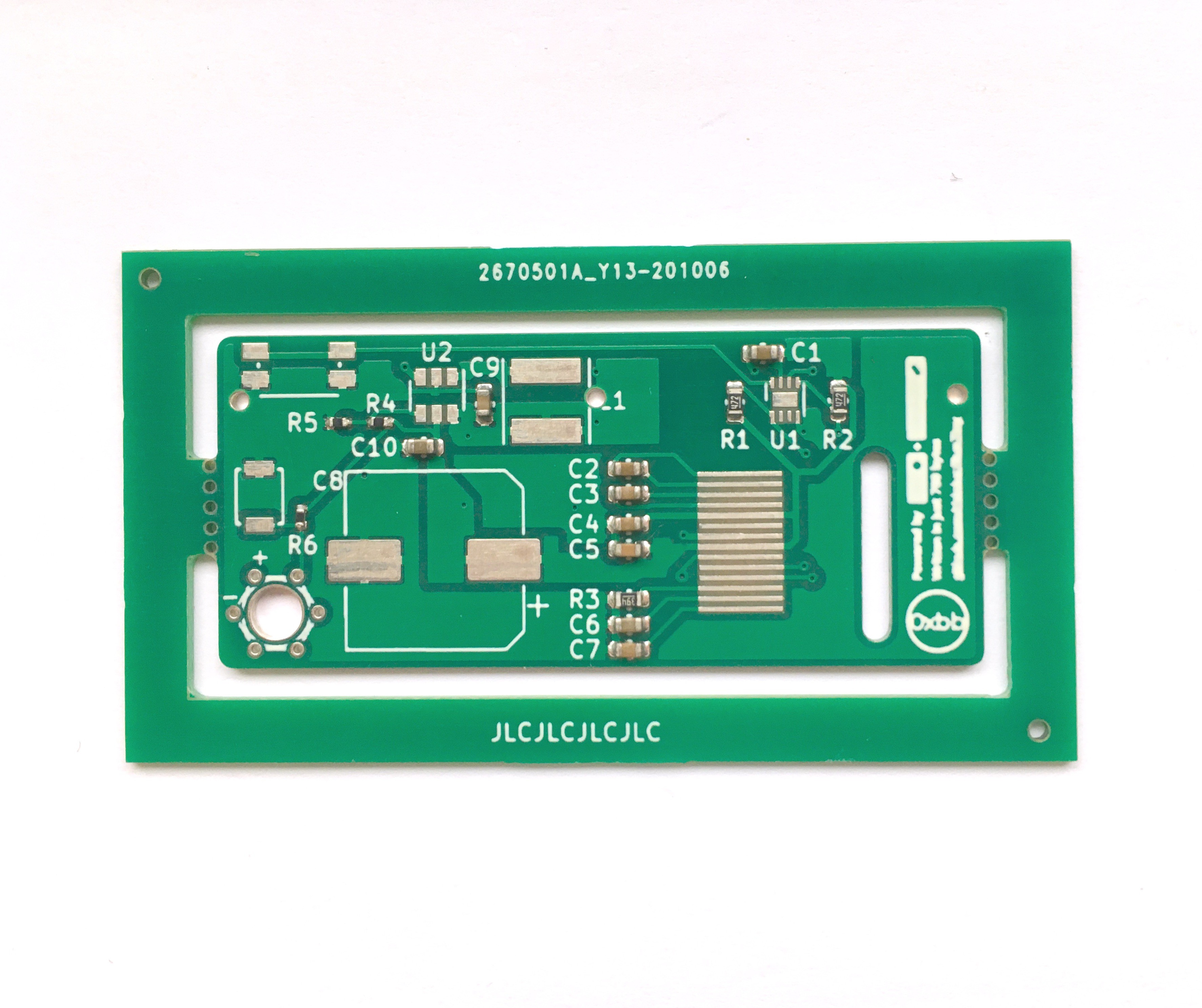

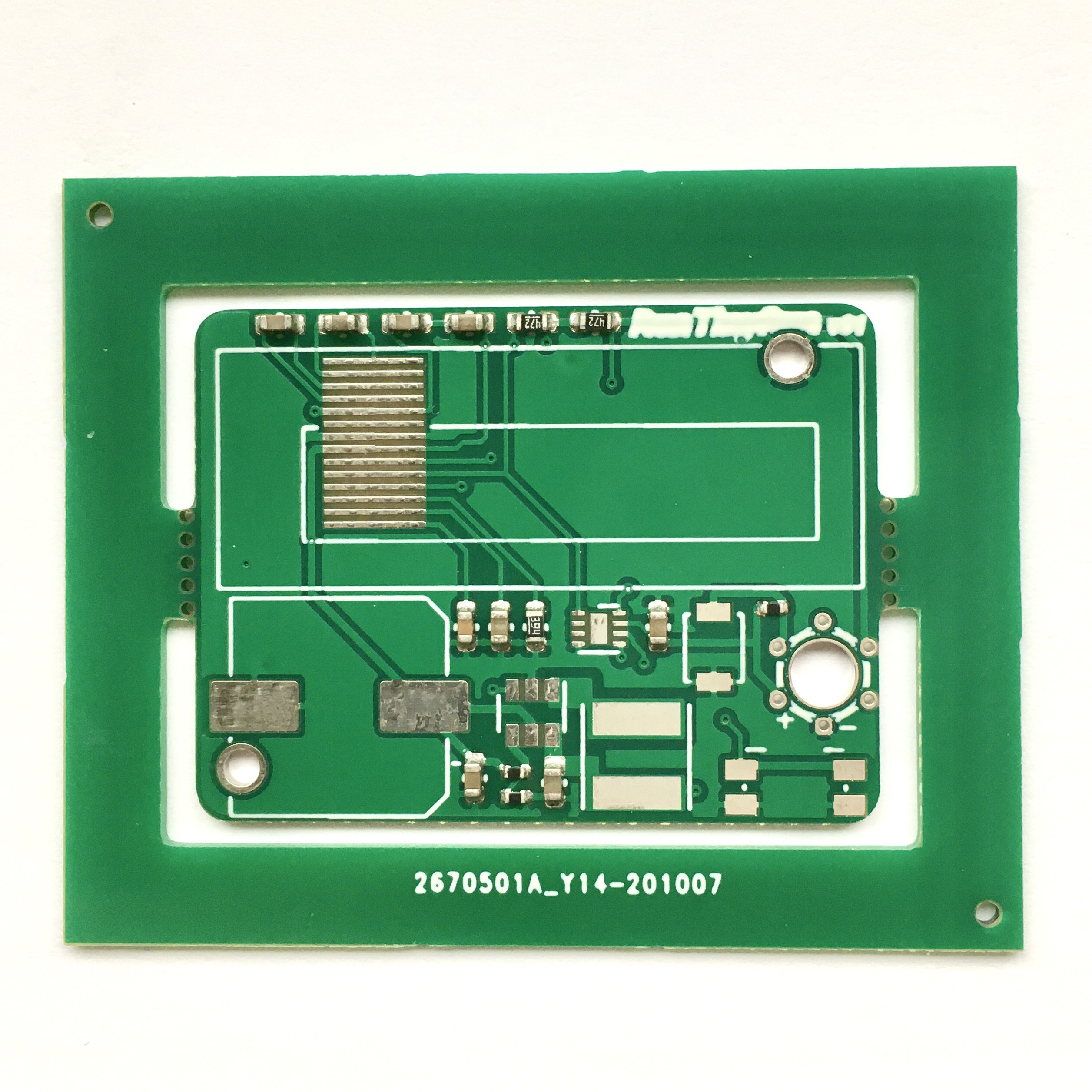

10/27/2020 at 09:22 • 0 commentsThe PCBs have arrived. I'm not impressed with the quality but hopefully they'll work.

Lesson learned No.1: check the minimum silkscreen specifics of the fab house. I did at some point but, changes after changes, I ended up with characters smaller than the minimum requirement. As a result, the silkscreen in unreadable.

The mousebites worked well. These could also be smaller as they seem quite strong.

The soldered components look good. I'm glad I spent a few bucks more to have these assembled. The 0603 package is so small I doubt I would enjoy soldering by hand.

No worries though, there is plenty of other small things to solder. This on the next log.![]()

-

Alternative PCB Layout

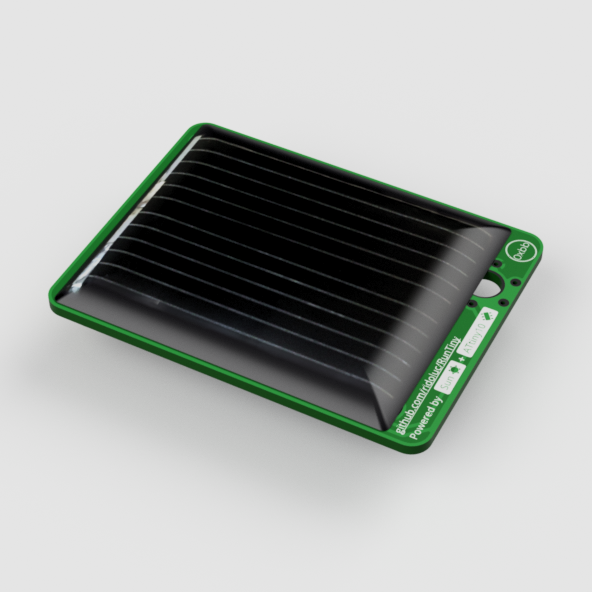

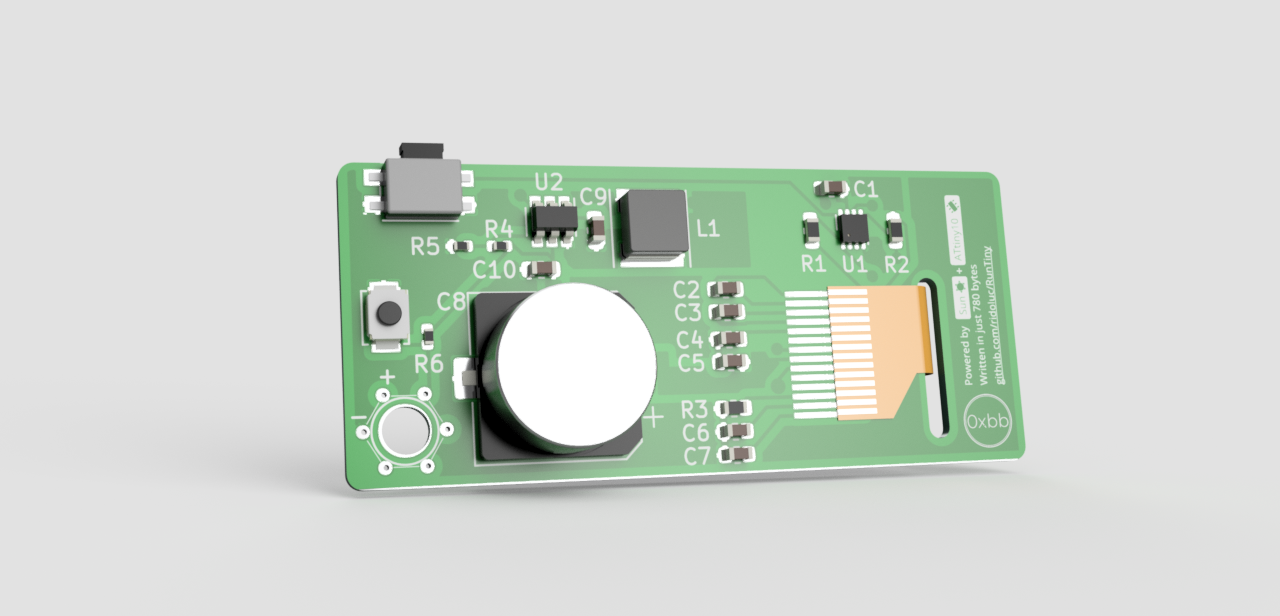

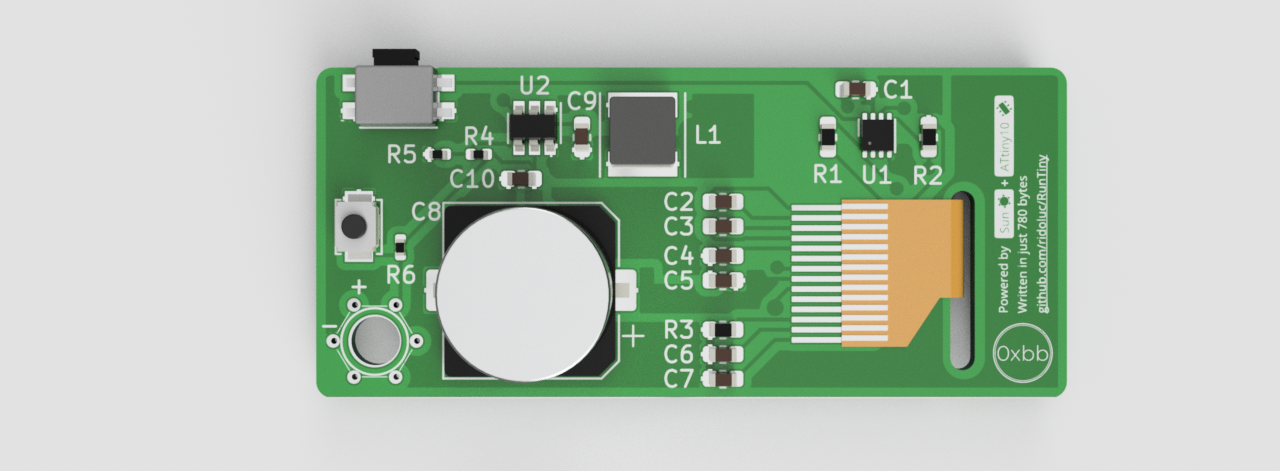

10/16/2020 at 21:41 • 0 commentsI like the first form factor of RunTiny and its design. However, I spent some time trying different options.

I came up with an even more compact solution that has all the electric components on the front and the solar panel on the back.

The size is 34x25 mm.

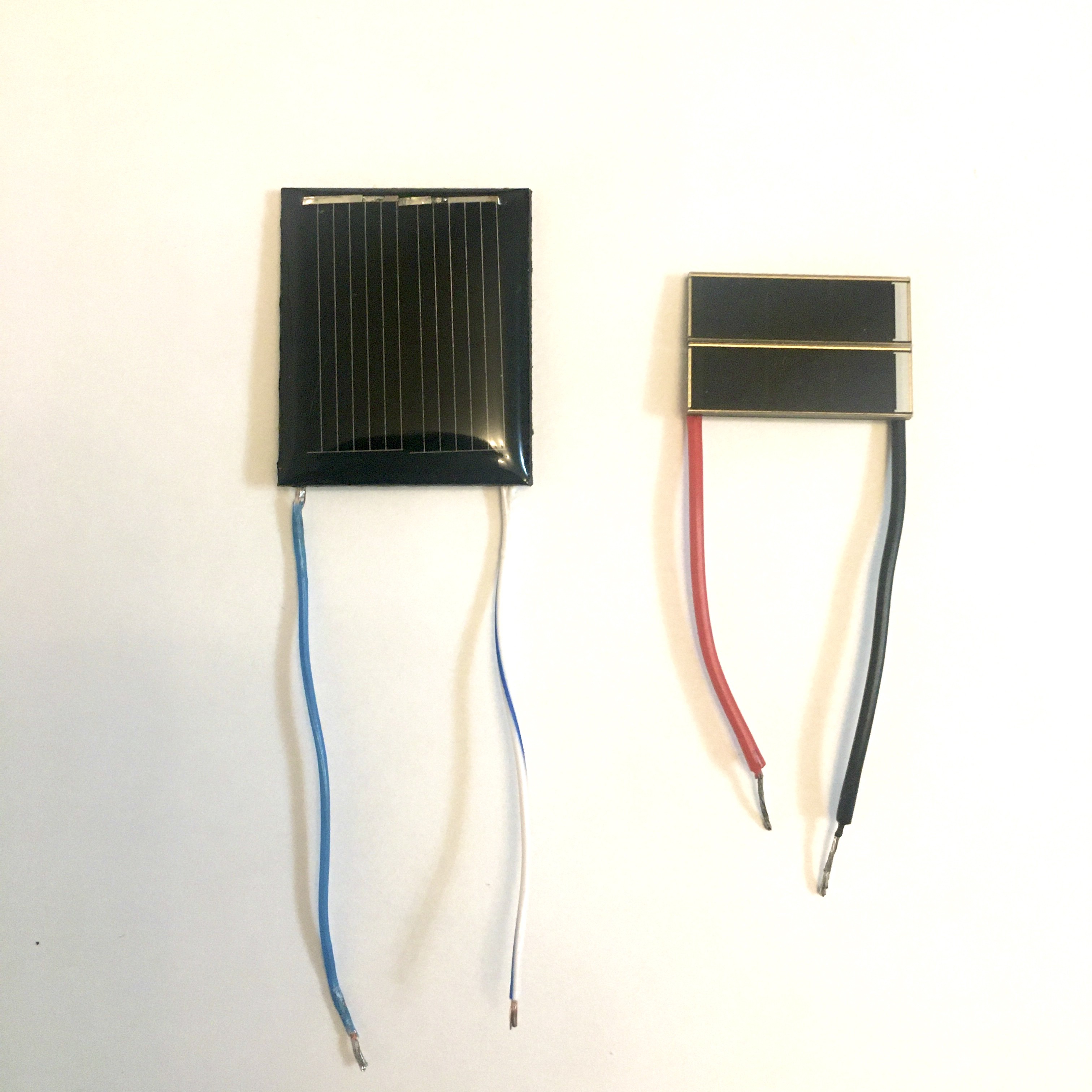

This version is using a cheaper PV cell (about $35c vs $2 of the IXOLAR solution).

Since this cell has a larger surface and produces higher current, it also charges the supercapacitor faster and works in lower light conditions.

I just need to make the order and I'll see which one looks better.

The PCB will be manufactured with the same frame as shown for the earlier version.Here some renderings.

![]()

![]()

![]()

-

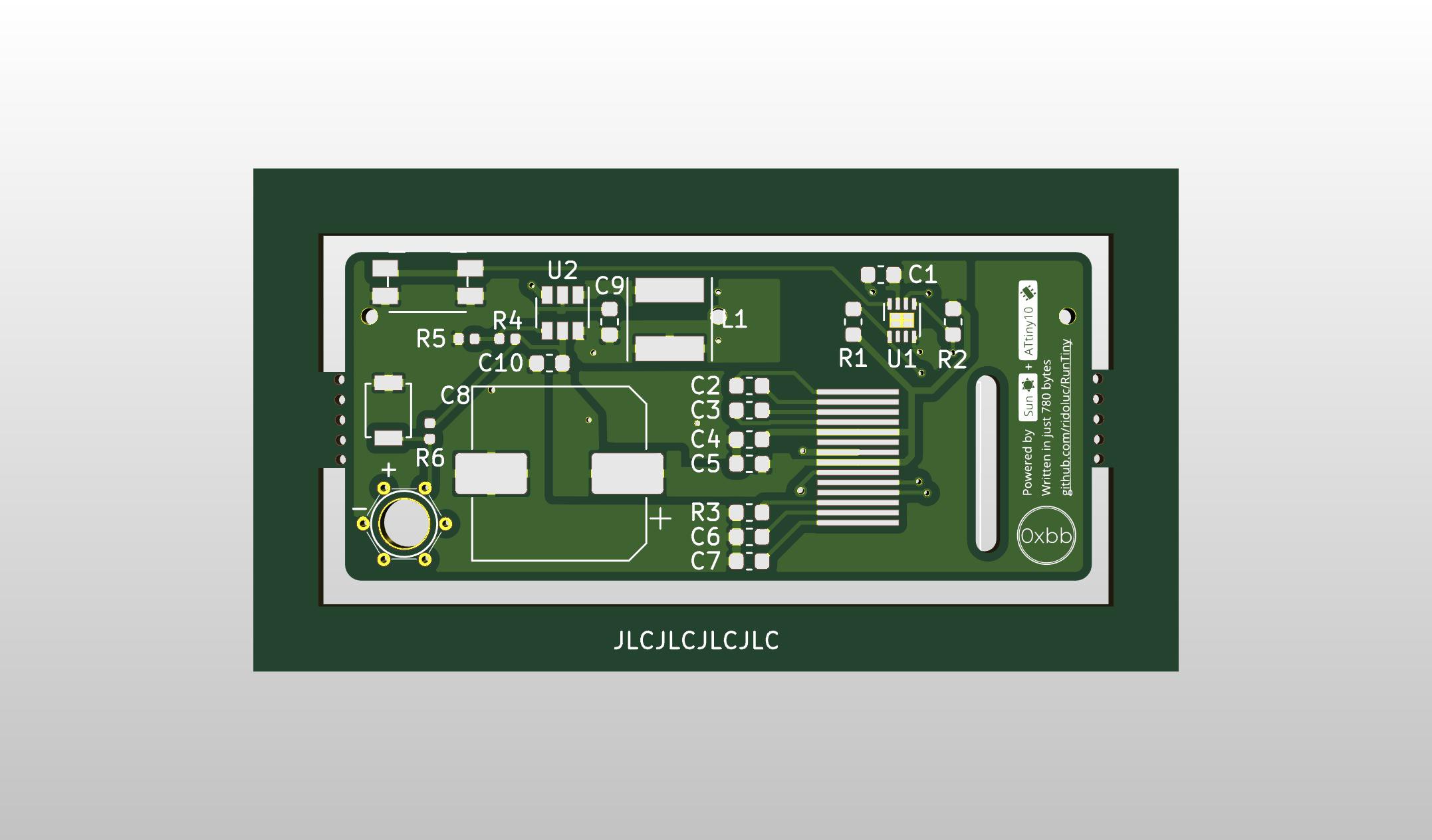

PCB Design. Done.

10/11/2020 at 16:09 • 0 commentsThe PCB design is ready. I tried several options, moving the large components all over the place in the quest of keeping the device as small as possible. It would have been nice to fit more solar panels but two should do the job nicely as anticipated by the breadboard prototype.

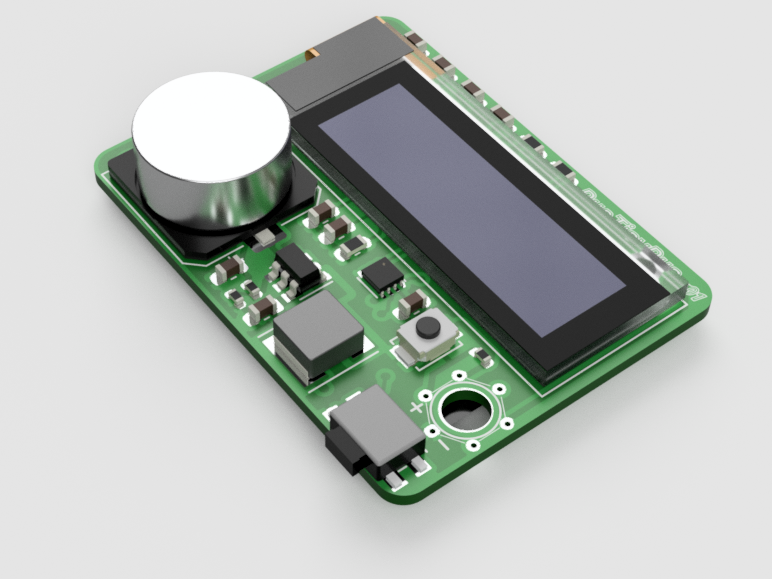

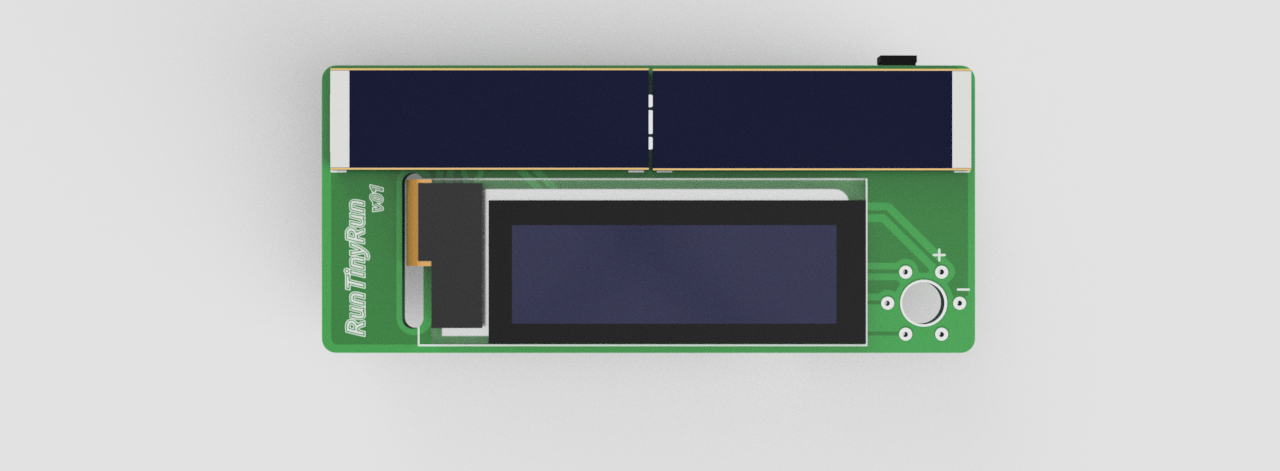

I placed the OLED display and the two IXOLAR panels on one side and all the electronics on the other side.

The OLED connector will pass on the opposite side through a slot.

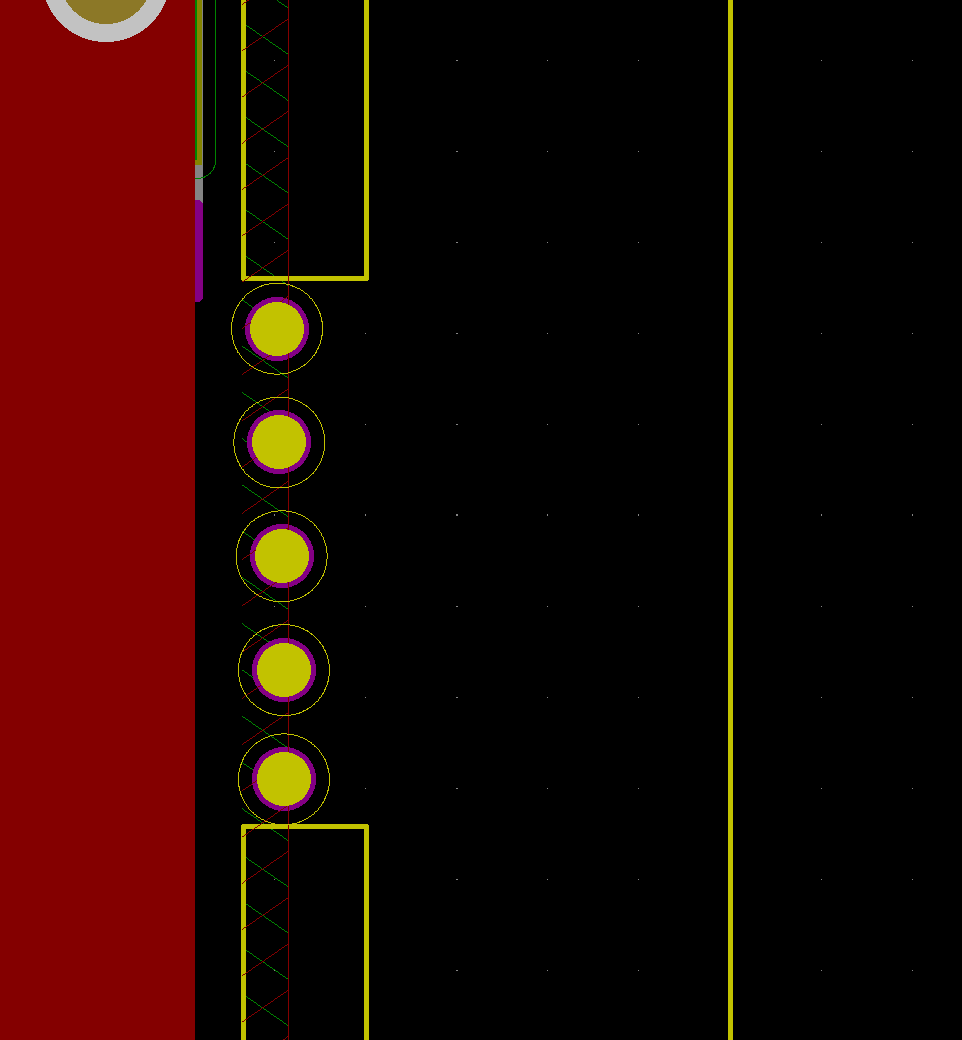

I placed large plated holes on the solar cells pads. These should facilitate the PV cells soldering.

I designed a circular TPI connector for programming the ATtiny10. This has 6 small plated through-holes placed at the vertices of a hexagon. The distance between these holes is 2.54mm so that I can easily build a connector with pogo-pins.The passive components used are mainly in a 0603 package apart from three resistors that are in 0402. I can't bother soldering these components. I will get the passive components assembled from the manufacturer and I will only solder the ICs, solar cells and the display.

Here it is a few renders from Fusion360 with the model imported from KiCad (I did some models like the display and the solar panels in Fusion360).

Front:

![]()

Back:

![]()

![]()

The manufacturer is going to place two or three tooling holes on the PCB for the assembly process. The holes should have a diameter slightly larger than 1mm and should not be plated. I really didn't want to have these on the board given the small space available. I thought about panelizing the design but after some research, I was still confused about the process to design the actual panel. Also, the board is too small for a v-cut machine.

The solution I found is to create a frame around the PCB and connect this with two handmade mouse-bites. The price will be the same and hopefully it will work as expected.

![]()

This is very simple to do in KiCad: draw two rectangles around the board on the "Edge.Cut" layer. Then connect the frame to the board with two more lines. To remove the outline on the mouse-bites just right click on the Edge layer and select create corner.

![]()

Finally add some non-plated holes. I can't tell the optimal number of the holes or what should be their size.

I have a lots fo doubts about the solutions I'm using. I guess I will find out if this design works and can be improved once I get the boards.

-

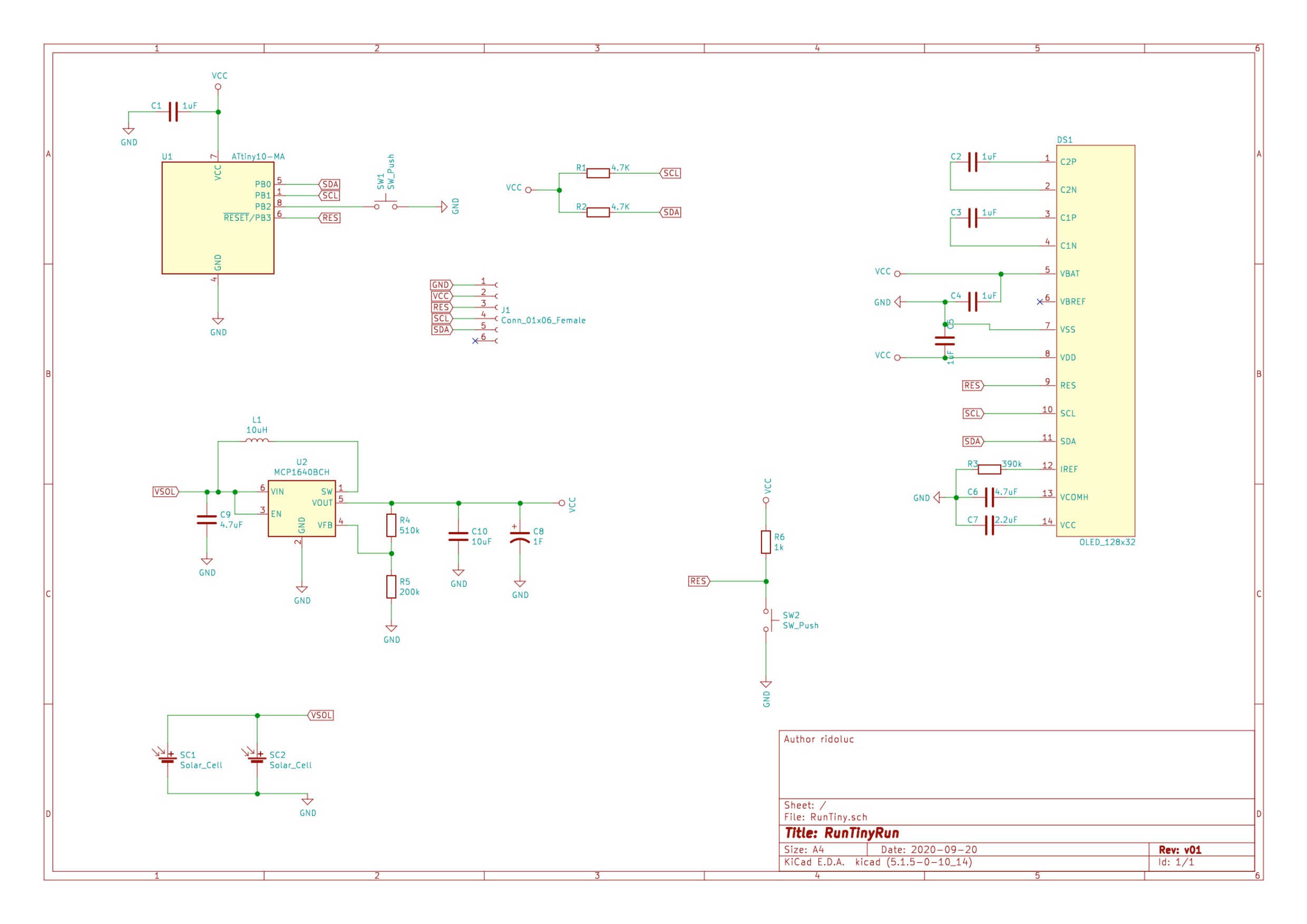

Solar powered circuit

10/04/2020 at 11:59 • 0 commentsI decided to build a proper PCB with the smallest size possible. I think it will be nice to carry the game as a keychain. Actually I don't see any other use...

I want to keep the circuit in view and cover everything with epoxy. I don't want to build a case for it.

I started evaluating what kind of battery I could use. I need a battery of at least 3V. A replaceable coin battery it's not an option and adding a rechargeable LiPo adds many complications like charging circuit, a connector, under-voltage protection etc...

So I started thinking about using solar energy. Indeed, it won't be usable at night or on a cloudy day, but it will be the smallest, solar-powered game console! Also, there is no need to charge it and it will have a theoretically infinite lifespan.

After some research and tests, I found an easy and cheap solution that works. There are also better alternatives, but these add cost and complexity. I may use them for version 2.

I wrote some simple notes about using solar energy for low power applications hereThe primary project constraint is the size. I want to keep it as small as possible. This is quite a challenge when working with photovoltaic. Obviously, a small solar cell will not be able to directly power the MCU and OLED display.

The solution is to have a supercapacitor that acts as an energy buffer: once this is charged will provide the required energy to the system for some time.---------- more ----------The circuit working voltage is ideally 3.3V. Given the size of the PV cells, it's not possible to have 3.3V and also enough current produced.

The solution here is to have a lower output voltage from the solar cells traded for higher current.

The voltage will be boosted to charge the supercapacitor.

I chose the MCP1640 as boost converter because of its low start-up voltage of about 0.7V.

Once the boost converter is started, it will need an input of just 0.5V to remain active.

I tested the circuit with two IXOLAR KXOB25-04X3F cells in parallel and also PV panel of size 25x30mm bought from a well known Chinese online shop. This is supposed to have an open-circuit voltage of 1V and a short circuit current of 80mA.![]()

It works with both, but the two IXOLAR cells need better lighting conditions.

Here the full circuit schematic:

![]()

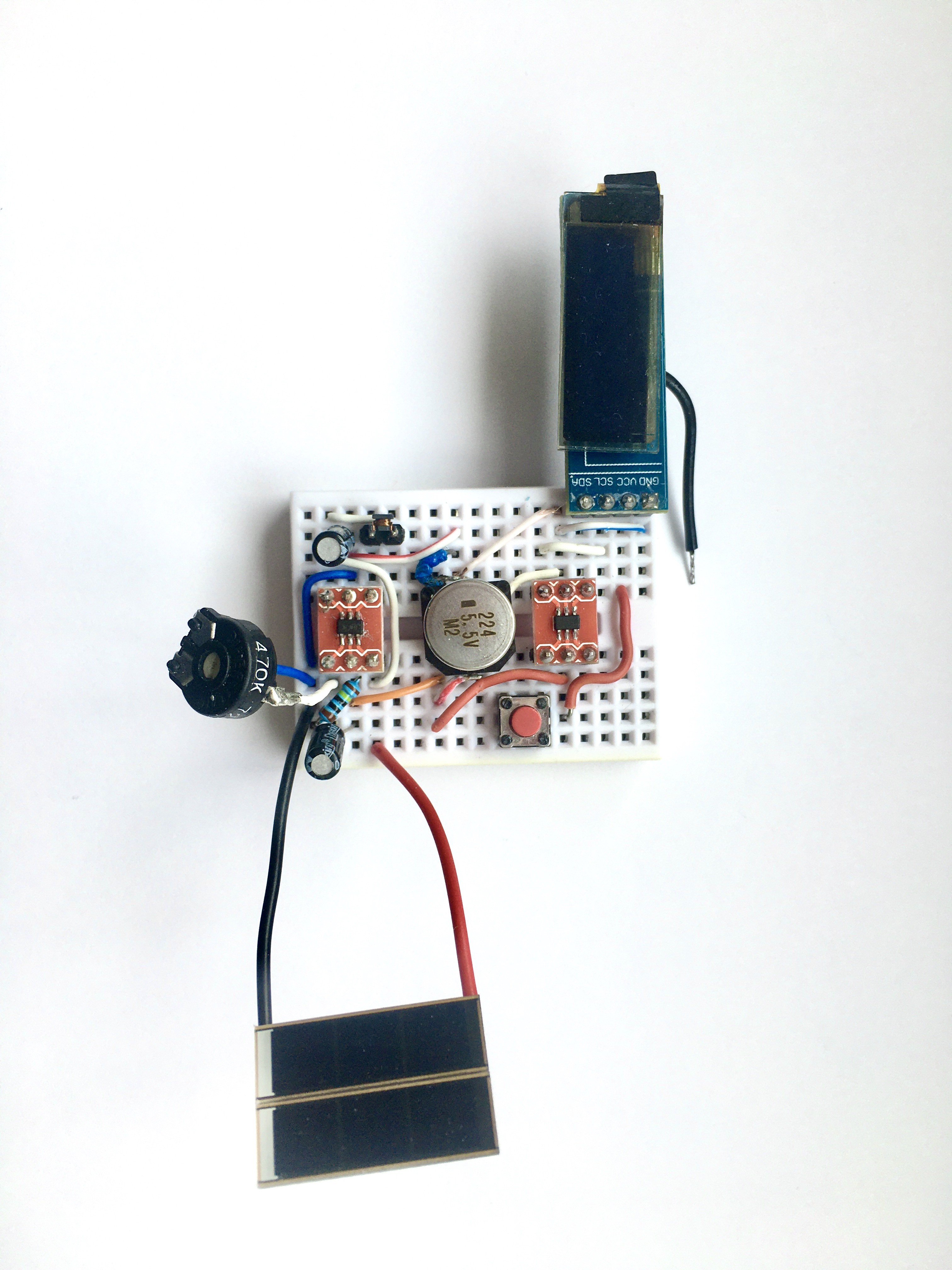

And this is the prototype on a breadboard:

![]()

When it's fully discharged, it needs about two-three minutes to charge. The supercapacitor charge will last for 20-30 seconds that are more than enough for some games. It stops working (actually the image will fade away) at about 1.9V. From here, the charging is much quicker because the MCP1640 is already active.

In any case, a strong direct sunlight is needed.Any suggestion to improve the circuit are welcome.

Next, PCB design!

RunTinyRun

Tiny, solar-powered gaming console driven by an ATtiny10 with a firmware of just 780 bytes.

ridoluc

ridoluc