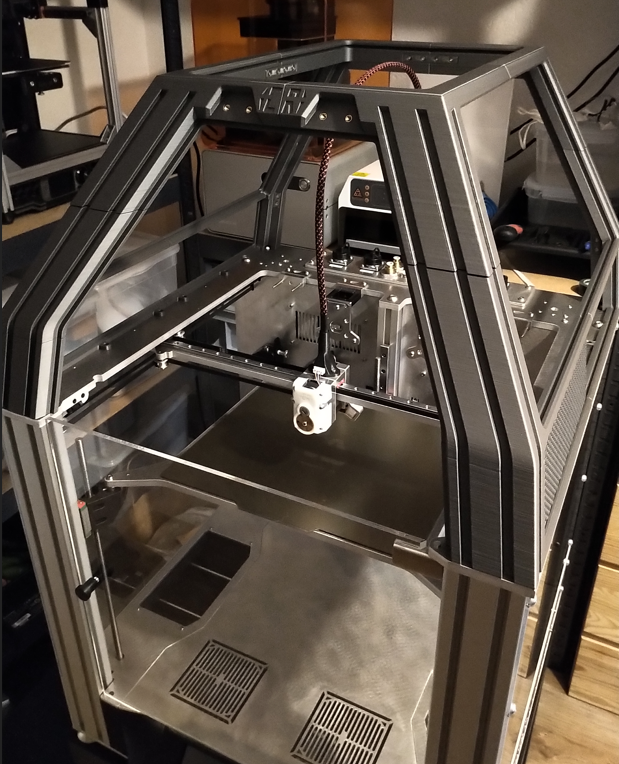

After some printing the topcover is finally completed (from the fdm point-of-view). I'll order the acrylic panels soon (drawings and dxf-files already prepared)

The frame of the topcover

A project log for CHANGER - a toolchanger new interpreted

CHANGER - a motion system which can be used for advanced 3D-Printing with up to four materials, PnP, PCB-Milling, Layer inspection, etc...

After some printing the topcover is finally completed (from the fdm point-of-view). I'll order the acrylic panels soon (drawings and dxf-files already prepared)

Discussions

Become a Hackaday.io Member

Create an account to leave a comment. Already have an account? Log In.

I really like the design of your topcover

Are you sure? yes | no

What do you mean with end-to-end lines?

If you're referring to the parting lines of the different sections than it will be solved after the fitment check with the acryilic panels. Because of the high tilt the boreholes where to tight and have to be drilled out slightly which caused the visible offset of the pin-centering feature. If I would print them again it would be solved right away (like you can see in the lower section, theres almost no gap visible)

But I don't want to waste any filament so I'll glue the top section together as soon as I ordered the acrylic panels. Sometimes you'll have to be flexible with solutions :D

Are you sure? yes | no

Wow I didn't even notice that the lower-mid section were 2 seperate prints.

Are you sure? yes | no

Looking nice (other than those end-to-end lines)

Are you sure? yes | no