-

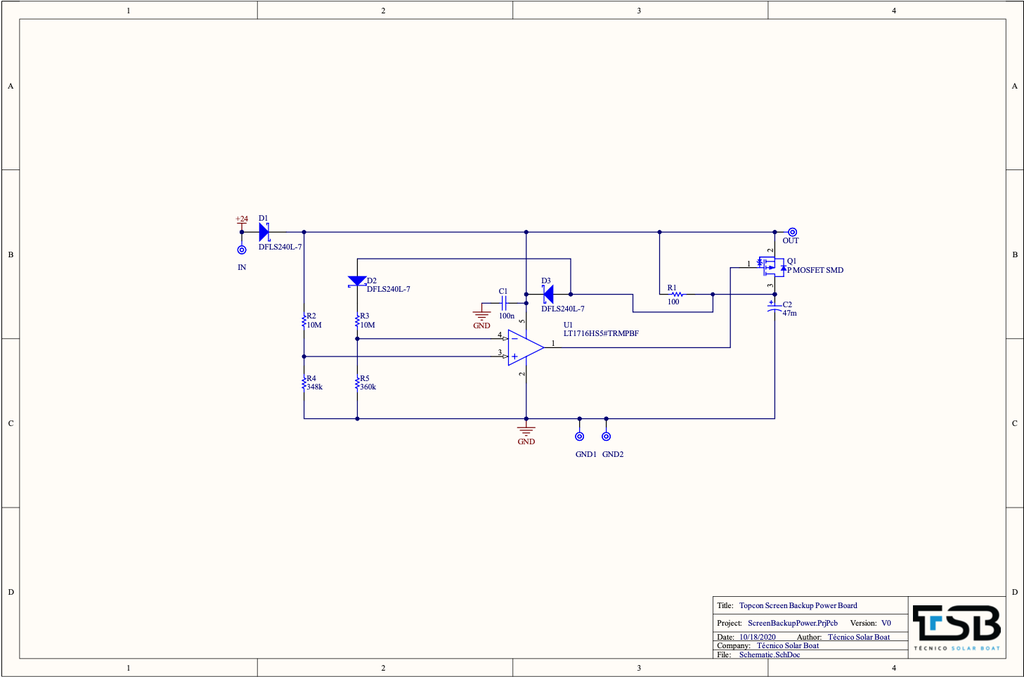

1Simulation of the Circuit

![]()

The first step before proceeding to design the PCB for holding the circuit it to simulate it in order to find out what capacitance should be used in order to have the circuit supplying power for the amount of time needed. It is also import to correctly choose the comparator input resistors so that it can turn on and off the MOSFET correctlly.

According to the manufacture of our dashboard, the power supply should be maintained for at least 5 seconds after the power from the ignition pin is removed. It is also import to refer that the dashboard works with a supply voltage between 24 and 9 VDC.

To do so we decided to use LTSPICE (simulation file attached). As it can be seen on the photo above, the circuit behaves like expected. The supply voltage, in green, is turned on and thus the output voltage instantaneously has 24 V. At the same time the pre-charge of the capacitor starts, this step is incredibly important due to the big capacitance, otherwise a current spike would happened when the system is turned on. When the voltage at the capacitor (V(precharge)) is within a safe threshold of the input voltage the gate of the MOSFET is pulled low and thus the current bypasses the 100 Ohm pre-charge resistor.

When the supply voltage is turned off (second 31) we can see that the voltage on the output (V(dashboard)) starts to decrease slowly. In fact it takes around 10 seconds for it to be below the 9 V mark, this proves that 47 mF gives us a 100% margin which is more than enough. On this simulation R7 simulates the load, which in real life will be the pilot dashboard.

-

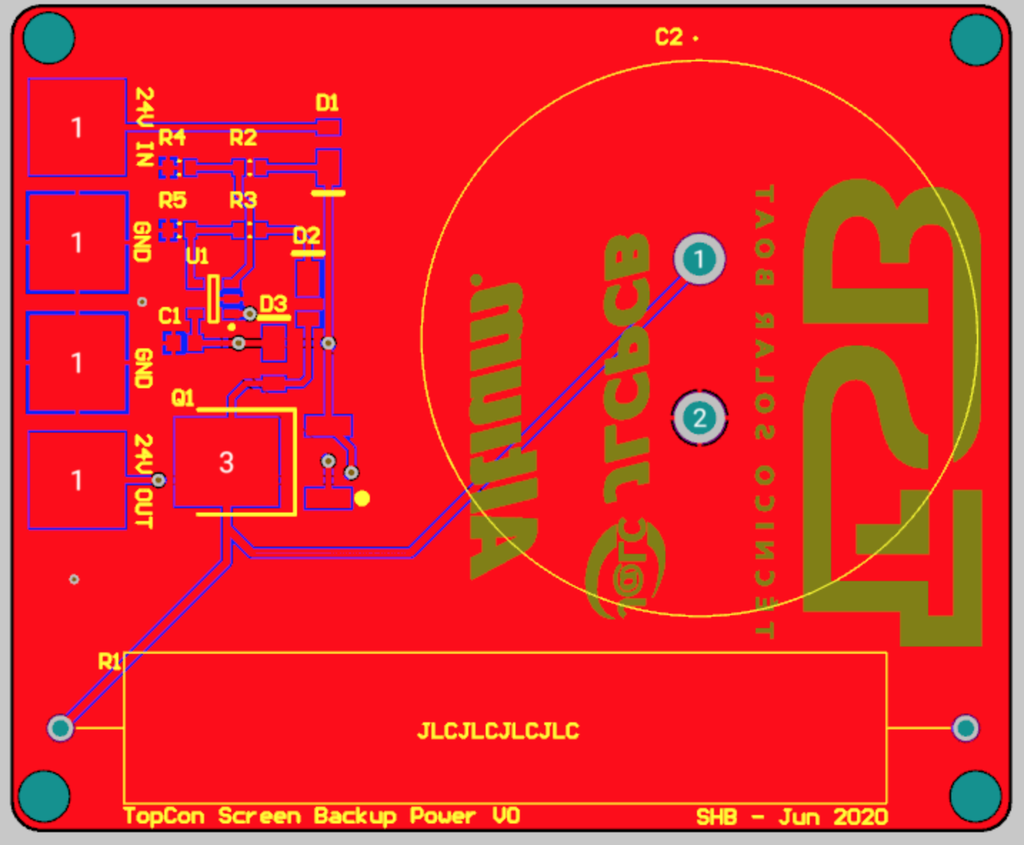

2Designing the PCB

![]()

![]()

With the circuit already in mind and the right components chosen it is now time to start the design of the PCB. To do so we used Altium Designer. The circuit is pretty straight forward and we will not get into much detail about it in this section.

-

3Ordering the PCB

After the design is complete it's time to order the PCB. To so we used the sponsor of this article JLCPCB.com

JLCPCB are also sponsor of this project. JLCPCB (Shenzhen JLC Electronics Co., Ltd.), is the largest PCB prototype enterprise in China and a high-tech manufacturer specializing in quick PCB prototype and small-batch PCB production.You can order a minimum of 5 PCBs for just $2. To get the PCB manufactured simply upload the .zip of the gerber files or you can also drag and drop the .zip files. After uploading the zip file, you’ll see a success message at the bottom if the file is successfully uploaded. You can review the PCB in the Gerber viewer to make sure everything is good. You can view both top and bottom of the PCB. After making sure the PCB looks good, you can now place the order at a reasonable price. You can order 5 PCBs for just $2 plus shipping. To place the order, click on “SAVE TO CART” button.

-

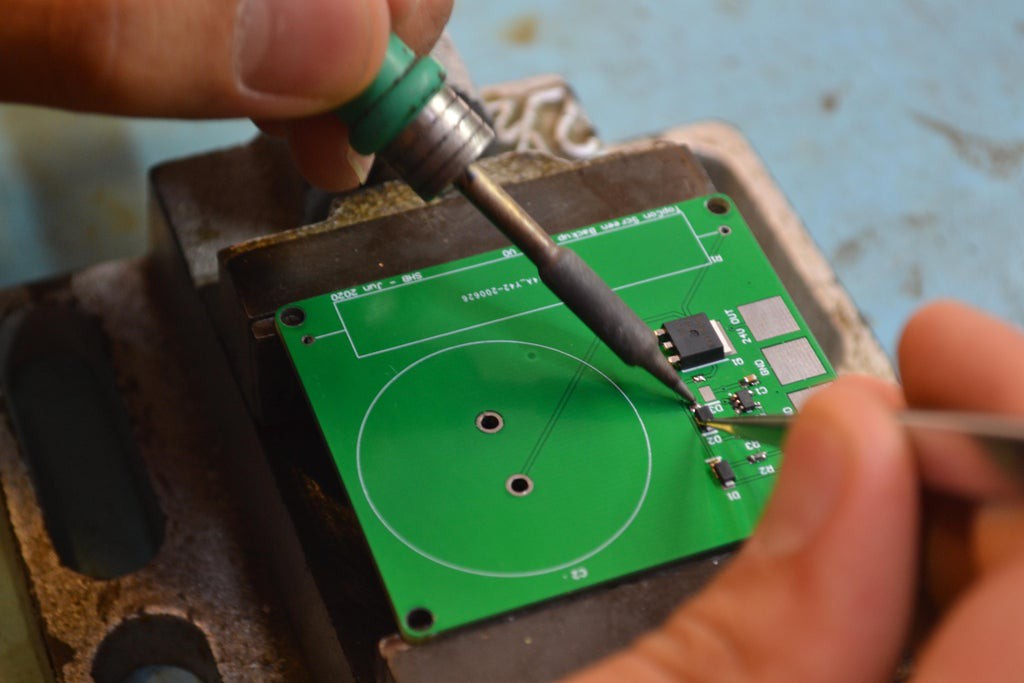

4Assembly

After approximately 1 week we had the PCB with us and it was now time to assemble it.

![]()

![]()

![]()

![]()

![]()

-

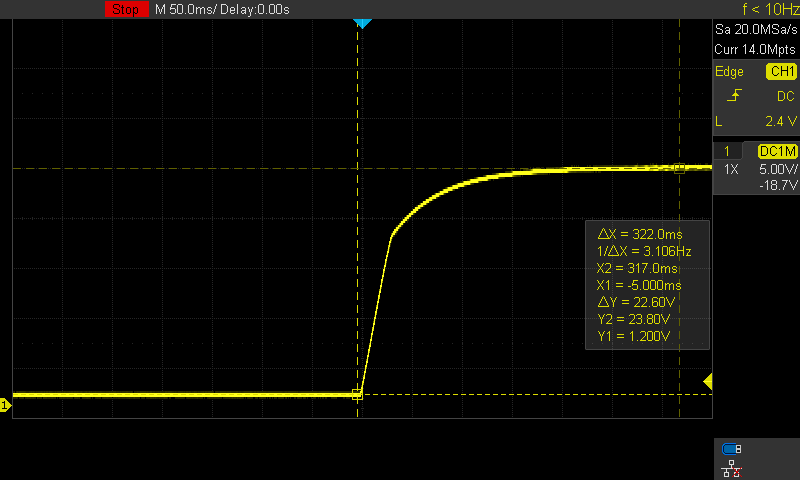

5Testing

![]()

![]()

![]()

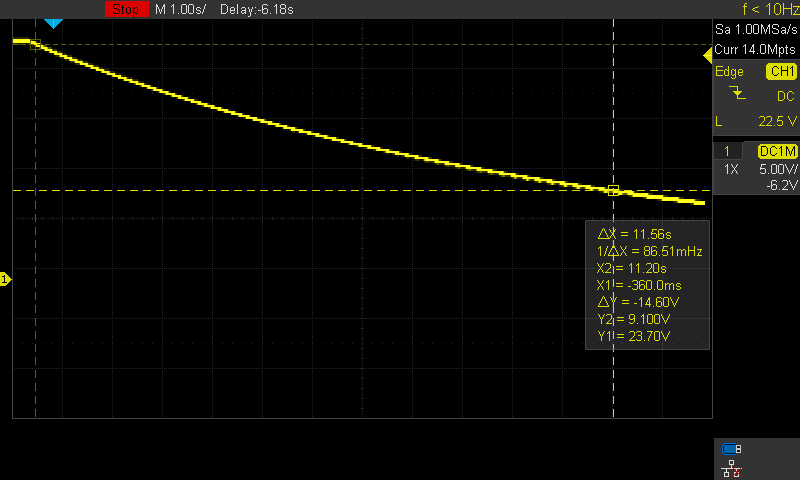

After the assembly, it is now time to make sure the circuit behaves as expected. To so we powered the circuit and we checked the voltage of the capacitor to make sure the pre-charging was working properly (first image), here we can see that the pre-recharge takes way less time than what was simulated, but that has to do with the difference between a real life capacitor and a simulated one.

After the pre-charge was done, we turned off the power supply and observed the voltage at the output. As we can see the output voltage decreased slowly, as expected, it took almost 12 second for the voltage to go below 9 V, which means our circuit works!

We would like to once again thank the sponsor of this article JLCPCB for their amazing support to our team with our PCB manufacturing needs! Be sure to order from them the next time you need PCBs.

Backup Power Supply for Proper Shutdown

A backup power supply is a circuit that supplies power to devices in case their main power supply goes down.

Técnico Solar Boat

Técnico Solar Boat

Discussions

Become a Hackaday.io Member

Create an account to leave a comment. Already have an account? Log In.