-

1Building the Starhopper

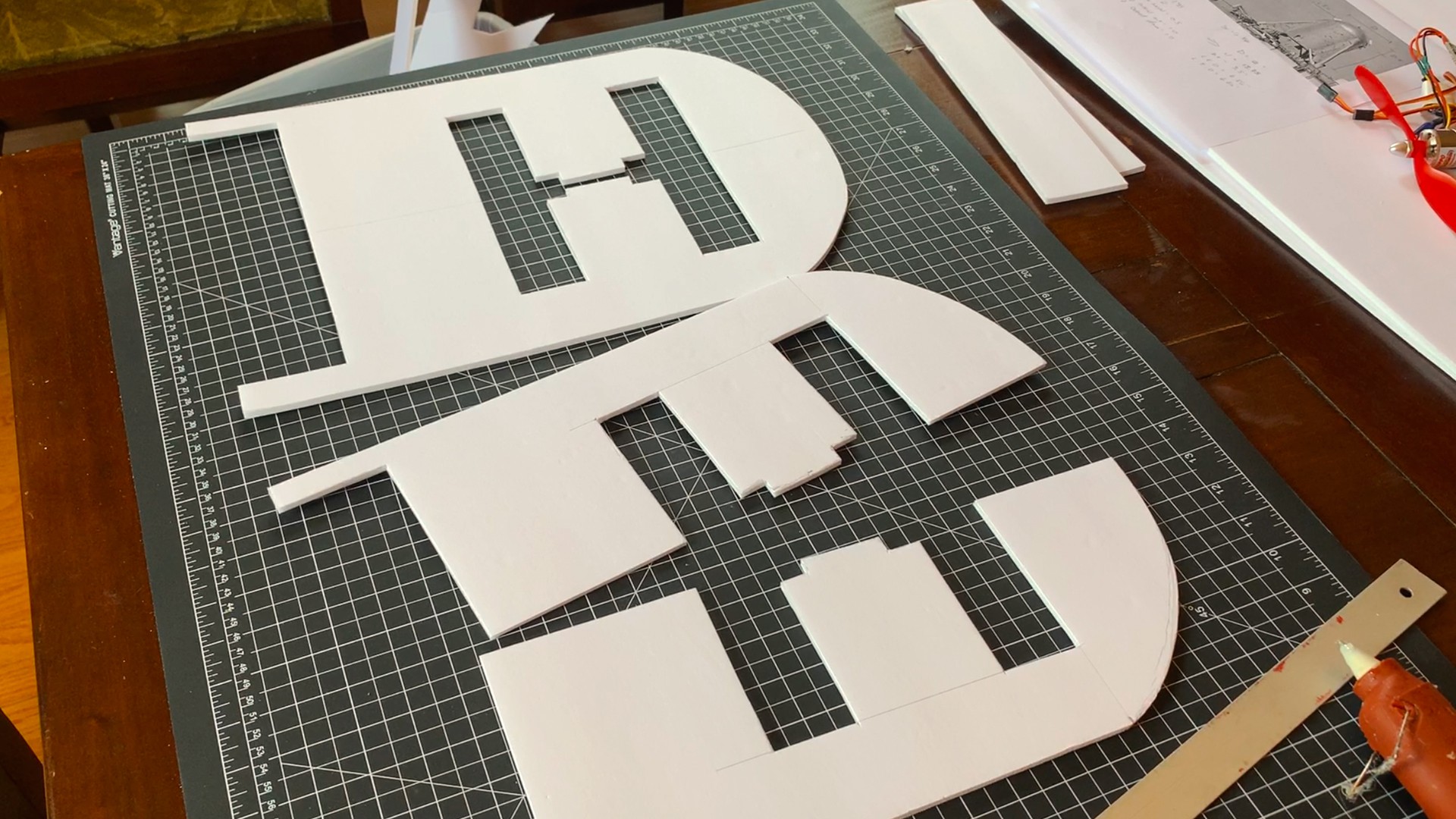

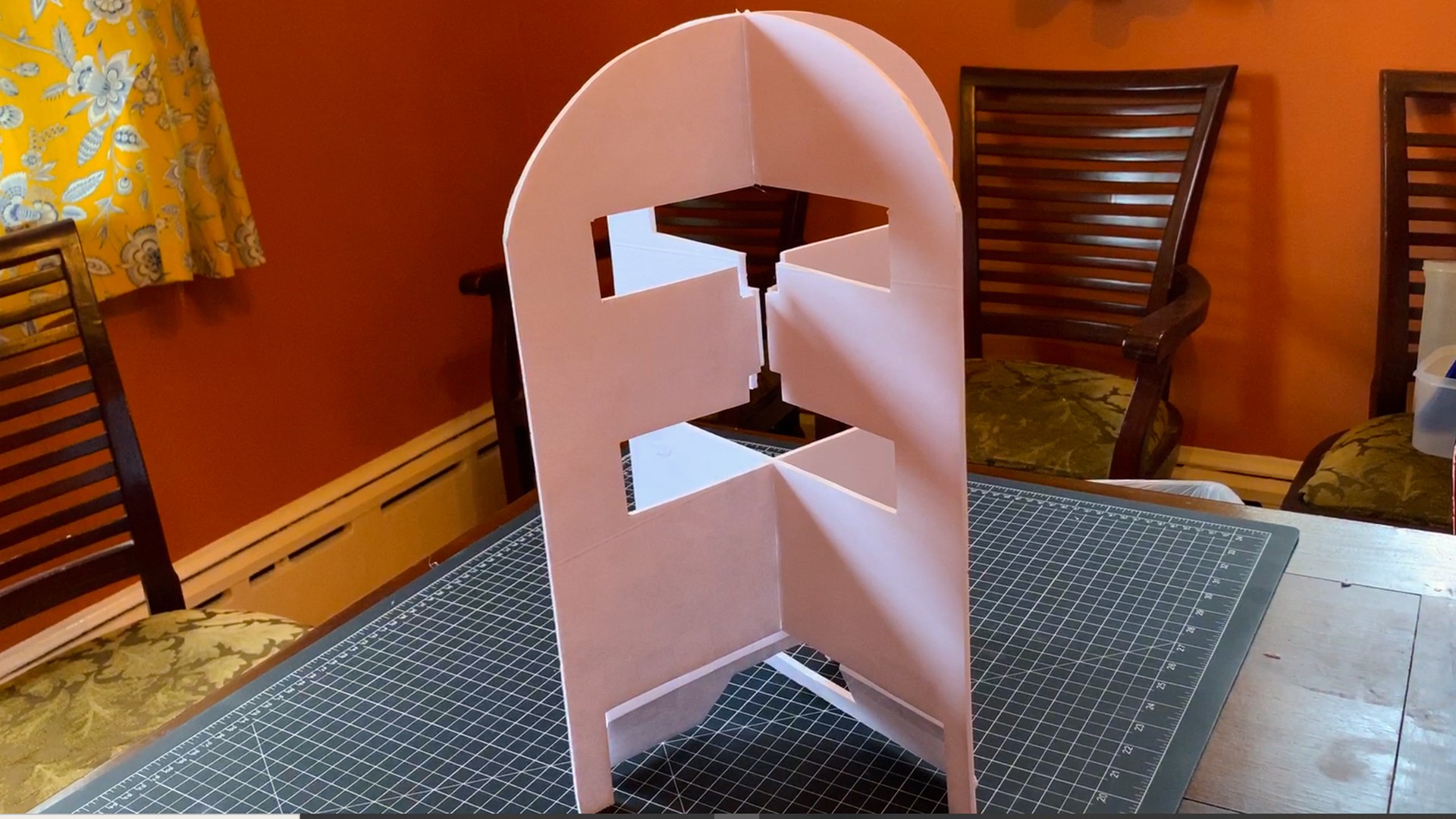

Cutting out and gluing together the internal structure from foamboard:

![]()

![]()

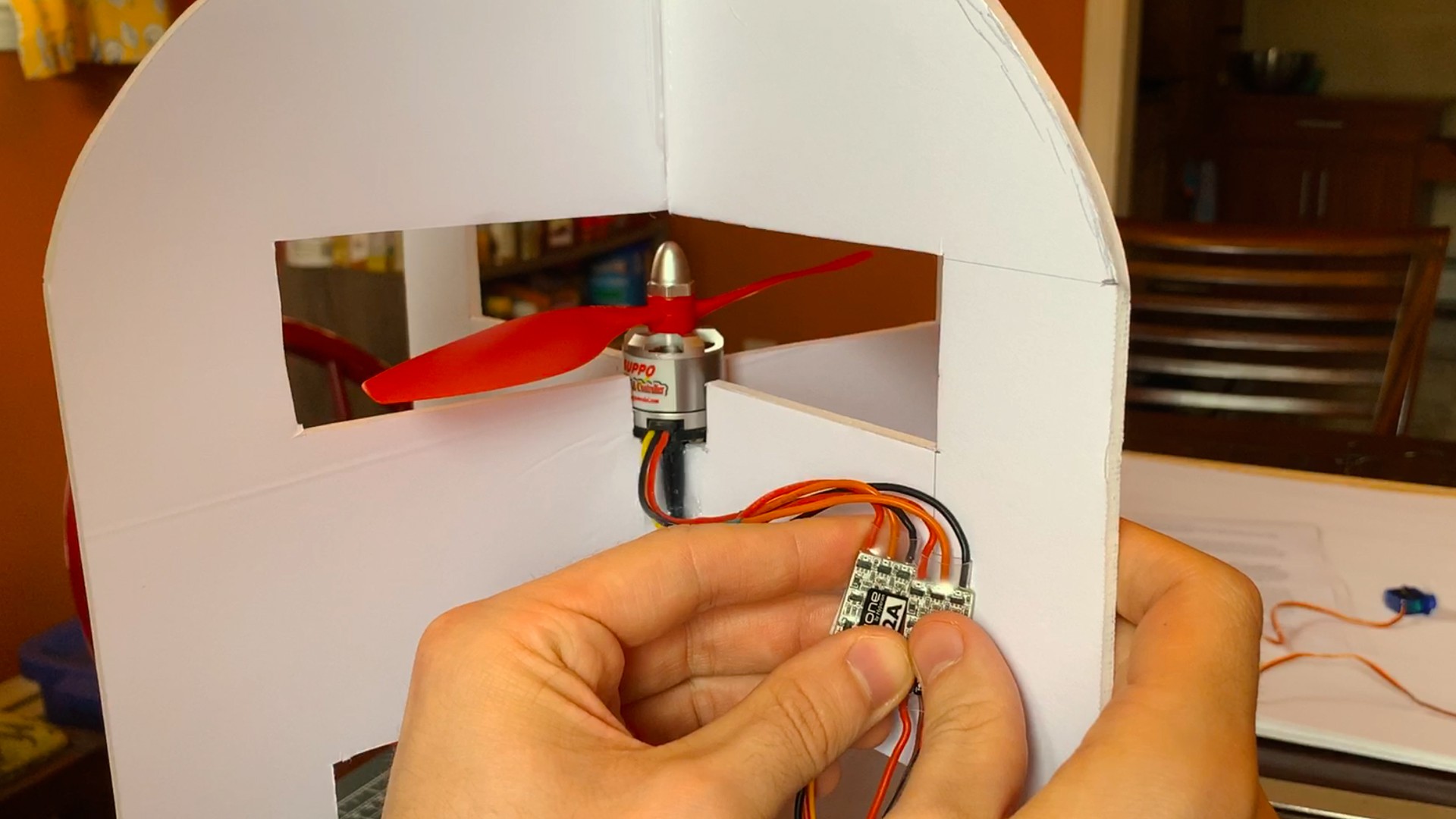

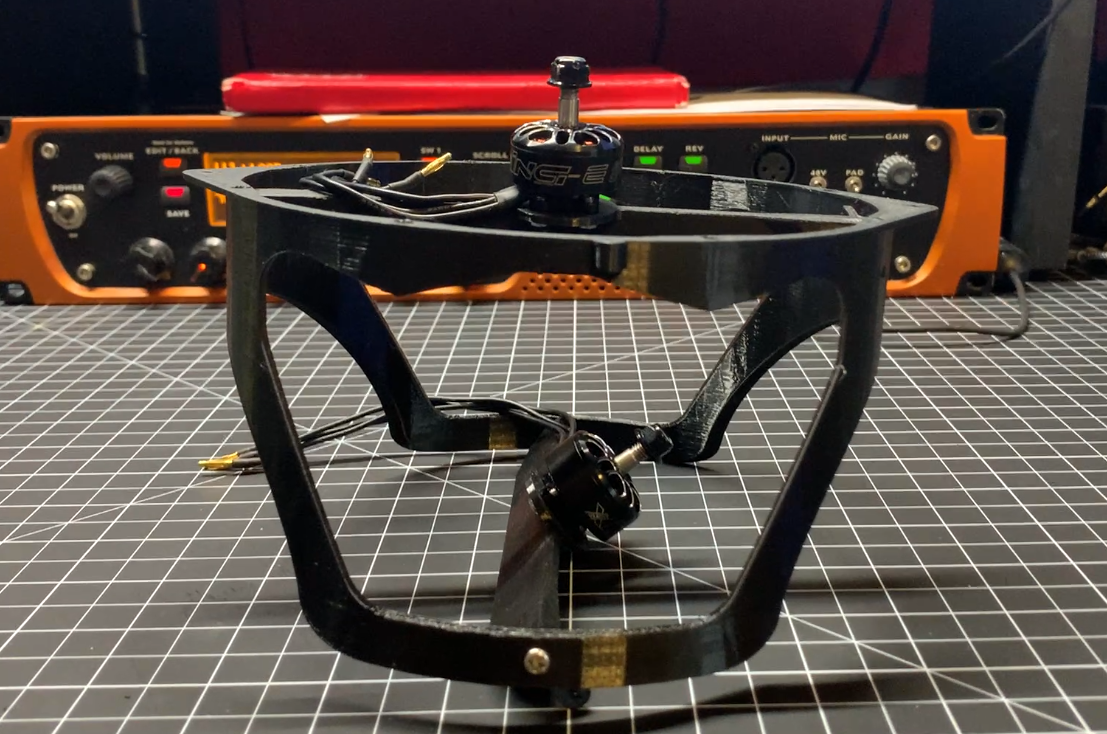

Motors attached to 3D printed motor mount and hot glued to the structure. ESCs attached with double sided tape:

![]()

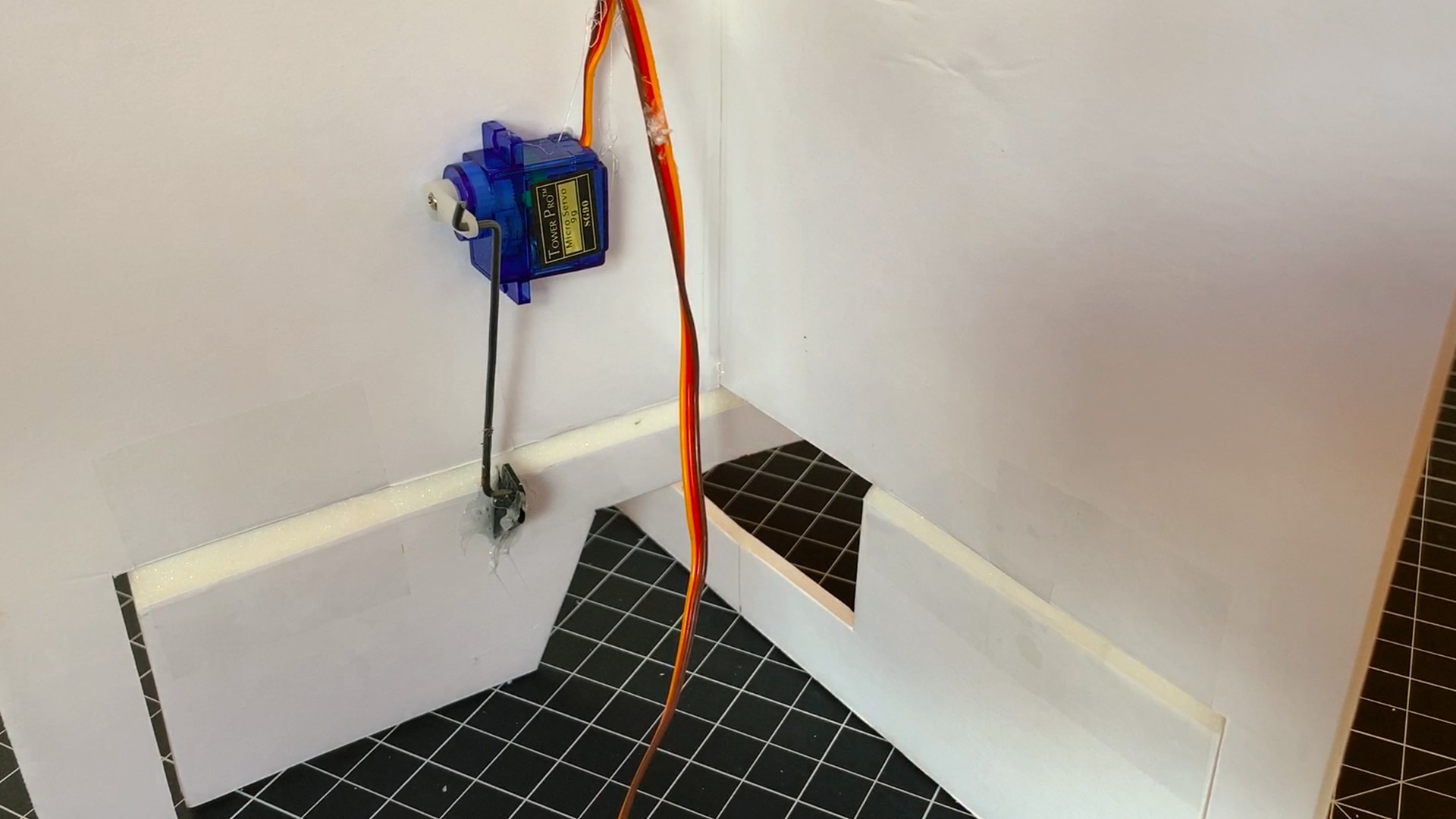

Connecting the servo linkage for the control surfaces:

![]()

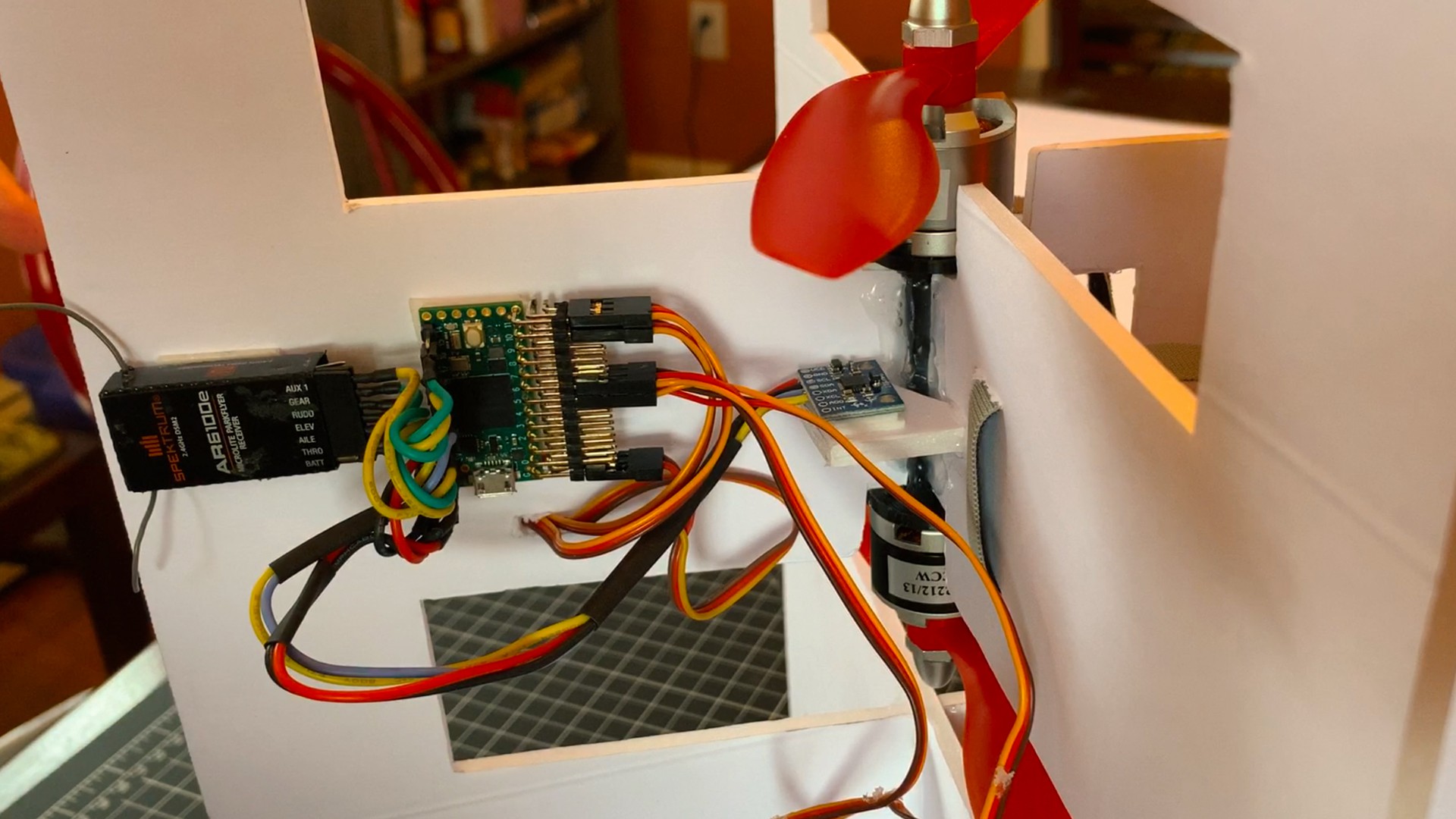

Installing receiver and Teensy 4.0-based flight controller:

![]()

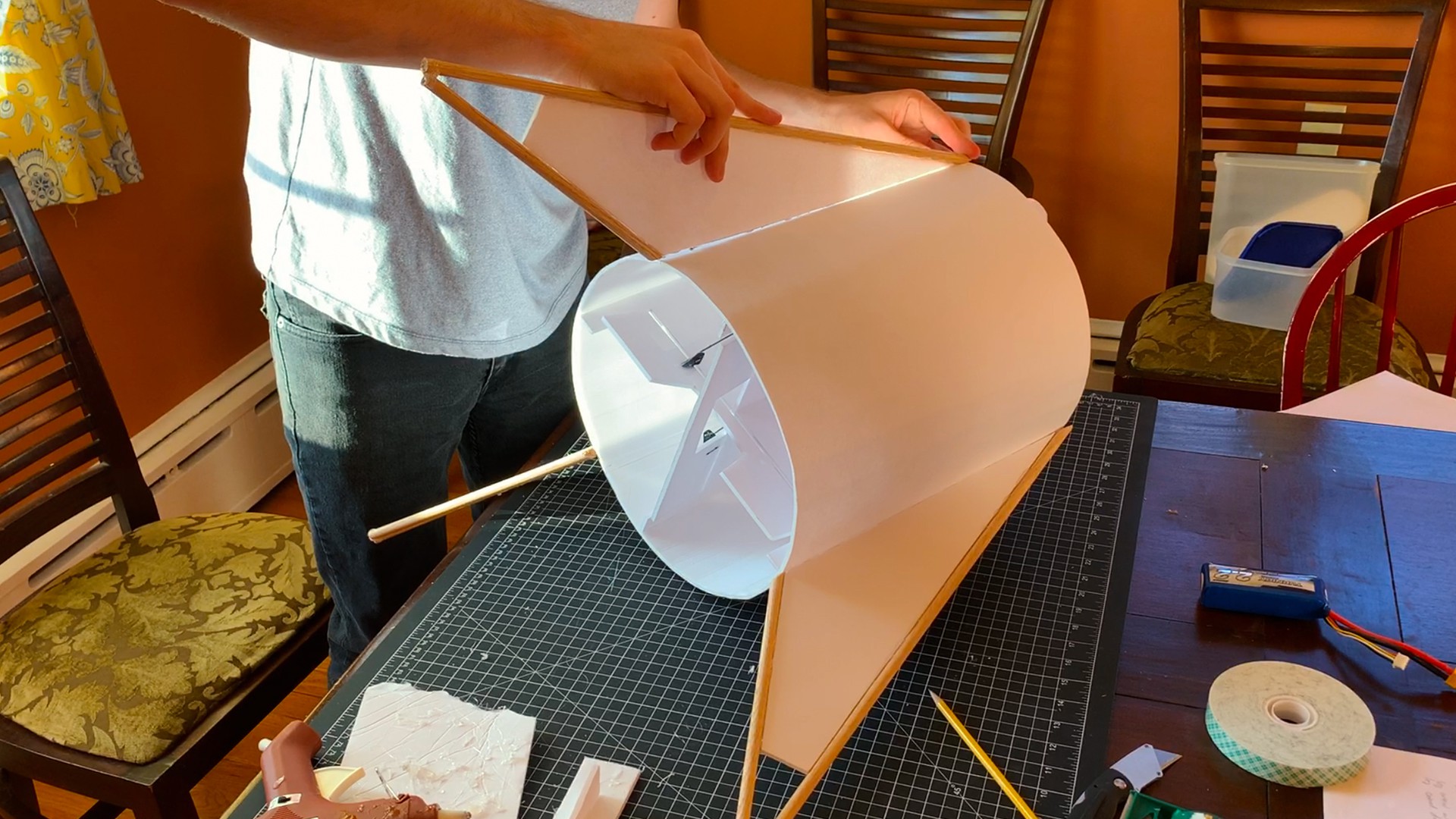

Internals wrapped in cylindrical foam and landing legs glued on:

![]()

![]()

-

2Building the StarShip

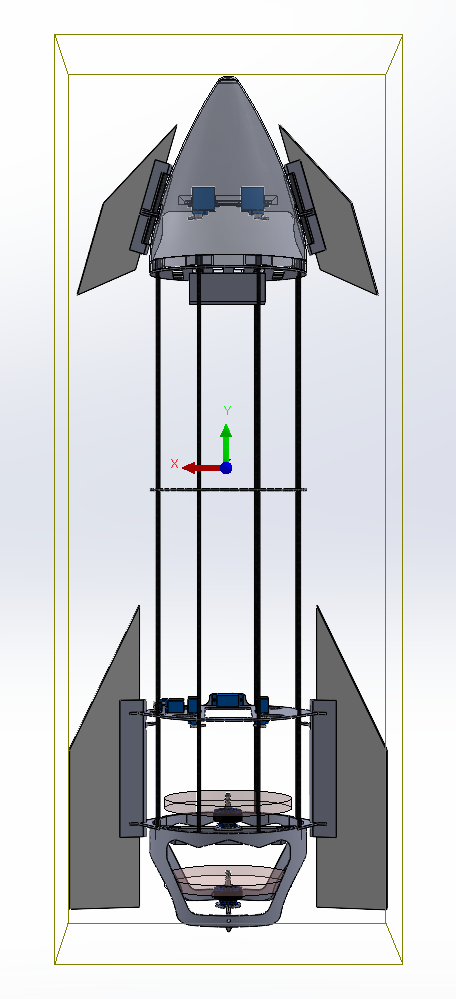

Parts all designed in Solidworks 2020 and masses used to estimate vehicle center of gravity:

Print all the parts in PLA or ABS (quantities of each part listed in part name):

Install motor mounts to motor bulkhead with m3 hardware:

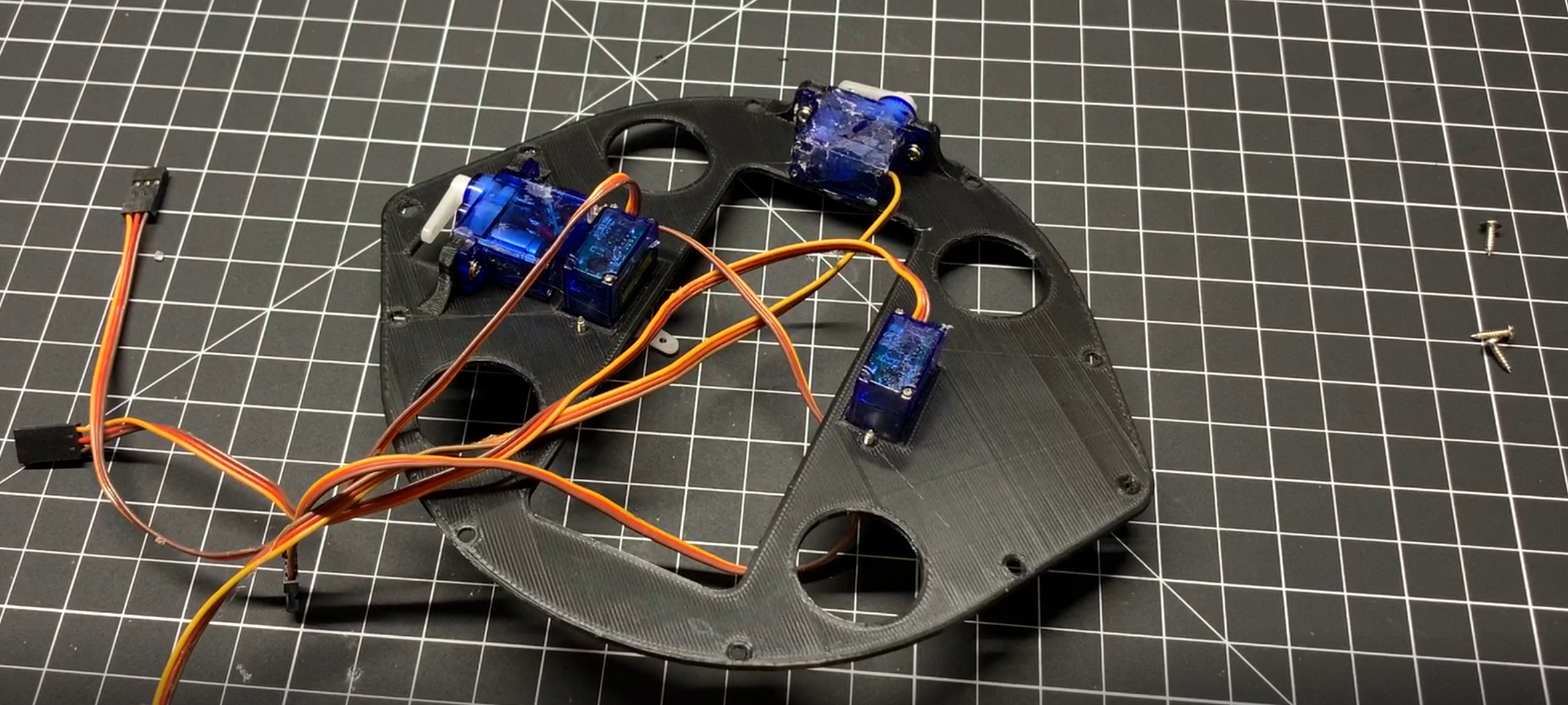

Install 4 SG-90 servos to servo bulkhead with hot glue and servo hardware:

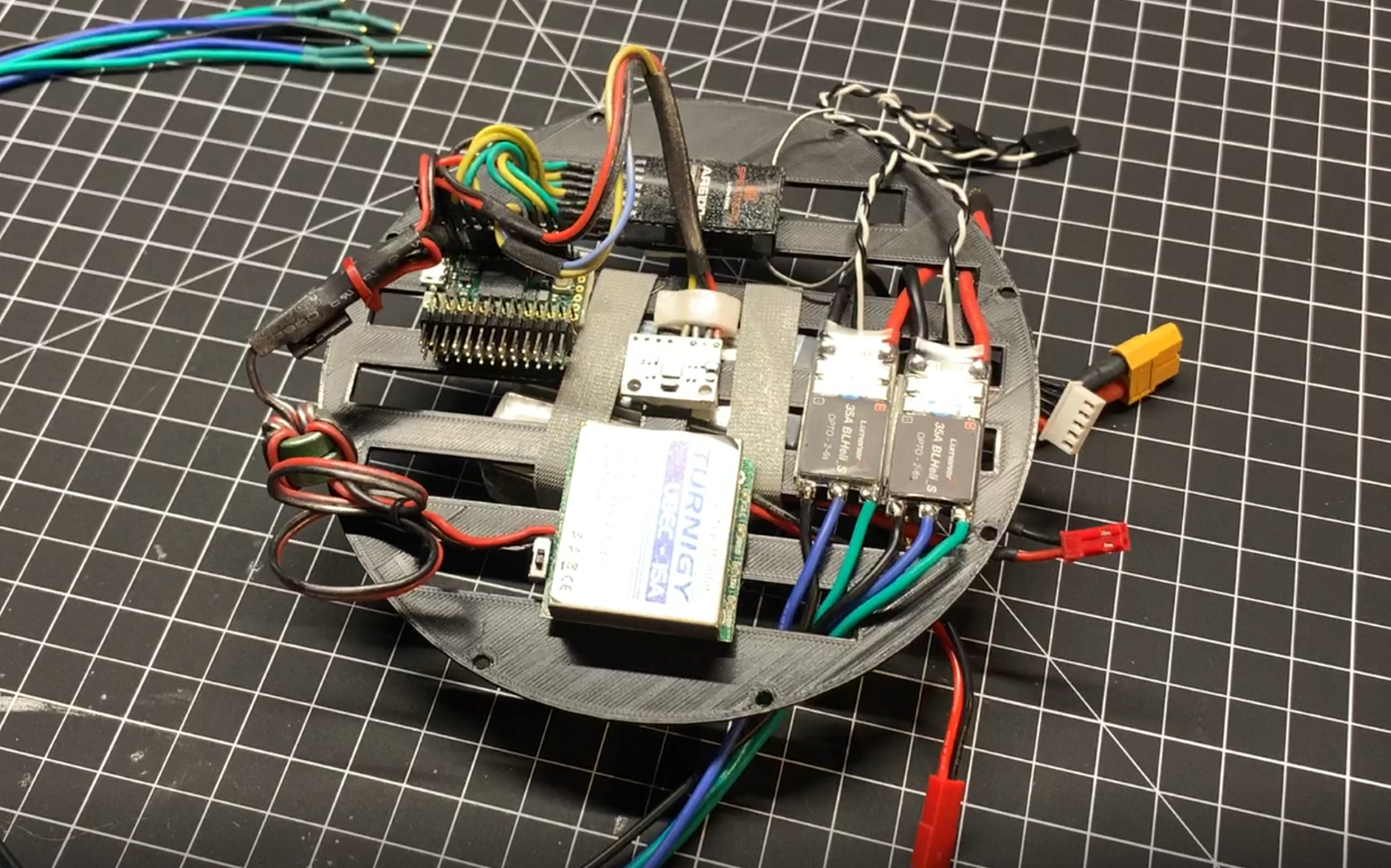

Install electronics on electronics bulkhead with double sided tape:

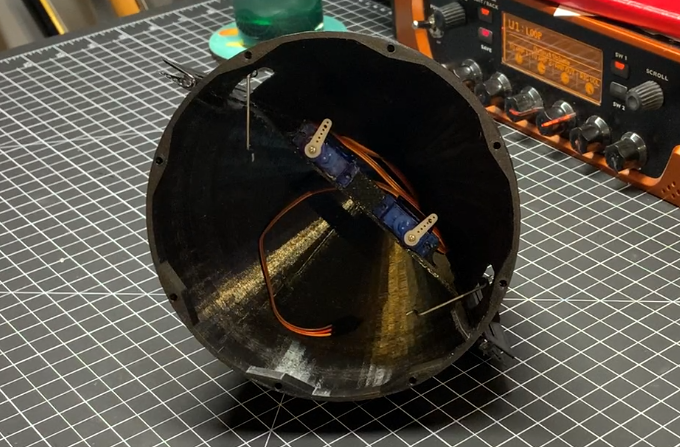

Install servos in the nosecose and assemble canard hinge:

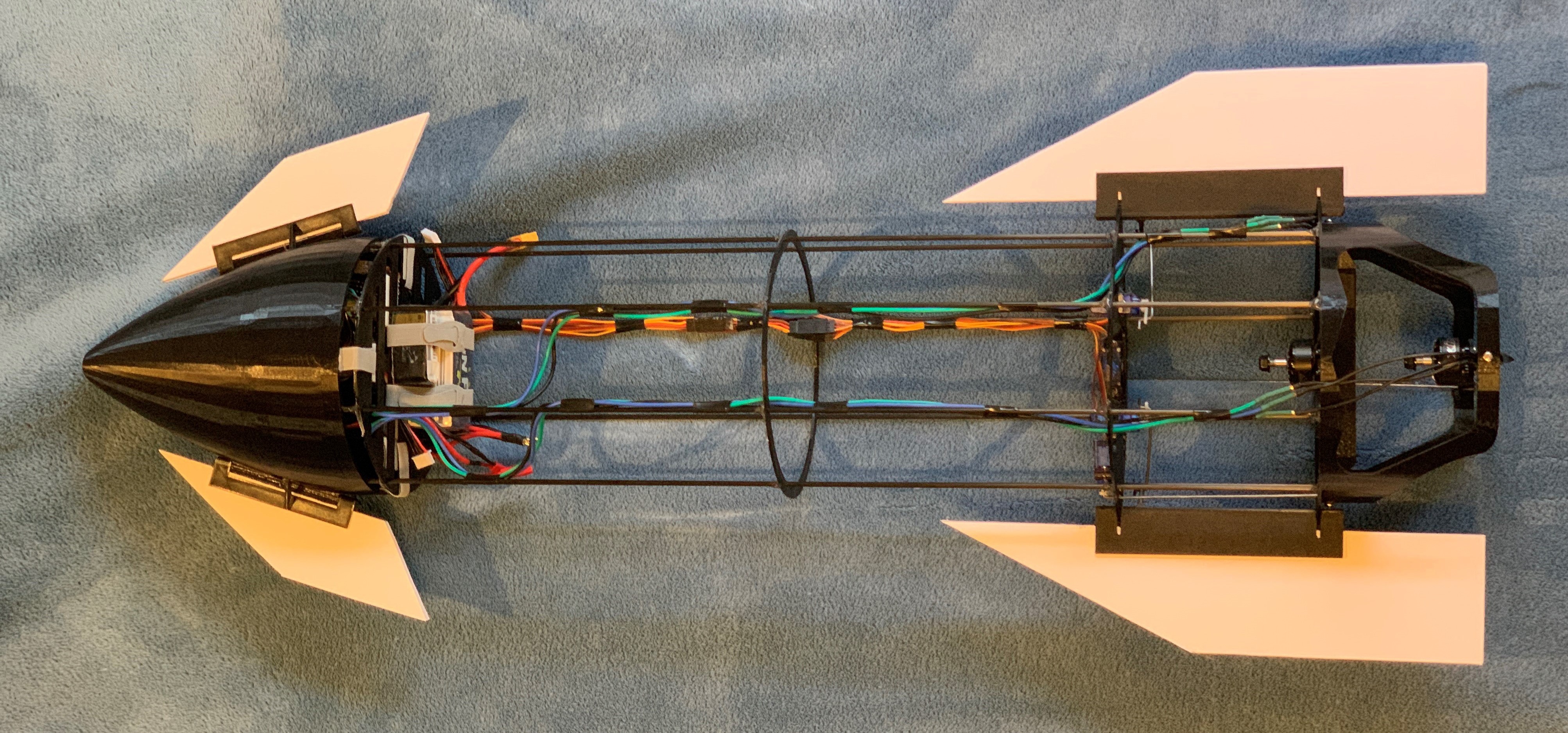

Slide all subassemblies over carbon spars of ~400mm length. Servo bulkhead placement is dictated by rear flap hinge. Pin all parts in place with hot glue. Cut out aerodynamic surfaces from foamboard and slide into hinge pieces:

Cut out foamboard to snugly wrap around outside and pin in place with tape so that it can be taken off later to access electronics:

Give it some paint:

Radio Controlled Starship Program

Trying to catch up to SpaceX's Starship program with my own radio controlled, electric version.

Nick Rehm

Nick Rehm

Discussions

Become a Hackaday.io Member

Create an account to leave a comment. Already have an account? Log In.