Compare the weight of a common copper heat sink and a sample:

To make the experience fit your profile, pick a username and tell us what interests you.

We found and based on your interests.

Compare the weight of a common copper heat sink and a sample:

MKJB bell.jpgfragment of rocket engine nozzle... ;)JPEG Image - 1.03 MB - 04/22/2021 at 18:51 |

|

|

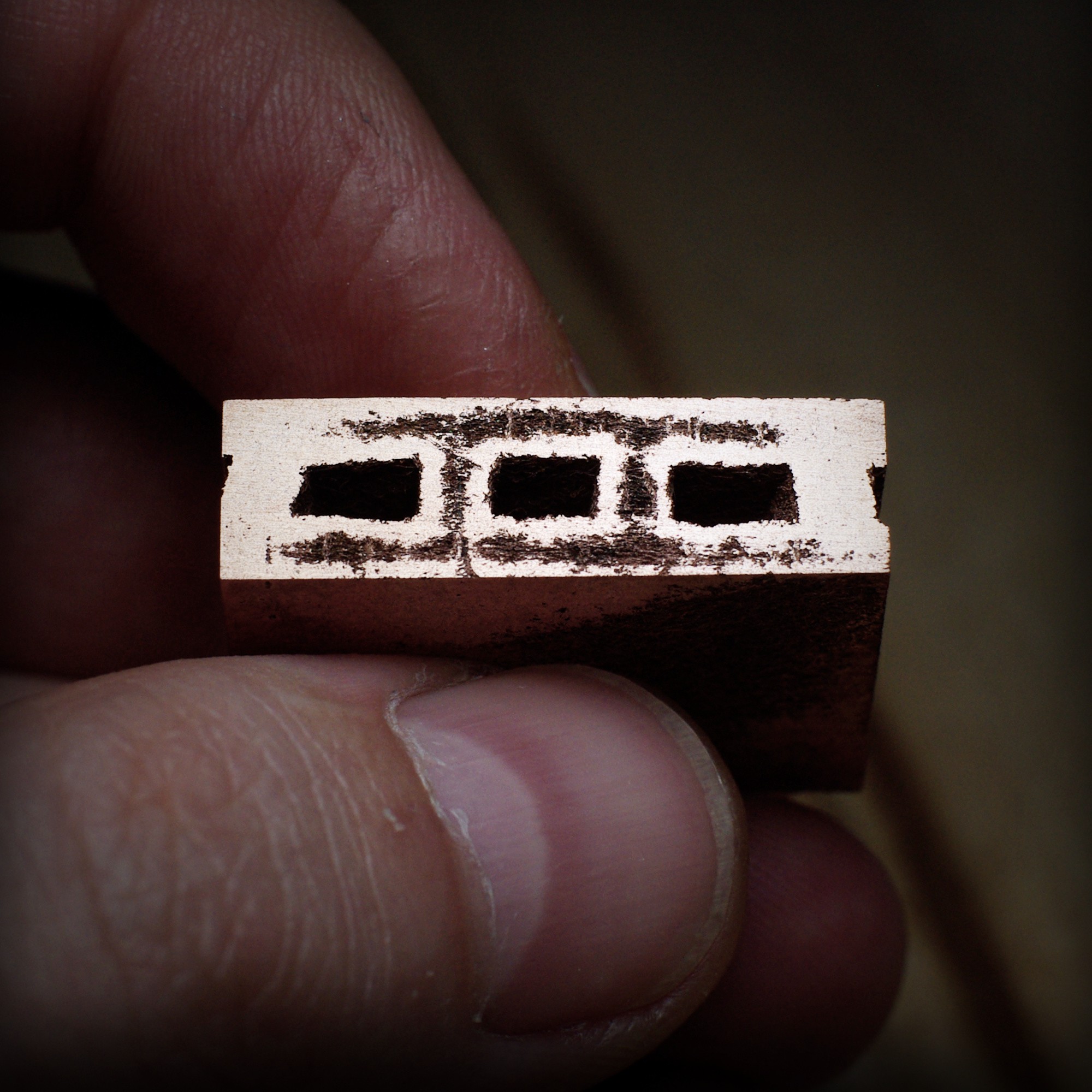

cross section (you can clearly see bone structure)

fragment of rocket engine nozzle... 6.5 g

Create an account to leave a comment. Already have an account? Log In.

You can create metal composites of any topology and internal structure. In easy and cheap way.

What sort of density compared to solid metal? Can you control the wall thickness? Can the inside foam be any size, or only a few mm like in the pictures? Does it only work in flat pieces, or could you make tubes with two thin walls separated by a layer of foam to increase stiffness, or even mold it in more complex/3D printed shapes? Does it only work in brass, or could you use aluminum?

Thank you for these questions!

One of the samples had a density 1.2g/cm3, so like a rubber. But! I can't bend it in my hands...

In general - you can change all parameters of this structure as you like. Size doesn't matter. A 1cm or 1m item will be created at the same time.

You can use almost all metals, in any configuration, alloys etc.

Of course, it is possible to automate the process and use solutions known in 3D printing. However, I am working on a much more efficient method. The object will be created freely in space, without mechanical contact with the robot arm or the printer head.

Sounds very useful! Are you planning to open source, patent, or take it to the grave?

Become a member to follow this project and never miss any updates

what am i looking at? not clear the point.