-

1Gathering The Required Parts

To build the dial, you’ll need to get the kit with all the required custom PCBs from my Tindie Store,you can get the boards alone and source the rest of the parts yourself, I also have the full assembly kit with all the required parts available and you can also get the dial as a fully assembled device.

3D printing files can be downloaded here.

The assembly process is pretty straight forward and quit satisfying, I have also prepared detailed step by step Build Instructions for all the variations of the dial.

Required Electronics and Hardware Parts

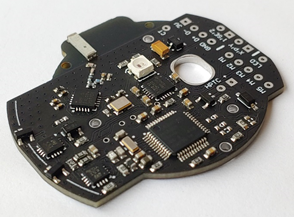

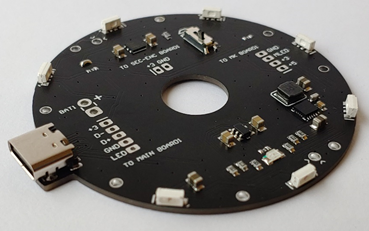

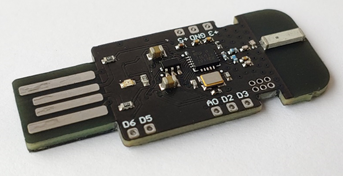

Ahmsville Dial v2 Main Board

USB C Board

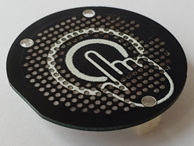

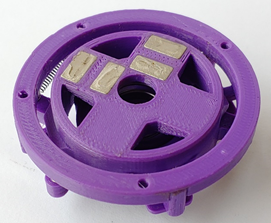

Capacitive Touchpad

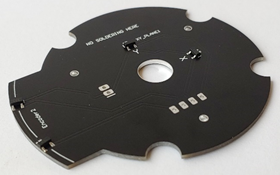

Secondary Encoder Board

Macro Key Board

Wireless Adapter Board

Vibration Motor

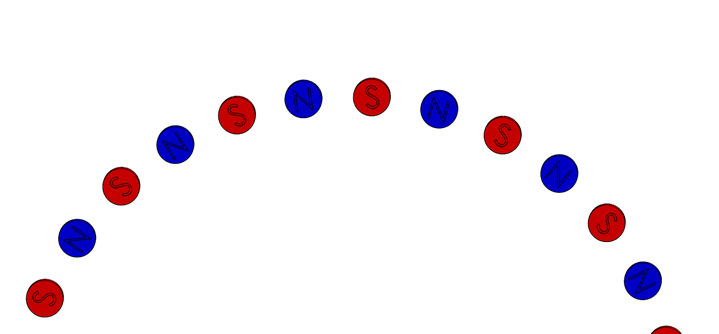

2x1mm Neodymium Magnets (90pcs)

Space Navigator Mechanism

M1.4x6mm Self Tapping Screws (2pcs)

M1.4x10mm Self Tapping Screws (19pcs)

M2x10mm Self Tapping Screws (4pcs) & M2x8mm Self Tapping Screws (4pcs)

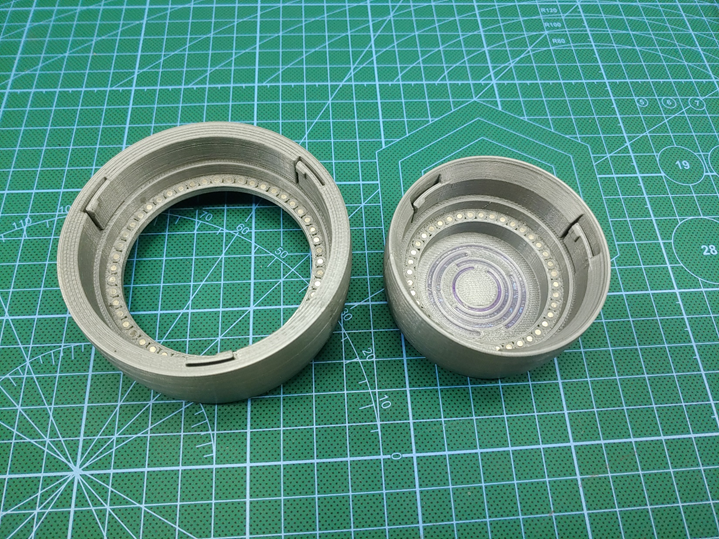

6809 Ball Bearing & 6811 Ball Bearing

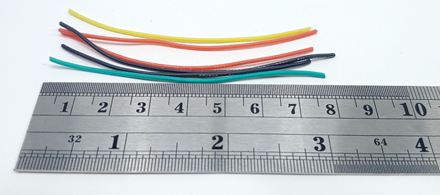

Thin Flexible Individually Colored Wires (14 colors, length – 150mm) (For Primary connections to the Main Board)

If you cannot get 14 individually colored wires, you can use a black permanent marker to create more colors, for example a plain blue wire marked with a black line becomes a blue-black wire.

Thin Flexible Wires (6pcs of length => 80-90mm) (For Secondary connections)

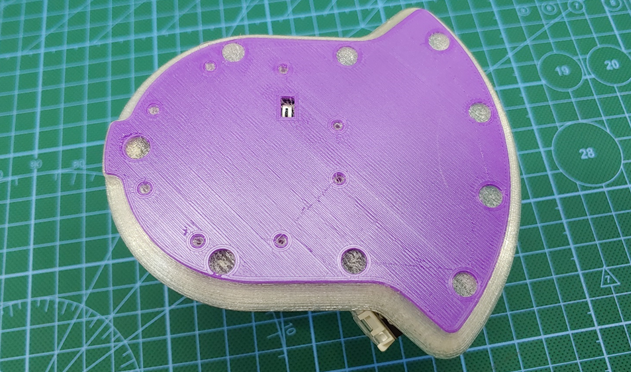

Silicone Rubber Base Pads (6x2mm 10pcs)

Lipo Battery (Max allowed size => 44 x 37 x 5.5mm)

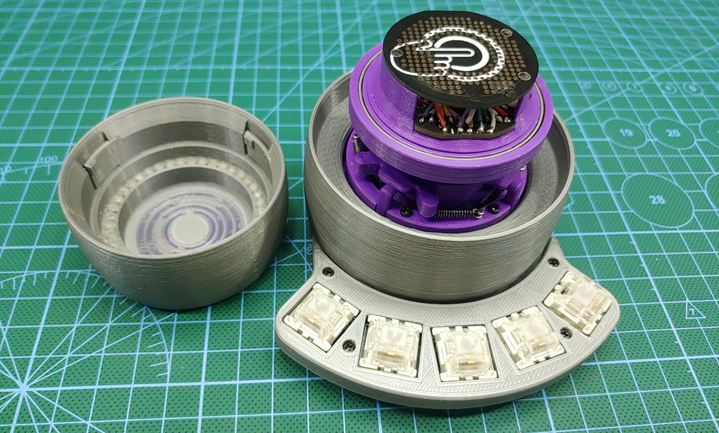

Required 3D Printed Parts

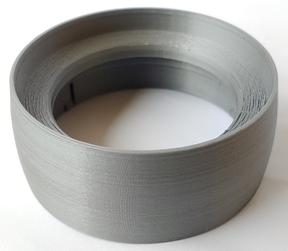

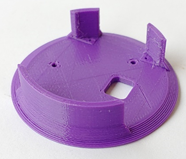

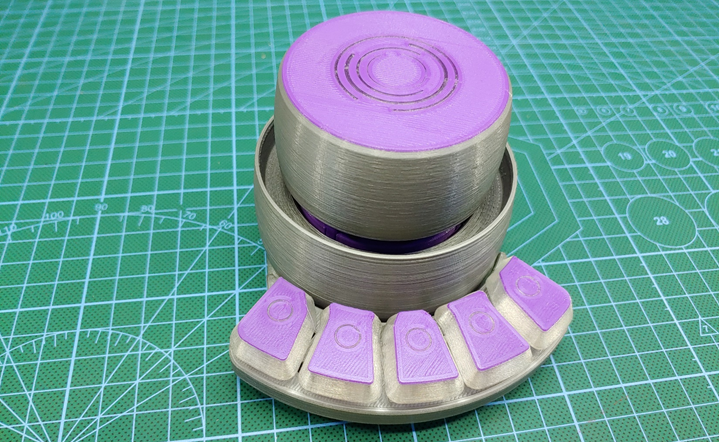

Knob1

Printed with three filaments (Purple, Transparent, Silver)

Material – PLA

Recommended infill % = >40

Knob2

Material – PLA

Recommended infill % = >40

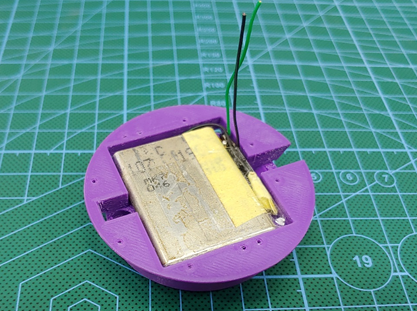

Battery Holder

Material – PLA

Recommended infill % = >40

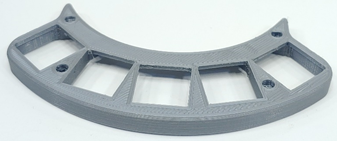

Secondary Encoder Board Holder

Material – PLA

Recommended infill % = >40

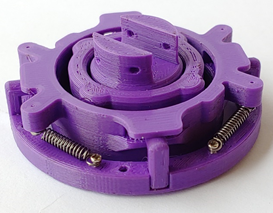

SpaceNav Mechanism Holder

Material – PLA

Recommended infill % = >50

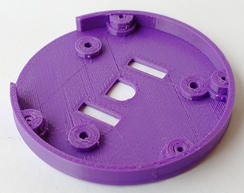

Main Board Holder

Material – PLA

Recommended infill % = >70

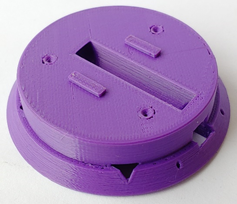

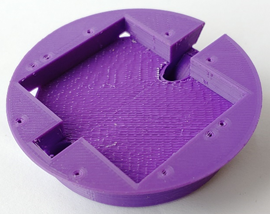

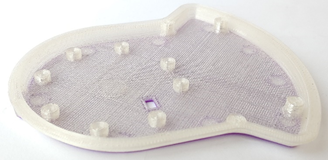

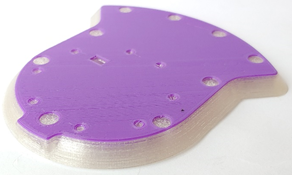

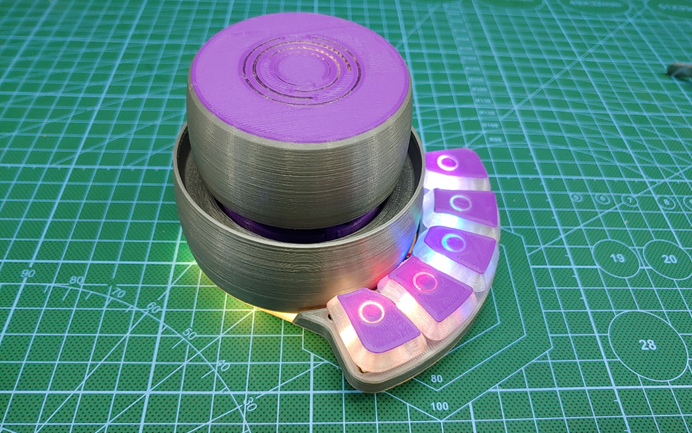

Base

Printed with two filaments (Purple, Transparent)

Material – PLA

Recommended infill % = >50

Macro Key Holder

Material – PLA

Recommended infill % = >40

Key Caps

Printed with two filaments (Purple, Transparent)

Material – PLA

Recommended infill % = 100

-

2Preparing To Assemble the Dial

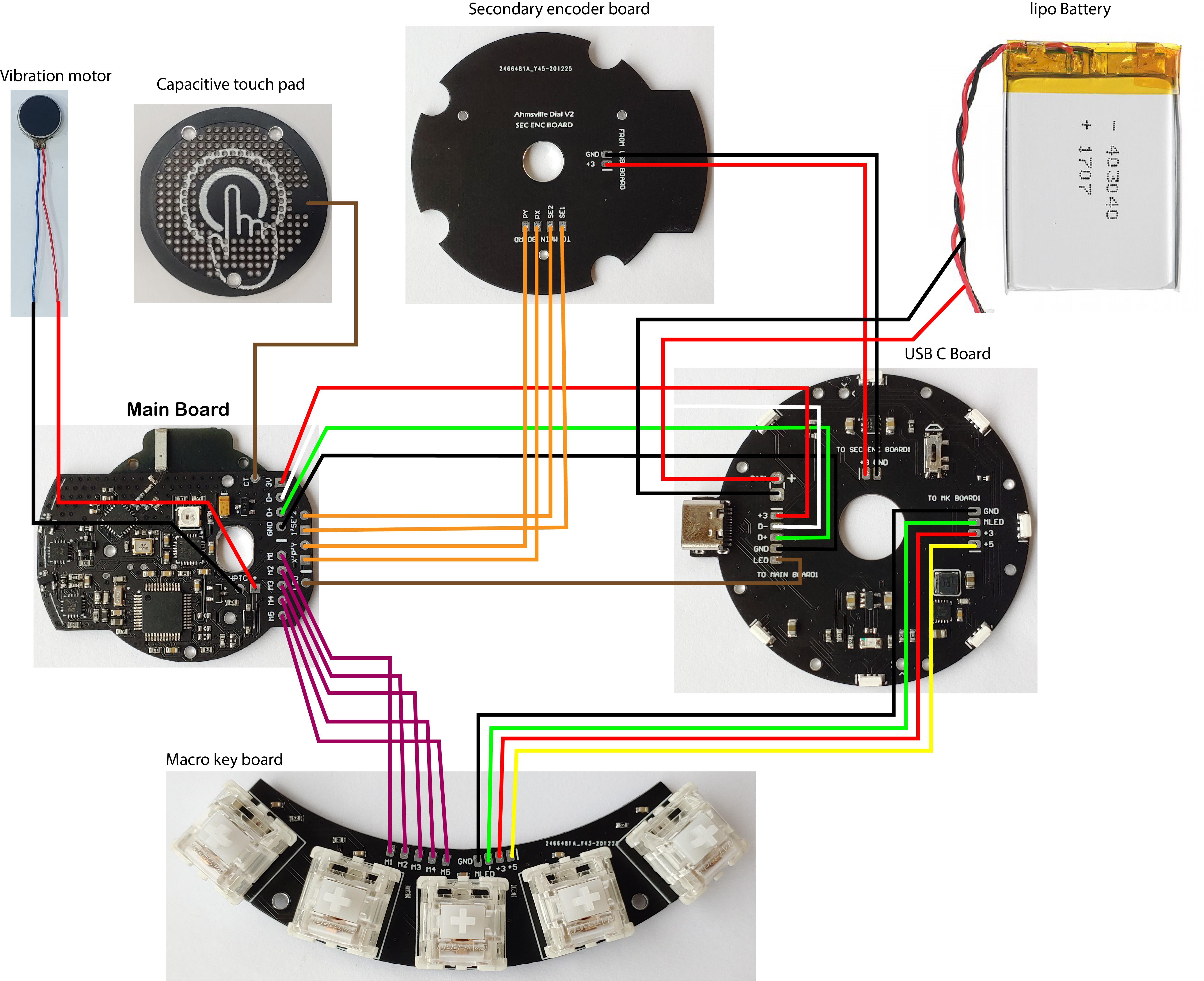

Before starting the actual assembly, i recommend taking some time to study the wiring diagram, understanding the wiring diagram will make the assembly a lot easier.

Wiring Diagram

![]()

-

3Assembling the Dial

Step 1

Insert lipo battery into the battery holder

Step 2

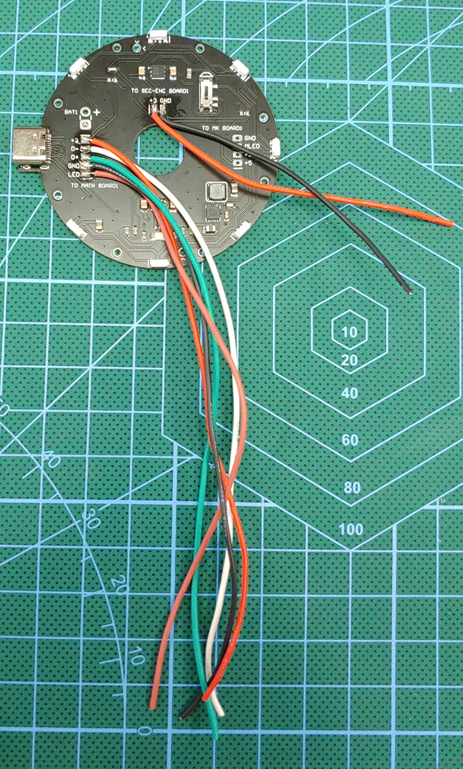

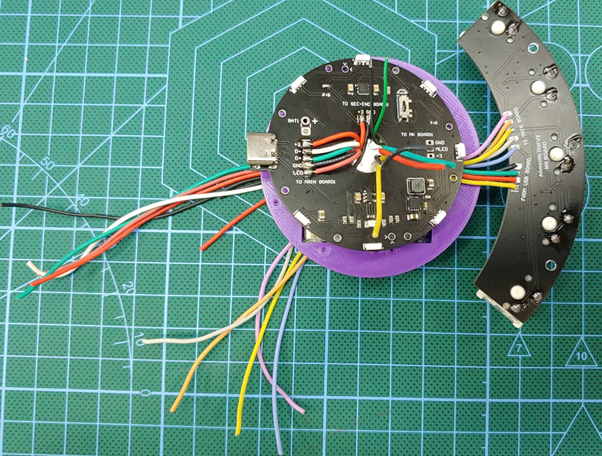

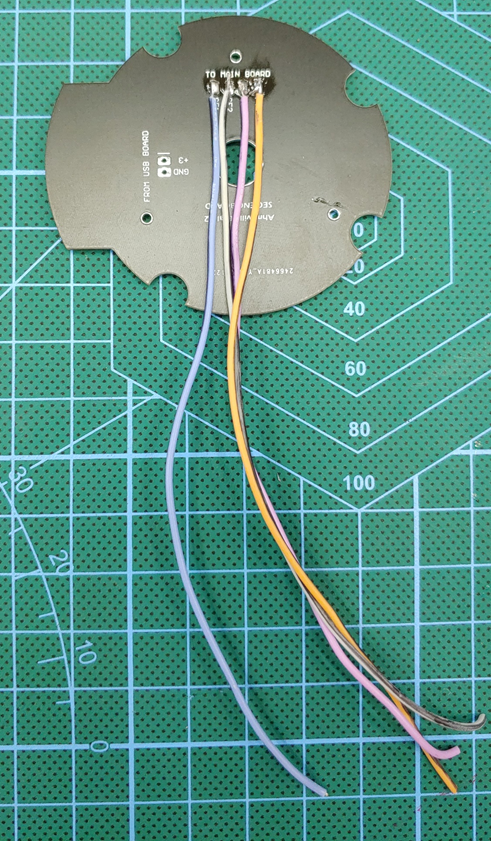

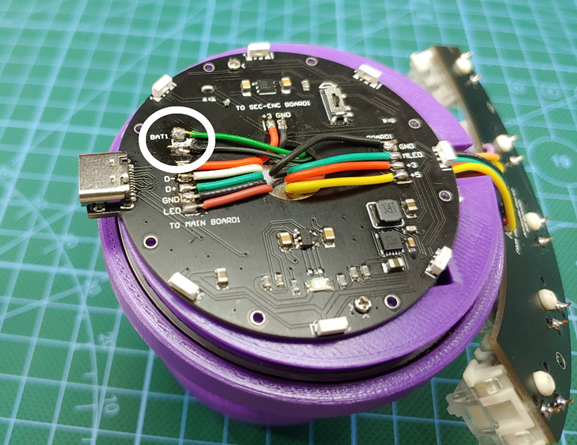

Solder five 150mm wires to +3, D-, D+, GND, and LED (TO MAIN BOARD).

Solder two 85-90mm wires to +3 and GND (TO SEC-ENC BOARD)

Step 3

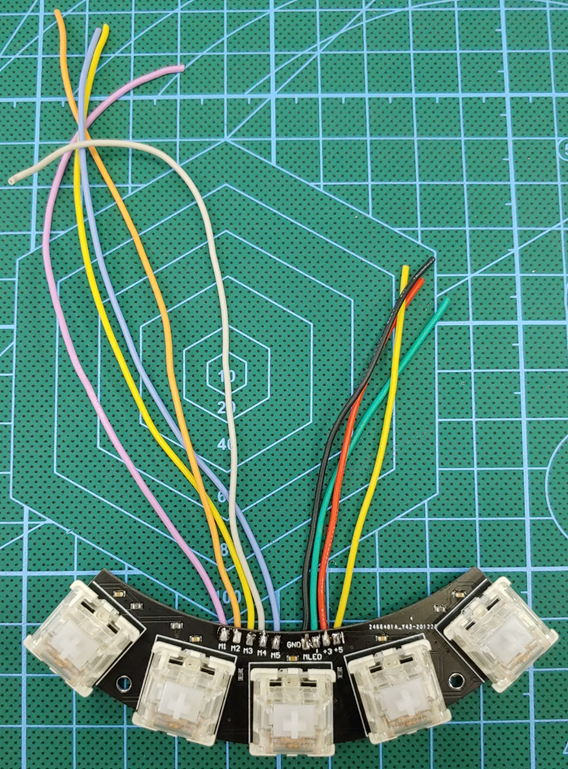

Solder five 150mm wires to M1, M2, M3, M4 and M5 (TO MAIN BOARD).

Solder four 85-90mm wires to +5, +3, MLED and GND (TO USB BOARD)

Step 4

Route wires through the USB board and the battery holder

Step 5

Terminate +5, +3, MLED and GND wires from the macro key board to the USB board.

Secure USB board with two m1.4x6mm screws.

Step 6

Install 6811 ball bearing on the battery holder

Step 7

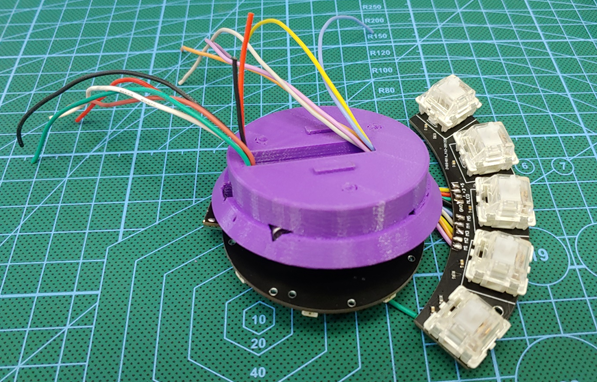

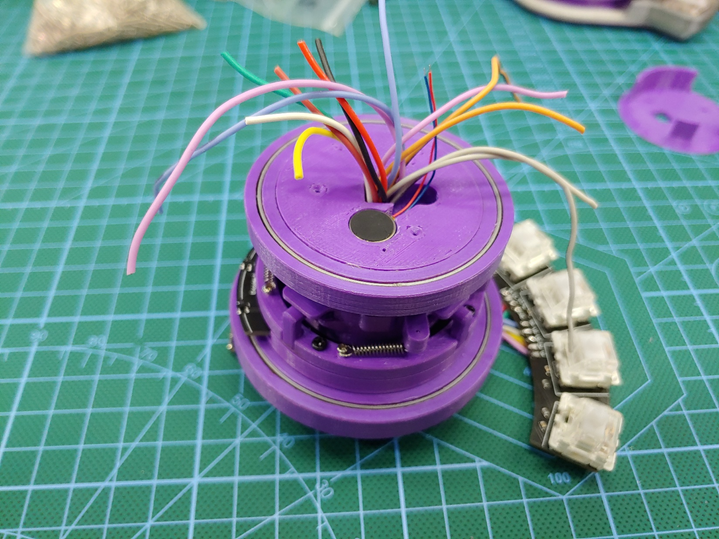

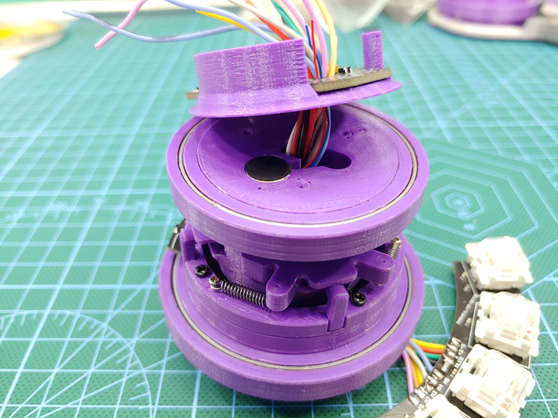

Attach secondary encoder board holder, making sure to route all the wires through the center hole.

Step 8

Solder four wire to SE1, SE2, PX and PY.

Take note of the connections using the wire colors as identifiers, you can write it down somewhere or simply take a picture of it.

Step 9

Terminate the short +3 and GND wires from the USB board to the Secondary encoder board, these wires provide power to the sec-enc board.

Step 10

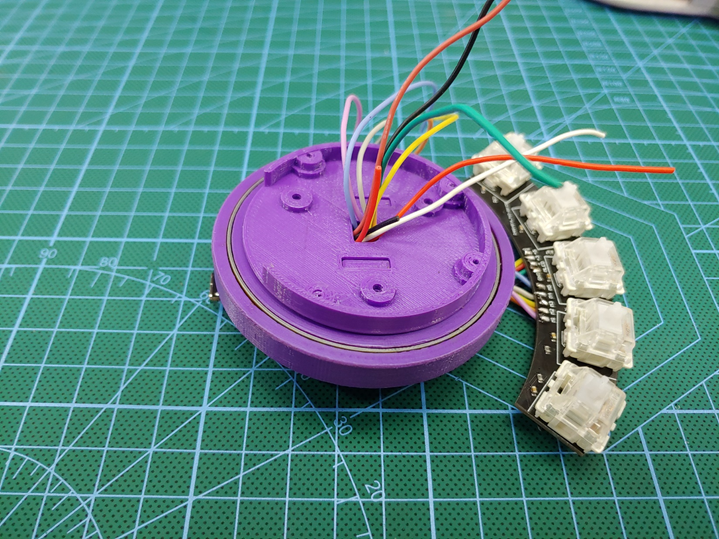

Attach the secondary encoder board to the holder, making sure to route all 14 wires through the center hole.

Secure the board and the holder with three m1.4x10mm screws.

Step 11

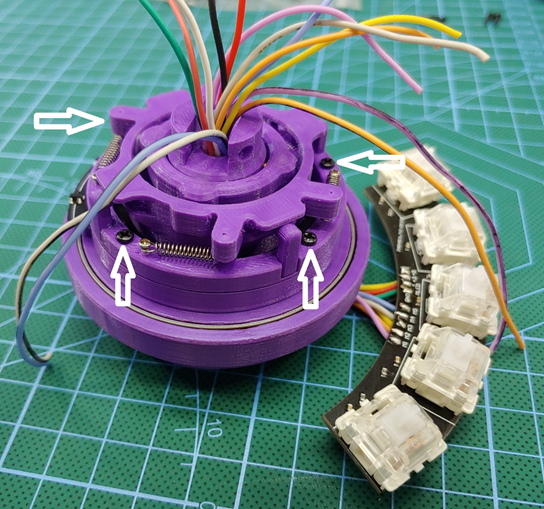

Install SpaceNav Mechanism, making sure to route all 14 wires through the center hole.

Secure the Mechanism with four m2x10mm screws.

Step 12

Attach the Spacenav mech holder, making sure to route all 14 wires through the center hole.

Secure the holder with two m1.4x10mm screw.

Step 13

Install vibration motor.

Step 14

Install 6809 ball bearing.

Step 15

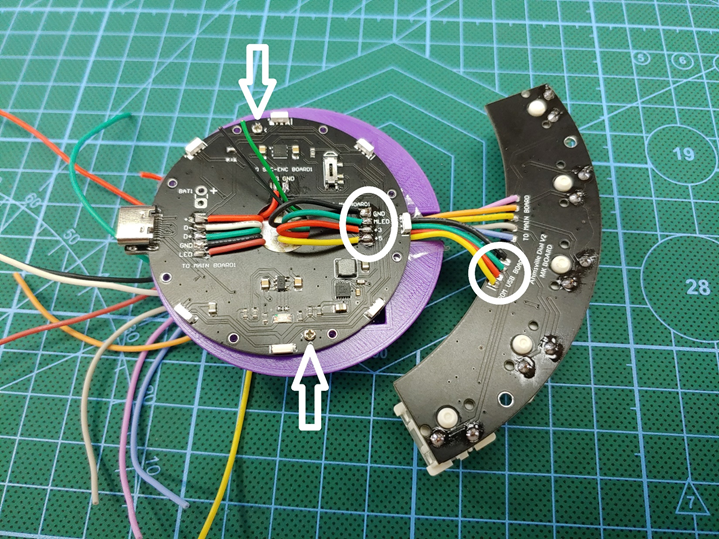

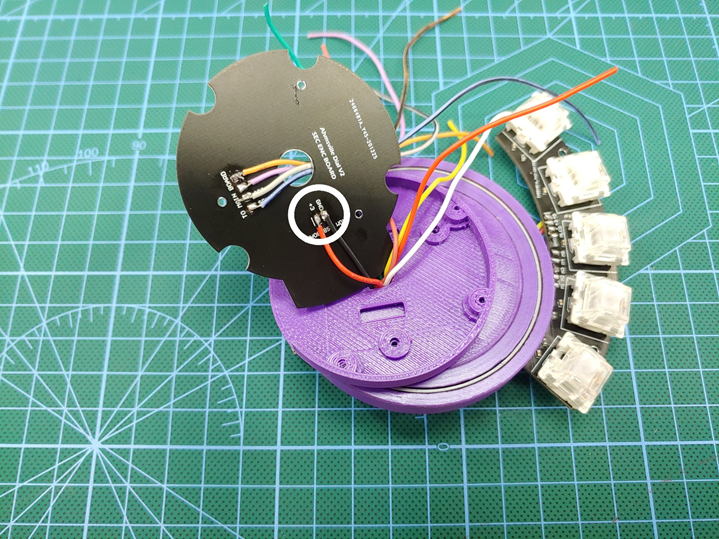

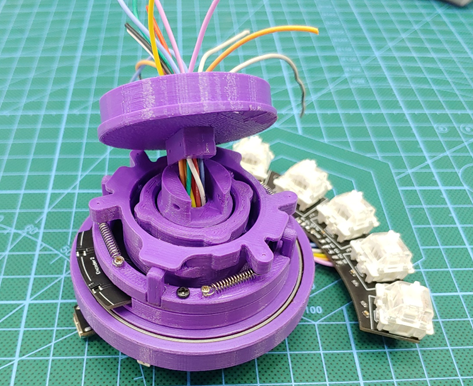

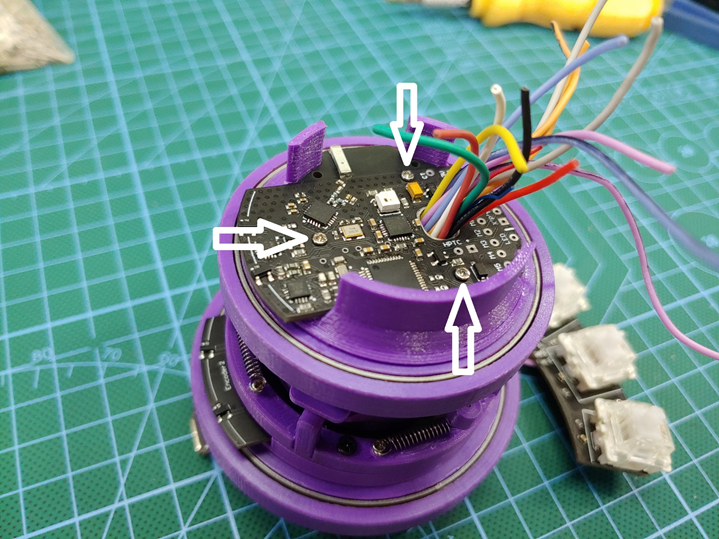

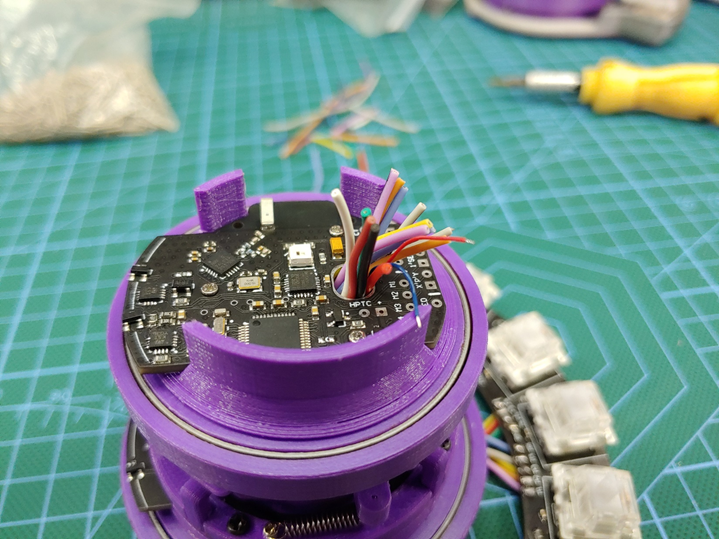

Attach main board to the main board holder.

Step 16

Install the main board together with its holder, making sure to route all 14 wires and the vibration motor wires through the center hole.

Step 17

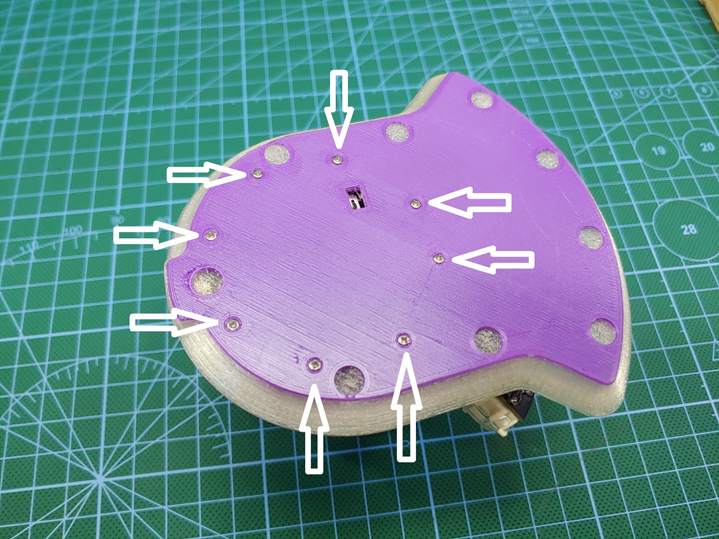

Secure the main board and its holder using three m1.4x10mm screws.

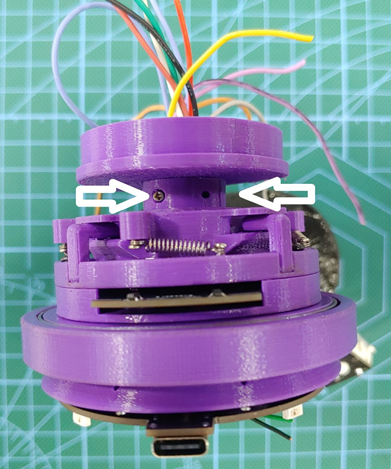

Step 18

Shorten all wires, be careful not to cut them too short.

Step 19

Terminate all wires to their appropriate spot, refer to the wiring diagram.

Step 20

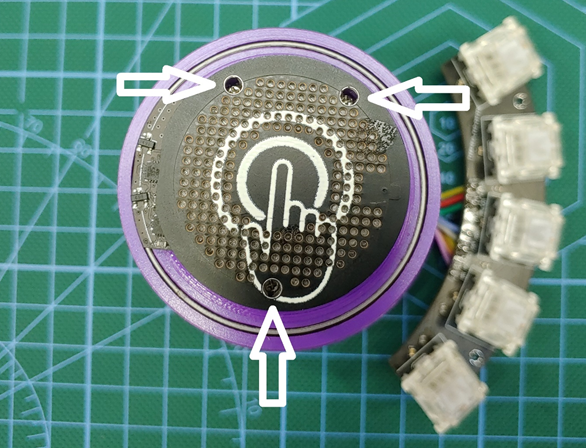

Solder a wire to the capacitive touchpad and terminate it to the CT pin on the main board.

Step 21

Secure capacitive touchpad with three m1.4x10mm screws.

Step 22

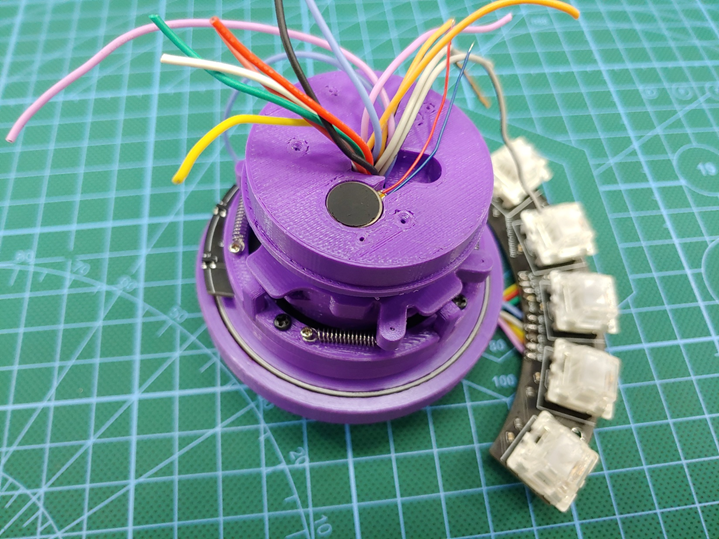

Solder battery wires to the USB board.

You may want to double check all your connections before doing this, make sure all your power connections are soldered to the right pins and with the right polarities.

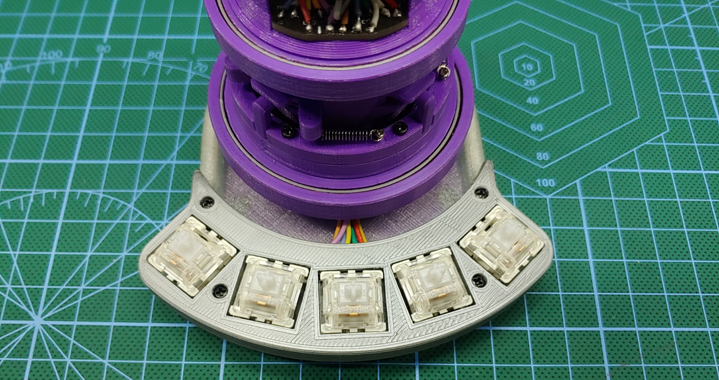

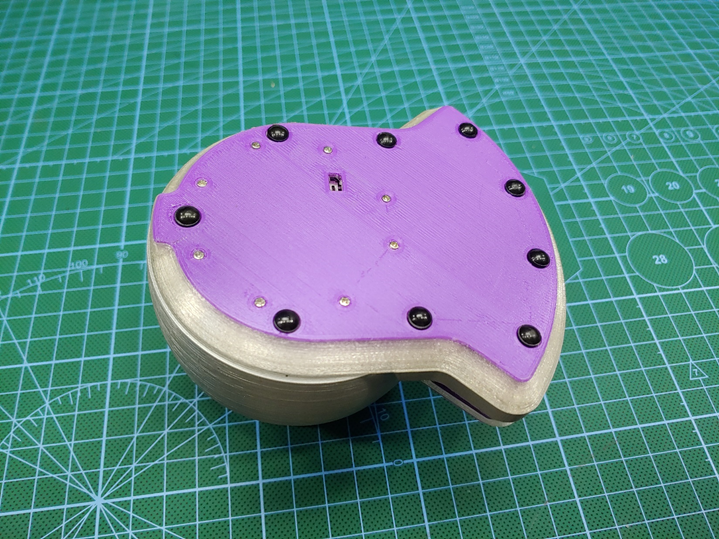

Step 23

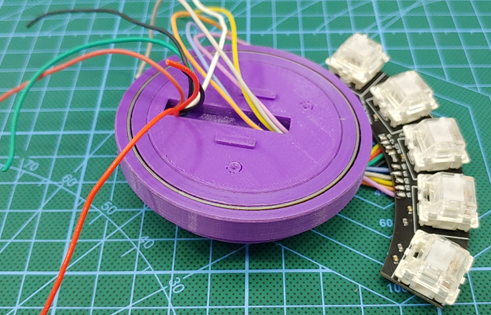

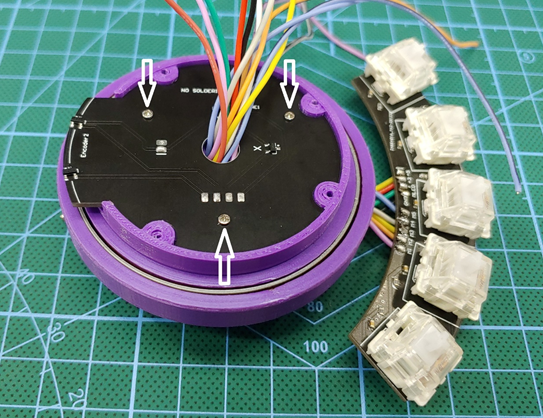

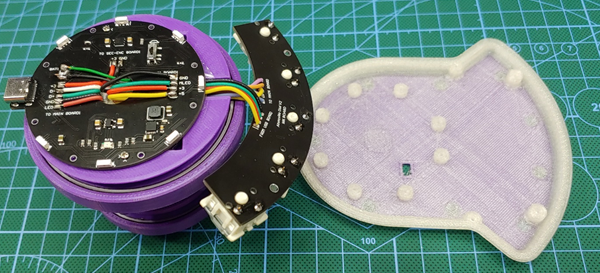

Attach the base.

Secure the base with eight m1.4x10mm screws.

Step 24

Attach macro key board holder and secure it with four m2x8mm screws.

Step 25

Install the neodymium magnets on the knob, the magnets should be arranged with alternating poles next to each other.

Depending on your 3D printer’s tolerance, you may or may not need to use superglue to secure the magnets.

Step 26

Attach the knob to the dial.

the knob has three self-locking tabs that helps it to grab onto the bearing, so you just need to gently force it onto the bearing and push down until the knob seats in place.

Step 27

Install Key caps.

Step 28

Attach rubber base pads.

Congratulations!!!

-

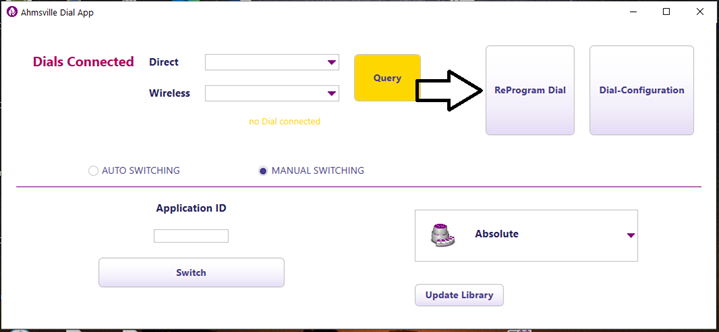

4Setting Up and Programming the Dial

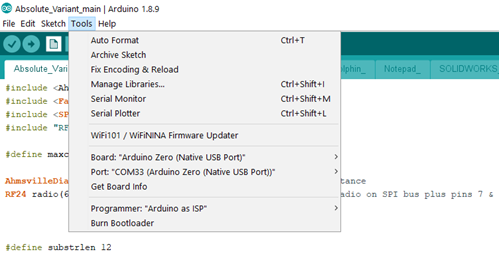

Select board as the Arduino Zero (Native USB Port) and select the COM-Port for the dial.

Ahmsville Dial v2 - https://github.com/ahmsville/Ahmsville-Dial-V2

Magnetic Rotary Encoder - https://github.com/ahmsville/Magnetic_rotary_encoding

Capacitive touch – https://github.com/PaulStoffregen/CapacitiveSensor

Adv – Capacitive touch – https://github.com/ahmsville/Advanced_capacitive_touch_detection

MacroKey – https://github.com/ahmsville/MacroKey

SpaceNavigator - https://github.com/ahmsville/SpaceNavigator

FastLED - https://github.com/FastLED/FastLED

RF24- https://github.com/nRF24/RF24

ADCRead - https://github.com/ahmsville/ADCRead

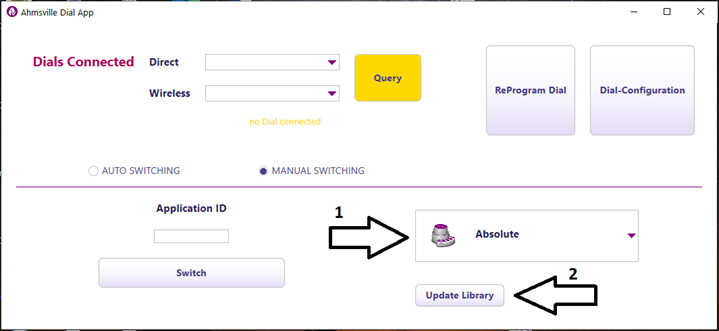

Select your dial variant and click on update library.

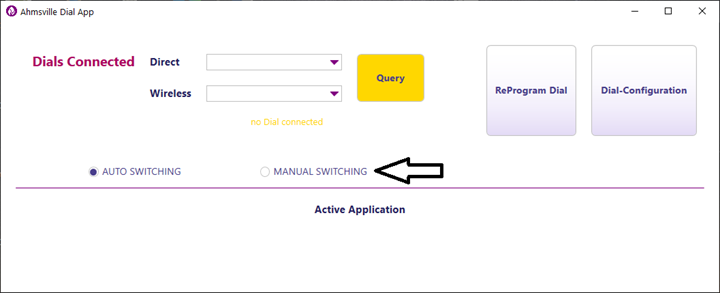

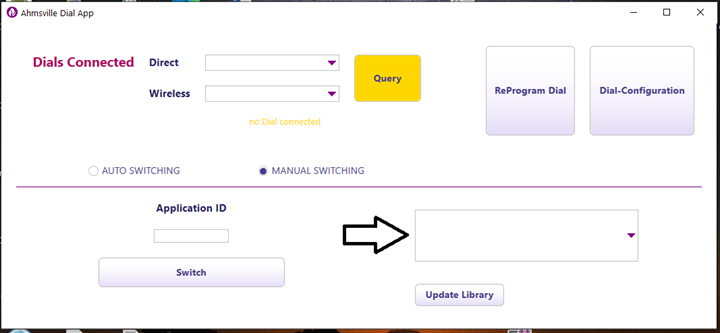

Open the Manual operation tab.

Step1 - Download and Install Arduino IDE.

Step2 - Download and install the Release installer file for the Ahmsville Dial App.

Setting up Arduino IDE for the Ahmsville Dial board

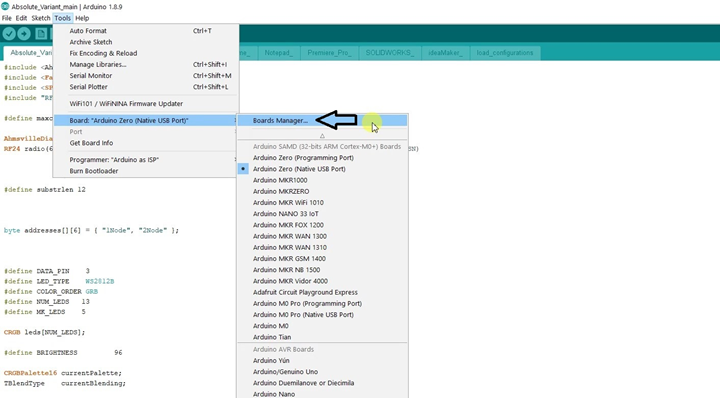

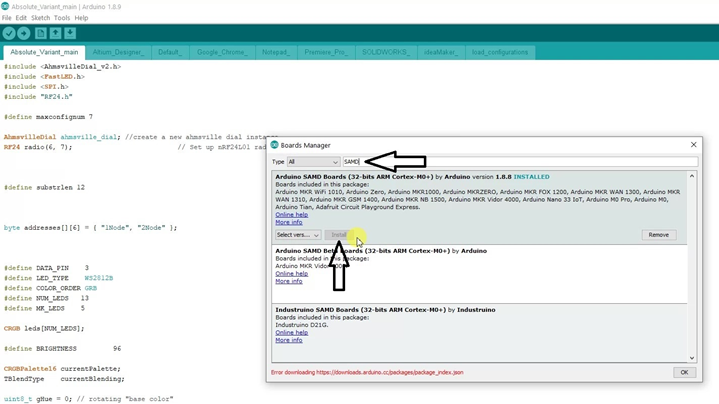

Step1 – Open up the Arduino ide and go to Tools >> Board >> Boards Manager.

Step2 – Search for SAMD and install the Arduino SAMD Boards package.

First time programming

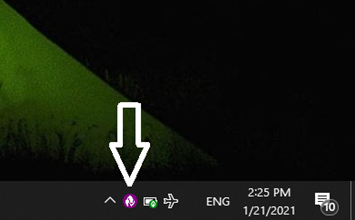

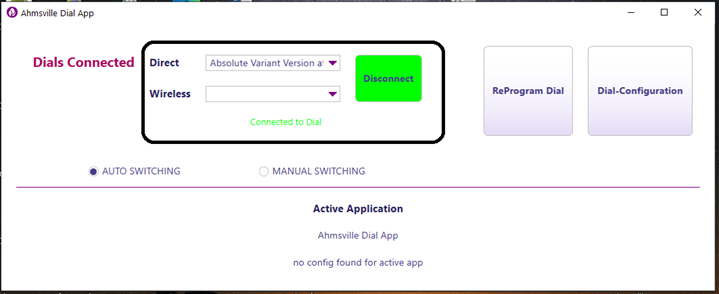

Launch Ahmsville Dial – this will launch the app in the background, you can then open the app from the notification area.

Open the Manual operation tab.

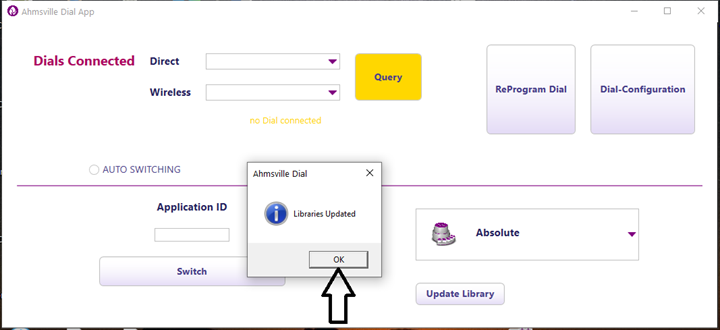

Select your dial variant and click on update library.

This will automatically install all the required Arduino libraries for you, but you can also get the libraries from the links below.

Ahmsville Dial v2 - https://github.com/ahmsville/Ahmsville-Dial-V2

Magnetic Rotary Encoder - https://github.com/ahmsville/Magnetic_rotary_encoding

Capacitive touch – https://github.com/PaulStoffregen/CapacitiveSensor

Adv – Capacitive touch – https://github.com/ahmsville/Advanced_capacitive_touch_detection

MacroKey – https://github.com/ahmsville/MacroKey

SpaceNavigator - https://github.com/ahmsville/SpaceNavigator

FastLED - https://github.com/FastLED/FastLED

RF24- https://github.com/nRF24/RF24

ADCRead - https://github.com/ahmsville/ADCRead

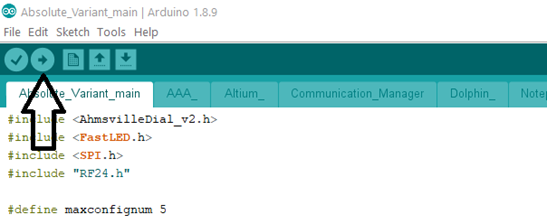

Now click on ReProgram Dial, which will open the Arduino sketch for your chosen dial.

Select board as the Arduino Zero (Native USB Port) and select the COM-Port for the dial.

The final step is to upload the sketch to your dial, connect the dial to the PC via a usb cable and click on the upload button.

Once the upload is complete, you dial should turn on and automatically connect to the App.

Your Dial is now ready, and you may proceed to creating control configurations for your desired applications.

Ahmsville Dial V2

A 3D-printed programmable wireless/wired controller for your PC, and other electronics devices.

Ahmed Oyenuga

Ahmed Oyenuga

Discussions

Become a Hackaday.io Member

Create an account to leave a comment. Already have an account? Log In.