Coil Winding Machine

To make a machine that winds coil around a steel rod to make an electromagnet.

To make a machine that winds coil around a steel rod to make an electromagnet.

To make the experience fit your profile, pick a username and tell us what interests you.

We found and based on your interests.

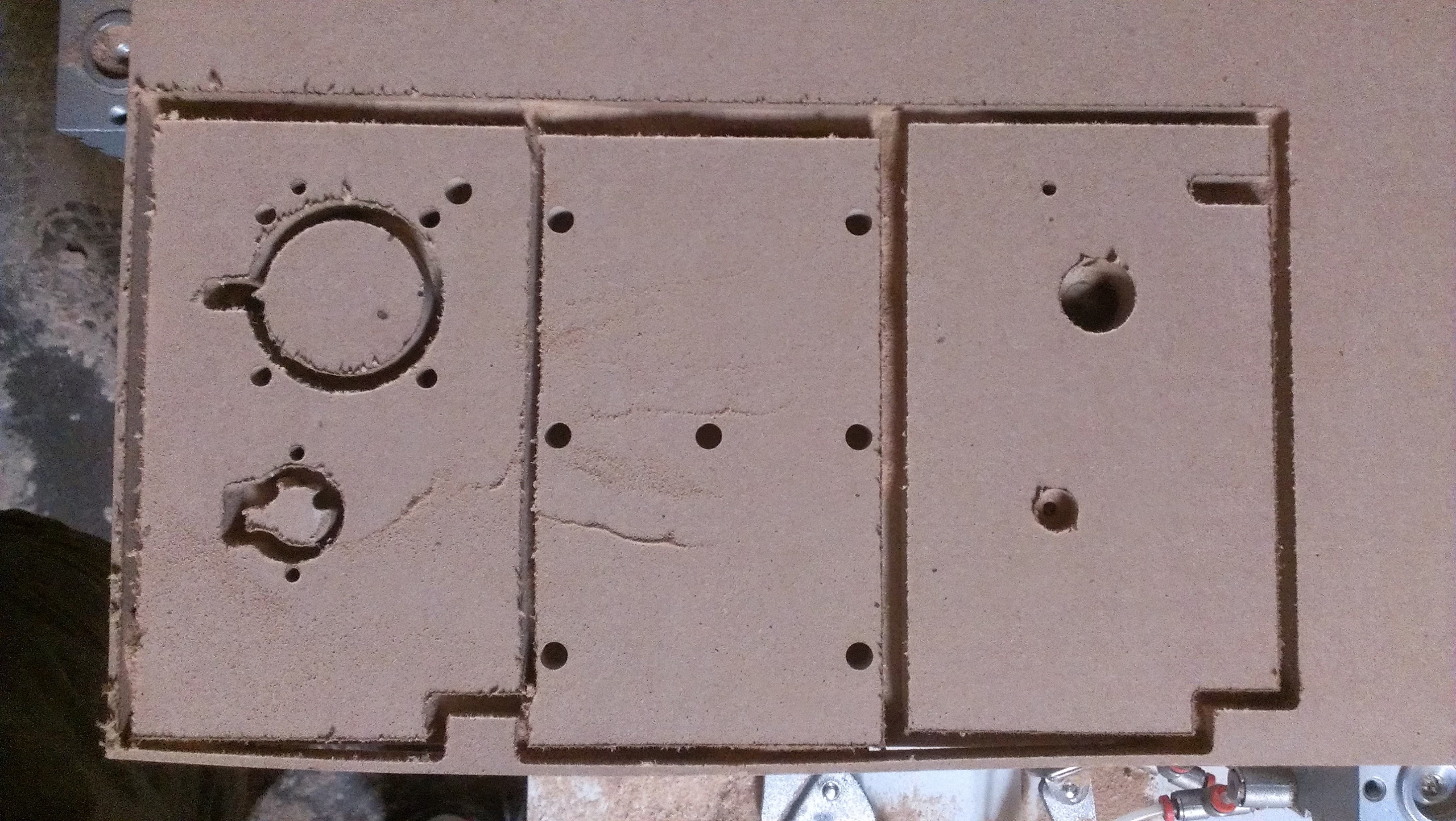

I used a cnc router to manufacture the structure of the coil winder out of MDF. At first when I was trying to make sure the program works, I was running the router really slowly. A really fast rpm along with a really slow feed rate caused a small flame.

After that small road block I managed to router out the parts.

Then with some wood glue and dowels I made a sturdy case for my machine.

Now the case is ready for mounting the electronics.

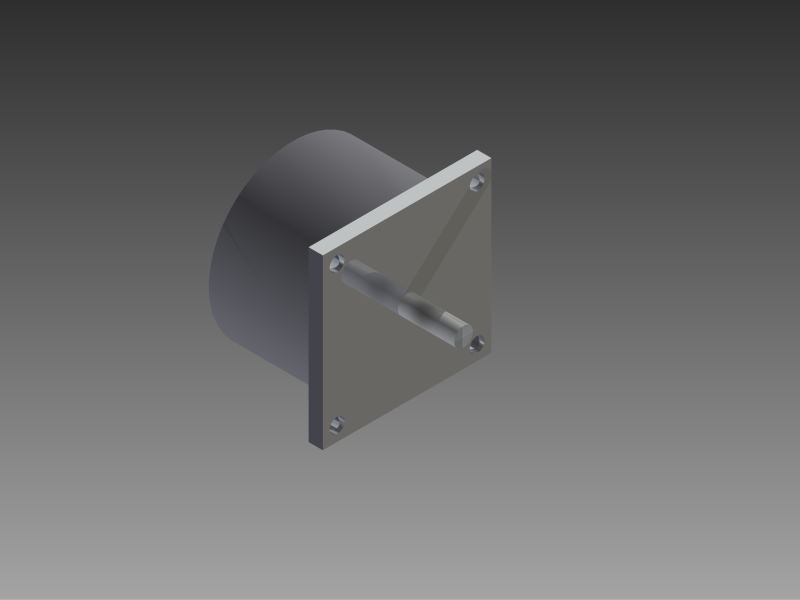

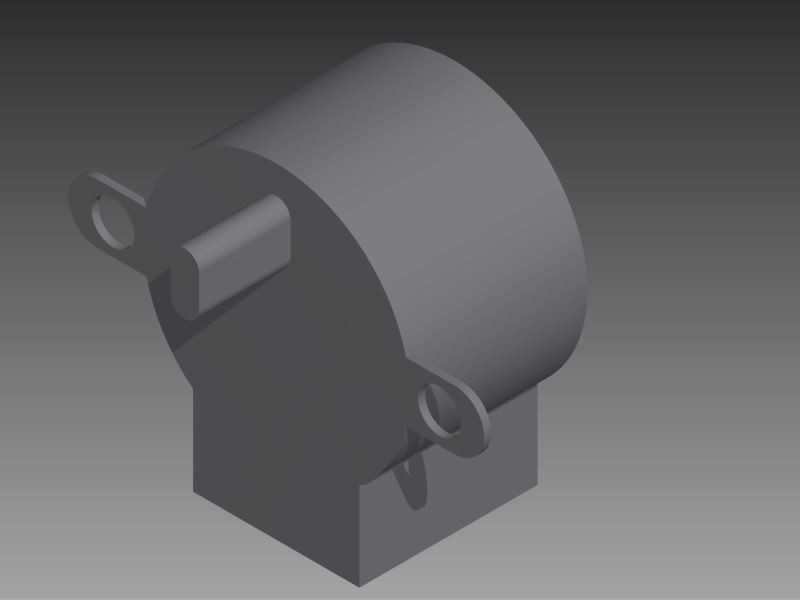

To begin my design process I found some old steppers I had and designed them using Auto-desk Inventor.

This is the motor used to turn the core

This stepper is used to turn the lead-screw, which adjusts the horizontal position of the wire

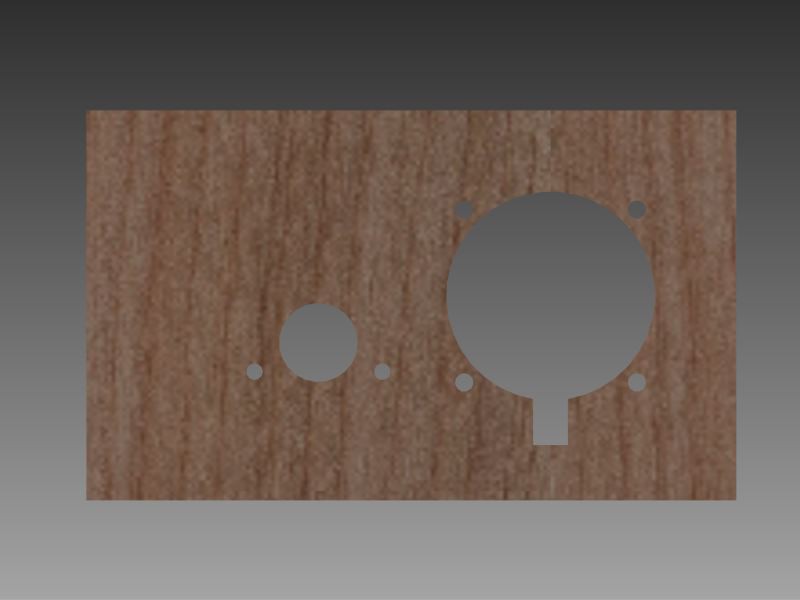

After the motors, I made the frame of the entire machine, planned out where I wanted the motors, and designed the frame.

The wall of the structure where the stepper motors will mount.

The opposite wall, where the ball bearings will go to support the shafts.

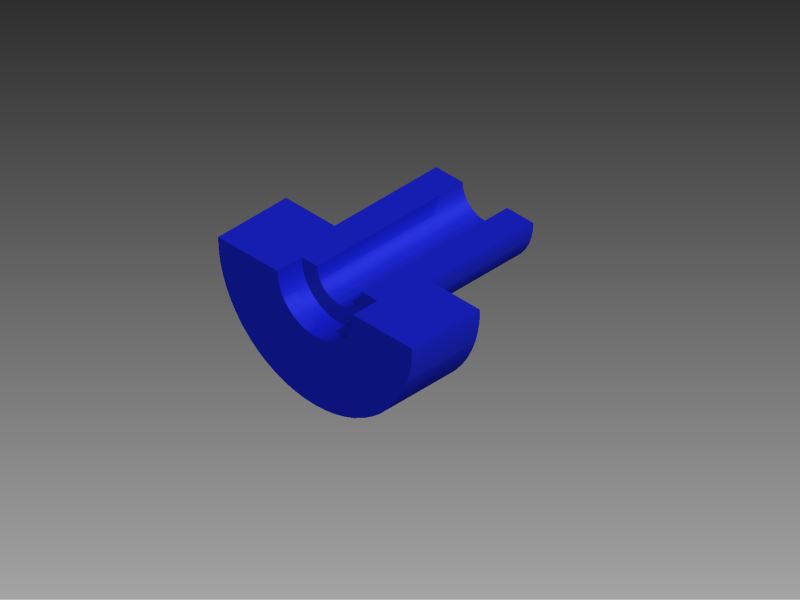

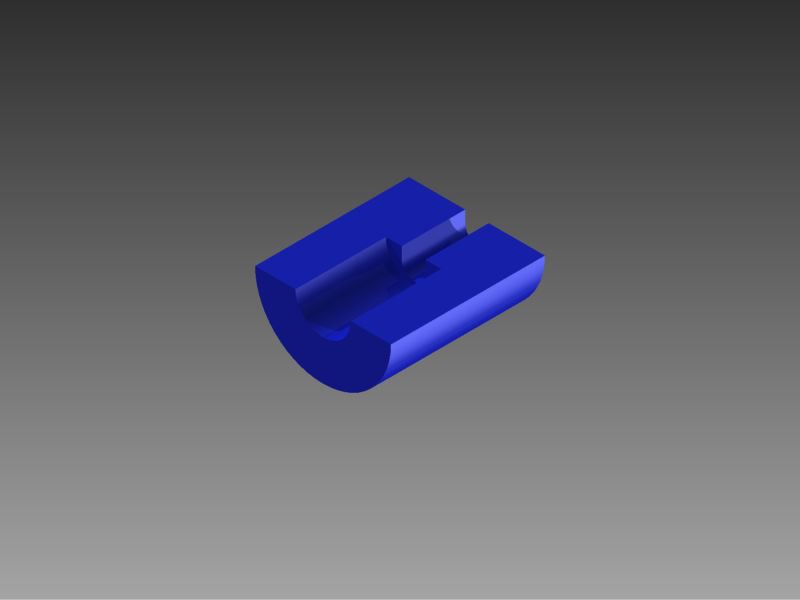

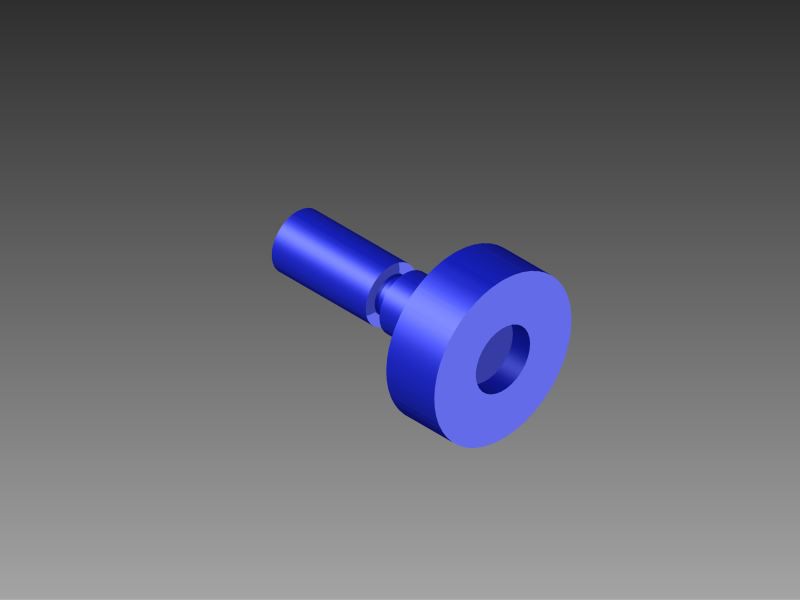

After designing the frame, I began designing the 3D printed parts there were a total of 3 parts.

The following two renders, are cut in half to allow easier viewing.

This is the piece that connects the main stepper motor to the core.

This is the part that connects the smaller stepper to the screw I will be using as a lead screw to control the horizontal position of the wire

This is the piece that connects the core to the ball bearing opposite to the main motor.

Before beginning the project, I needed to figure out what features I need to have in the mechanism. So I 3D printed some pieces to hold on to the core so I can experiment with winding a coil by hand on a lathe. After a couple hours of winding, and unwinding coils, i figured out I needed at least two moving parts, one to rotate the core, and one to move the wire horizontally according to where the wire needed to be wrapped. With those design limitations I began designing in Inventor.

Create an account to leave a comment. Already have an account? Log In.

You are correct, as I understand it an iron core would have produced a stronger magnetic field. If I remember correctly, at the time I was working on this project I could not find an iron core that fit my needs.

Also, at the time I had no idea how to approach using a control system to control the output of the electromagnet, and having a weaker electromagnet probably helped me more that it hurt.

Oh, okay.. I see! It was because it's difficult to find a cylindrical iron rod.

I checked Online Metals and Mag Inc., and neither of them had anything. This is the only source I came come across:

https://www.xump.com/science/Soft-Iron-Rod.cfm?SID=12&gclid=CjsKDwjw6qnJBRDpoonDwLSeZhIkAIpTR8IndOodhPBDQOOKy5VsZ7qSJzOzL_lcxtQ7VCfif1_3GgJRYfD_BwE

Adding a control system to the electromagnet sounds like it would be a fun project! What was the intended application?

@Greg Stephens Yeah after doing some more searching now I was able to find find a few other sources also. I guess my sourcing skills were not great two years ago haha.

The purpose of even making this electromagnet winder was to automate the electromagnet production for a model maglev train I wanted to create. Here is a write up I did a few years ago about the preliminary designs. https://sites.google.com/site/jacksprojectspage/projects/electroma

Sadly I never got a chance to complete the Maglev as I moved off to college and haven't really had the chance to put more work into it.

That's awesome! ..i'm with you on how amazing magnetic levitation is.

They demand too much time out of engineering students. There's just not enough time to work on passion projects as ambitious as a maglev trains (outside of capstone).

But, maybe you can still work on parts of it at a time. Like, check out this Levitating Lamp I saw at the maker's faire this year. I'm sure an EE professor would accept this as a capstone.. since you need to setup a control system to regulate an electromagnet in response to feedback from a Hall Effect sensor.

idk. Maybe you've seen this before. I thought it was amazing though.. I am considering the attempt to levitate magnets for myself.

Become a member to follow this project and never miss any updates

I guess this project is kind'of old by now. ..but, i'm curious. Why use a steel rod instead of iron for your electromagnet core?