-

images: assembly from ready parts vs. fabrication

10/27/2021 at 06:57 • 0 comments(This is mostly a place to stash photos for reference from other text)

Certainly many people have made very low cost CNC machines from scavenged parts, scrap materials, an equipped shop, and a fair idea of what they were aiming for.

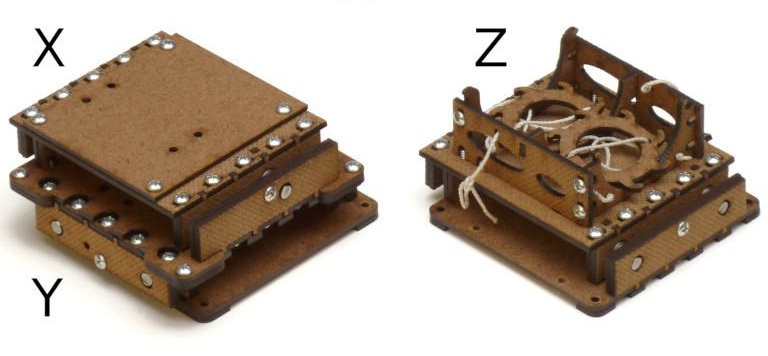

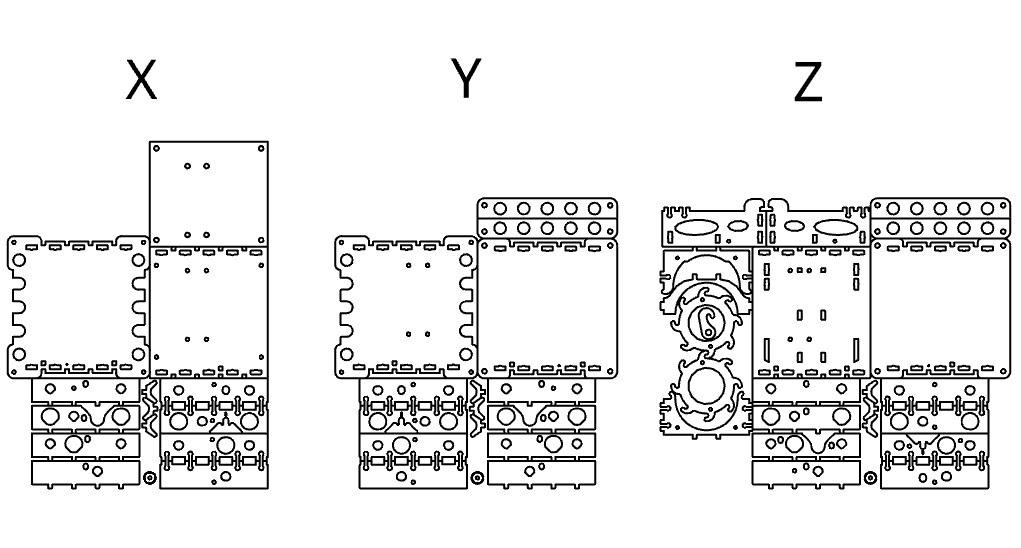

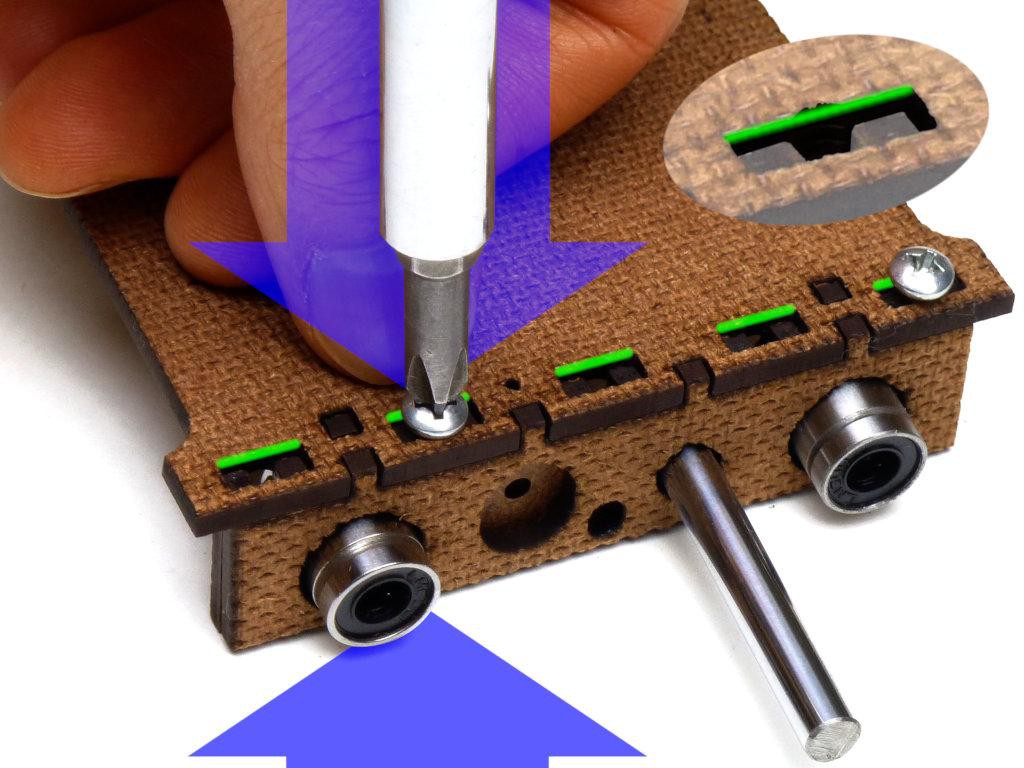

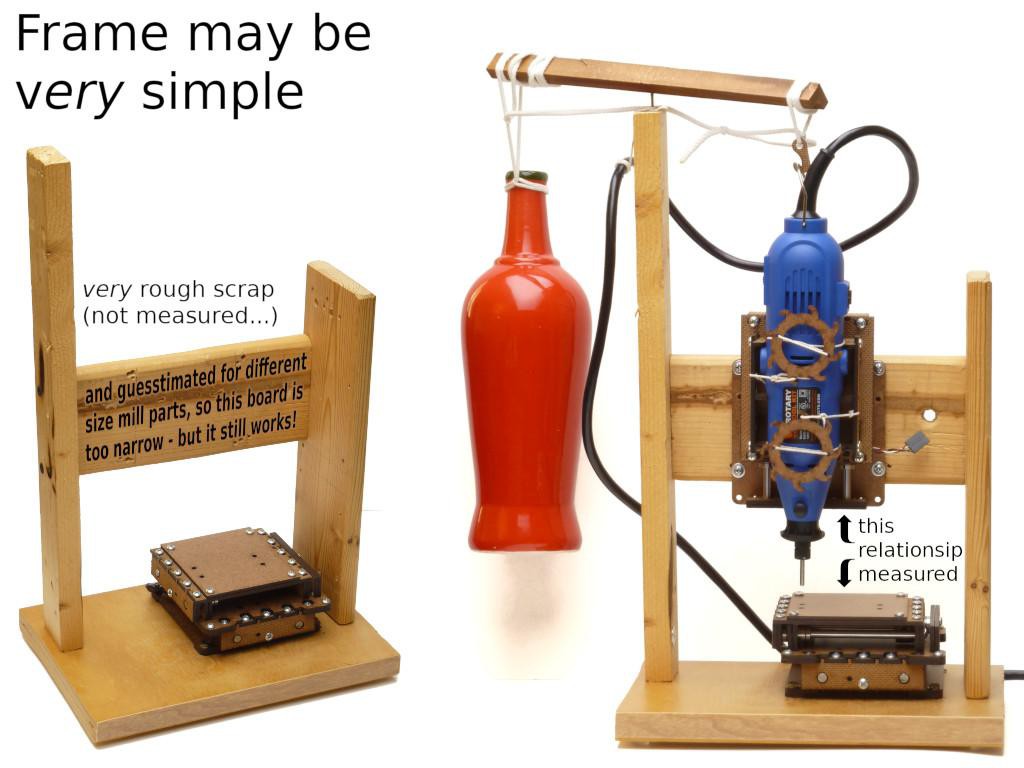

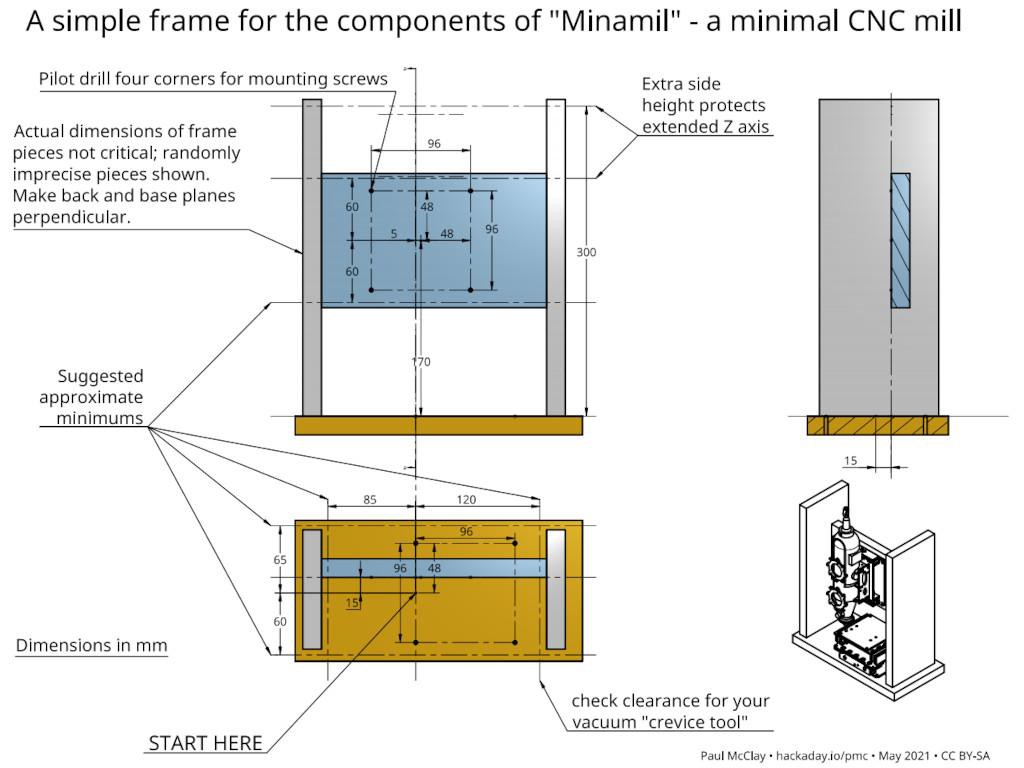

This project presents a design based on two main assemblies – the X+Y axes, and the Z axis+tool clamp – built from a few specified hardware parts and some laser cut flat pieces following detailed illustrated assembly instructions.

![]()

![]()

![]()

![]()

The frame that holds the Z axis over the X+Y axes does call for ad hoc construction from available material, but that can be made to eyeball precision from practically any rigid flat-ish material and would not benefit from over-specification.

![]()

![]()

-

Minimally milling fine-pitch circuit board features

10/23/2021 at 07:26 • 0 comments(copypasted from mainline project: #Minamil: a minimal CNC mill. And friends. )

Responding to a comment on an earlier log, I wrote:

I haven't written much yet about the blue Wen dremeloid used for most of this project so far to keep it cheap. The main trick [...blah blah...] acceptable runout. I don't think it was ever going to cut the SSOP footprint tho.

Since then, I got some renewed motivation to try again...

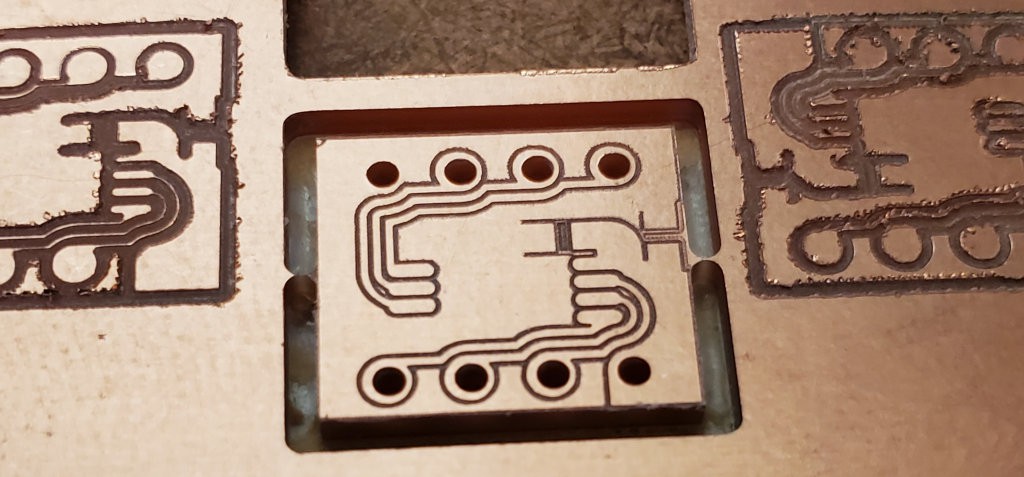

![]()

...and made it happen. A perfect spindle would be nice, but in the spirit of pushing down the hardware requirement and frustration with the "better" tool, I went back for another round of tweaking away runout. I'm finding more tricks but don't really have that down to a method for a good how-to yet.

The overall process for milling this example went something like:

- use stable magnification

- I've used a phone (camera) held in a phone claw on a tripod...

- ...until gaining unfair advantage coincident with this iteration

- tweak the v-bit to small runout (...see? just type the words and its done...)

- adjust spindle speed to minimize resonant vibration at v-bit tip

- I've read of doing this by sound and/or feel, but I had to actually watch the tip of the bit under magnification while adjusting speed

- assuming speed control either onboard or external to the rotary tool

- peck a hole just through the copperplate

- 1 oz. copper is nominally 0.035 mm or 1.4 mil thick

- measure the breadth of the hole - I did it like this:

- using magnification...

- turn the v-bit sideways to view the tip edgewise as a fine point

- set jog step to 0.025 mm = one whole step (20 steps/rev, 2 revs/mm)

- position the bit over the hole just a step above the surface

- jog a few steps to one side

- step the bit point back toward the hole and stop at the first edge

- continuing in the same direction, count steps across to the other edge

- hole diameter = steps * 0.025 mm

- ideally 4 steps for a narrow-angle 0.1 mm v-vbit

- more likely 5 for a "perfect" setup, and 6 or 7 will be pretty good

- use measured peck diameter as tool diameter for generating gcode

Tool changes for drilling and milling won't be so carefully precise. Notice in the video below:

- pilot drilled the through-holes with the v-bit in an attempt to help the center the less carefully chucked drill bit

- maybe might have helped with precision of through-hole locations maybe

- didn't prevent the swinging drill from carving an oversize hole in the top surface

- drill did self-center and exit holes are not oversize

- narrowing of through-holes with depth somewhat visible in vid thumbnail below

Sub-2-minute video for eye-candy:

- use stable magnification

-

Non-selected bid for "Challenge 3: Reimagine Supportive Tech"

08/23/2021 at 01:10 • 0 commentsThis was my shot at "Challenge 3: Reimagine Supportive Tech"...

It was a little Procrustean. Others hit closer to the mark. Leaving this here for the history.

1. Discuss the challenge the project addresses.

This entry addresses Challenge 3: Reimagine Supportive Tech

Create technology that acts as ... more inclusive ... beginner-friendly tech for aspiring engineers!

Many projects across the maker community begin life as the solution to a problem. How can we fill a gap in hardware? ... How can we bring more people into the fold through more accessible and entry-level projects? ...

Your solution should make it easier for others to build electronics or make electronics devices more accessible; modular, hackable, or affordable.This could look like:

...

* Creating beginner-friendly projects or jumping off points into STEM educationWithin a focus on electronics

A trend toward making new ICs available only in fine pitch SMD packages increasingly defeats many low-cost circuit assembly techniques apart from making custom PCBs to a level of precision that challenges homebrew etching. This makes new electronics components increasingly more exclusive, less beginner-friendly, less affordable, and less accessible to beginners and STEM students. While several services now provide high quality PCBs in small quantities at low prices, the "low" cost includes weeks of waiting for delivery to most locations. Such long cycle times quash fearless iteration for beginners and students.

Beyond electronics

3-axis CNC milling, the traditional "CAM" of CAD/CAM, resists commoditization and remains a complex and often difficult art. Learning generally requires perseverance and access to costly equipment. Pandemic lockdowns keep students away from institutional teaching facilities. Even at the low end of "hobby" mills, costs in hundreds of USD and dedicated space requirements exclude many potential beginners or home-study students.

2. Discuss how the project will alleviate or solve the problem that the project addresses.This project presents a 3-axis CNC mill of novel design that can mill very fine PCB features, and provide entrée to real 3-axis milling, at much lower cost than any other ready-to-assemble option that I have found to date.

Specifically in regard to electronics, this project significantly drops the cost of milling PCBs for immediate use and with precision suitable for very fine SMD pin pitches required for access to increasingly many new electronics components available only in fine pitch packages.

Generally in regard to CNC machining, this project significantly drops the cost of entry to learn full 3d CAM by building and using a real machine to make real parts from usefully strong materials.

The mill presented in this project features:

- extremely low cost

- much lower than any other option I've found without relying on "lucky" scavenging and/or part fabrication from stock

- detailed <$50 BoM

- ready-to-assemble parts

- vs. plans for fabrication

- extremely compact

- store on a shelf and use in a small space on busy desk

- specific bill of materials

- vs. "scavenger hunt" parts list

3. Publish at least one (1) image illustrating how the project might be used. This may be a sketch, schematic, flow chart, rendering, or other type of image.

Above, log entries, and Gallery

4. Link to any repositories (e.g., Github).Instructables

primary: Low(est?) Cost Reproducible 3-axis CNC Mill

refers to: A Cheap Compact Linear Motion Slide

Onshape (CAD)

primary: Minamil - a minimal CNC mill

imports from: pmc's cheap linear slide

Vimeo

5. Document all open-source licenses and permissions as well as any applicable third-party licenses/restrictions.

6. Submit the project to the 2021 Hackaday Prize using the “Submit project to...” option found on the published Project Profile.Submitted 30 July 2021

Is this a unique solution to a particular challenge facing the world today?

That’s a biggie! Let’s suppose that many potential solutions to particular challenges facing the world today involve prototyping with progressively shrinking electronic components. People trying new ideas without industrial support face a particular challenge of access to costly tools to make circuit boards with precise tiny features for shrinking components.

Accessible options for individuals include “isolation routing” circuit boards from copper-clad PCB stock using a sufficiently precise CNC machine. Existing capabilities and costs include thousands or hundreds of dollars

Other options have different advantages and disadvantages:

- Some industrial circuit board makers promote themselves by making small boards in small quantities for loss-leader prices like $2 or free -- plus either time for economical shipping or multiplied cost for faster shipping which is still not instantaneous. That’s hard to beat, especially for production from a known design. On the other hand, the immediacy of self-made boards can accelerate prototype development up to multiple iterations in a day or enable direct feedback and fearless exploration in STEAM education.

- Masking and etching copper-clad boards has decades of hobbyist development and far greater variety that I'll write here. In principle, it can be done with minimal inputs. However, masking for very fine pitch components generally requires a printed mask. For "toner transfer" the mask must be printed with a laser printer or very precise photocopier; inkjet printed masks may be used with specially prepared photosensitive board stock. Normal undercutting at mask edges complicates fine features. Etchants may have limited shelf life. Waste contains copper compounds subject to legal/responsible disposal requirements.

Oh yeah, and it's a little 3-axis CNC mill that can make other parts for building up a complete prototype, or provide a solid start for learning the CAM end of CAD-CAM.

How thoroughly documented were the design process & design decisions?

tl;dr: tried an idea for a least possible step up from a CD/DVD optical deck and it worked so I kept going -- here's the one big read.

I think I can fairly say: documented more thoroughly, or at least with more words, than most people will want to read.

- starting from #CDCNC (also Hackaday.com and HaD podcast 082)

- note re transition

- continuing through >30 log entries at #Minamil: a minimal CNC mill. And friends.

- with a sidebar at #"Desk Accessory" CNC Milling Machine

- since the start of "Challenge 3", log entries on this project

Or a little more selectively:

- about design process & decisions

- the X and Y that were -- review before redo

- progress but frustration

- dense

- did I say frustration?

- some of the basic ideas that seem to be working -- extended review

- so why go vertical when horizontal was such a win before? -- current since HaD Prize contest start

- about an unexpected major problem

- XY table wroks!

"Unexpected problem: the XY axes don't handle a descending load well but chatter."

- backlash, chatter and fine parallel finishing

- homework

- thank you Orang

- XY table wroks!

- about a simplification that became a spin-off sub-project

- about circuit board milling

- second look at PCB milling: looks promising

- milling T/SSOP breakout - 065mm pitch -- current since HaD Prize contest start

- useful tssop 8 breakout almost -- current since HaD Prize contest start

- teaser...

- about failure

- about performance/capability testing

- "mill" or "router"?

- naming the project/instance/class -- last paragraph

- compared to what? -- end note 1

How easily can this design be implemented by other people in future projects?"Easy" is a primary project goal!

To be clear, I expect this to continue as a DIY project rather than a turn-key consumer item ready to chug out all the best parts on delivery. By "easy" I mean easy for hack-ish people with aptitude for assembling something from pieces, and then learning a tool that returns delayed gratification for initial patience. That said, making it easier for more people to get started on the 3d CNC “subtractive” learning curve for real, including milling PCBs, is also a primary project goal.

And here's the how:

- make yer own! (that took a while...)

- Low(est?) Cost Reproducible 3-axis CNC Mill -- Instructable

- parts prices

How complete is the project?Two answers:

- It works well right now!

- I think this project has lots of potential for further development!

- validate buildability

- improve build documentation - try video

- given rising price of the specific CH-SM1545 motor and falling prices of similar but longer generics: adjust dimensions to fit the longer screws which are no longer much more expensive and apparently available from more sources. (oh, heck yeah - price bumped again)

- optimize flat part details to reduce commercial laser cutting cost

- adapt for more expensive but faster-cutting material, e.g. acrylic, to net reduce commercial laser cutting cost

- try again 2x motors for X & Y - first try effective when synced but too easy to un-sync; try again with limit switches & soft limits

- extremely low cost

-

Compared to... what?

08/20/2021 at 19:54 • 0 commentstl;dr: Minimal appears able to produce finer PCB features than common low-end generics.

To what existing baseline can we compare Minamil's PCB milling capability?

The "cheapest" CNC

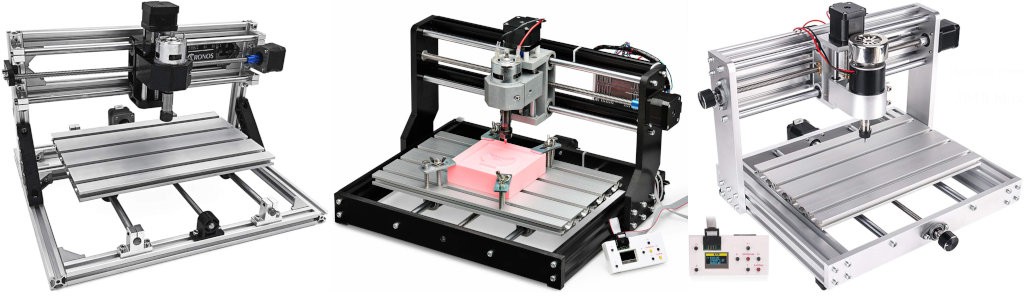

As of August 2021, it looks like the dominant “cheapest” CNC machines for PCB routing[note 1] and other (very) light hobby use are variations of “3018” - a generic design with 30cm x 18cm work area, and typically 4-5cm Z travel. Other “xxyy” designations indicate similar machines with larger or smaller work area. Various sellers offer machines of very similar design built to various levels of cost & robustness. Current examples listed by Amazon include: basic <$150, “pro” ~$200, and “max” ~$300.

![3018: lightest, lighter, light 3018: lightest, lighter, light]()

images from linked Amazon seller listings Smaller machines of similar kind include essentially all the same parts and do not cost very much less. Construction from shorter lengths of similar linear rods & extrusions may give smaller units greater stiffness.

I have not yet found where this design comes from, or when. My current best guess is that “CNC 3018” was already generic before English speakers wrote much about them on Teh Internetz. Please comment if you know.

Not having one myself, I don’t really know what they can do. After a bit of searching I’ve found several mentions of milling/routing PCBs on these machines, but little indication of use for very fine pitch components or high density of small features.

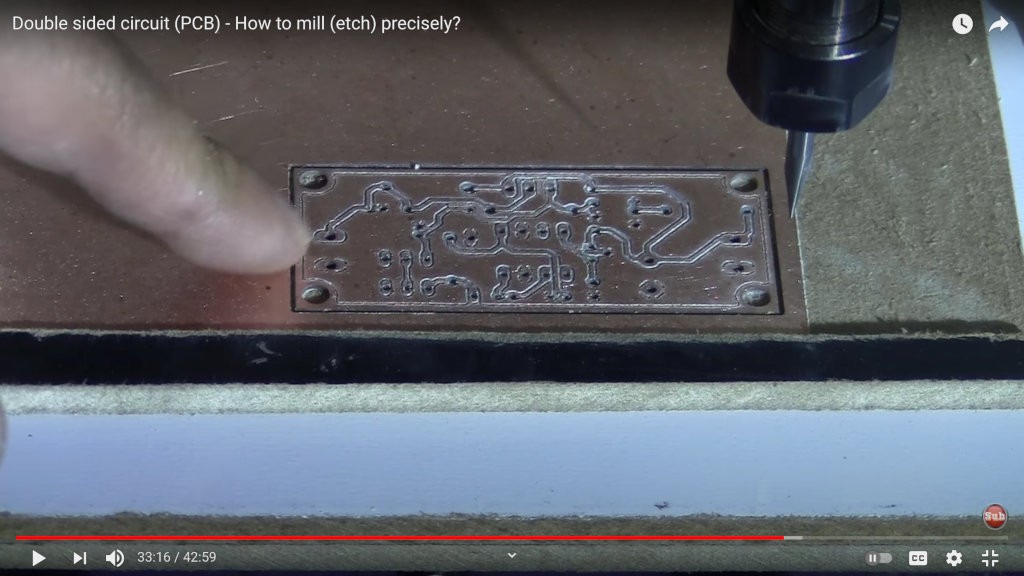

- At the beginning of this year, Electronics Weekly blogger Steve Bush wrote one of the better overviews of this category that I’ve found so far. That post was the second of a two-part series. In the first part he wrote “However, like so many people before, I am tempted to have a go at modify[ing] the little cnc to [...] have, maybe, 0.2mm accuracy with softer stuff [than aluminum]”. He recommends a youtuber’s videos, one of which details how to mill a PCB “preceisely” on a 3018. That video, from Sep. 2019, shows fairly coarse through-hole features:

![]()

That gives data points at "0.2mm accuracy" and coarse through-hole (0.1") scale PCB features.

- YouTuber bitluni’s video “The Cheapest CNC Milling Machine” from April 2020 shows a failed attempt to cut SO (0.05”) pitch features, and then a usable result with 0.1" through-hole and sparsely placed 0603 discrete surface-mount parts:

- YouTuber HomoFaciens, specialist in building high function from extremely low tech/cost inputs, posted a video “Isolation milling a PCB with the CNC 3018Pro from Mostics” in Feb. 2021. It shows his spindle running with obvious significant runout and he produces a board with coarse through-hole features:

- Teaching Tech’s Oct. 2020 video “Homemade custom PCB guide using free KiCAD software” discusses design compensation for wide milling tracks and shows a board with coarse through-hole features and thinned tracks:

- For a non-graphical example, guidance at Hackerspace Nijmegen (currently displaced due to COVID-19) advises minimum 0.5mm separation with between traces: "Milling PCB's with 3018 Chinese Desktop CNC"

- DIY TECH BROS on YouTube have the cleanest example that I've found so far. Their “CNC PCB - high quality with the budget 3018 CNC” shows, with dramatic flair (a la WEGSTR CNC?), a clean SO-pitch breakout board. From the photo, I think it looks like their isolation path width is about 0.2-0.22ish mm.

In a very extensive tutorial series + discussion "Milling PCBs with cheap Chinese "desktop" CNC-router" spanning Aug 2018 to Sep 2020, author esaj reports "I've made boards with 0.3-0.4mm traces". Although he doesn't focus on fine-pitch parts, his sample photos show some very finely cut traces. If I've figured right, this photo crop below shows isolation grooves cut as small as ~0.18mm:

![crop from board by esaj crop from board by esaj]()

source He reports generally configuring 0.15mm as a tool diameter for isolation path generation when cutting with 0.1mm 30° V-bits, and discusses tool & path parameters at some length.

He tried a high-rpm motor upgrade for a while but abandoned it. About speed and runout, he reports: "I usually run the spindle at full RPMs [...]. With the original 7k or 9k (I no longer remember which it was) RPM motor and ER-11 chuck, there's very little runout. With the 20k RPM motor I had in use for a while, the runout was often way too much for higher RPMs, so I couldn't run it really at full speed most of the time (although sometimes it just "worked" and I could get good cuts at 800mm/min)."

About depth of cut in FR4, he recommends very shallow cuts, even taking the shallow isolation cuts in two very shallow steps.

Nine months into that thread, he reports "Looks like I found the limit of the machine tolerances on the CNC" with 0.1mm traces on 0.5mm centers for an MSOP package:

![]()

source The next day esaj reported: "I ran another board today, with slightly different settings (slower cuts, first with 30-deg 0.1mm bit at 100mm/min, then again with 15-deg titanium 0.1mm bit to clean up). This time the traces are closer to 0.2mm." With isolation paths reduced from 0.4mm to 0.3mm.

![]()

source These two are the only examples of milling a 0.5mm pitch footprint on a 3018-type machine that I've found, neither case leaving the intended 0.3mm breadth of lands for the package. While I think the first image shown above from his tutorial shows sufficiently narrow ~0.2mm isolation paths, he apparently did not succeed in replicating that at will for this small footprint. In discussion he attributes that to "motor + bit vibration".

He did populate the board with 0.1mm traces, apparently successfully:

![]()

ibid.

So it looks like the baseline for PCB milling on "cheapest" desktop CNC machines is mainly around through-hole or 0.1" pitch density, with best case examples of clean SO/0.05" pitch or marginal 0.5mm pitch footprints.

"Minamil"

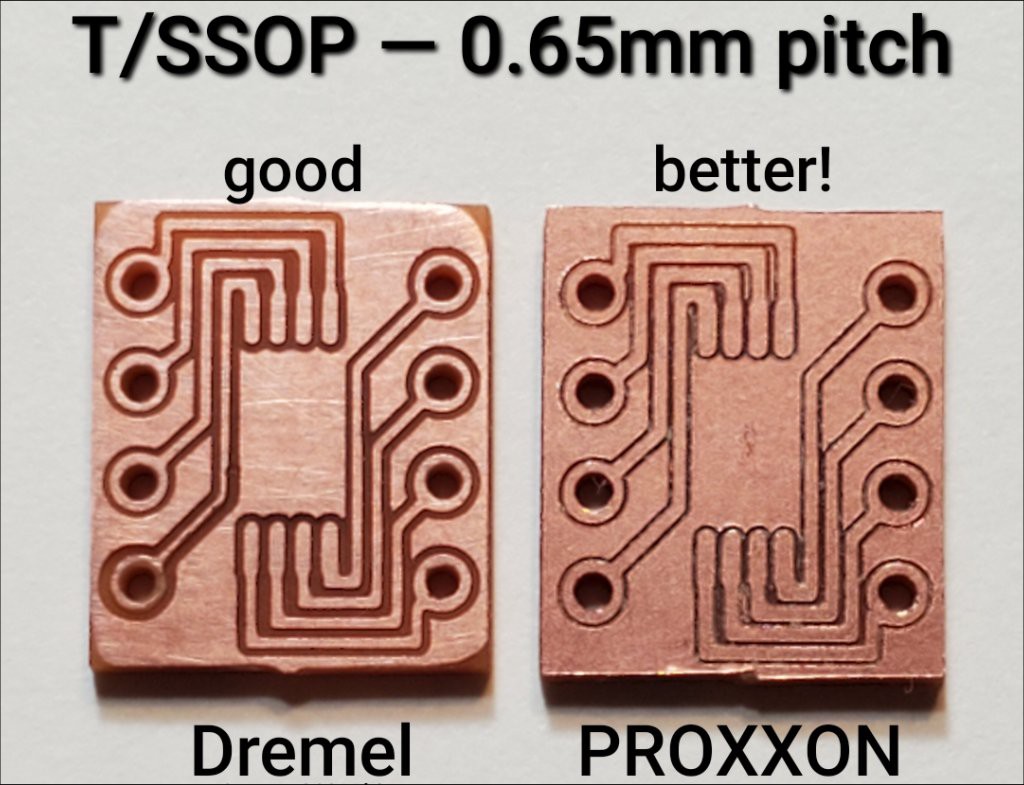

For the comparison, here is an image crop from a July log entry about milling an SSOP footprint:

![]()

While the SSOP footprint has pads on 0.65mm centers instead of 0.5mm, the horizontal traces crossing each end of the DIP footprint lie on 0.5mm centers. Using a beater old Dremel for a spindle, Minamil[note 2] cut isolation paths slightly narrower than half of that interval, or <0.25mm wide, leaving traces at least wider than 0.25mm if not fully 0.3mm wide for nominal 0.5mm pitch footprint. Cutting the same part using a PROXXON IBS/E for a spindle left traces over 0.3mm wide on 0.5mm centers separated by isolation paths under 0.2mm wide. So far I haven't found an example of a "cheap" 3018-type CNC router matching that.

Advantage: Minamil. For less cash in a smaller footprint.

In the baseline case, it's pretty clear that the 775 motor spindles contribute to spreading out minimal isolation path width by runout and vibration. Also relatively low speed for standard motors -- 8k to 12krpm -- limits cutting edge speed for tiny tool diameters, and limits feed rate.

Minamil uses a general-purpose rotary tool, which will almost certainly spin up faster than the 8k-12k rpm range for typical "3018" spindles, and may achieve lower runout than most 775-derived spindles.

Because the vertical axis must necessarily have a counterbalance, Minamil can easily accommodate the greater mass of a general-purpose rotary tool.

A general-purpose rotary tool has a cost advantage in that it can earn its keep doing other stuff when not making PCBs.

Notes

- So is it "mill" or "router"?

I wrote a little about that earlier. I doubt there is a concrete specific answer. My over-simplified rubric goes like this:

- Router - Relatively compact/light Z axis moving laterally (say, X) on a gantry (that may also move in Y) around a relatively large work area. Typically broader than tall. Penalizes Z mass because axis & spindle accelerate and move in X or XY plane.

- Mill - Relatively massive fixed Z axis with spindle moving only in Z, maybe ponderously, while relatively small work area moves in XY underneath fixed Z. Typically taller than wide. Z axis and spindle may be much more massive & slow relative to XY table.

Always exceptions; if your gantry has an operator’s cab, please call it anything you want.

Also from the earlier log entry: “... And the pretentiousness of calling it a "mill" hides in plain sight the pretentiousness of calling a toy-scale device a tool at all. Kind of like an Easy-Bake® "oven".” But seeing that it works, I don't mind calling it a tool.

- "Minamil" essentially as published but with a modified Z axis that I haven't published yet. I think that won't make a huge difference.

- At the beginning of this year, Electronics Weekly blogger Steve Bush wrote one of the better overviews of this category that I’ve found so far. That post was the second of a two-part series. In the first part he wrote “However, like so many people before, I am tempted to have a go at modify[ing] the little cnc to [...] have, maybe, 0.2mm accuracy with softer stuff [than aluminum]”. He recommends a youtuber’s videos, one of which details how to mill a PCB “preceisely” on a 3018. That video, from Sep. 2019, shows fairly coarse through-hole features:

-

"useful" T/SSOP-8 breakout ... almost

08/15/2021 at 08:11 • 0 commentsupdate: add photo at end

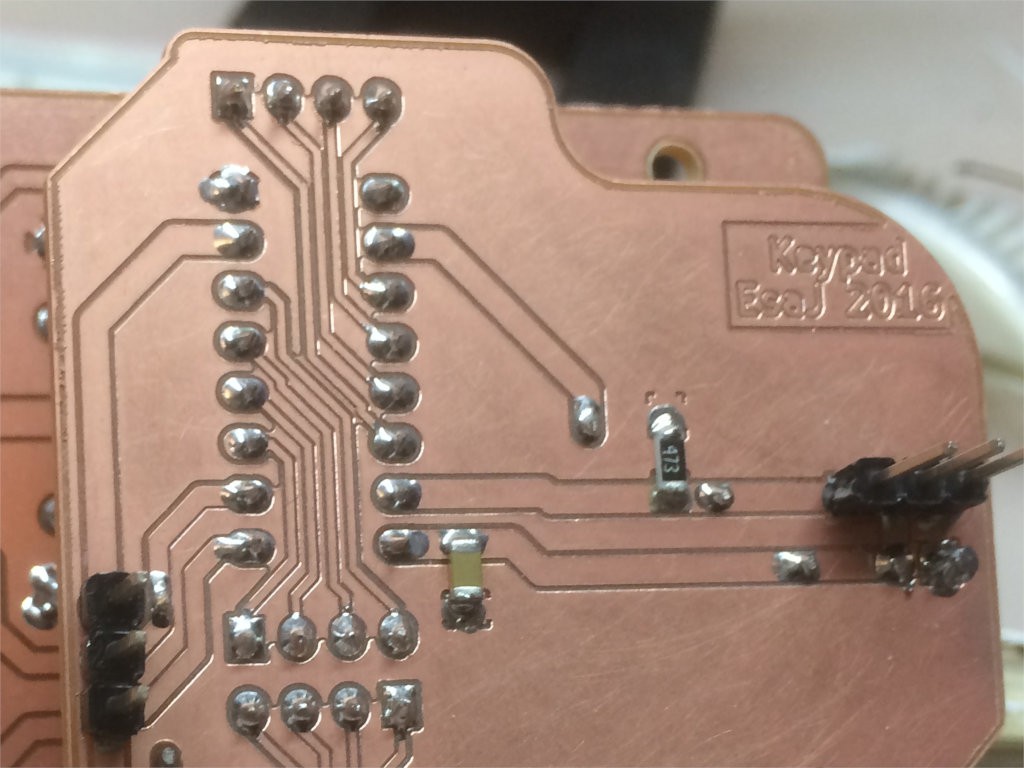

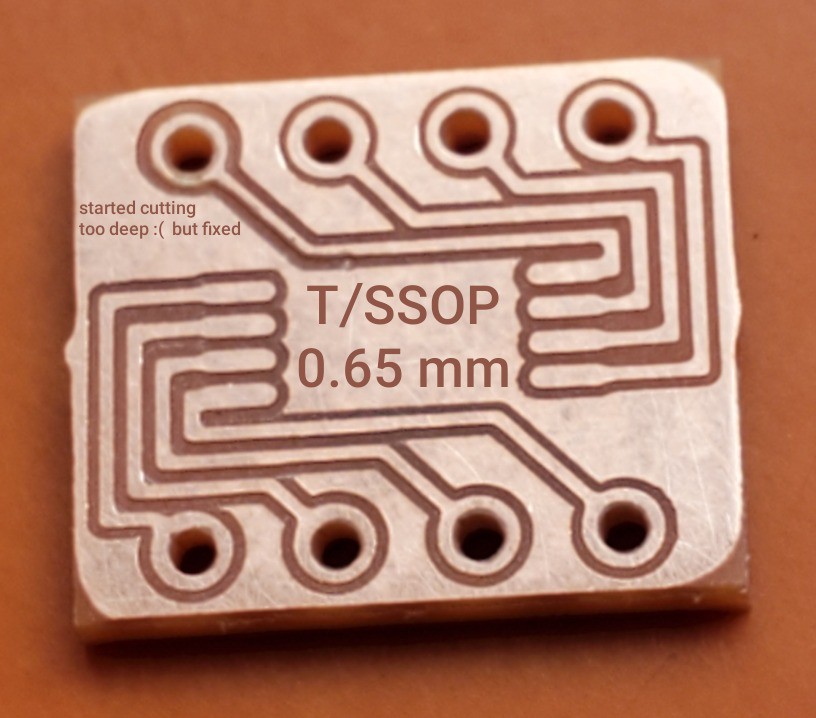

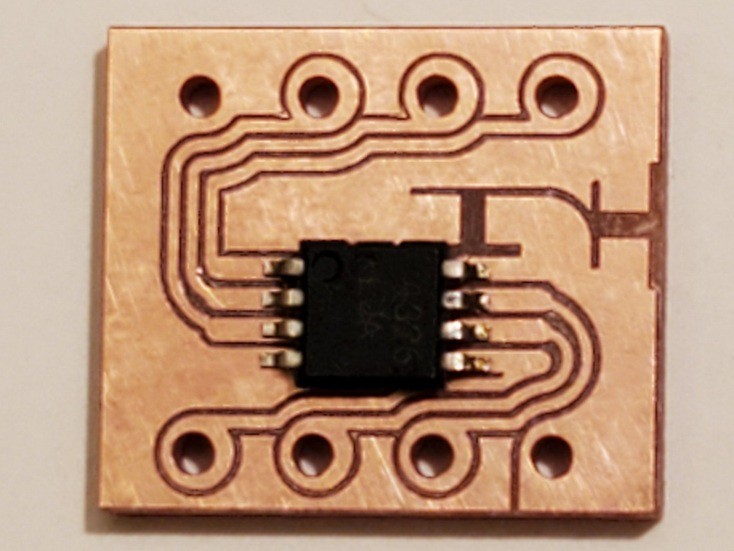

Earlier I milled a simple T/SSOP-8 breakout board to validate milling for 0.65mm pin pitch.

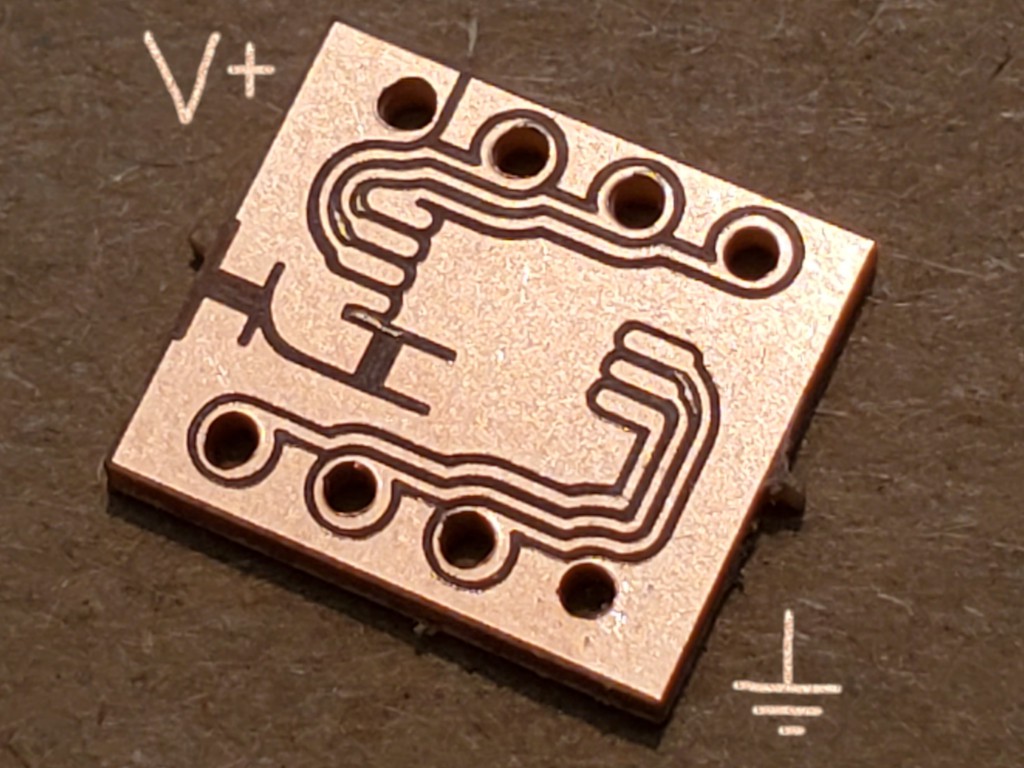

While doing that I checked what I might have in SSOP-8 to put on it and found some MAX4326 op amps on an old laptop mobo. The datasheet recommends two bypass capacitors ",,,as close as possible to the device supply voltage input [and] the ground end of these capacitors near the ground plane...", which is likely serviceable for nearly any 8-pin dual op amp, and also for many other 8-pin packages. [note 1]

Hmm. Only single-side copper-clad board on hand, so no ground plane. Can I do something with a single copper plane? Doodle doodle...

![]()

through-holes slightly munged because finished by hand (more about that below) Yes, there's a loop in the ground trace -- it's really small. I haven't tried to figure at what frequency it would start to matter but I'm pretty sure it's a disregardably large number of 10ᵐᵃⁿʸ Hz for anything in DIP-8.

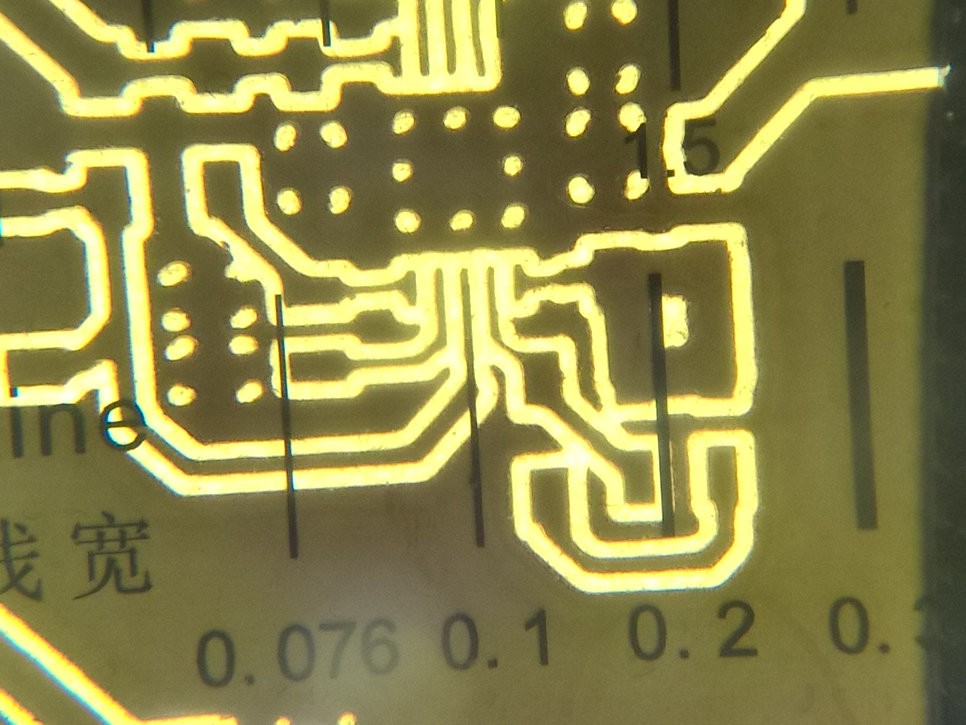

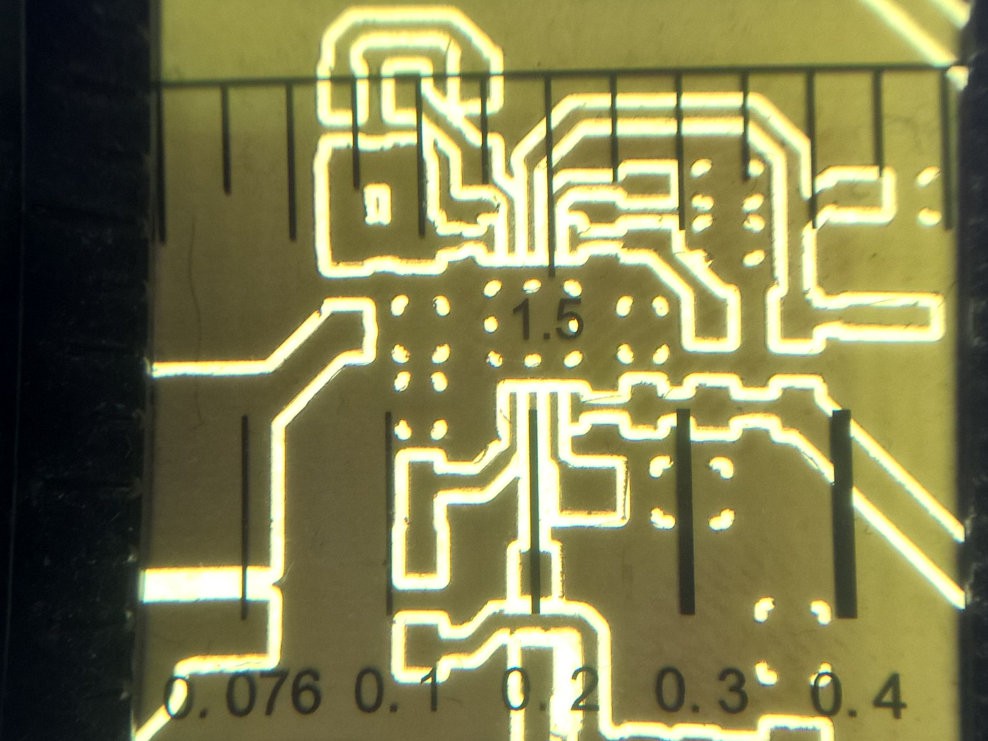

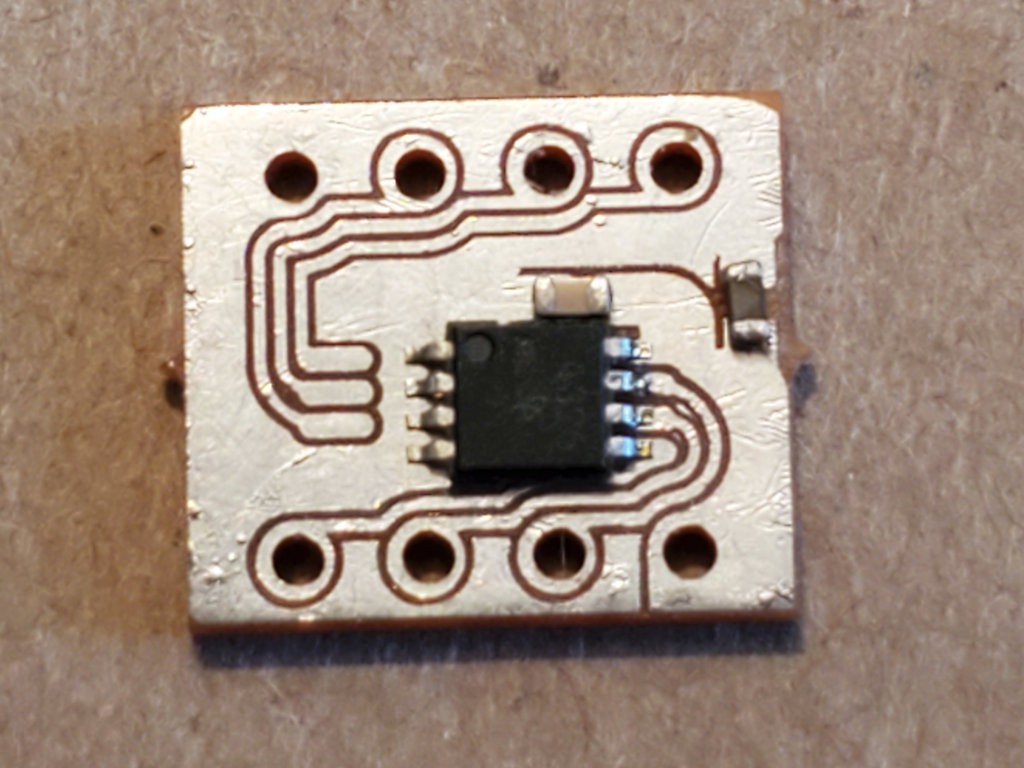

Actually this project is supposed to be more about milling than PCB design so... The adjacent traces are 16mil (0.4mm) center-center. The traces and grooves look pretty close to the same width, or about 8mil (0.2mm) each. Each groove cut in two passes about 3mil (0.07mm) apart. That suggests it's cutting about a 5mil (0.13mm) groove. The paths around these little islands where the two outlines diverge a little are not far from 5/8 the width of the rest of the grooves, so that seems to be about right.

![]()

Cut with a 0.1mm 20° V-bit. That's pretty small runout - which is mostly about the nice spindle - which doesn't really fit the "cheap"/accessibility theme unless you already have one. However the generality of the separate rotary tool allows amortizing its cost, whatever that may be, over many other uses. The point being that the little mill can make good use of a good spindle. Given a nominal tool diameter smaller than the trace separation, FlatCAM generated toolpaths with a little separation between the adjacent trace outlines, which made room for an additional small loop to fully clear the space between the capacitor lands. The space between the capacitor and the chip supply pin was too wide to clear with two outlines but not wide enough to fit another full loop (fit four outlines) so a little island remains.

LESSON: designing a PCB for isolation milling with simple offset outlines requires more attention to tool path widths - and overlaps. Kinda like designing features as multiples of shell thickness in 3d-printing, but for even multiples of tool size if using simple outlines. Or smarter software that can pick up uncut slivers between offset outlines... which is not trivial... for small pass overlaps.

SO MAYBE: Geometrically, I think limiting "pass overlap" (stepover) to a tick over (under) 50% might solve a lot of that. (Or a more clever approach like #PCB Isolation Routing Software.)

To be clear, this isn't all about stuffing a fancy $pindle in the cheapest mill. An old garage-sale Dremel® cut lines of two passes that look like less than half of 20mil (0.5mm) center-center in the prior example:

![]()

...so it should be able to cut traces on 16mil centers too. That earlier example was set up for a bit diameter closer to the designed clearance between traces, so the two outlines in each groove were practically on top of each other with very little separation, which gives 3mil back to the Dremel.

Cutting this bypassed breakout took more tries (time) than really needed if I had a better idea of how to use the tool.

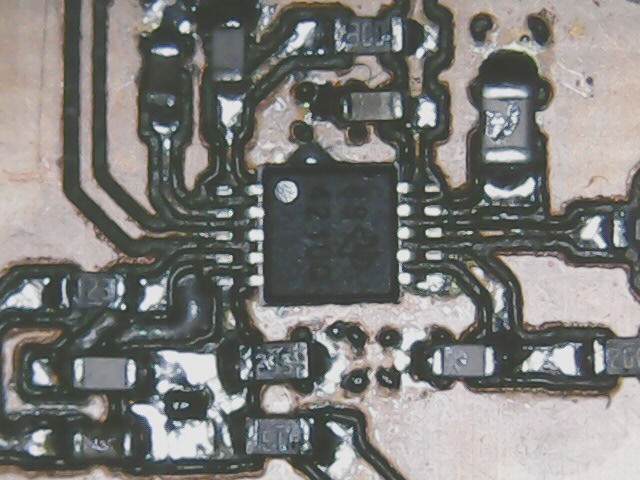

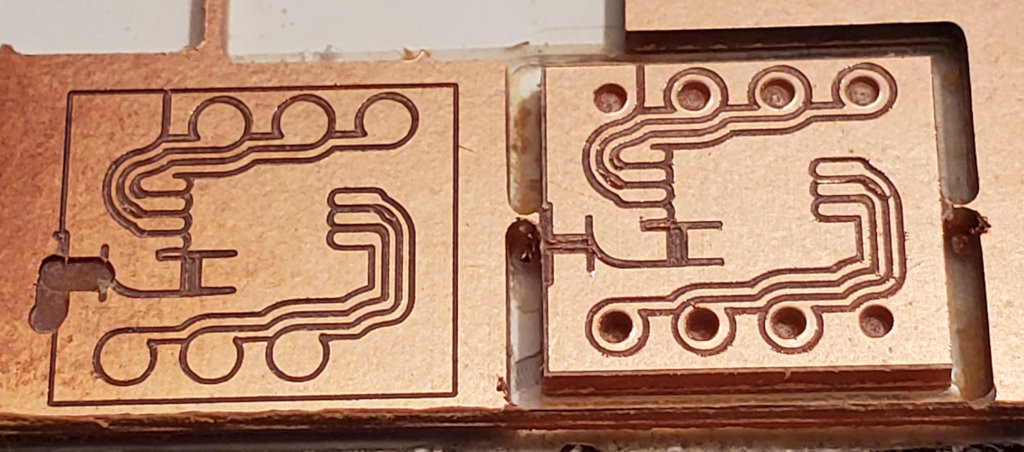

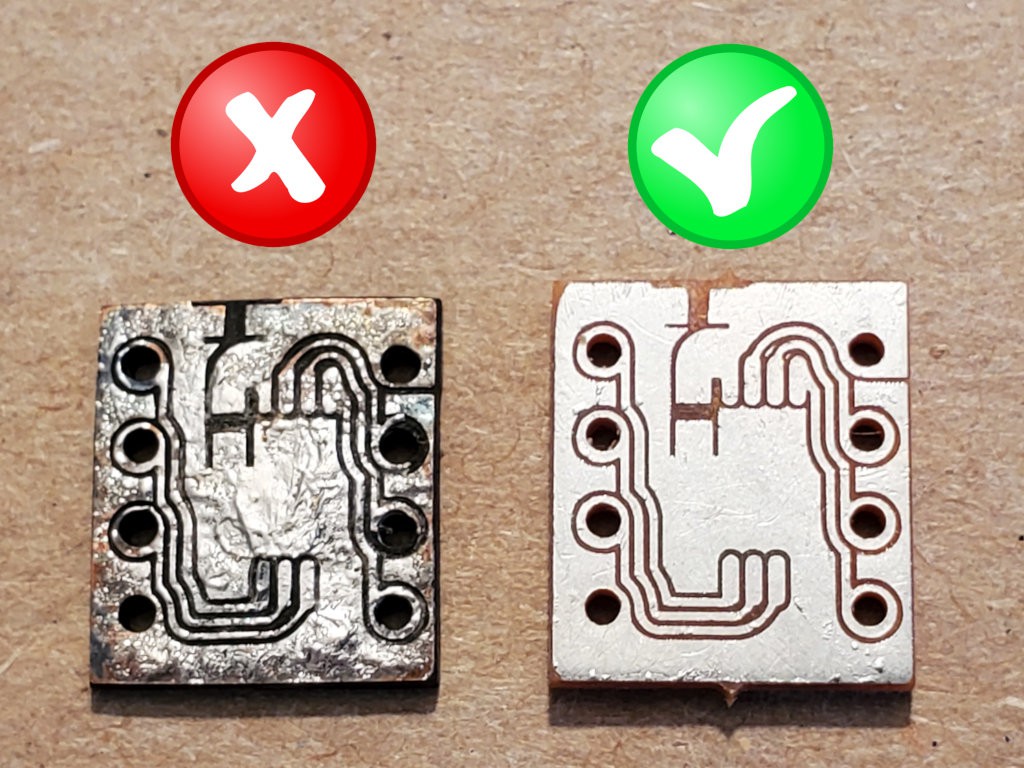

This picture shows the first (left) and last (right) attempts to cut the little breakout:

![]()

On the first try (left) I got a clean outline, then forgot to load new gcode after changing bits to bore the through-holes. In hindsight, I think that looks like I could have finished it and been done - because the bigger bit only went between a pair of capacitor lands and I think a cap would still bridge that gap. After promptly interrupting the wrong gcode, I could have recognized that the goof wasn't mortal and simply loaded the correct gcode and finished the board. But I didn't.

The last one (right) came out pretty well, except that the through-holes don't go through. They were bored from near left, left-to-right, then the far row left-to-right -- and get shallower in that order. That answered whether or not I could get away with drilling them with the end mill I was using (answer: not for long). Something got failure started, then it got duller in each hole. After that it just polished the copper outline for a few passes before breaking through the copper plate and cutting incompletely through the board, slipping Z steps. It finished the outline ok after I changed the cutter & re-set Z. If I were better at thinking about what I'm doing with this tool, I would have chucked up a 1mm drill and run the drilling code again to finish the part. But I didn't.

The holes off center in the copper pads show one of two imperfections (I don't remember which for which piece): 1) homing is kinda soppy with my current limit switch arrangement - and I screw up often enough to loose position often enough for that to matter, or 2) something moves while changing bits, and I don't know what yet.

Question: can 1mm (or 0.9mm for less over-sized through-holes) "corn cob" milling cutters drill too?

And there were other attempts between first and last:

![]()

The middle one is ok, but the operations are imperfectly aligned because I screwed up something and lost position (and homing remains imperfect). The flanking attempts got cut too deep while I was confused by a peculiarity of Z probing & autoleveling in bCNC: the position after a Z-probe is where Z stopped not where the probe triggered (unless, perhaps, if moving v...e...r...y slowly) while autoleveling uses the probed values.

Then I tried a couple of ways to tin a PCB, one of which worked:

![]()

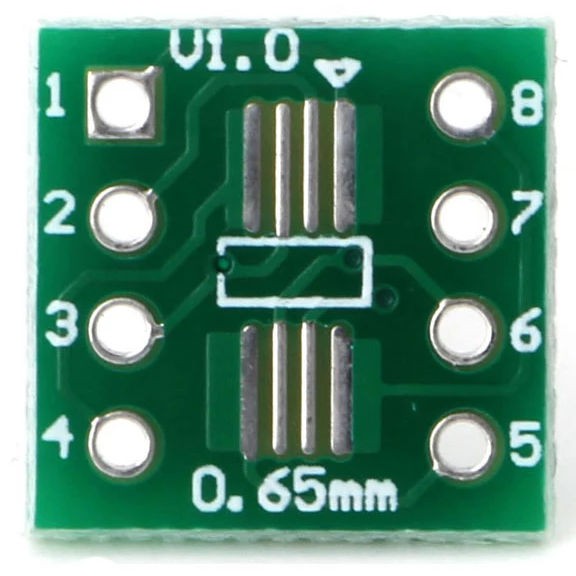

And then I remembered that SSOP packages can have different widths:

![]()

not soldered I knew that; just wasn't thinking of it while drawing traces. That would be why commercial T/SSOP8 breakouts have super long lands:

![]()

generic image used by many sellers FITNR, maybe.

teaser...

![]()

Dunno why drill holes are offset...

Note

[1] 0.1µF and ≥1µF. Overkill apart from narrow edge cases, I suspect, especially with same size/package (i.e. inductance) caps. I had a more compelling story in mind for using both caps but was thinking of a different amp + not thinking of other stuff. One 1µF MLCC + fatter trace area might work better. But I'm just making stuff up unimpeded by actual competence. It's so much easier that way.

-

So why go vertical when horizontal was such a win before?

08/15/2021 at 00:21 • 0 comments[this log entry copied from #Minamil where it was created 9 Aug 2021]

When HaD editors gave #CDCNC , the one-off precursor to this project, its 15 minutes of fame, they commended the Z-horizontal layout which avoided lifting the heavy tool with a tiny motor & gave chip clearance for free. So why abandon those advantages?It wasn’t the plan. The new axes were going to be about the same size as in CDCNC, so I was just going to swap new parts into the old frame. What could go wrong?

This design uses 0.5mm pitch screws, instead of 3mm or longer pitch used in optical sleds, to get more linear force from the same little 15mm motors that just barely make CDCNC go. The finer pitch screws are also self-locking, not backdrivable, so the machine will keep position without constant power to the motors -- another benefit, right?

The ‘what’ that could go wrong is that self-locking leadscrews with little rotational inertia will chatter hard when loaded with force in the direction of motion[1]. So while these screws can drive a fair load upward, opposed by gravity, they’re helpless to let even an empty slide come back down, assisted by gravity, with any useful speed. Counterintuitive, if you didn’t already know this. I don’t recall any mention of it in the tiny slice of CNC lore I’ve read.

So axes of this design won't be moving anything vertically without adding stuff to neutralize gravity. In which case it makes sense to turn the heavy, slow, and more often stationary axis back up to vertical.

That adds complexity and brings back the chip-clearing problem. But in trade we get a much smaller footprint.

[1] from Dr. Orang Vahid Araghi's thesis, page 187 first paragraph:

The first condition states that the lead screw must be self-locking. The second condition requires that the force applied to the nut be in same direction as the nut translation. The third condition defines a [...] limiting value for the mass of the translating part (depending on the lead screw inertia, coefficient of friction, and geometry of lead screw), below which instability does not occur.

Minamil: a minimal CNC mill - HaDPrize 2021

Minamil: a minimal 3-axis CNC mill that works. Build from laser-cut hardboard with a screwdriver (mostly). Mill fine-pitch PCBs.

Paul McClay

Paul McClay