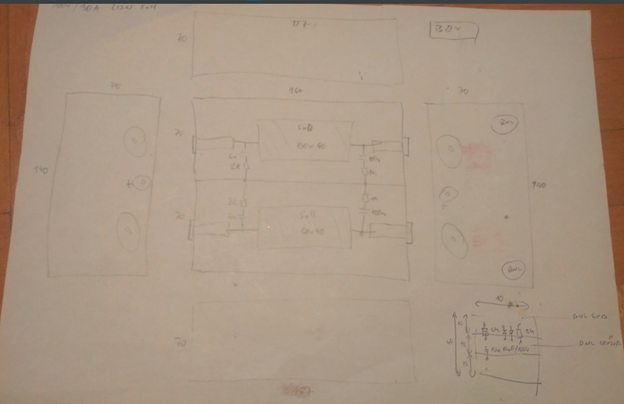

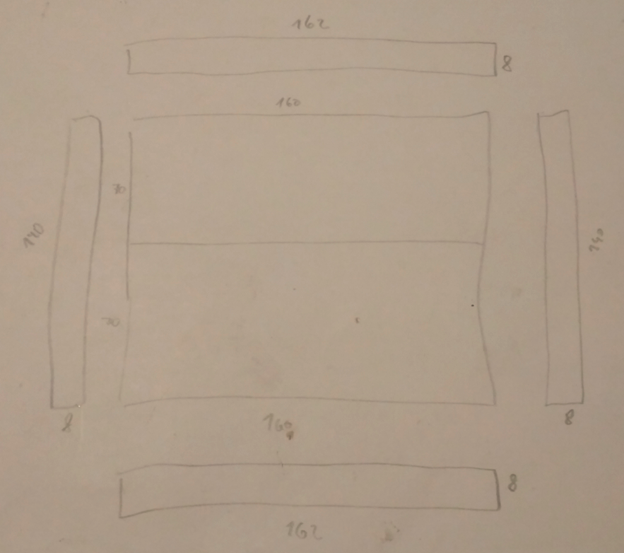

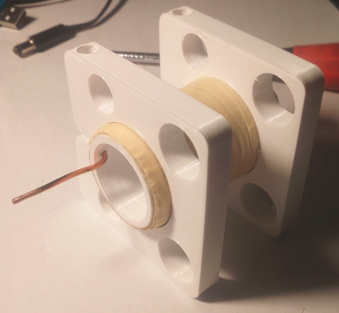

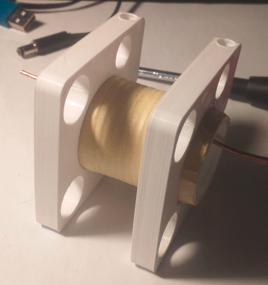

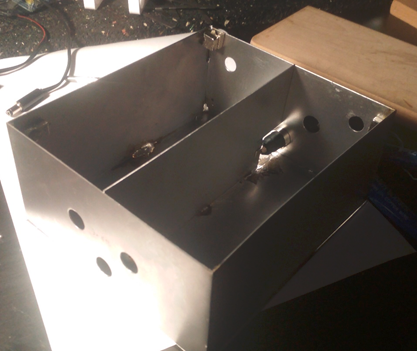

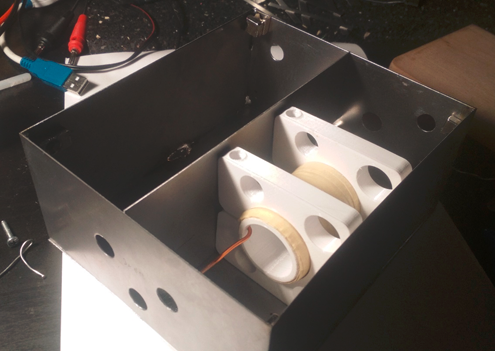

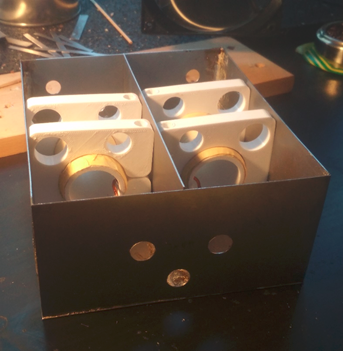

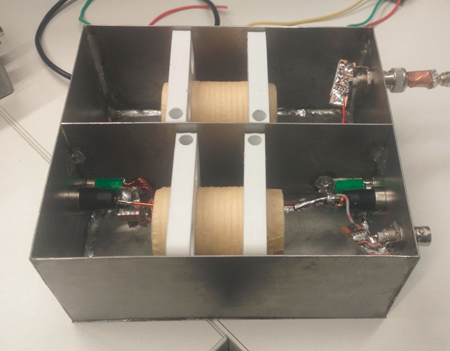

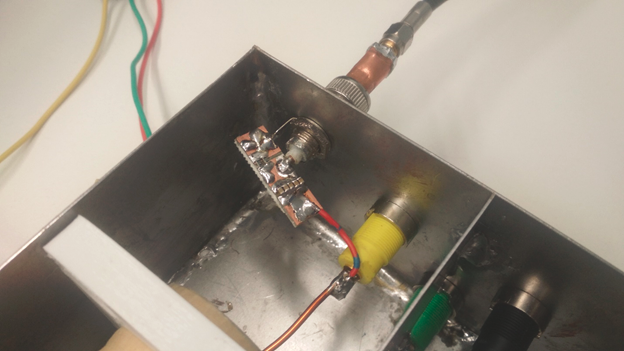

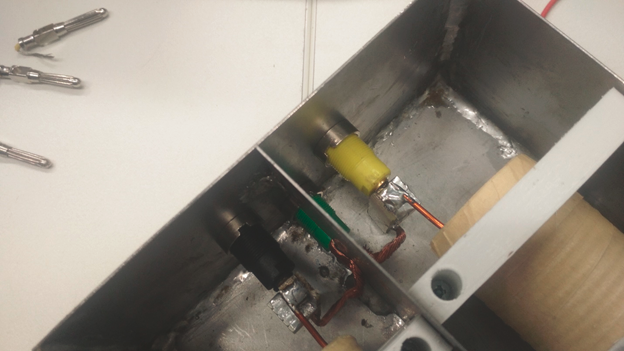

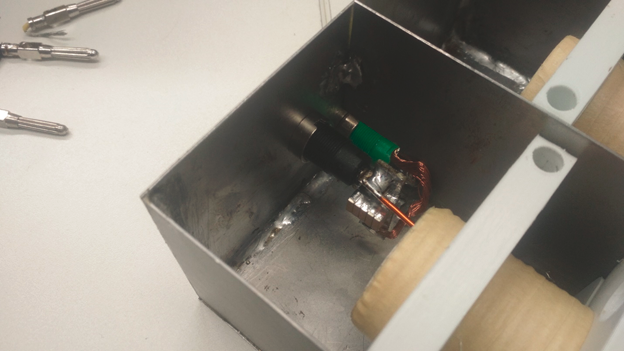

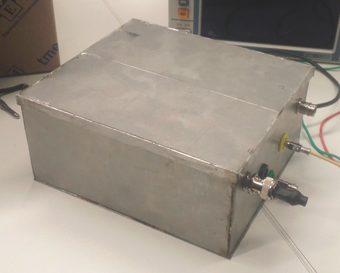

Whole LISN was assembled into DIY metal box from solderable metal sheets 1mm thick, 70mm high and 1000mm long (rather permeable and very soft iron). I would recommend to make the box at least 50% bigger to allow greater inductor separation from walls. Reason for this will be clear after validation measurements. Should I build it again, I would create separate housing for each LISN as all the manufacturers do. There is a great reason for it!

Sorry for very bad dimension drawings… this is what is available.

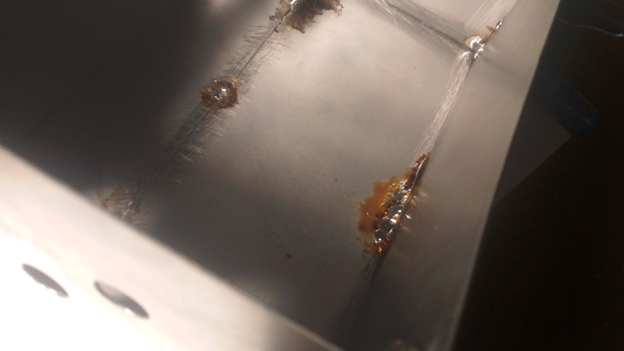

All the parts were cut from sheet using bench scissors and soldered together. This took quite a lot of patience from my wife as quite a lot of solder flux smoke was released across our flat 😊

kevarek

kevarek

Discussions

Become a Hackaday.io Member

Create an account to leave a comment. Already have an account? Log In.