-

Minimal stand

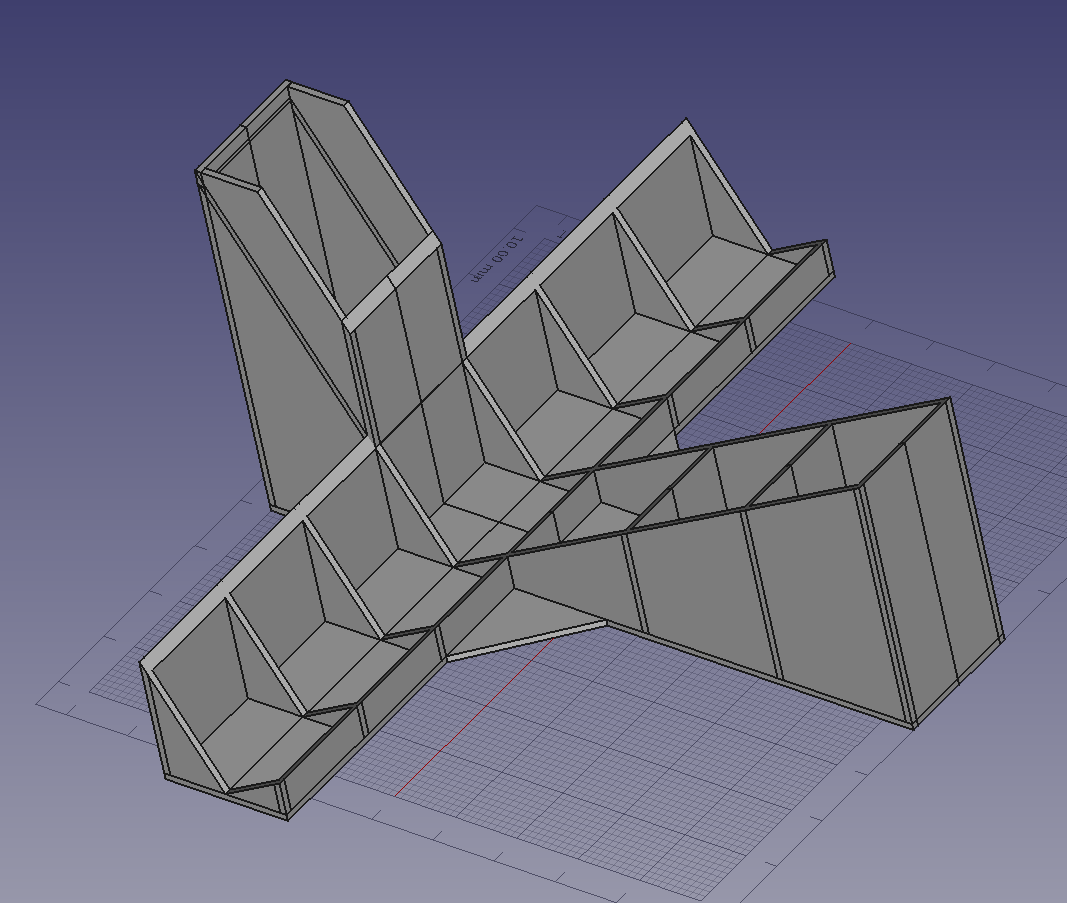

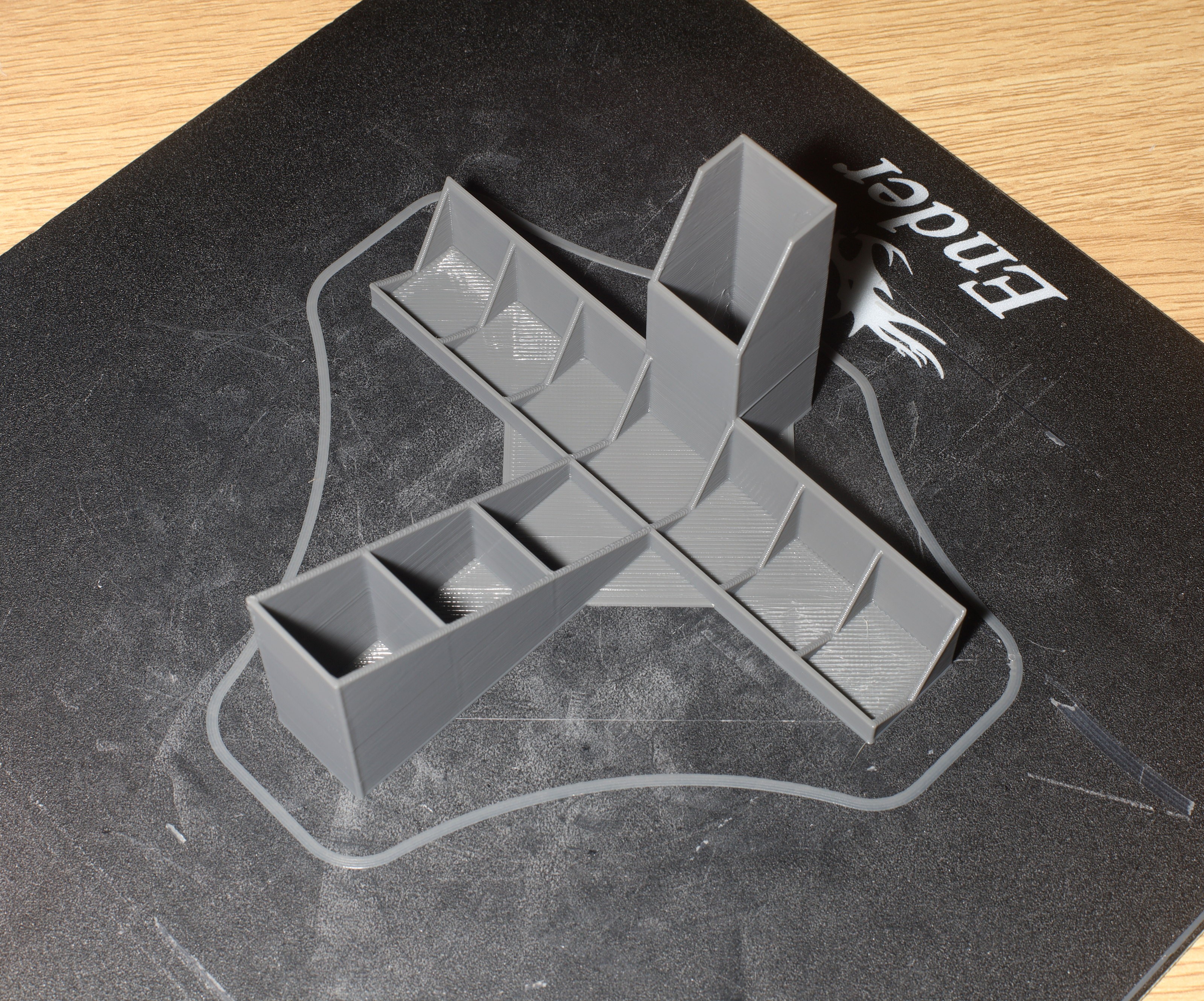

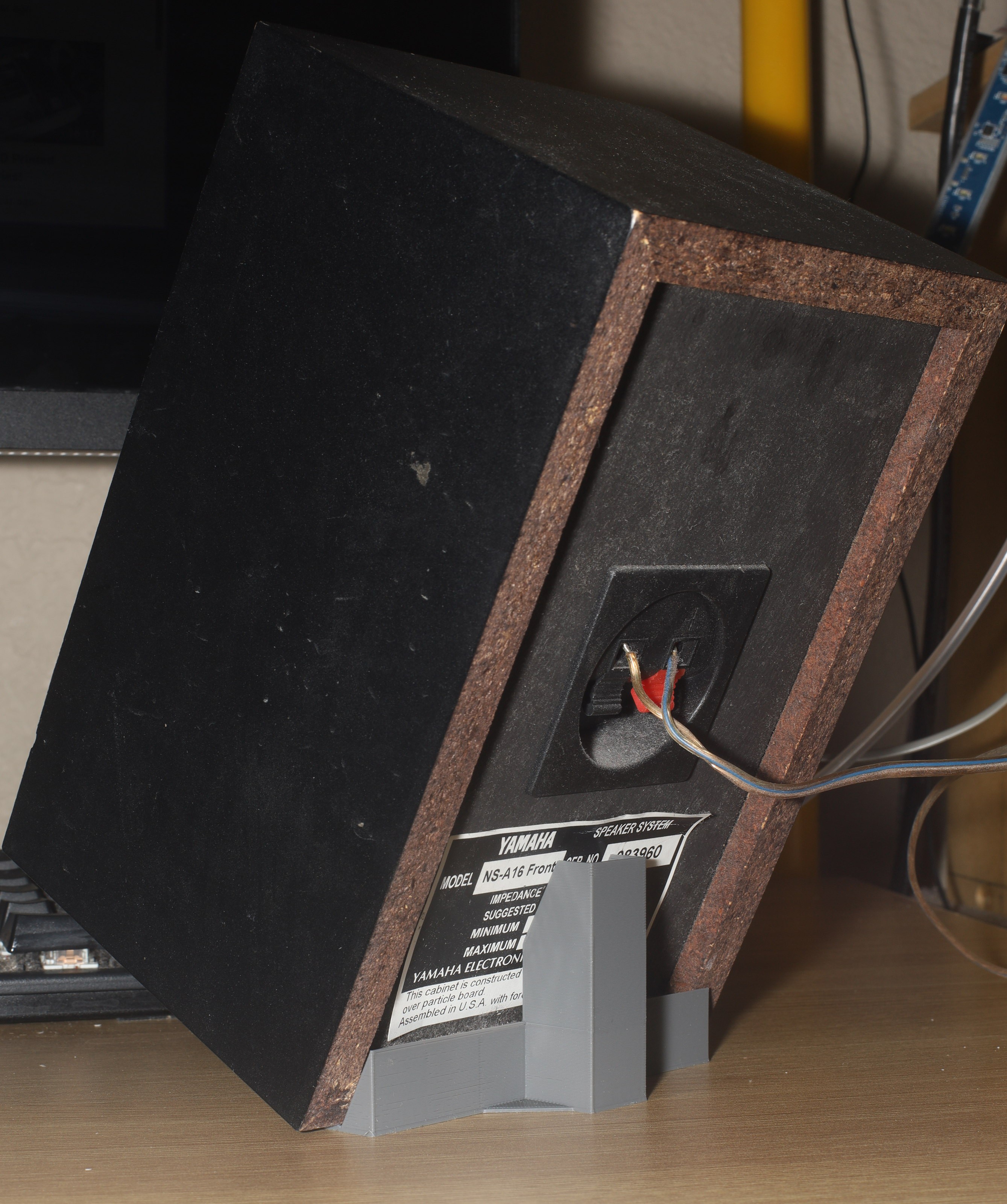

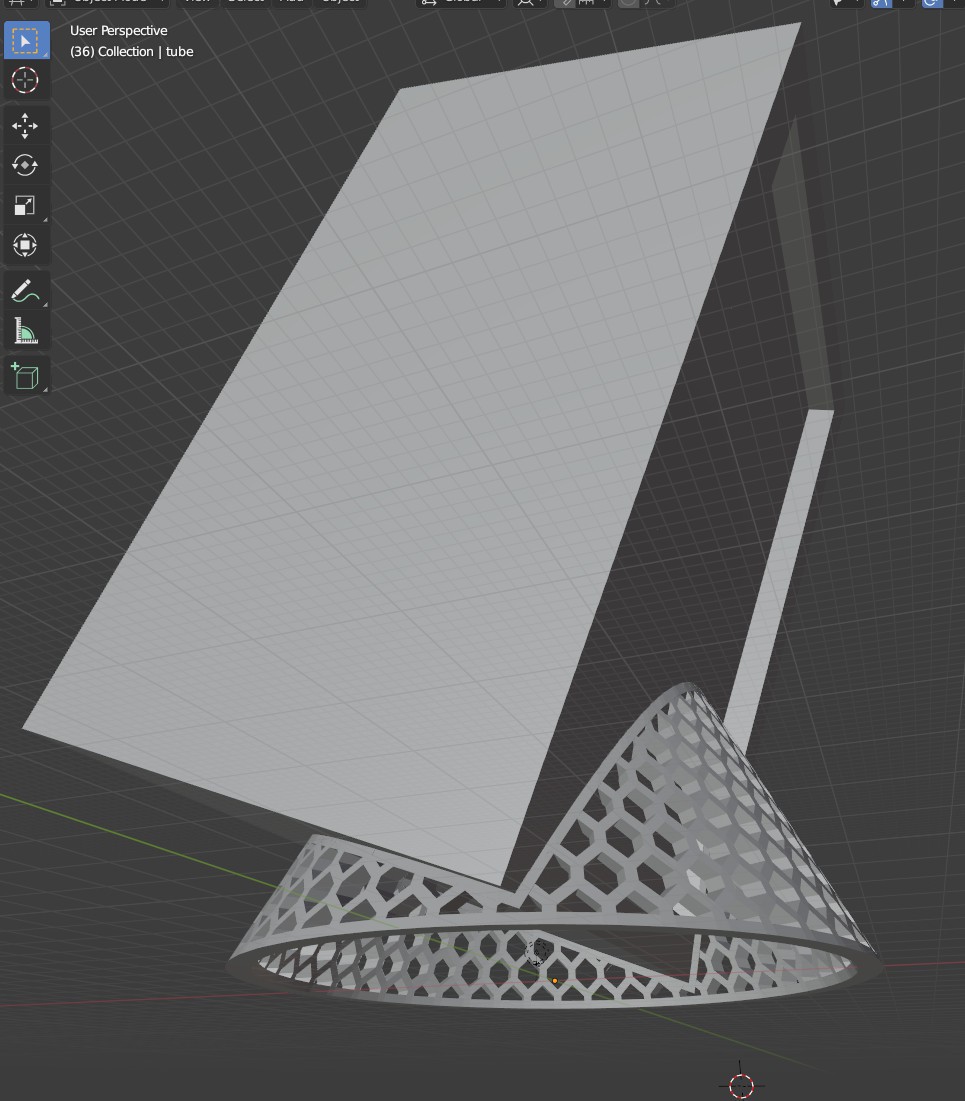

09/26/2021 at 02:38 • 0 commentsWith peak artwork unprintable & 1 week wasted, the lion kingdom switched to peak efficiency.

![]()

A simple cross would do the job in the least space. It's barely visible, so artwork would be a waste of time. It's true that the front corners have no support, but these speakers haven't had any diagonal falls.

![]()

![]()

![]()

![]()

This design worked & was parametric, so changing the angle was just a matter of changing a number & printing out another one. The ideal angle is between 25 & 28 deg. It also depends on how high the seat is, how close the speakers are.

-

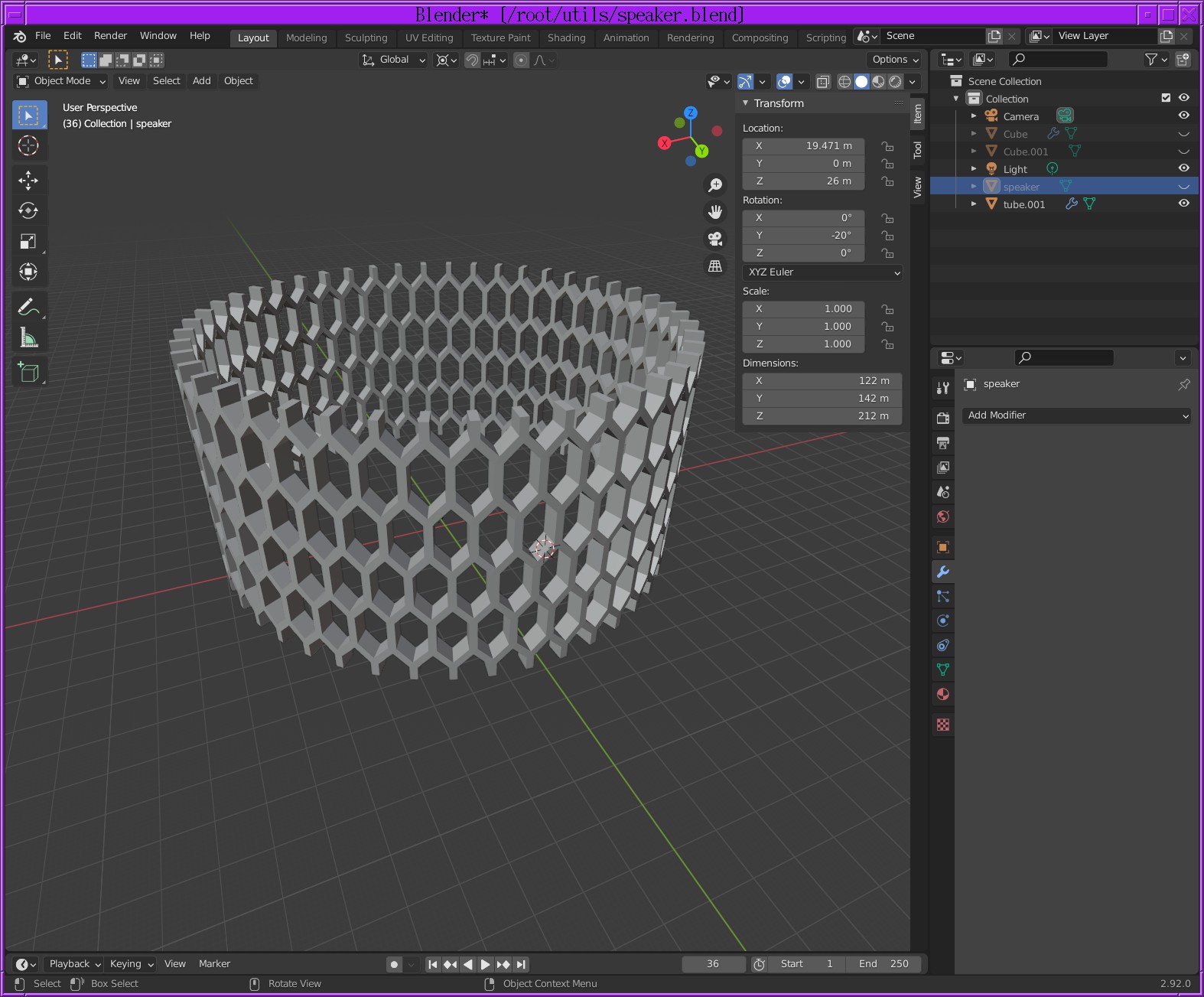

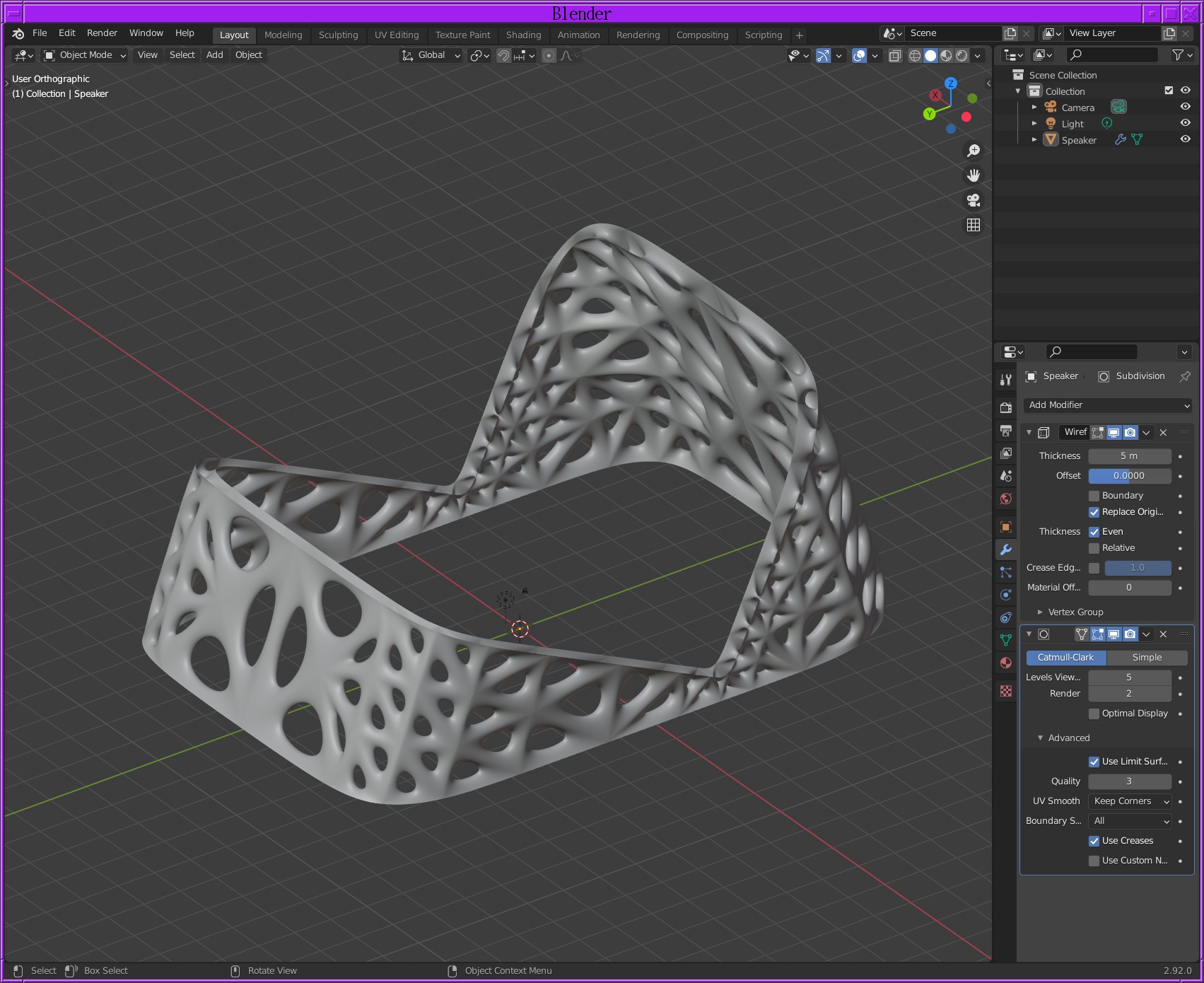

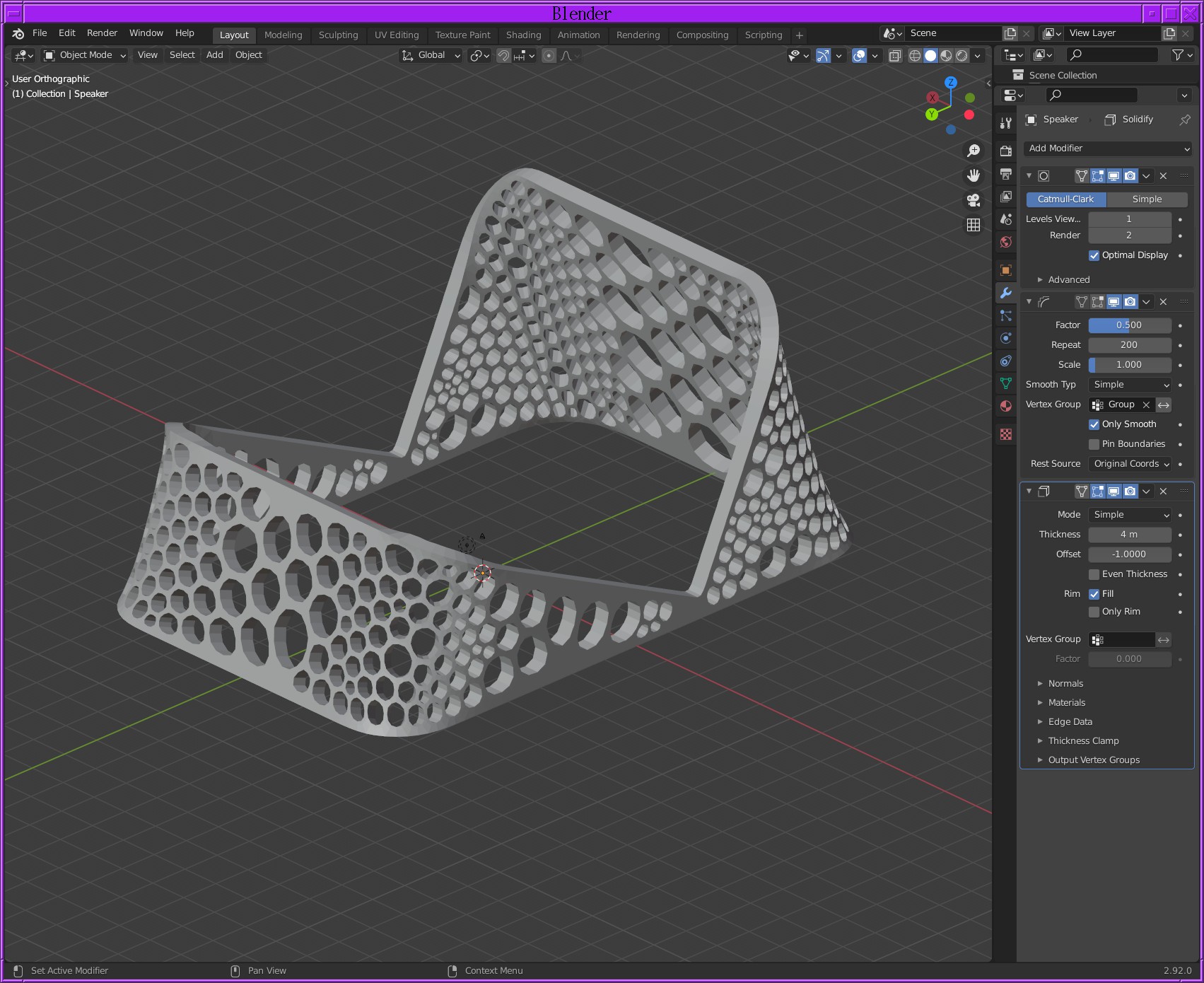

Procedural hex cylinders

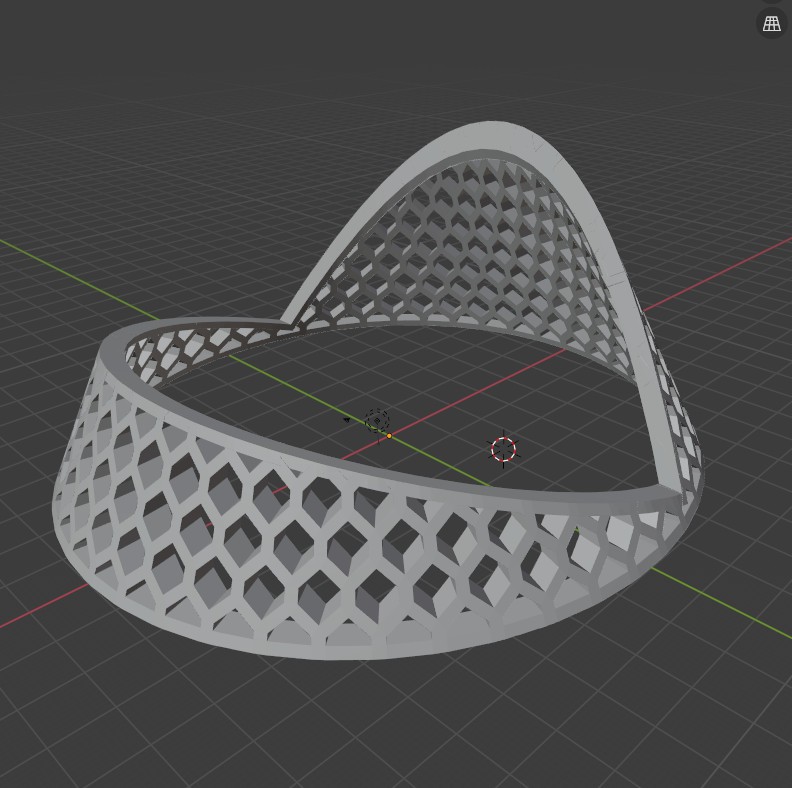

09/24/2021 at 05:49 • 0 commentsThe long process of chasing shrinkwrap algorithms & voronoi algorithms finally led to a procedurally generated, straight cylinder. It was an epic procedurally generated hex tube to be carved into a cylindrical stand.

![]()

A 250 line python script generating paw coded faces was deemed the easiest way to make a hex cylinder surface. Then, the solidify modifier & some paw coded mesh editing could extrude it.

![]()

A gap in the back would be filled with foam.

![]()

Unfortunately, once the top layer was added, it had horizontal overhangs. It could be printed in sections, but would always have some overhangs.

![]()

![]()

The hex tube & outline can be separate segments, but still have a lot of junk to remove. The top hexes would have to be solid, but that would add a lot of material.

![]()

To be sure, a solid cylinder would be instantly printable, definitely more artistic than the commercial options, but it wouldn't be the most artistic or efficient. For someone who just needs a speaker stand, the solid cylinder is a good compromise between art & function.

-

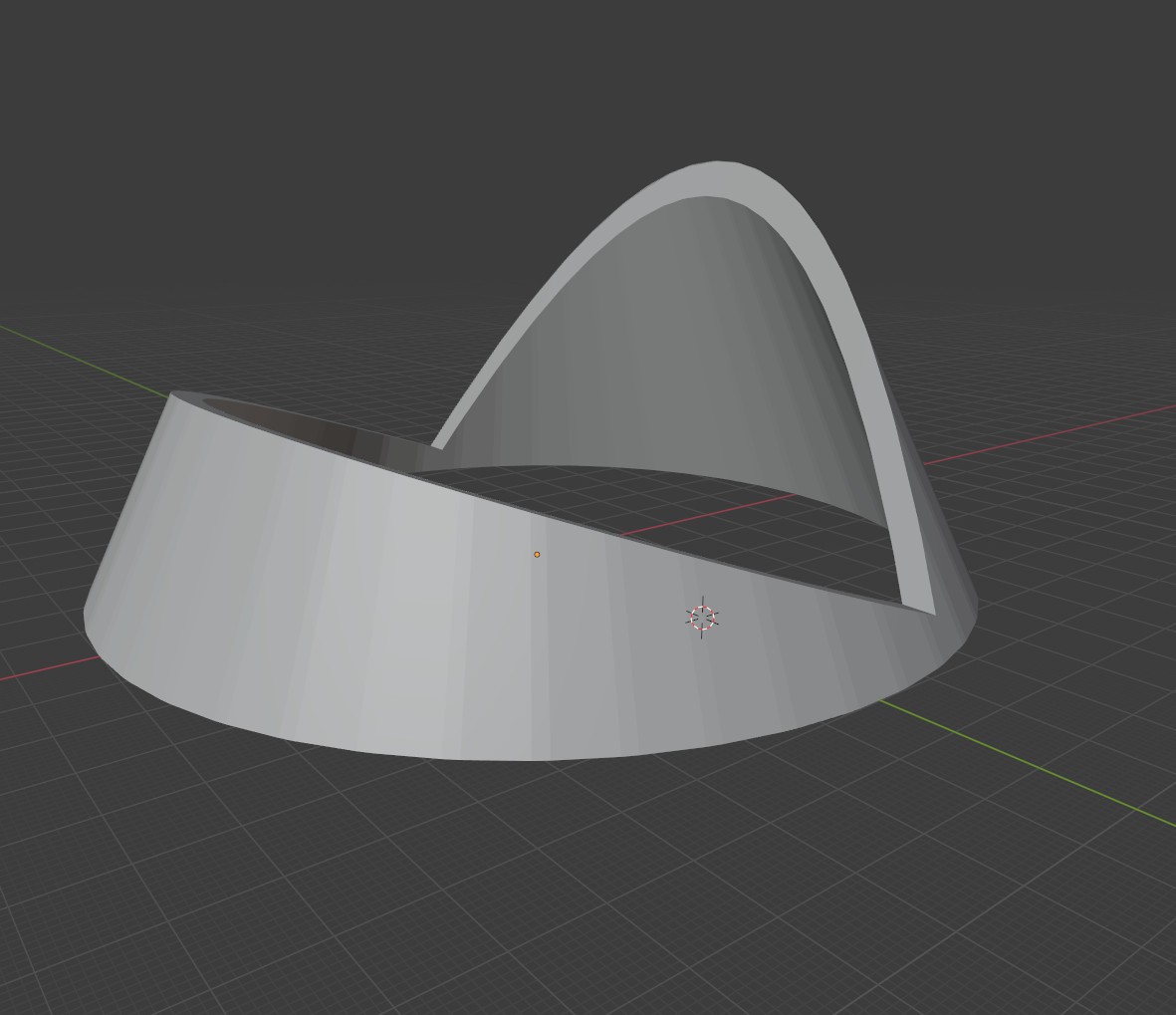

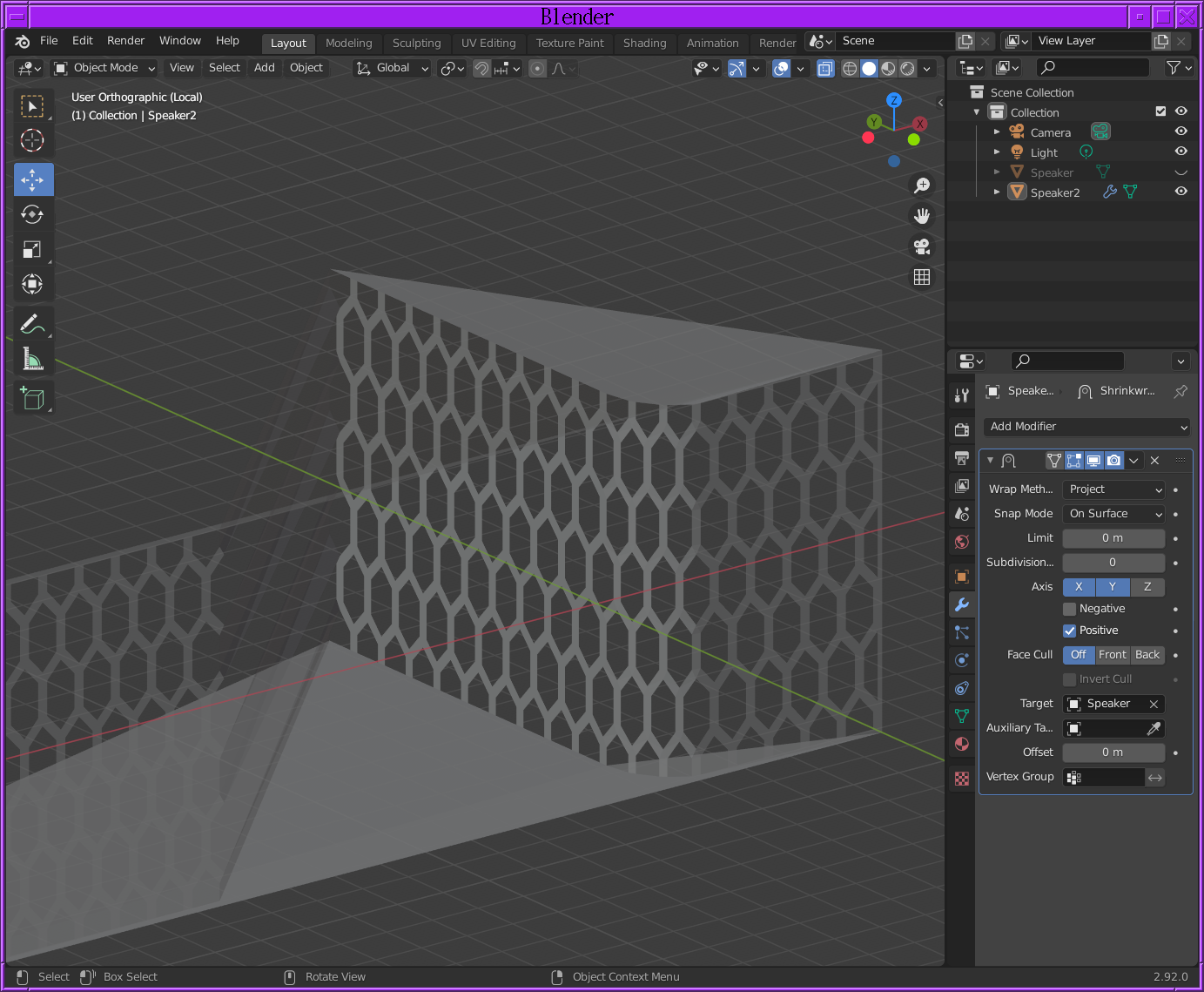

Shrinkwrap a grid on an arbitrary surface

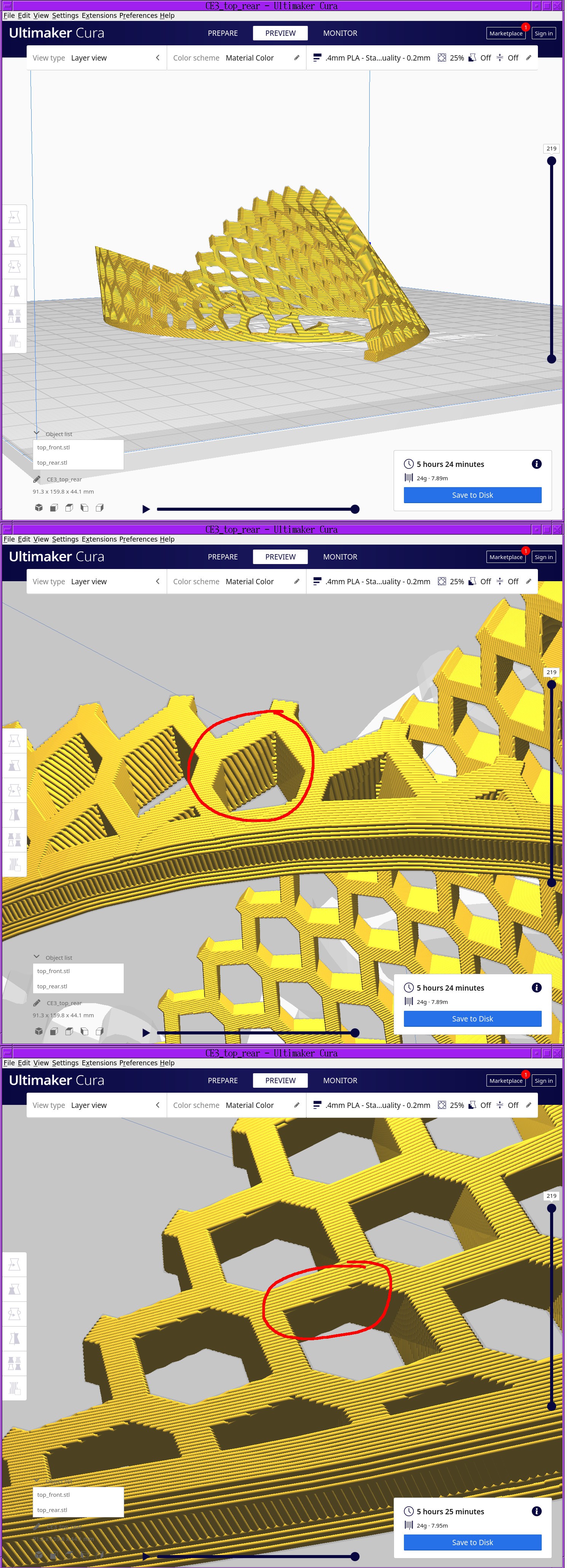

09/22/2021 at 05:24 • 0 commentsThe decision was made to shrinkwrap a traditional printable grid pattern on a smooth speaker stand shell. The thinnest horizontal walls in PLA are .4mm. A .4mm vertical wall requires a .2mm nozzle & a lot of time, so it would be a .5mm thick shell.

![]()

Blender happens to shrinkwrap surfaces on surfaces. The trick is selecting Project, X & Y axis. Then, it properly creates a solid with the solidify modifier.

The target needs to have parallel walls. The process leaves a lot of junk. It's not parametric. After creating a generic corner section, the corner sections would have to be fused & transformed in Blender to make the stand. There would be a solid column where the corners joined & the fusion would just use booleans.

There could be a simple python program which mapped a sketch on a hard coded corner section.

-

Voronoi patterns in blender

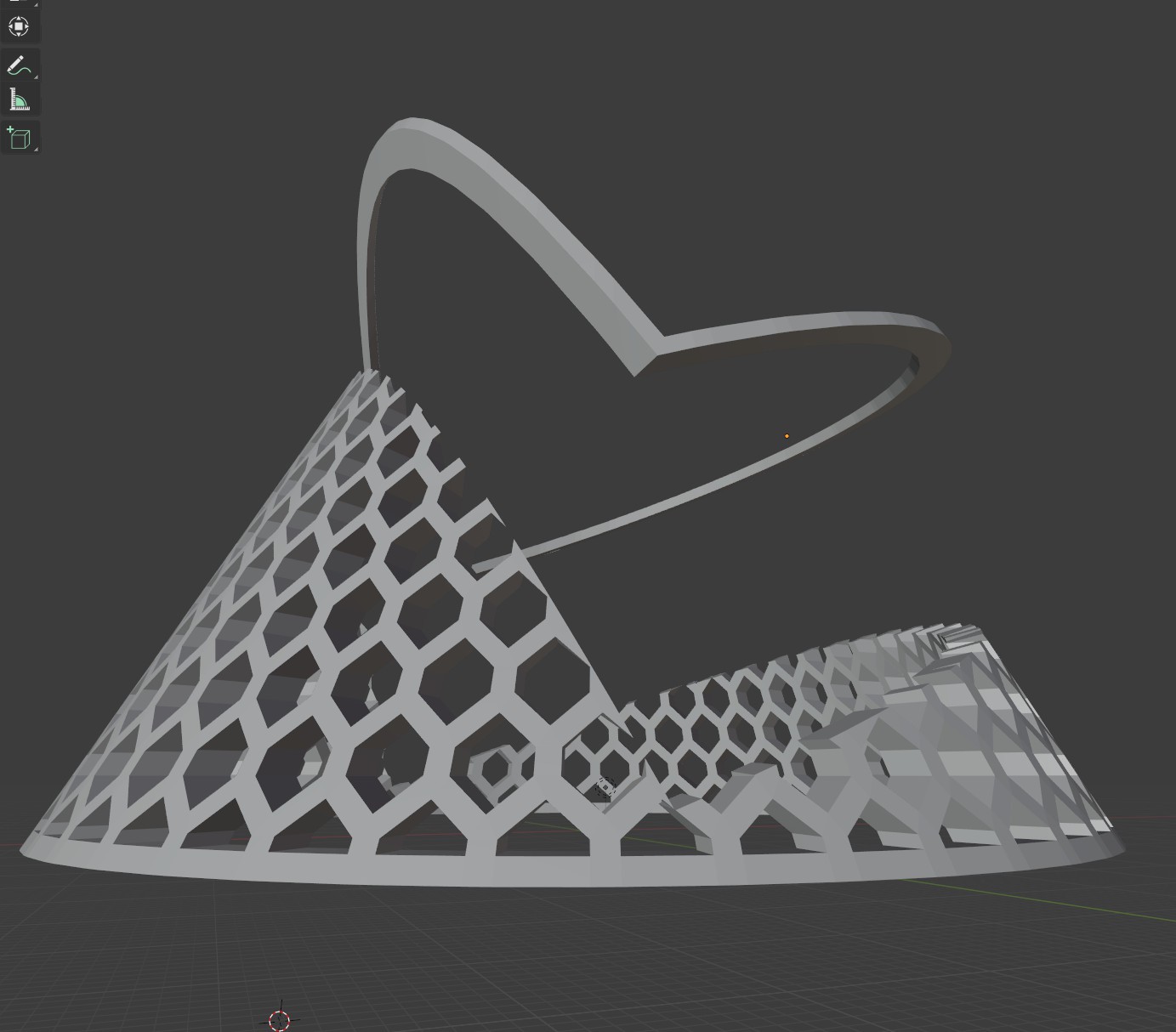

09/16/2021 at 05:07 • 0 comments![]()

So tesselation in Freecad with netgen -> very coarse was a starting point for a voronoi pattern. 1 problem is the fatness of the corners depends on the number of faces in the polygons. Triangles give the fattest corners. Circles give the thinnest corners. The most efficient structure would have circular holes.

This method requires being in face select mode instead of vertex select mode when beveling the vertices. Face select mode causes it to not bevel some of the vertices, so you have to do a 2nd pass after manually selecting the missing vertices in vertex mode.

Also, it can't select a face loop for the speaker stand. Instead, you have to select the top & bottom vertices with ALT +SHIFT, then invert the selection to select all the vertices between the top & bottom.

![]()

The tesselation was done with netgen -> fine. The vertex beveling was 100%. Some booleans could flatten the top & bottom surfaces. The mane problem is it has too many horizontal overhangs. The vertex beveling needs to create no horizontal overhangs.

lion mclionhead

lion mclionhead