-

200 micron mesh

12/02/2021 at 23:56 • 0 commentsJust tried it with some 200 micron mesh (0.008" hole size). Works even better then the 400 micron (40 USA mesh size, 0.016" hole size) that I made the project with.

I was able to take a nice picture showing the new mesh going through the PLA.

![]()

-

Close ups of mesh/PLA interface

11/23/2021 at 21:01 • 0 commentsAs I don't have a dissecting stereoscope (donations accepted), I had to make a very cheap microscope ($1.50) using the collimating lens from a laser pointer. Here are some close up's showing where the mesh and PLA are fused together. Each image is around 180X.

![]()

![]()

-

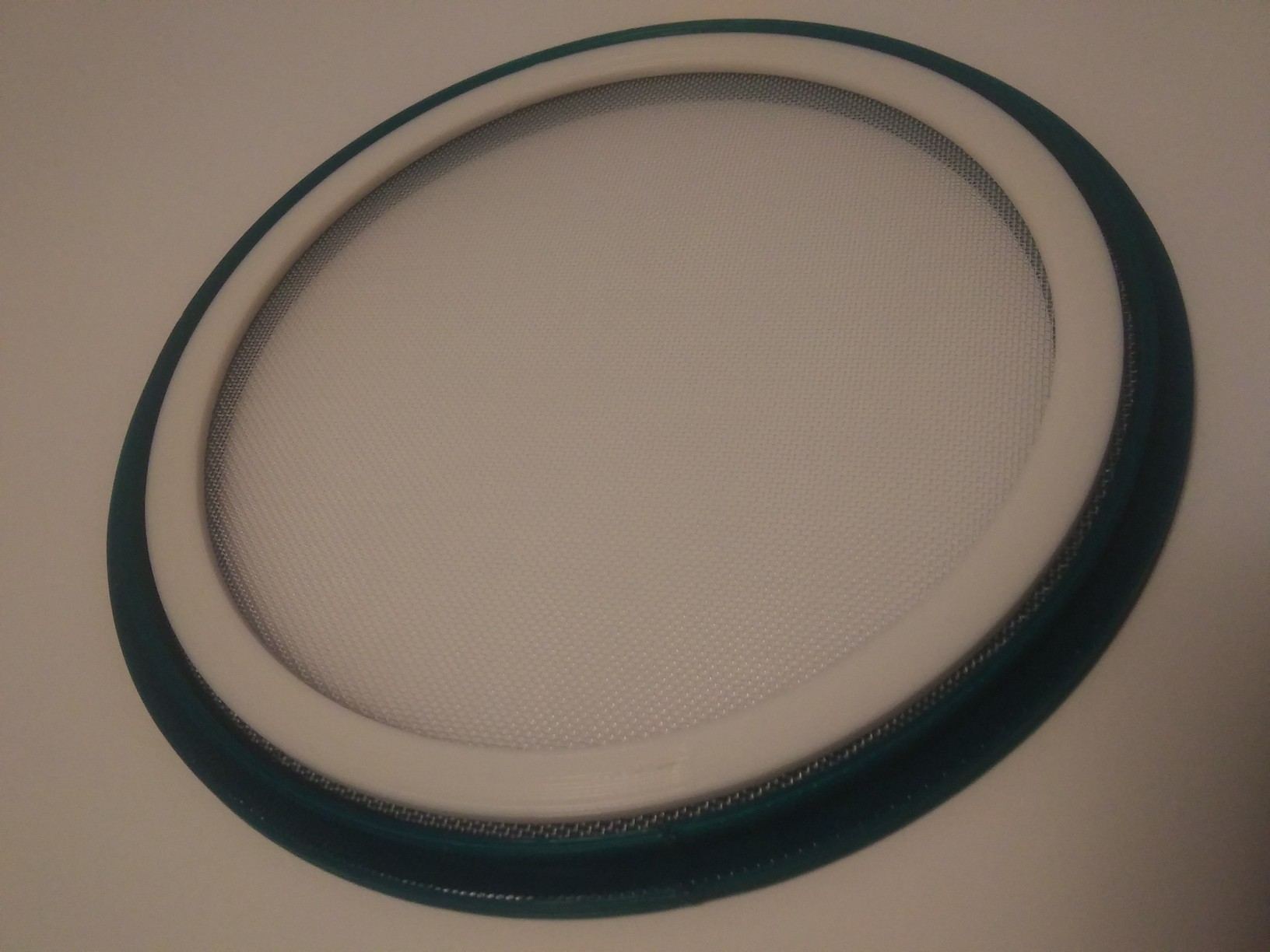

Superglue plus a holding ring still doesn't work quite right

11/18/2021 at 04:52 • 0 commentsOk. Since I couldn't just squirt the superglue through the mesh, and I couldn't put down a layer of glue, then press the mesh on top of it, what if I had a ring that I could use to make a mesh sandwich.

So I printed a ring sized to fit inside the part and proceeded to make the mesh sandwich.

First I put a nice fat layer of superglue on the lip of the part. Then I gently laid the mesh on top that, then pressed the ring down onto the mesh.![Mesh sandwitch Mesh sandwitch]()

Mesh sandwich without glue Less sticky this time, and the glue pressed though the mesh so that it was in contact with the lip and the bottom of the ring.

However...

It didn't set. I left it overnight and it still wasn't set, probably due to the dryness of the PLA. So using accelerator, I set the glue and happily proceeded to make another one.

The next one set fine but when tested showed that this wasn't vary viable, as it had low strength and the unevenness of the print allowed fine particles through.

![Failed! Failed!]()

mesh sandwich with superglue failure There must be another way.

-

Superglue alone is not the answer

11/18/2021 at 04:34 • 0 commentsSo for the first attempt, I simply tried to glue a precut mesh onto a lip on the inside bottom of the print using superglue. Here's a picture showing the mesh laying on the lip (not glued).

![Mesh lying on lip Mesh lying on lip]()

Mesh lying on lip inside of print, not glued or attached If you have worked with superglue, then you probably can guess what happened. I ended up gluing myself to both the mesh and the print.

Once I pried my fingers off of both parts, sprayed superglue accelerator onto the glue, a quick strength test resulted in rapid failure of the connection between the mesh and the print. I believe that this is a result of the glue no being applied in a consistent manner around the inner lip. Having big clumsy fingers, there was no way I could do this without clogging the filter and/or making it look pretty bad. I found this out by trying to glue it on many times. Obviously this is not a method I can use.